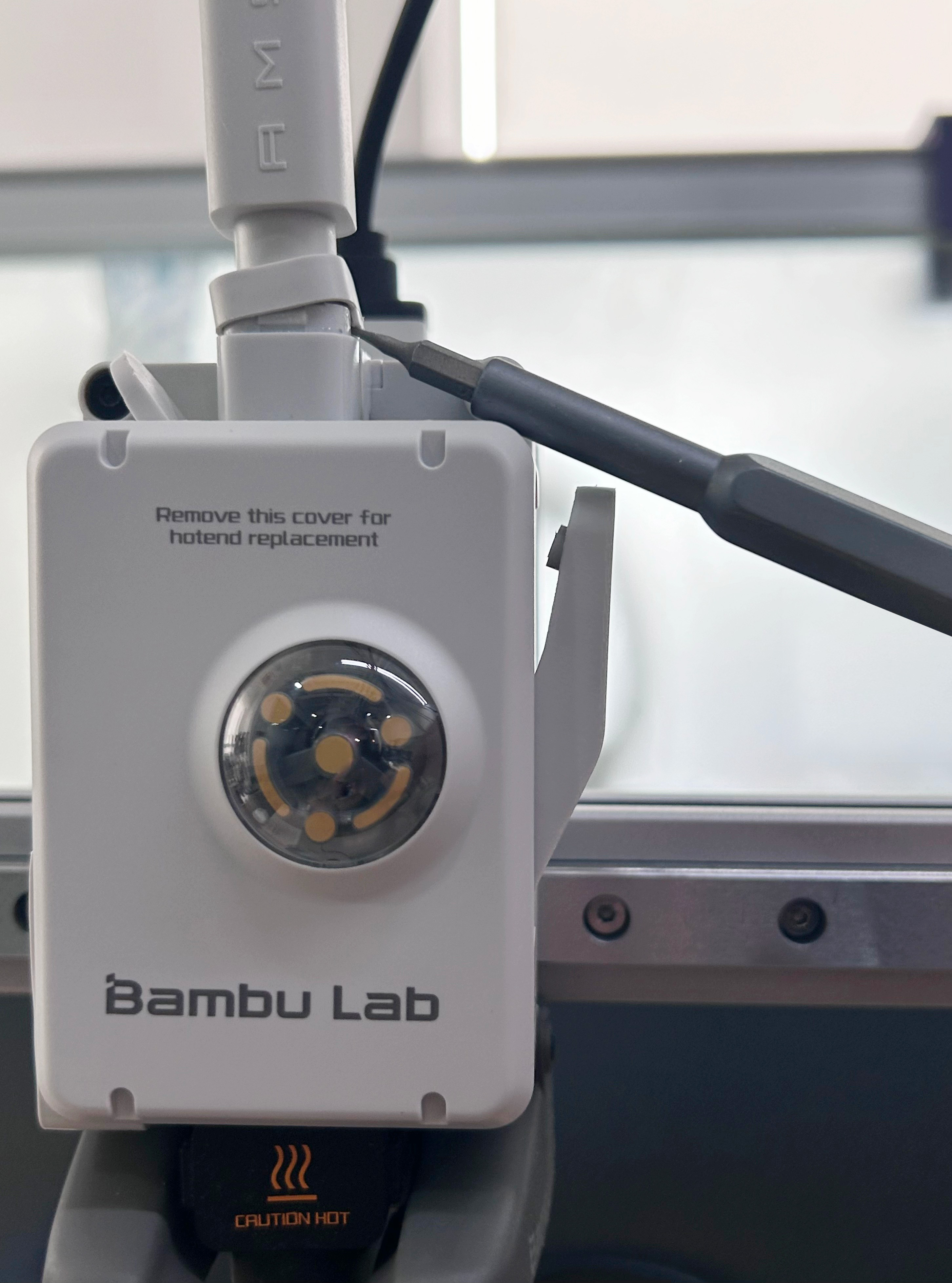

¶ Filament Sensor Base

The filament sensor base is installed on the top of the extruder unit of the tool head and is used as a fixed base for mounting the filament sensor (Hall Board) on its side. It also serves as the base for the filament hub of A1 series printers.

¶ When should you replace the Filament Sensor Base

In most cases, the filament sensor base has little possibility of being damaged. However, the head tool collision or improper disassembly of the filament hub may result in a damaged frame or broken fixing latch of the base. To ensure the smooth filament loading process, it is noted to replace the filament sensor base promptly.

¶ Tools and Materials Required

To replace the filament sensor base, the tools below are required:

- H1.5/H2.0 Hex Key Tool (Included in the Accessories Pack)

- Wrench

¶ Screw List

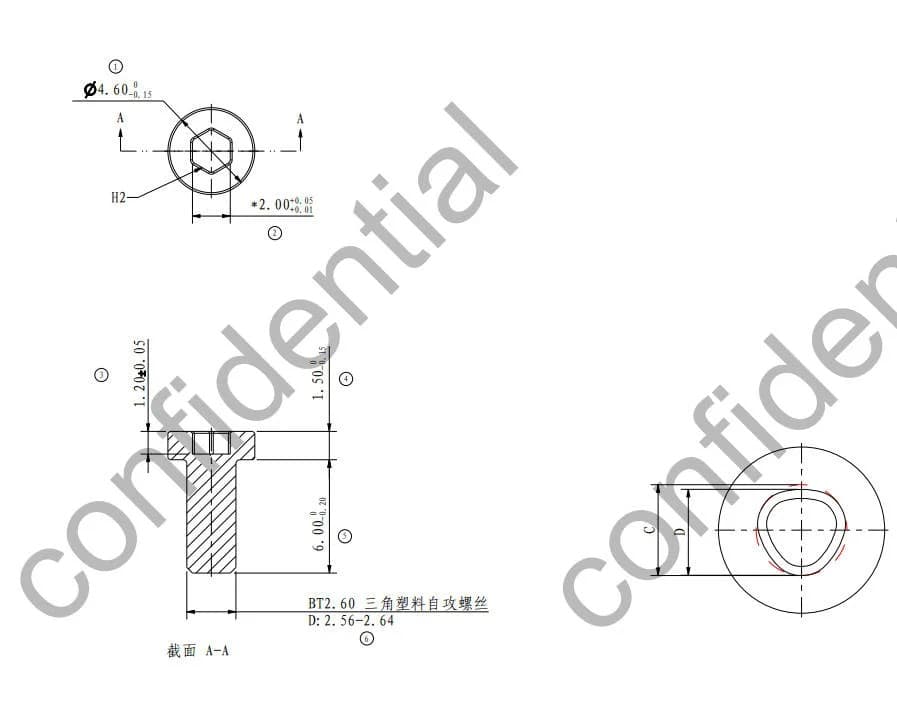

| Model | Position | Drawings | Model | Position | Drawings | ||

| Screw A | BT2.6*5 B00204 |

Filament Sensor Base (2PCS) |  |

Screw B | BT2*5 B0017 |

Filament Sensor (2PCS) |  |

Note: Please ensure that you properly store the screws that are removed during maintenance. Losing screws may result in the inability to properly install filament sensor base.

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenane or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Steps for the Operations

¶ Step 1: Unload the filament from the printer (for standalone printer)

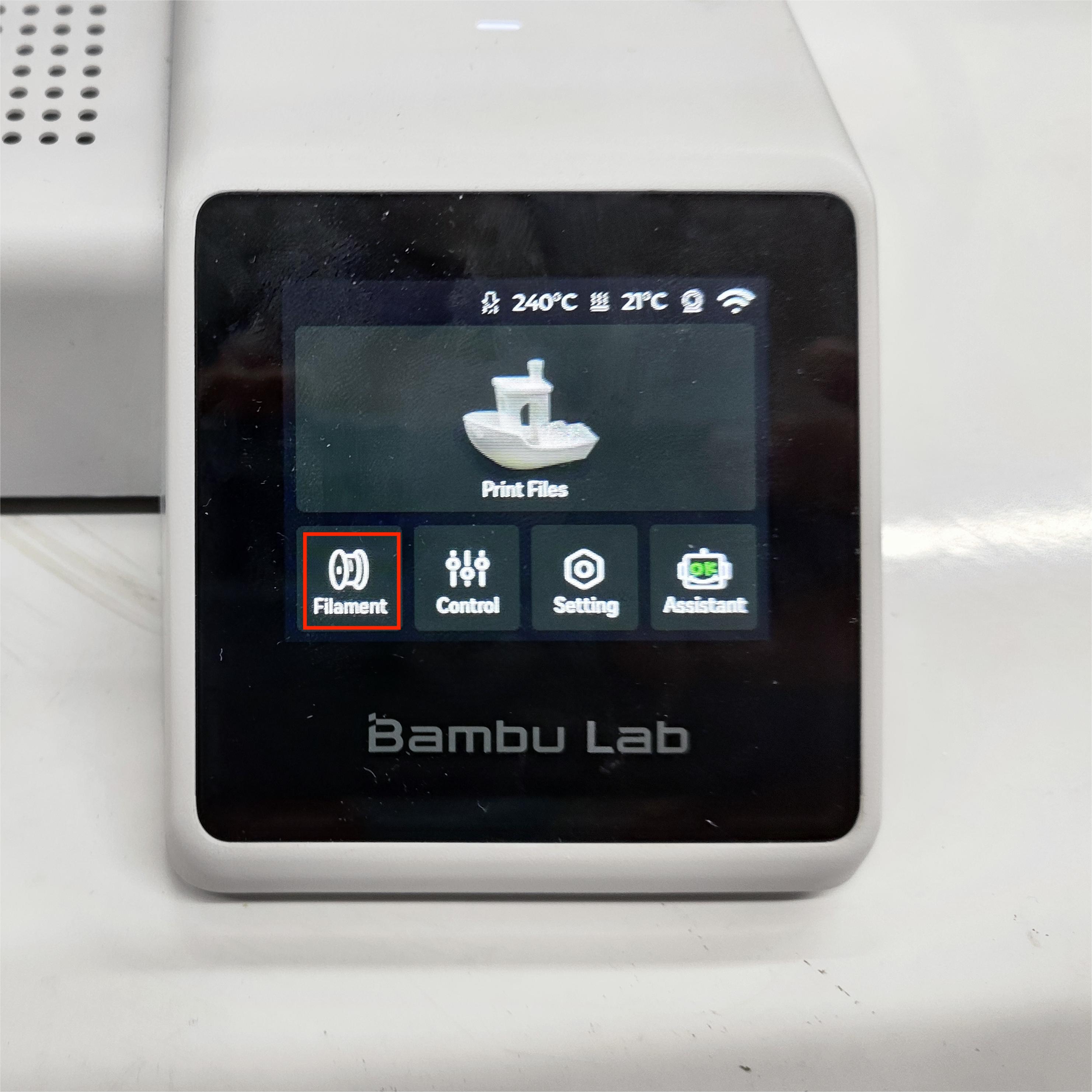

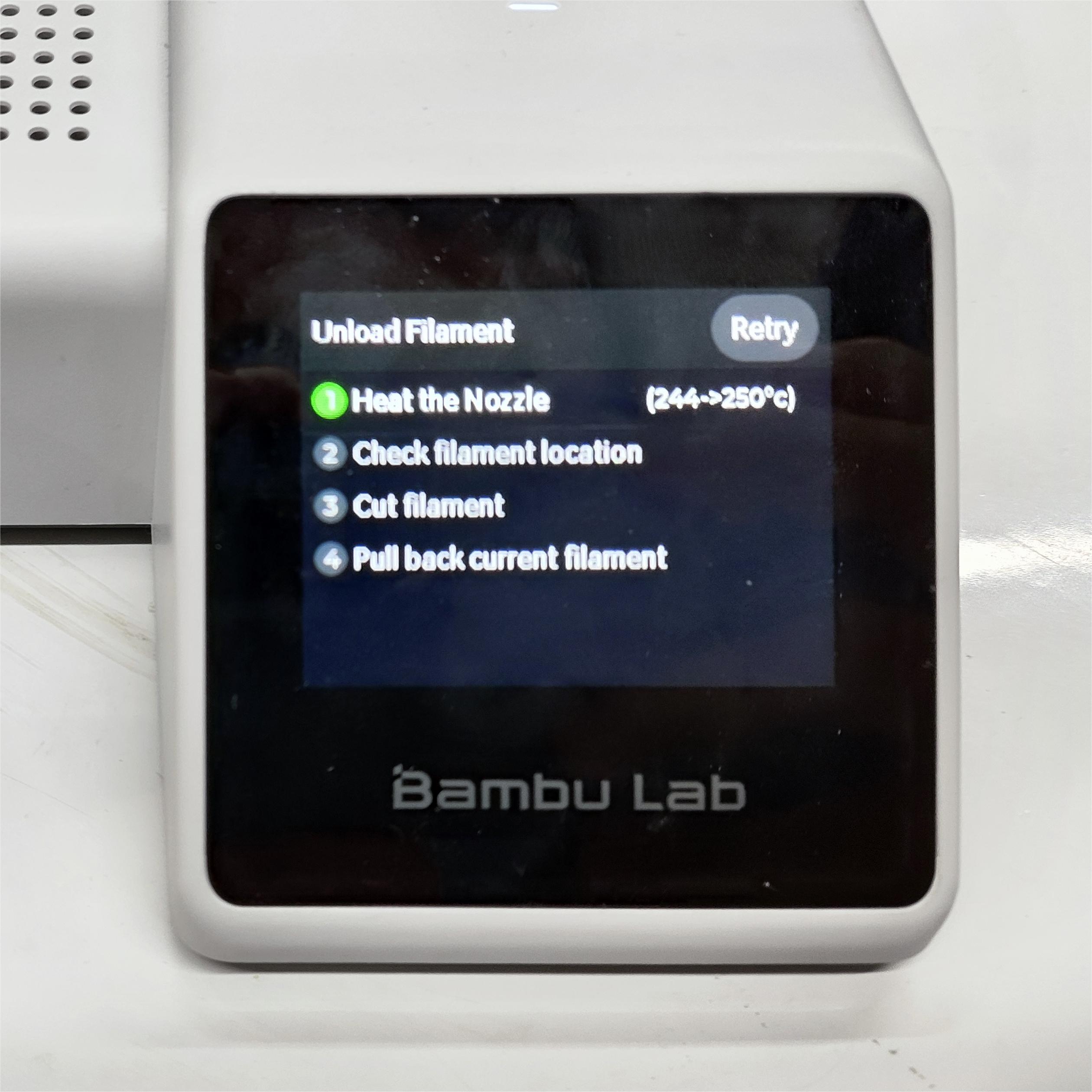

Method 1: Unload the filament by operating the printer (when the printer is powered on)

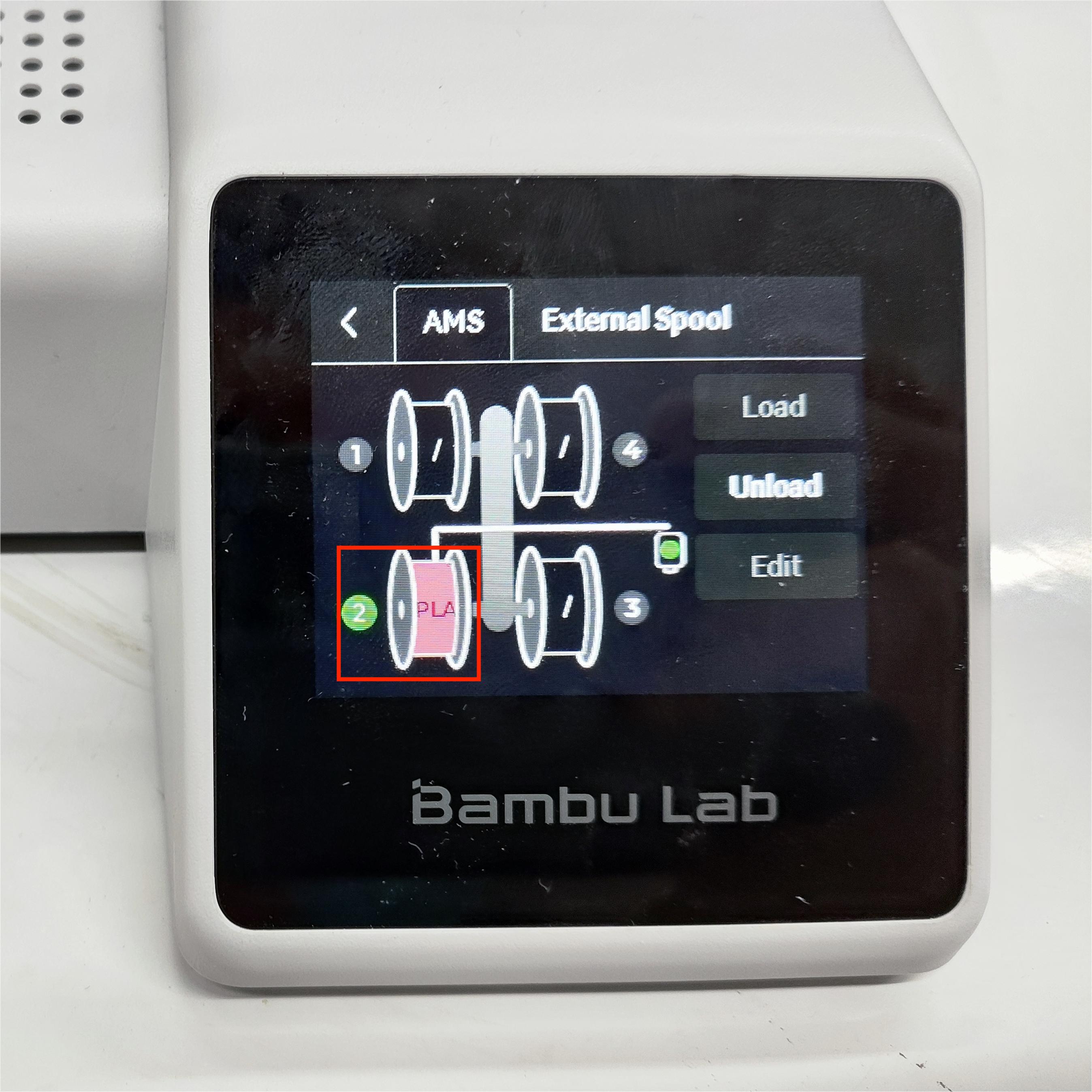

1. Click "Filament" on the printer screen, and select the filament slot you want to unload

|

|

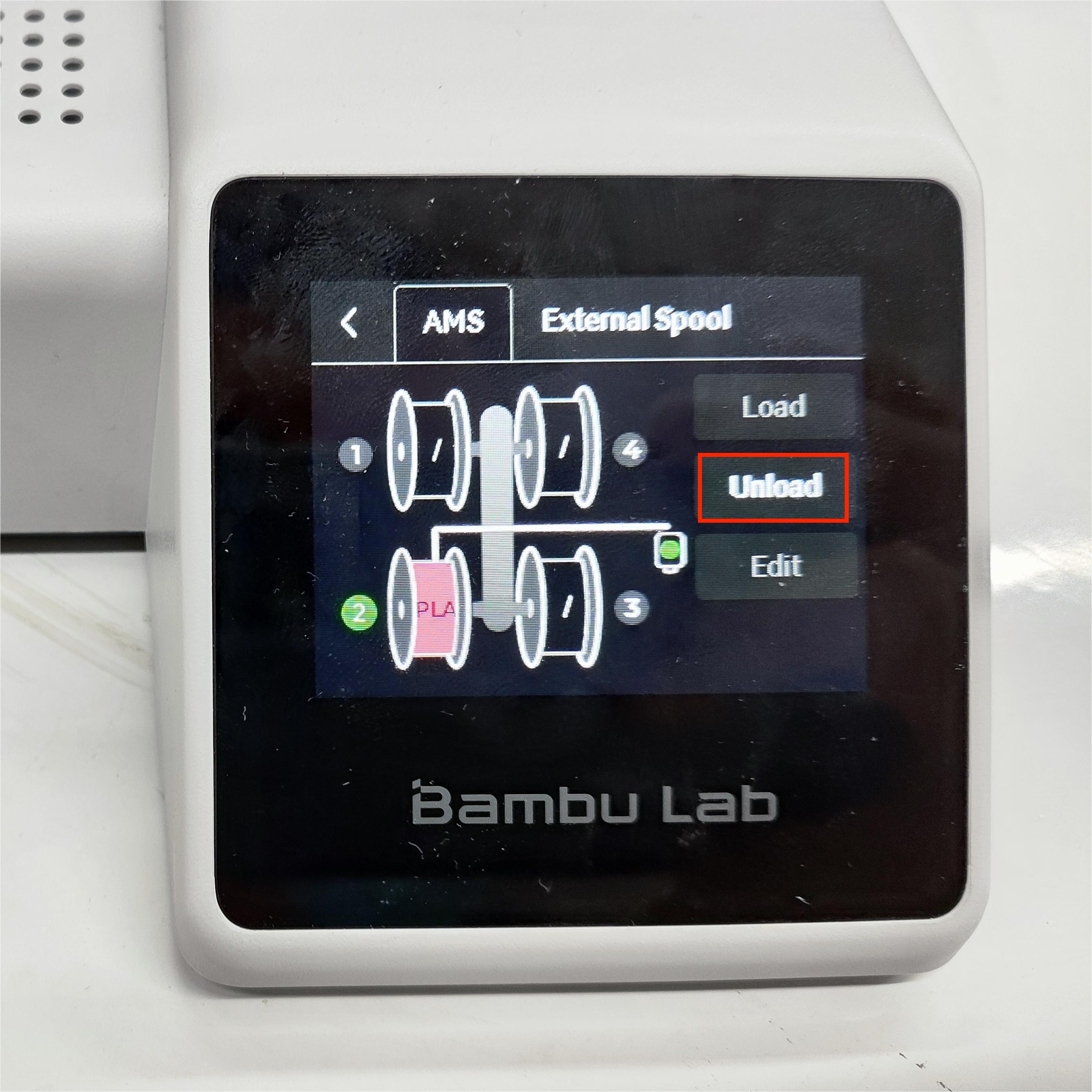

2. Click the "Unload" button set up the unloading process and wait for about 3 minutes to finish.

|

|

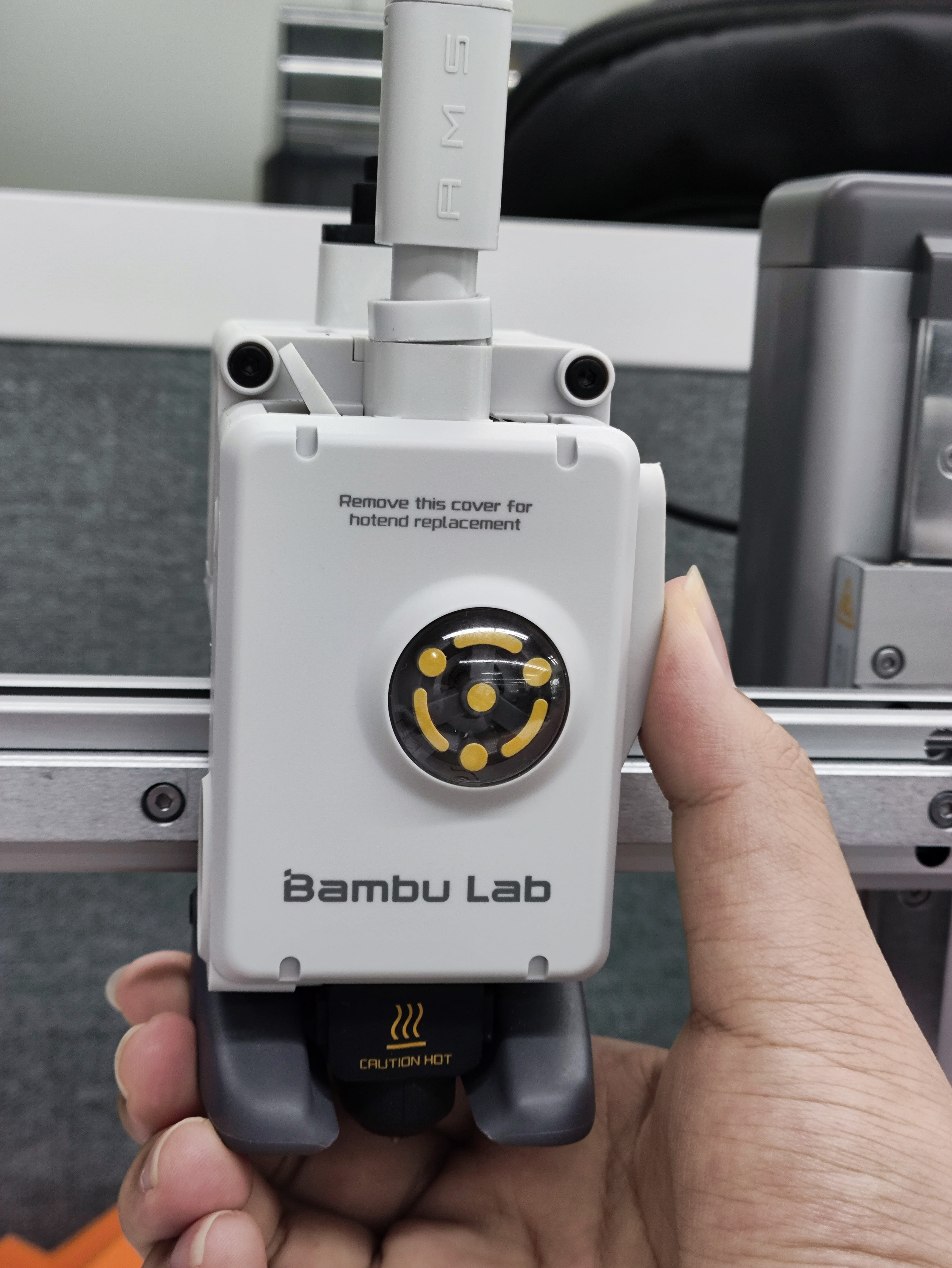

Method 2: Cut the filament with the filament cutter and unload the filament manually (when the printer is powered off)

|

|

¶ Step 2: Power off, and remove the filament hub assembly

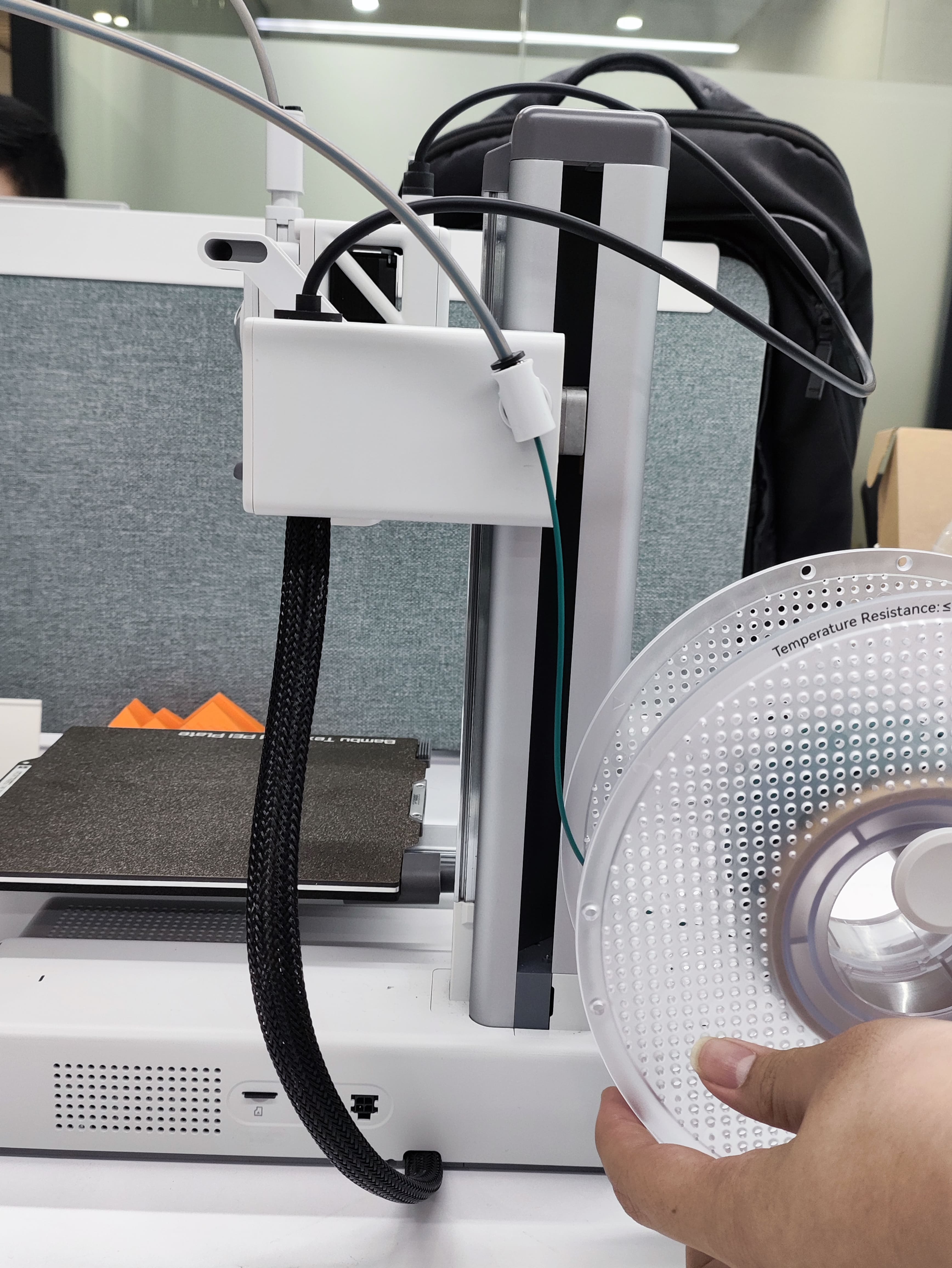

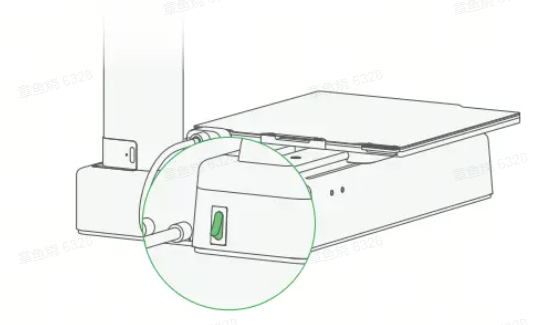

1. Press the switch button to power off the printer and disconnect the power cable. (skip if you take Method 2 in Step 1)

|

|

2. Use a wrench to delicately pry off the Filament Hub Cap, then remove the Filament Hub Assembly and the corresponding spring from the top.

|

|

|

|

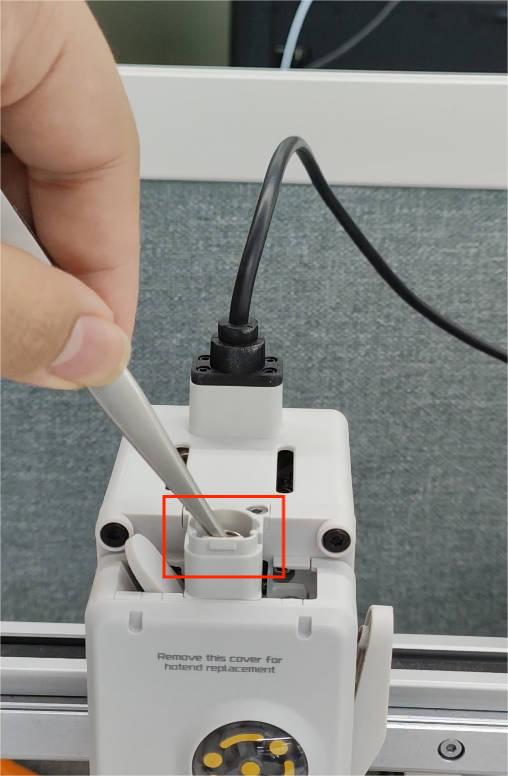

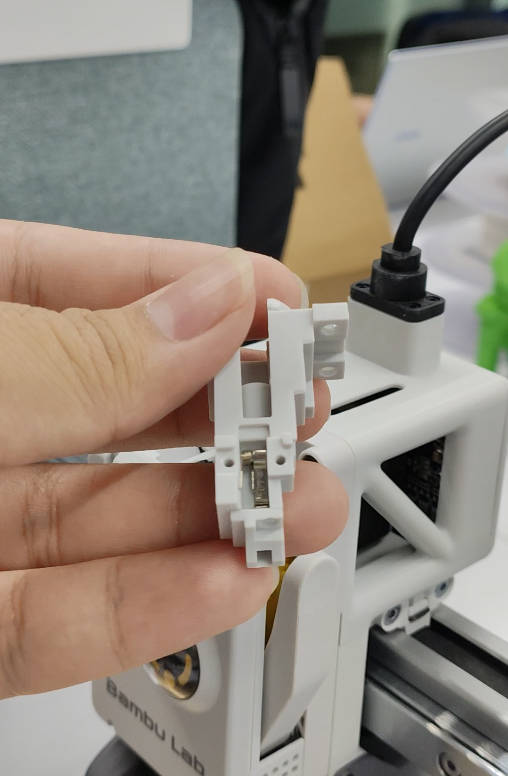

¶ Step 3: Remove the Filament Sensor and Replace the Feeding Bracket

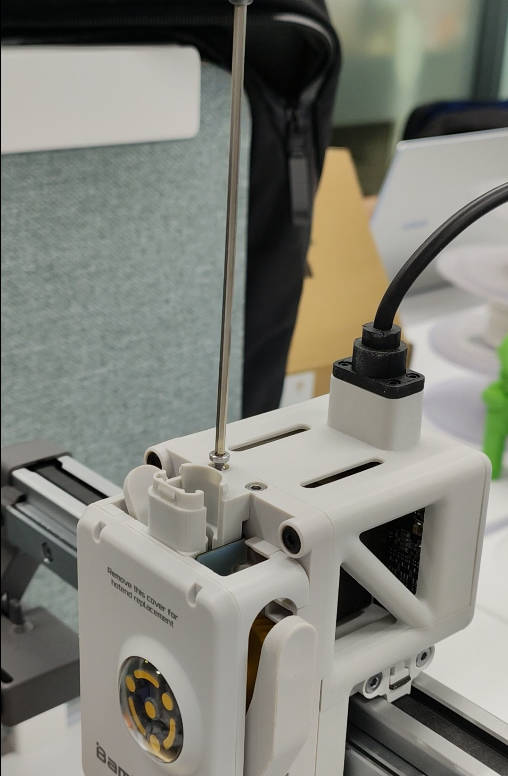

1.Use an H2.0 hex key to unscrew two screws and pull up the filament sensor base

|

|

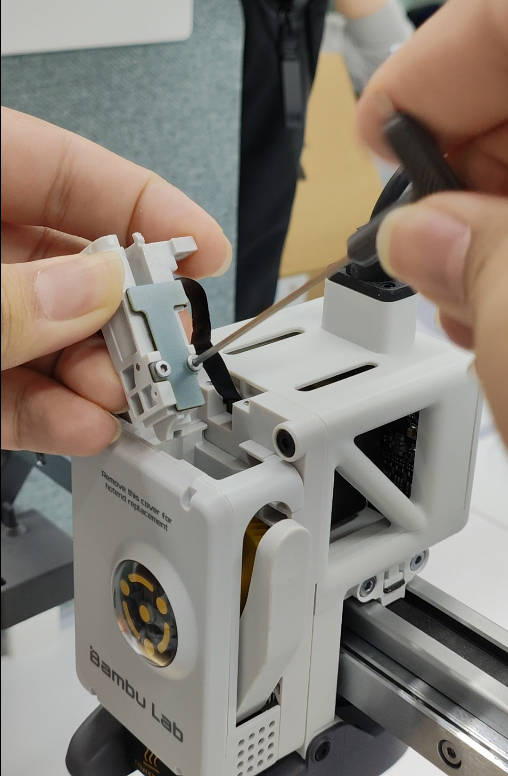

2. Use an H1.5 hex key wrench to unscrew two screws, disconnect the Filament Sensor and replace the filament sensor base

|

|

Attention: To install the filament sensor base, simply follow the reverse process of the reference disassembly. Please be careful to arrange the connection wiring properly to avoid any bending or damage.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.