¶ What is the Build Plate Position Detection?

As we all know, in the 3D printing process, the nozzle extrudes the molten filament on the build plate to build a 3D model, so the build plate needs to be placed on the heatbed before printing.

The A1 series printers are equipped with the build plate position detection function, the printer can detect whether the user has placed the build plate properly before the printing starts, avoiding direct printing on the heatbed and causing printing failure or even damage to the heatbed. The following image is an error demonstration of a printer printing directly on the heatbed:

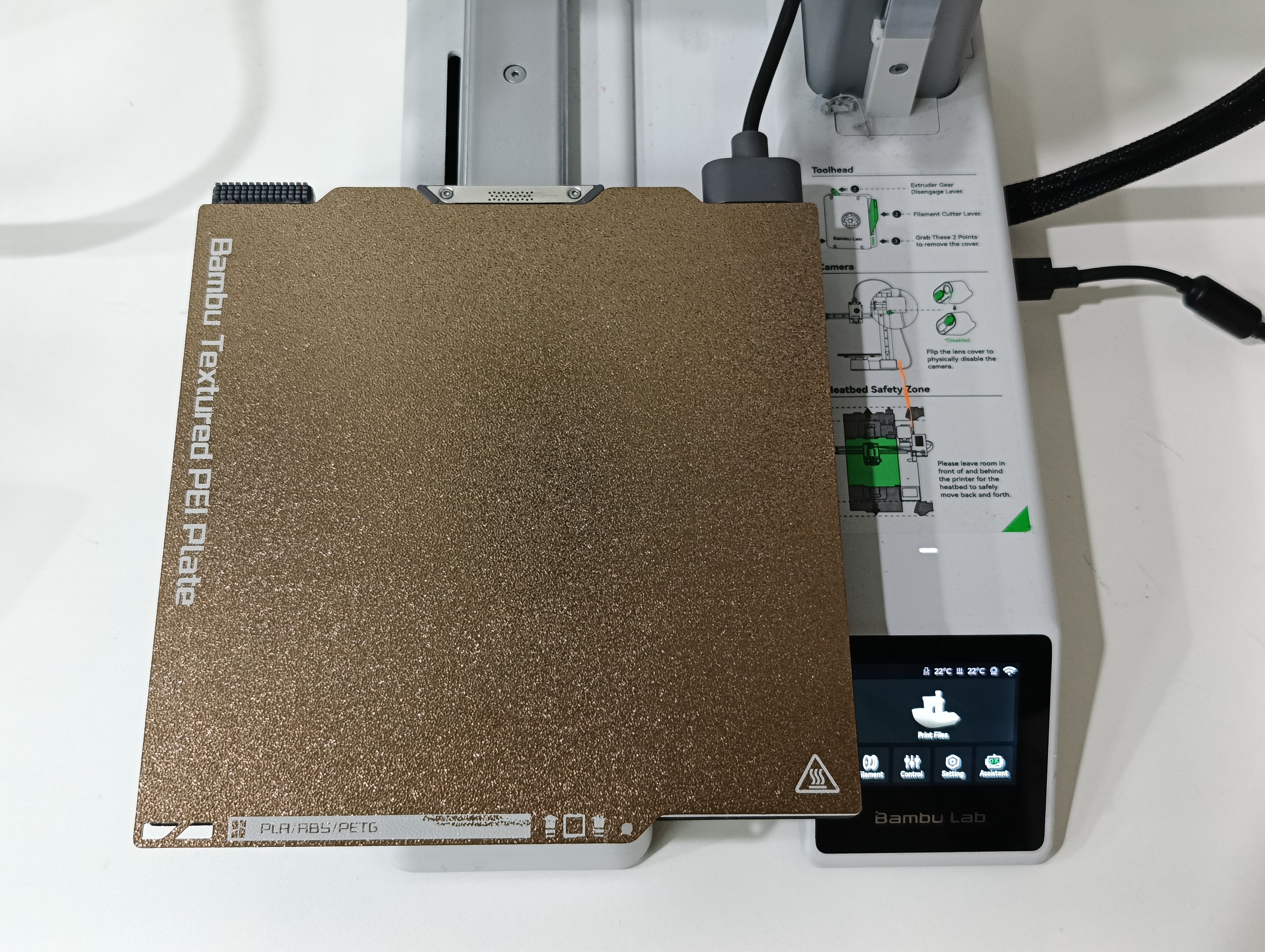

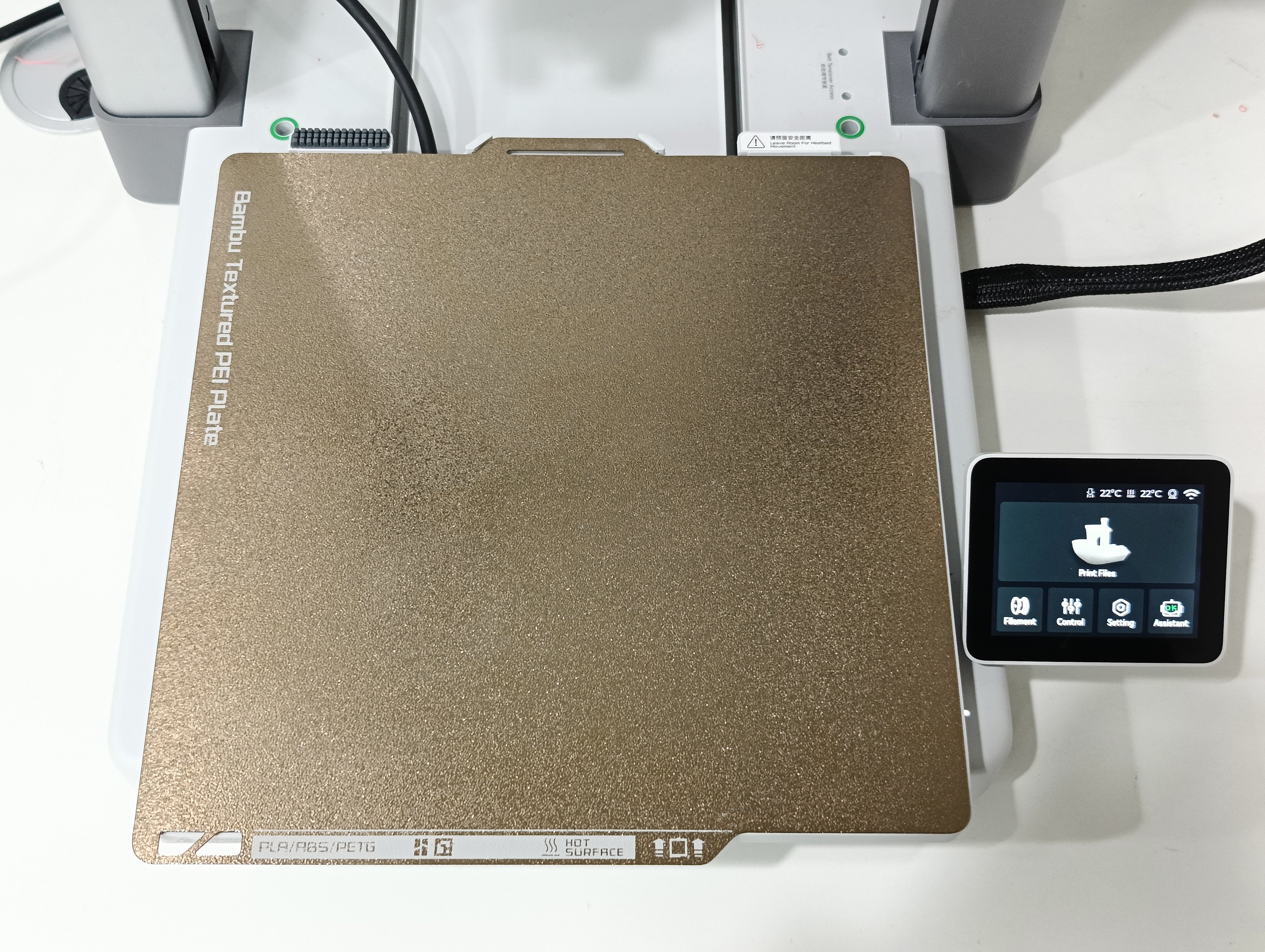

The build plate needs to be properly placed on the heatbed before starting the printing task, as shown below:

|

|

¶ How to Detect the Build Plate?

The principle of build plate position detection is to use the extrusion force sensor (eddy current sensor) in the tool head to detect the build plate. When it starts the detection, the printer first lowers the tool head so that the nozzle touches the heatbed to confirm the zero coordinates in the Z direction. Then move to a specific position and move the tool head downwards to allow the nozzle to make a probing touch. If the build plate is placed, the nozzle will touch the part of the build plate to detect the change in force. If the build board is not placed, during the movement, it will only touch the air and no change in force will be detected, and the printer will determine that the build plate is not placed.

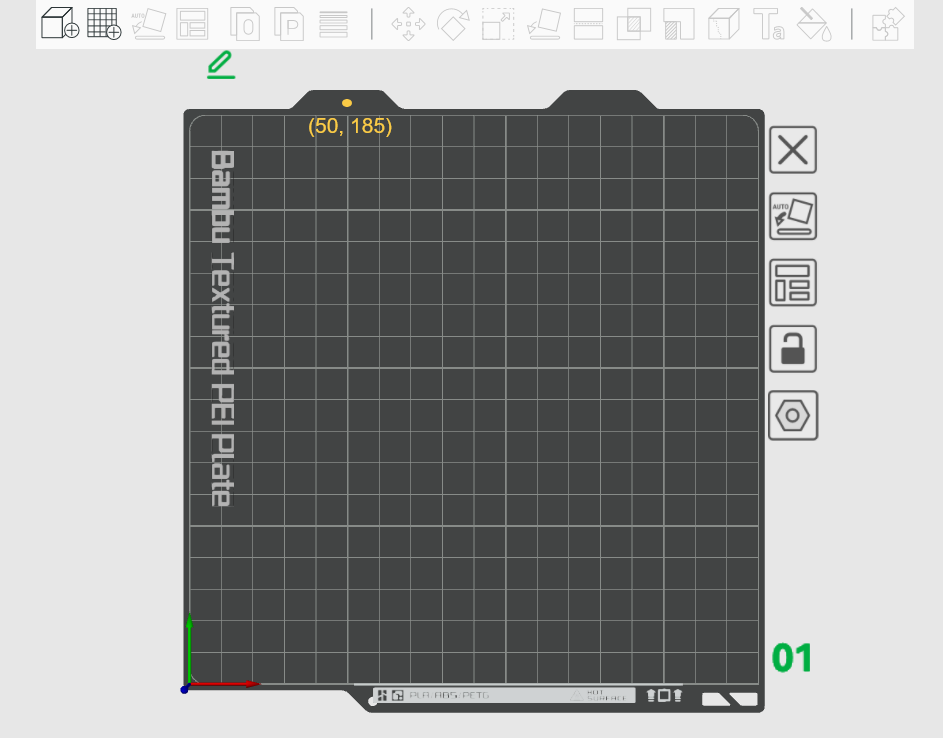

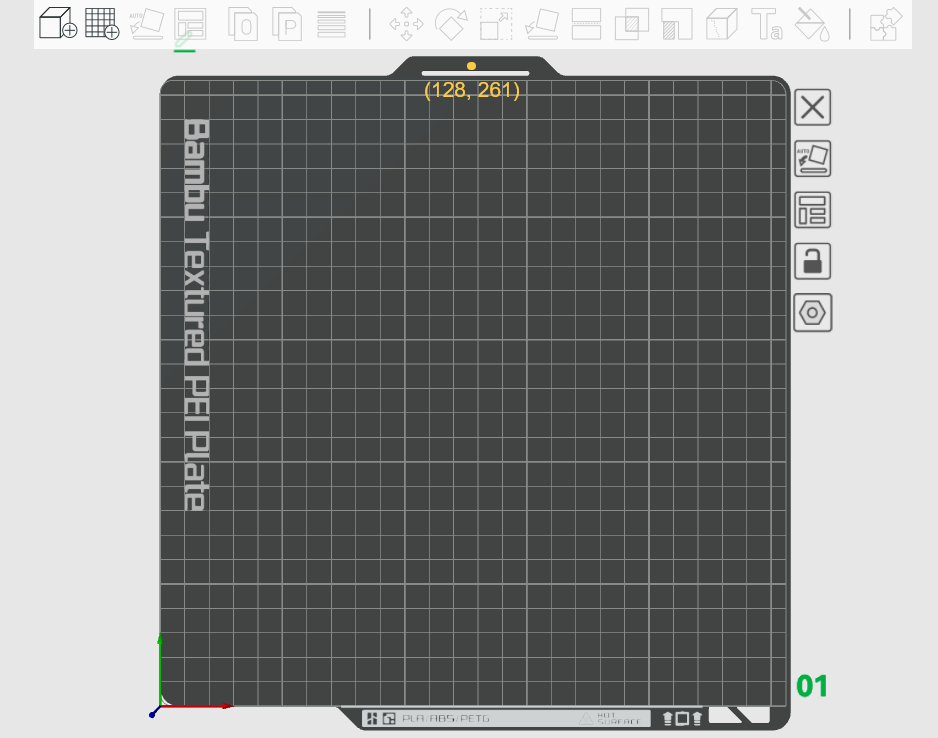

The specific coordinates of the nozzle when performing the build plate position detection: A1 mini (X 50, Y 185, Z -2), A1(X 128, Y 261, Z -2). As shown below:

|

|

The action of the build plate position detection process is shown as follows:

|

|

¶ Enable the Build Plate Position Detection

You can enable the Build Plate Position Detection function on the Print Options page of the screen, as shown in the following figure:

|

|

Firmware/software version requirements for enabling the build plate position detection:

Firmware version 01.02.00.00 or later, Bambu studio version 1.8.4 or later.

¶ End Notes

We hope our guide was helpful. If you have any questions or concerns about the process, please contact our customer service team. We're here to assist you.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.