¶ The cause of the error

When the A1 series printer is used with AMS lite, the filament is properly extruded during the loading and printing process. When an exception is detected, the printer pauses and reports an error. For more information, you can refer to the wiki: Air printing detection | Bambu Lab Wiki

Loading process: When AMS feeds the filament to the extruder, the extruder extrudes a new segment of filament, and the printer checks the information from the odometer in the AMS. If the extrusion length of the filament is abnormal, the printer will pause and report an error. Only by extruding a sufficient length of filament during feeding can the printer determine whether AMS lite has successfully fed the filament into the extruder and successfully grabbed it.

Printing process: When the firmware of the A1 series printer is upgraded to the 01.02.00.00 firmware version, air printing detection during printing is supported. When the printer is printed with AMS lite, the printer monitors the extrusion distance of the extruder in real time and the odometer information in the corresponding slot of the AMS lite. When it is detected that the extruder cannot extrude material and is "air printing", the printer will automatically cut the filaments, pull the filaments out, pause the printing and report the error.

¶ Solution

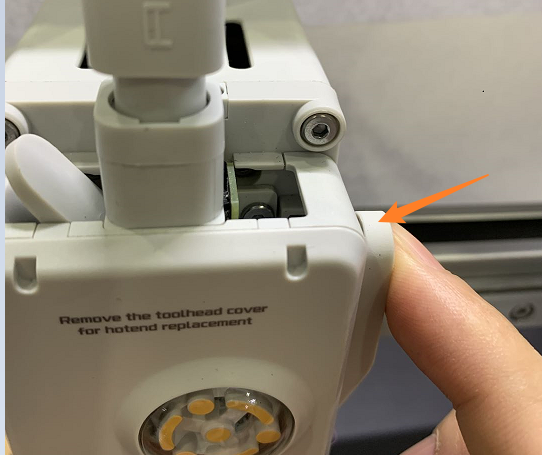

1. If the extrusion failure is reported during the feeding process, please manually press the tool head cutter to cut off the filament. If an error occurs during the printing process, go to Step 3.

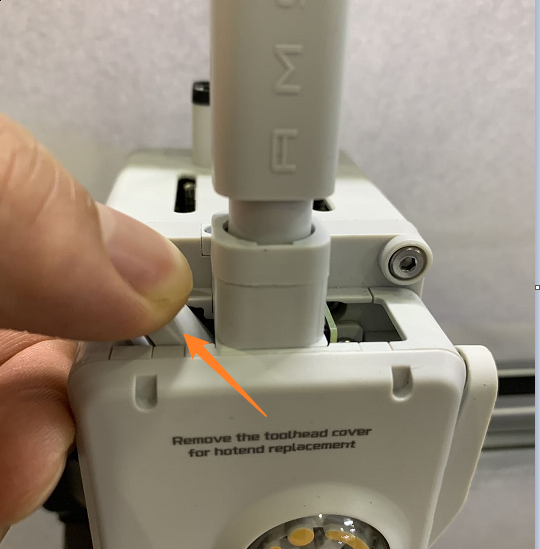

2. Manually press the drive wheel holder of the tool head and pull the filament from the feeder side.

|

|

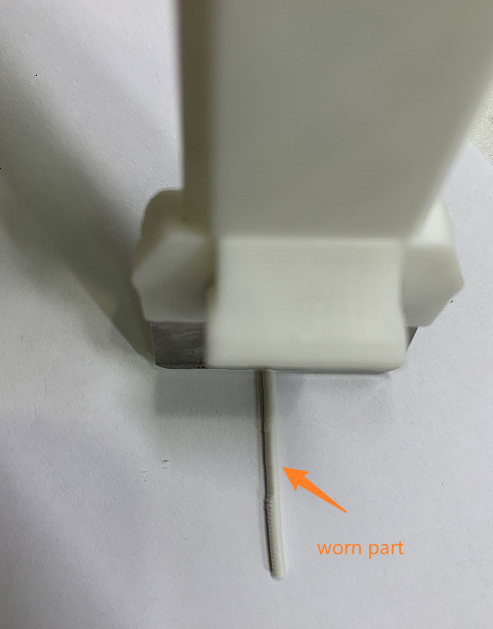

3. After pulling out the filament, check if there are any signs of wear on the filament. If so, cut the worn part, then insert the filament into the corresponding slot and retry.

4. If the problem still exists, please check whether the extruder or hot end is clogged, if the nozzle and extruder are not clogged, you can check whether the filament is too thin, whether the filament is slipping with the extruder gear, etc., you can also replace a roll of filament and try again. If multiple rolls of material will encounter this problem, it may also be that the extruder gear is abnormal, and can not successfully grab the filament.

5. If you are still unable to resolve the problem through the above steps, please submit a support ticket to contact the after-sales support team.

¶ Error code

HMS_1202-2000-0002-0006: Failed to extrude AMS3 Slot1 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1202-2100-0002-0006: Failed to extrude AMS3 Slot2 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1202-2200-0002-0006: Failed to extrude AMS3 Slot3 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1202-2300-0002-0006: Failed to extrude AMS3 Slot4 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1203-2000-0002-0006: Failed to extrude AMS4 Slot1 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1203-2100-0002-0006: Failed to extrude AMS4 Slot2 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1203-2200-0002-0006: Failed to extrude AMS4 Slot3 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1203-2300-0002-0006: Failed to extrude AMS4 Slot4 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1200-2000-0002-0006: Failed to extrude AMS1 Slot1 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1200-2100-0002-0006: Failed to extrude AMS1 Slot2 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1200-2200-0002-0006: Failed to extrude AMS1 Slot3 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1200-2300-0002-0006: Failed to extrude AMS1 Slot4 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1201-2000-0002-0006: Failed to extrude AMS2 Slot1 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1201-2100-0002-0006: Failed to extrude AMS2 Slot2 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1201-2200-0002-0006: Failed to extrude AMS2 Slot3 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

HMS_1201-2300-0002-0006: Failed to extrude AMS2 Slot4 filament; the extruder may be clogged or the filament may be too thin, causing the extruder to slip.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a Technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.