¶ What it is

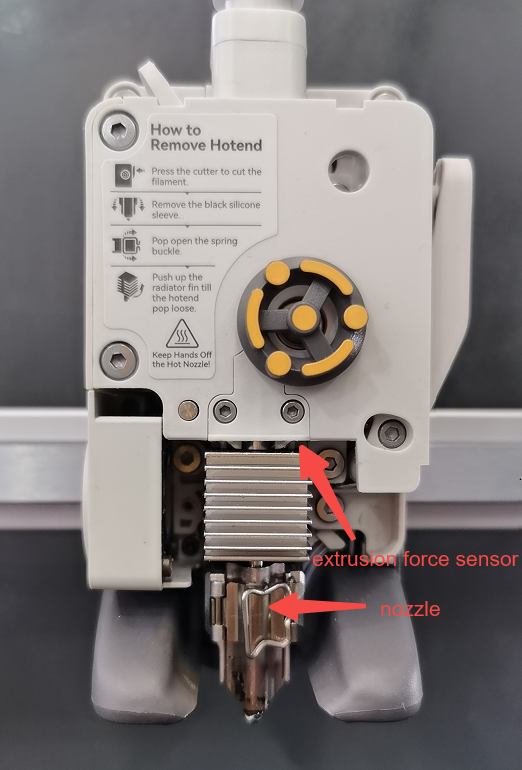

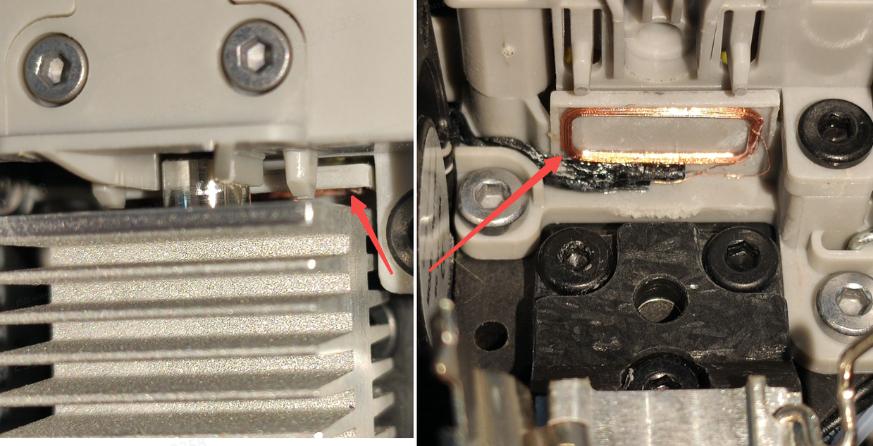

After the nozzle is installed, the distance between the hot end heat sink and the extrusion force sensor (rectangular coil) is too large, resulting in the sensitivity of the extrusion force sensor to detect the nozzle force being too low, thus affecting normal printing.

Possible causes:

1. The assembly tolerance of the hot end is too large

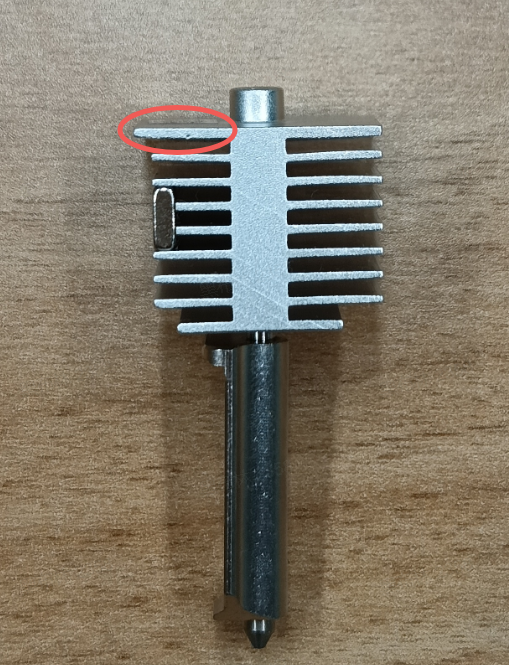

2. The top surface of the heat sink is deformed, such as downward warping.

¶ Solution

Remove the hot end and observe whether the heat sink has deformed and warped downwards; If there is no obvious deformation, reinstall the nozzle according to the instructions, and click the "Home" button on the screen to observe whether it can home normally. If the homing succeeds, the fault is resolved. If there is a noticeable downward warping on the heatsink, please take a picture and submit the ticket to contact the support team.

¶ Error message

HMS_0300-1800-0001-0002: The sensitivity of the extrusion force sensor is low, the hotend may not installed correctly.

“The sensitivity of the extrusion force sensor is low, the hotend may not installed correctly.”

0300-1800-0001-0002

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a Technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.