¶ Applicable models of printers

A1

¶ Y-belt for A1

The Y-belt is installed on the Y-axis. It connects the toolhead with the Y motor and drives the toolhead to move along the Y-axis.

¶ When to use?

- It is worn.

- It is broken.

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, we recommend submitting a technical ticket regarding your issue and we will do our best to respond promptly and provide the assistance you need.

¶ Tools and materials needed

- New Y-belt (Purchase link: Y Belt - A1)

- H2.0 hex wrench

- tweezer

- 20 minutes

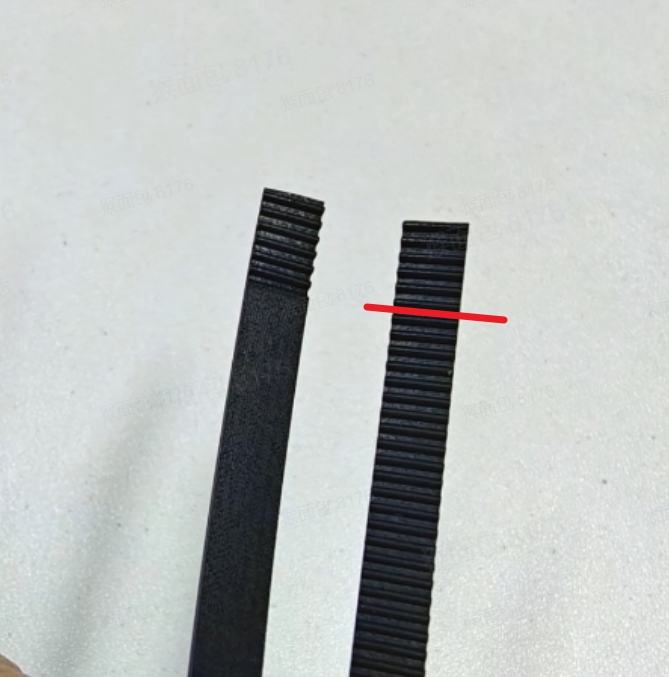

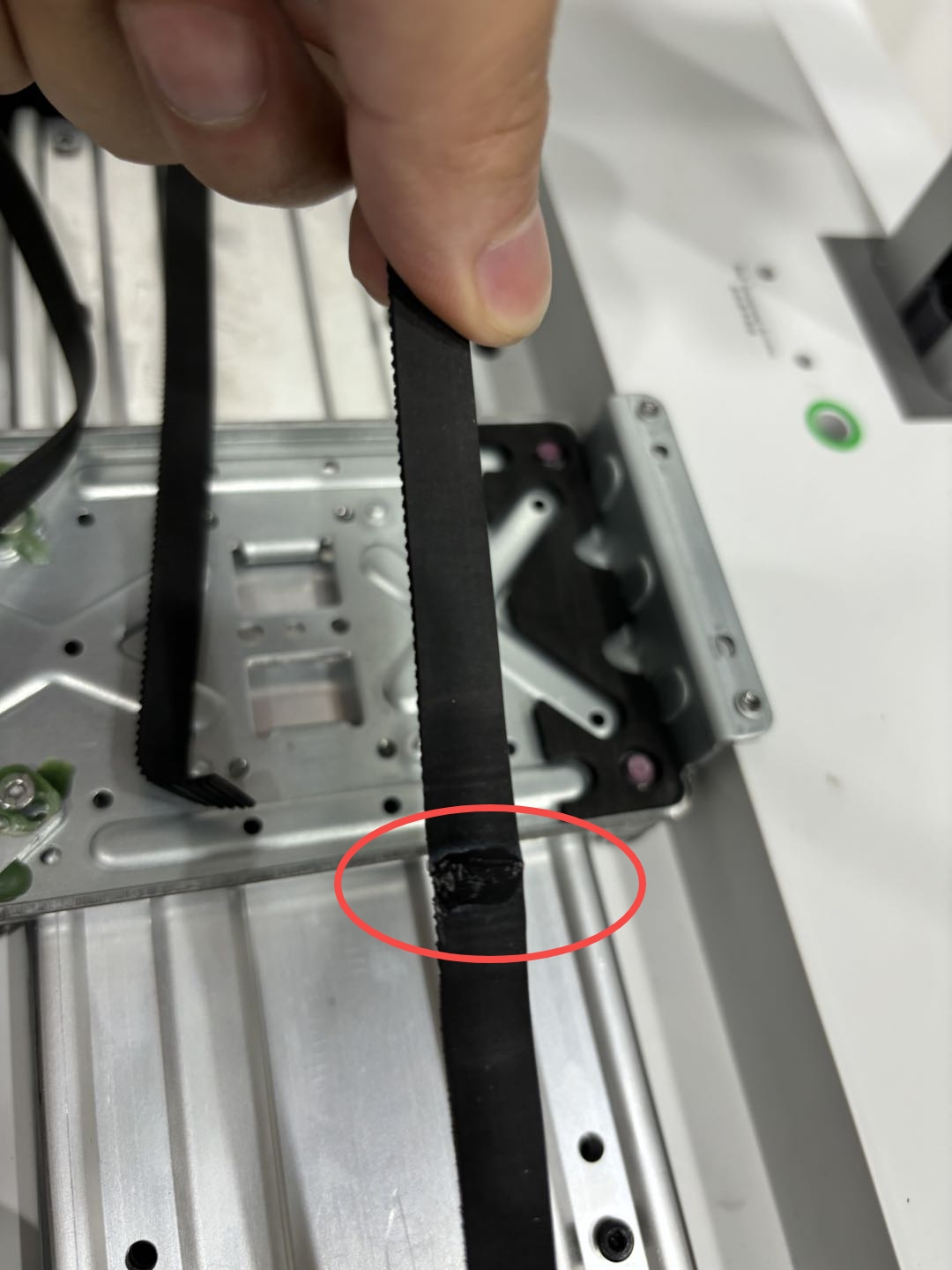

Note: When you receive the new Y belt, please first record the length of the new belt, then compare it with the length of the old belt. If the new belt is longer than the old belt, you need to shorten the belt by cutting 6 teeth from the side with more teeth, as shown in the diagram below:

¶ Remove the Y-belt

¶ Remove the heatbed and Y-axis top cover

Step 1: Place the A1 printer on a flat desktop with the X-axis rising to the top;

Step 2:Move the heatbed forward to the bottom and remove the Y-axis top cover.

|

|

Step 3:Then move the heatbed back to the end.

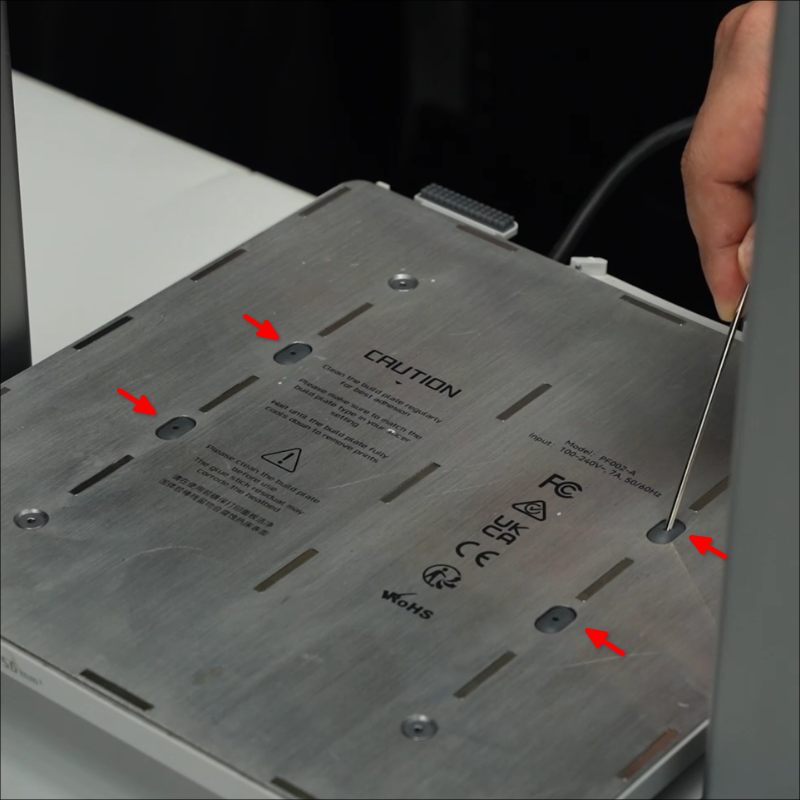

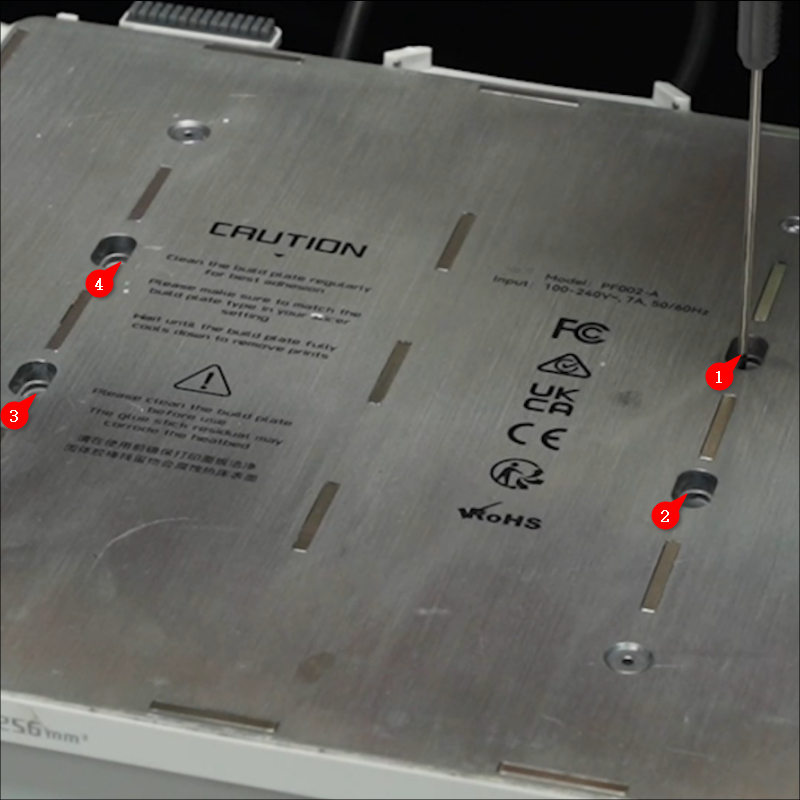

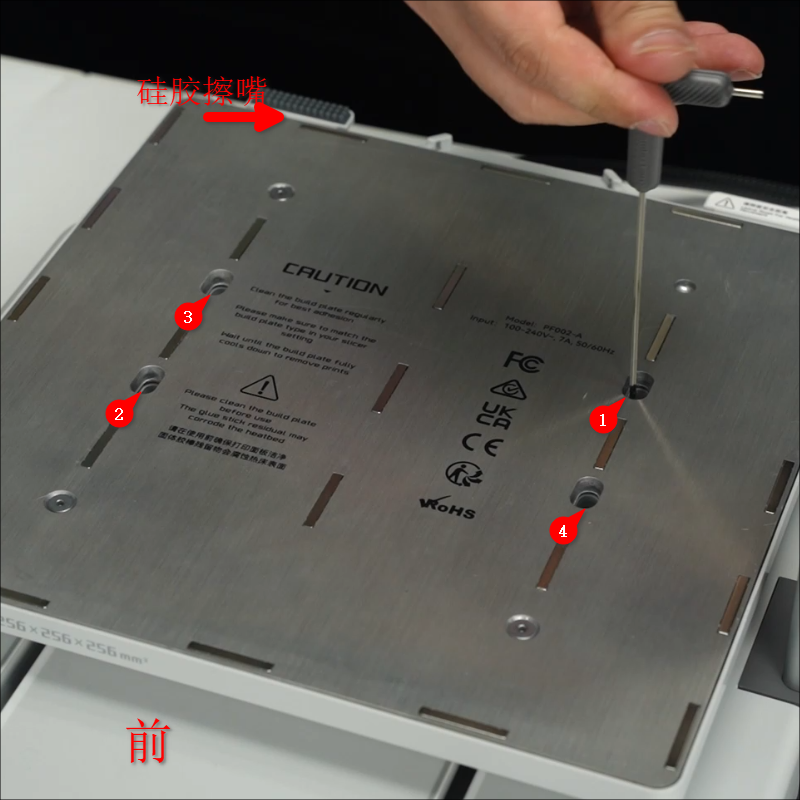

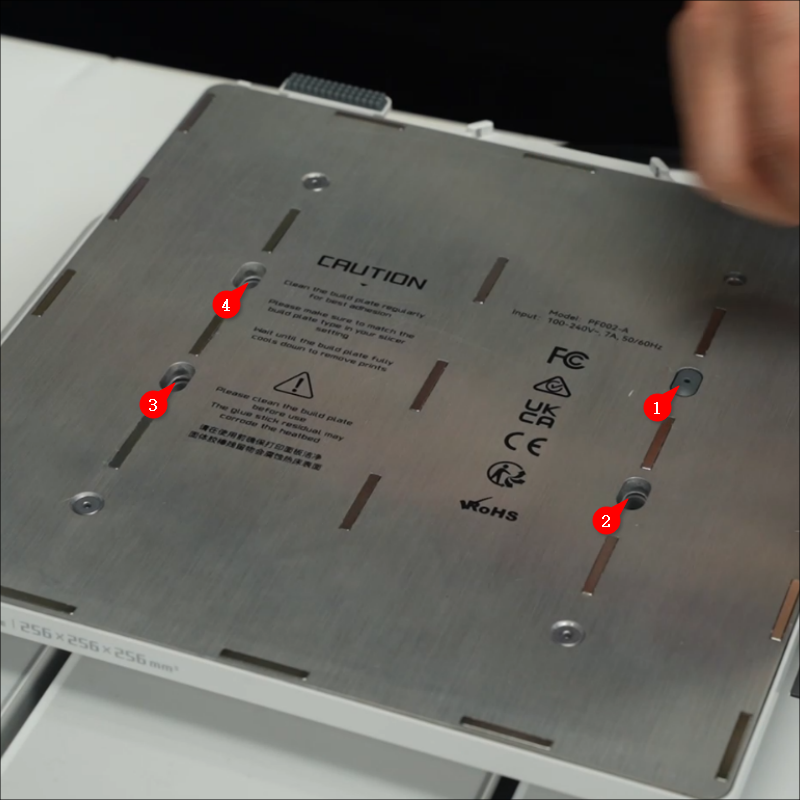

Step 4:Use an H2.0 hex wrench to remove the four soft rubber plugs, completely loosen the 4 screws, remove the heatbed from the base, and place it on the table.

|

|

|

¶ Remove the printer bottom cover

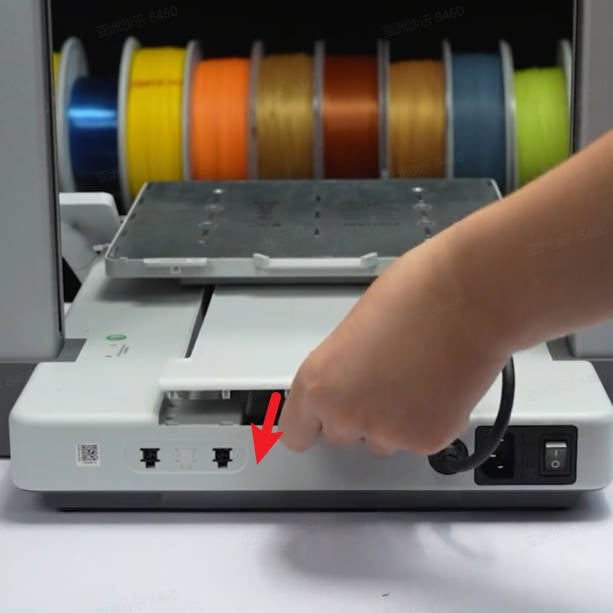

Step 1: First flip the screen to its side and then gently place the printer face down as shown in the picture below. It is recommended to use a box of supplies to lift the head to avoid crushing the machine and screen.

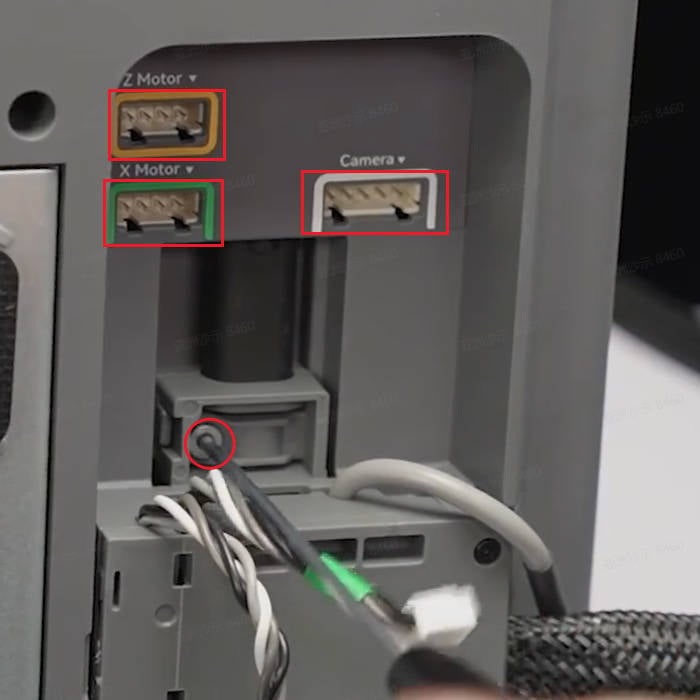

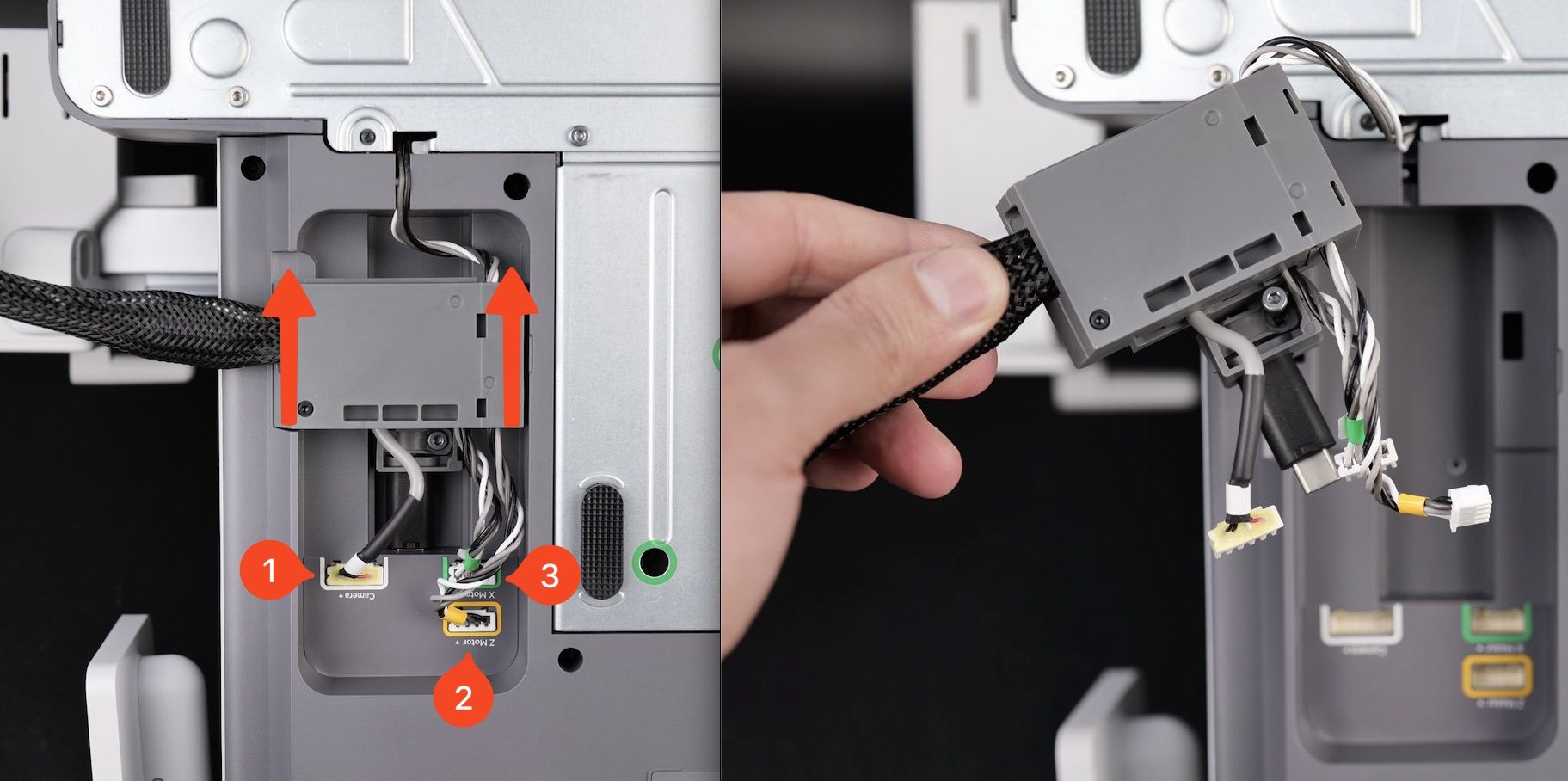

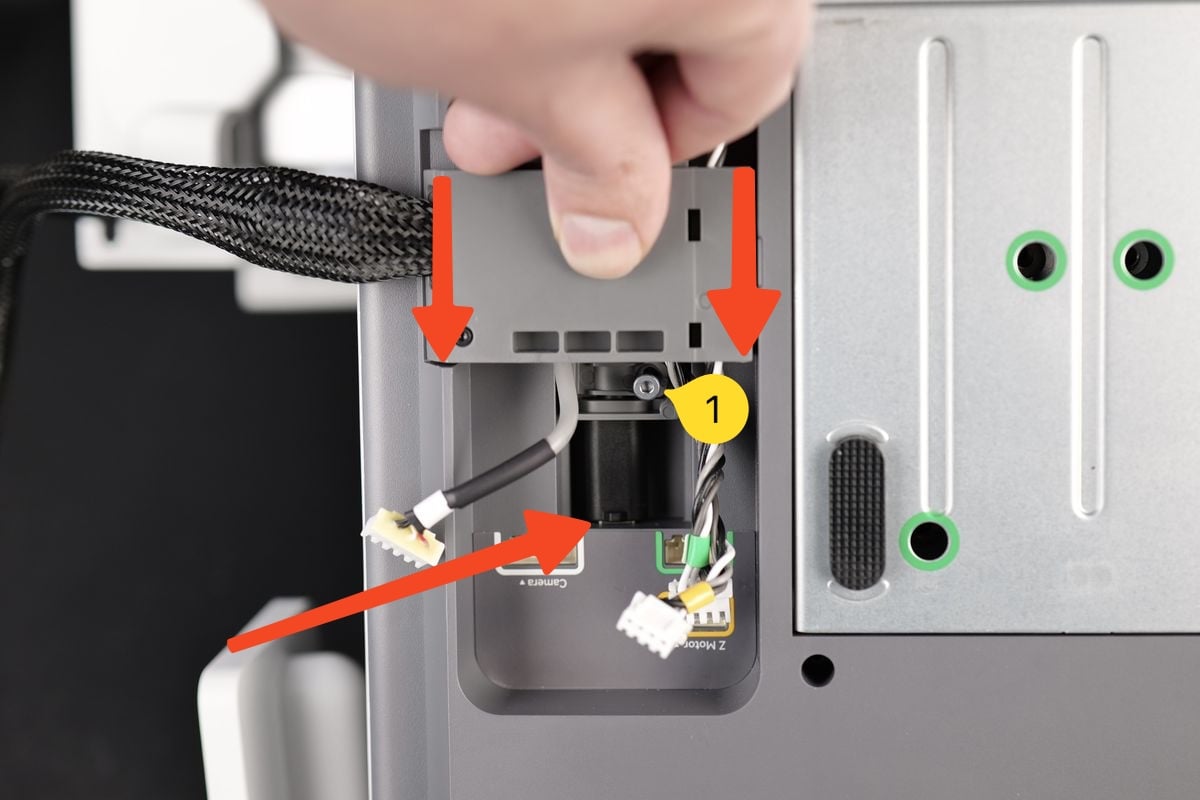

Step 2: Disconnect the cables from the camera, X-axis motor, and Z-axis motor, and then loosen the screws shown in the picture below (just loosen them, do not unscrew them completely!).

Then, push up on the cable holder to disconnect the USB cable.

Step 3: Remove the SD card from the printer.

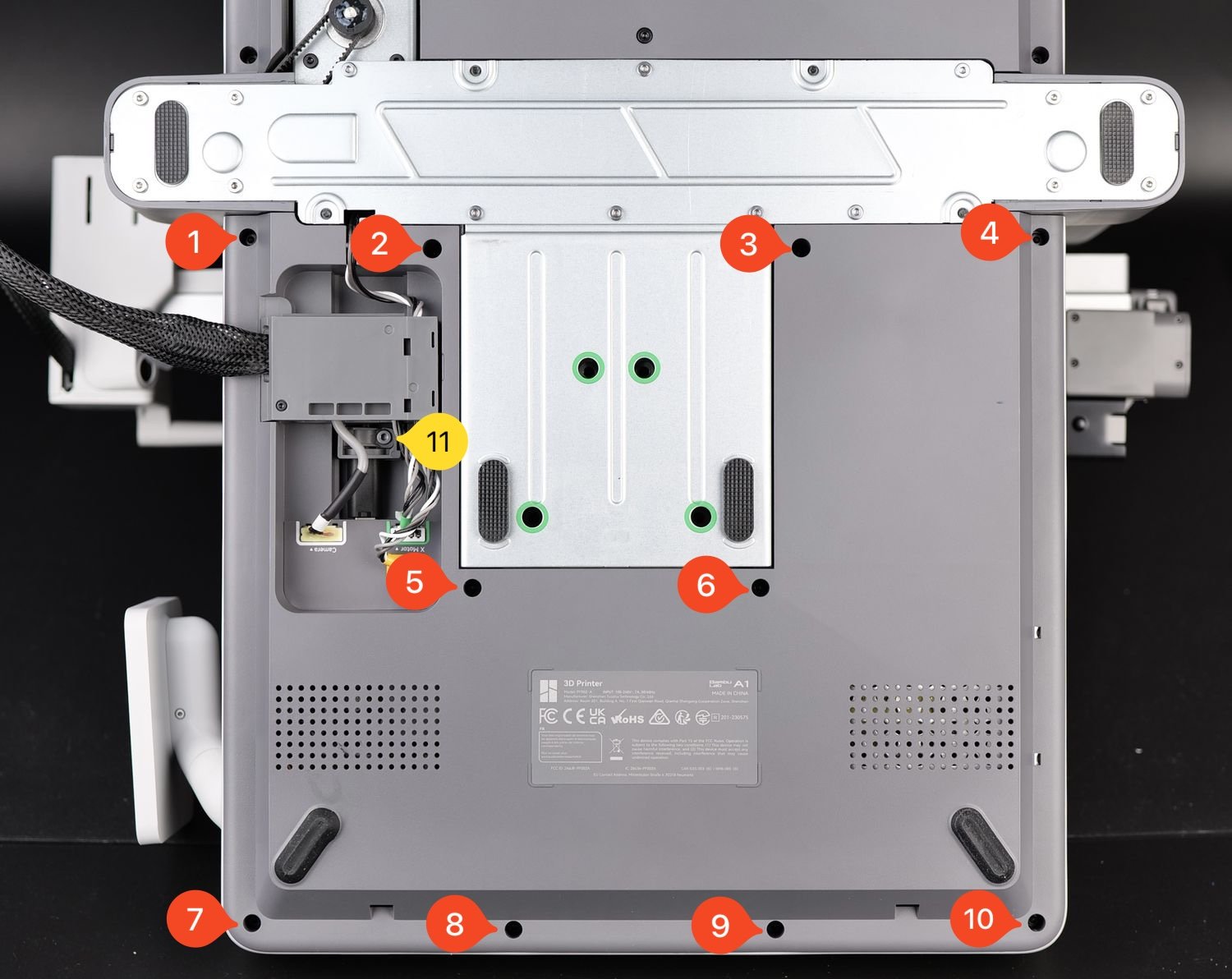

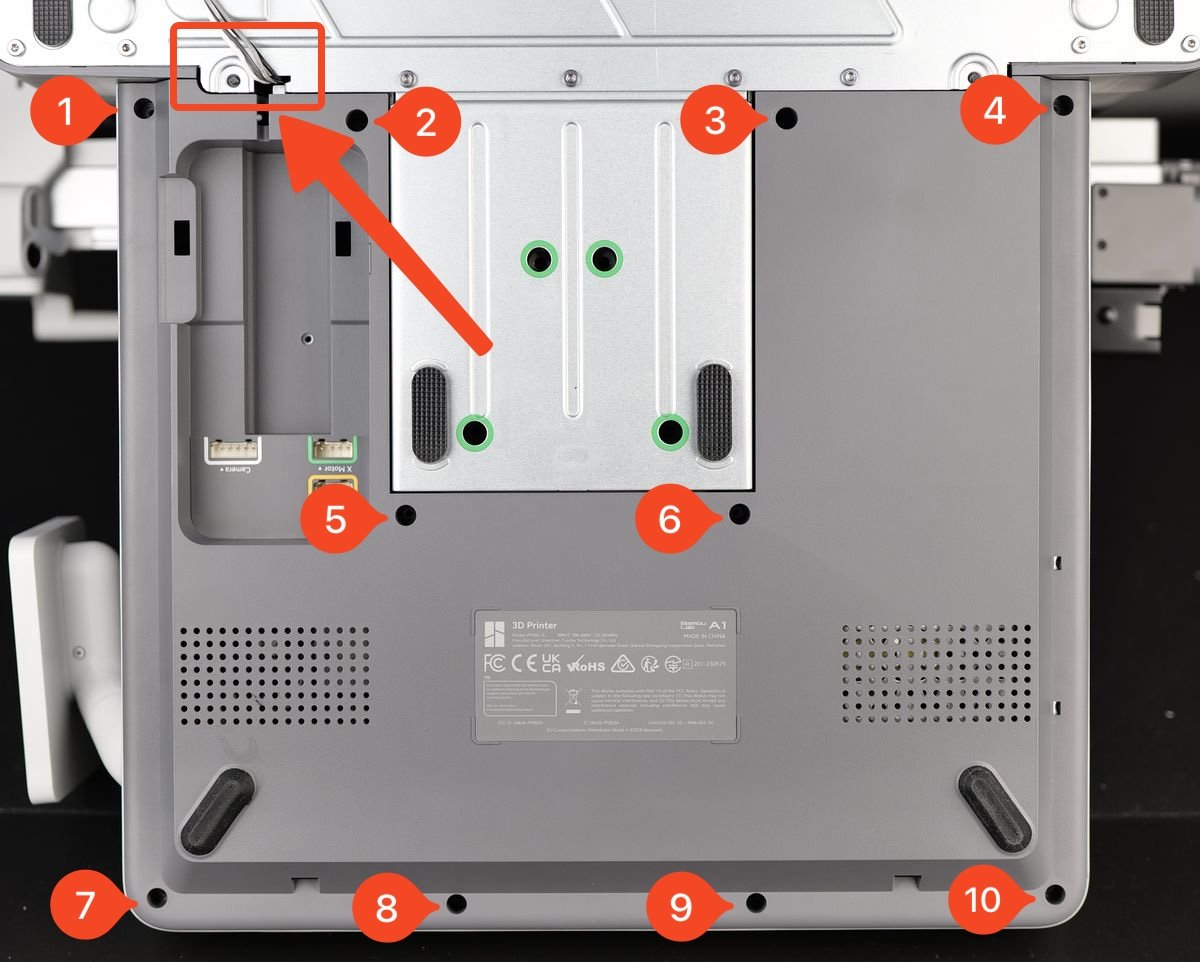

Step 4: Remove the 10 screws marked in red.

¶ Release Y-belt torsional spring and remove the belt clamp

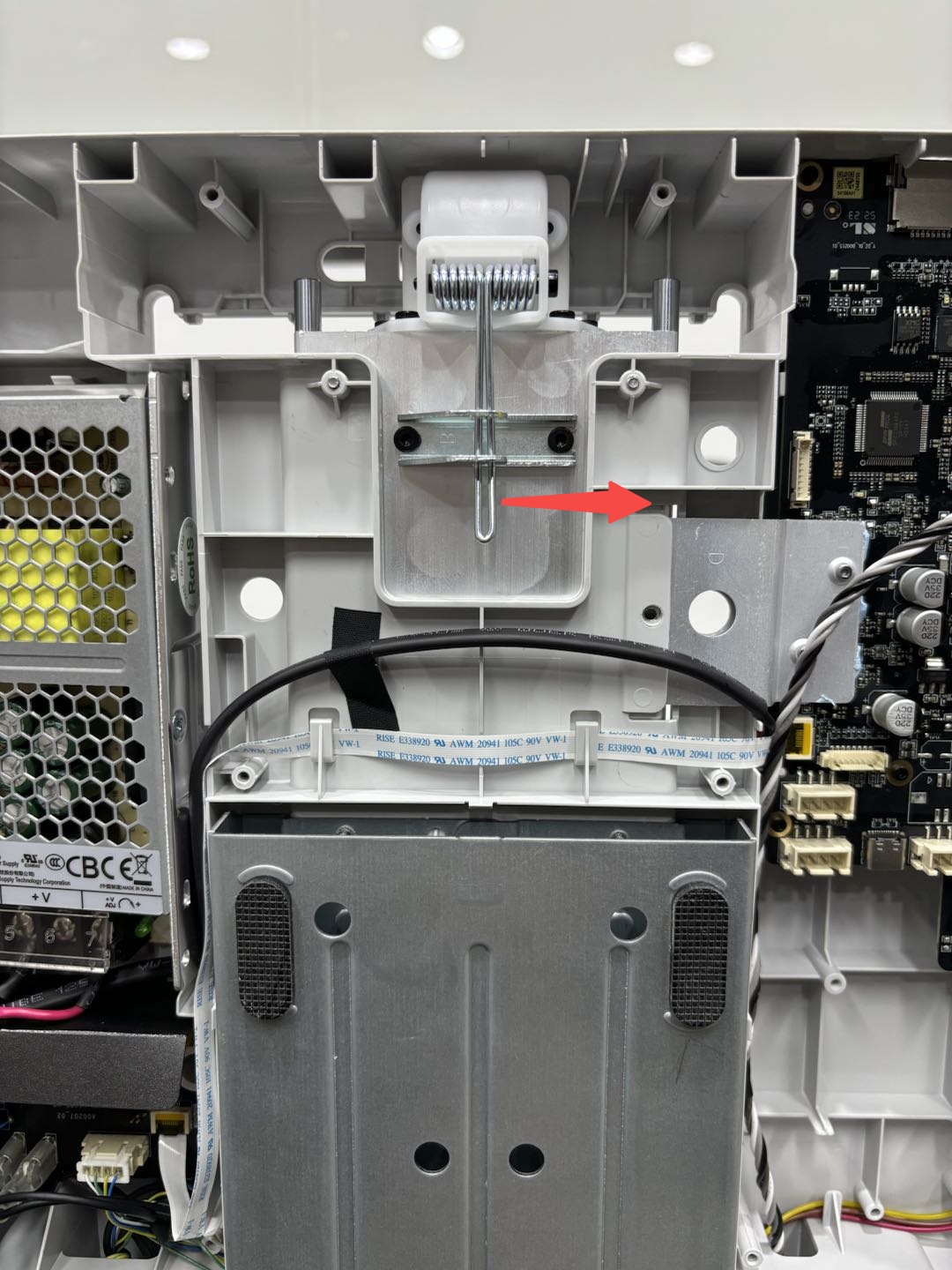

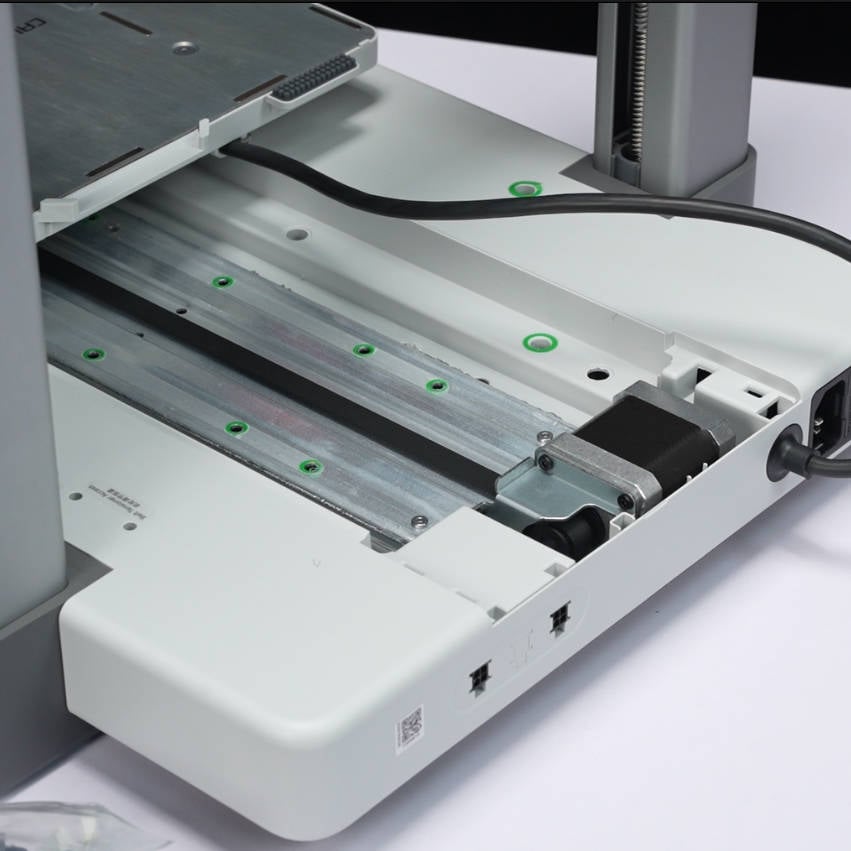

Step 1: Turn the printer over and place it on a stable table.

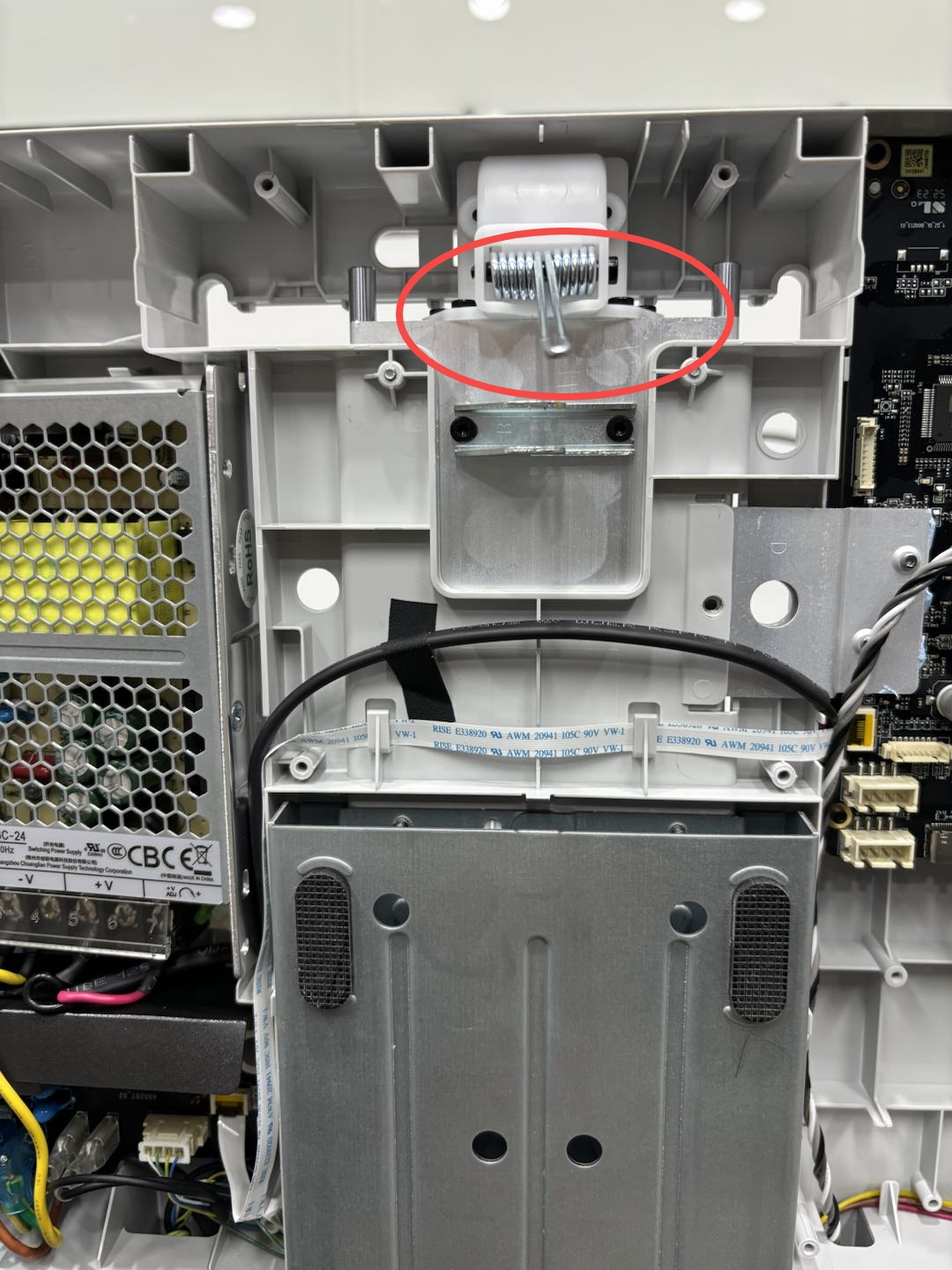

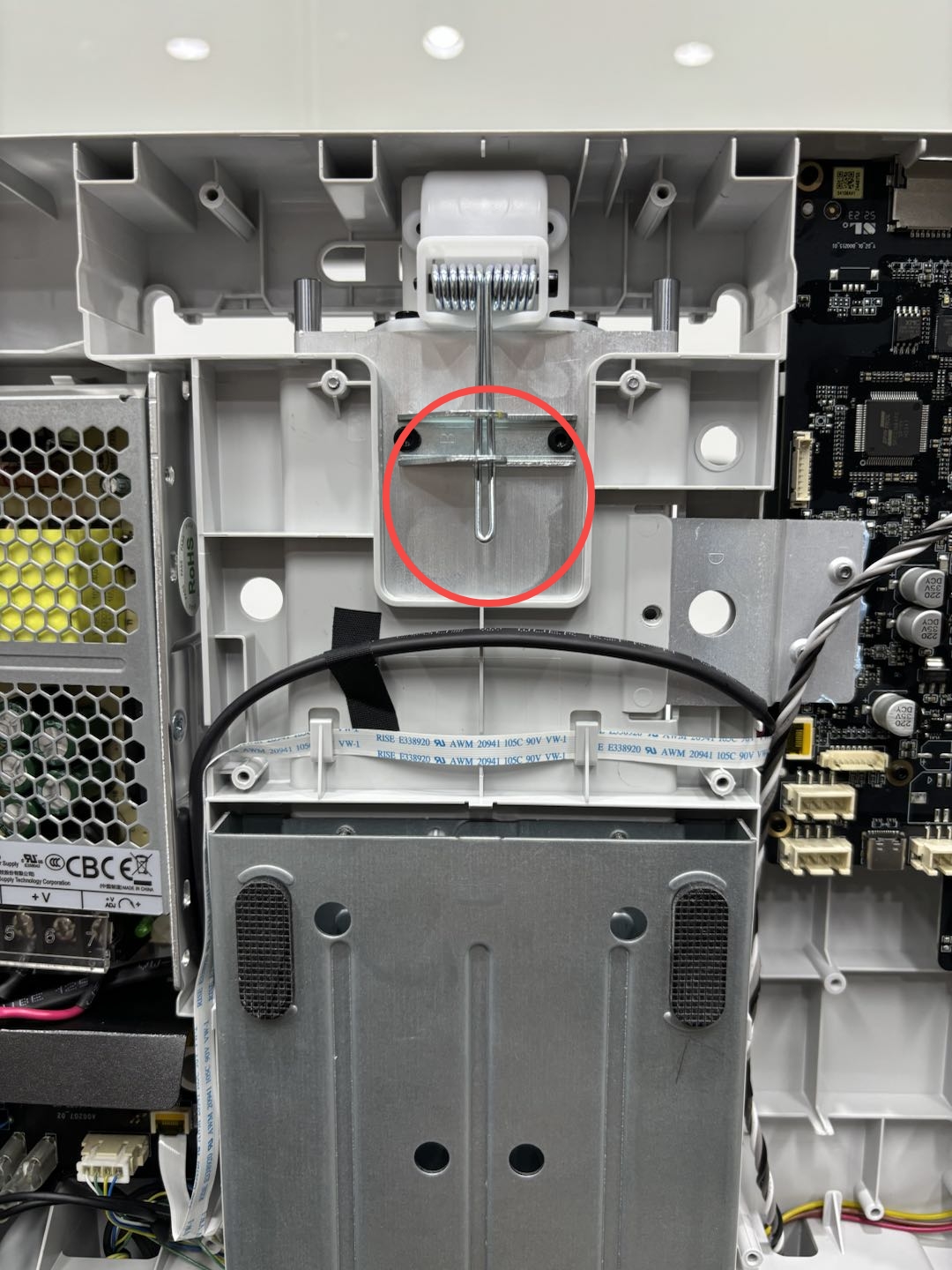

Refer to the picture below to release the Y-belt torsion spring:

|

|

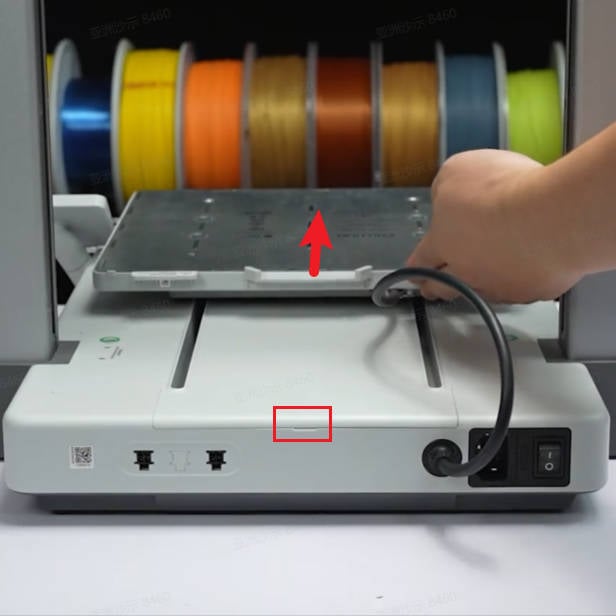

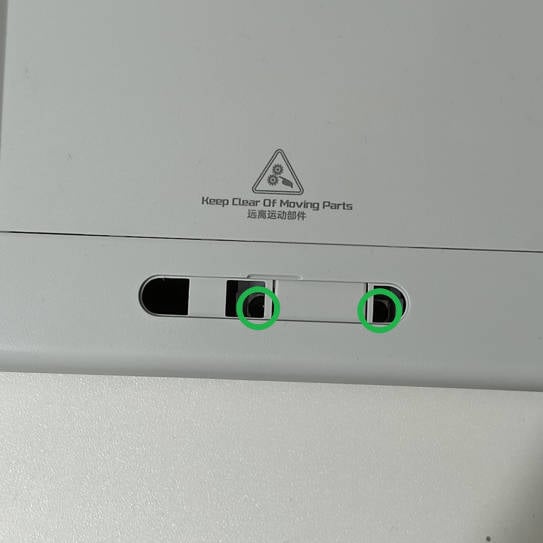

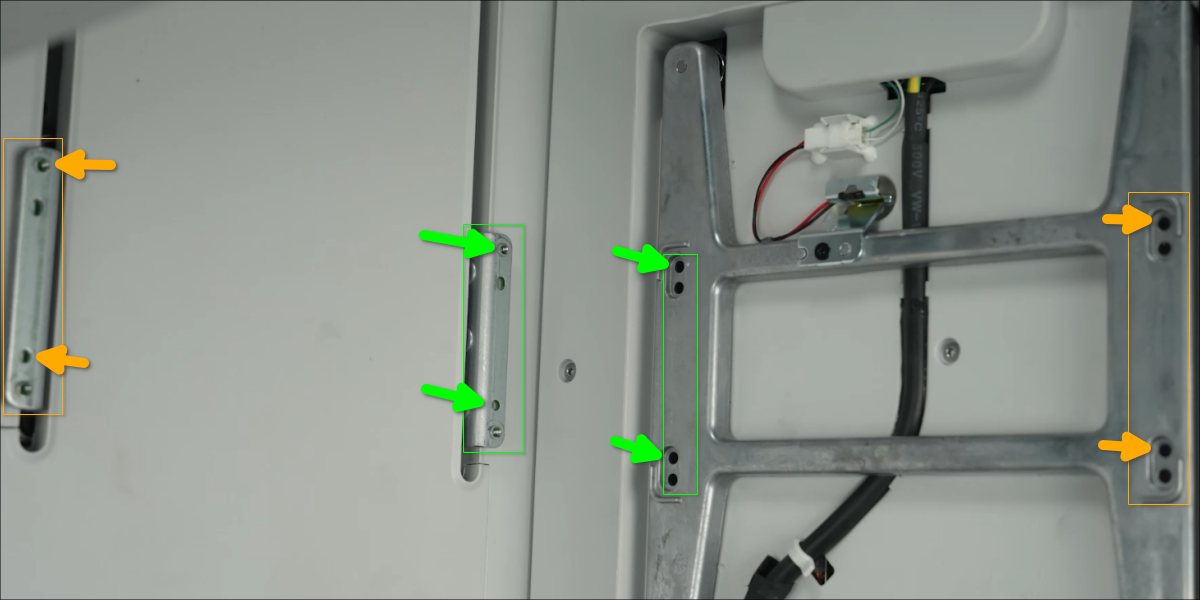

Step 2: The tension position of the Y belt is in front of the base and is covered by a cover. Please remove the cover first. Then use an H2.0 hex wrench to loosen the two tension screws one turn (do not loosen completely)

Note: Do not completely loosen or remove the Y-axis tension screw or you may need to reassemble the Y-axis tensioner.

|

|

|---|

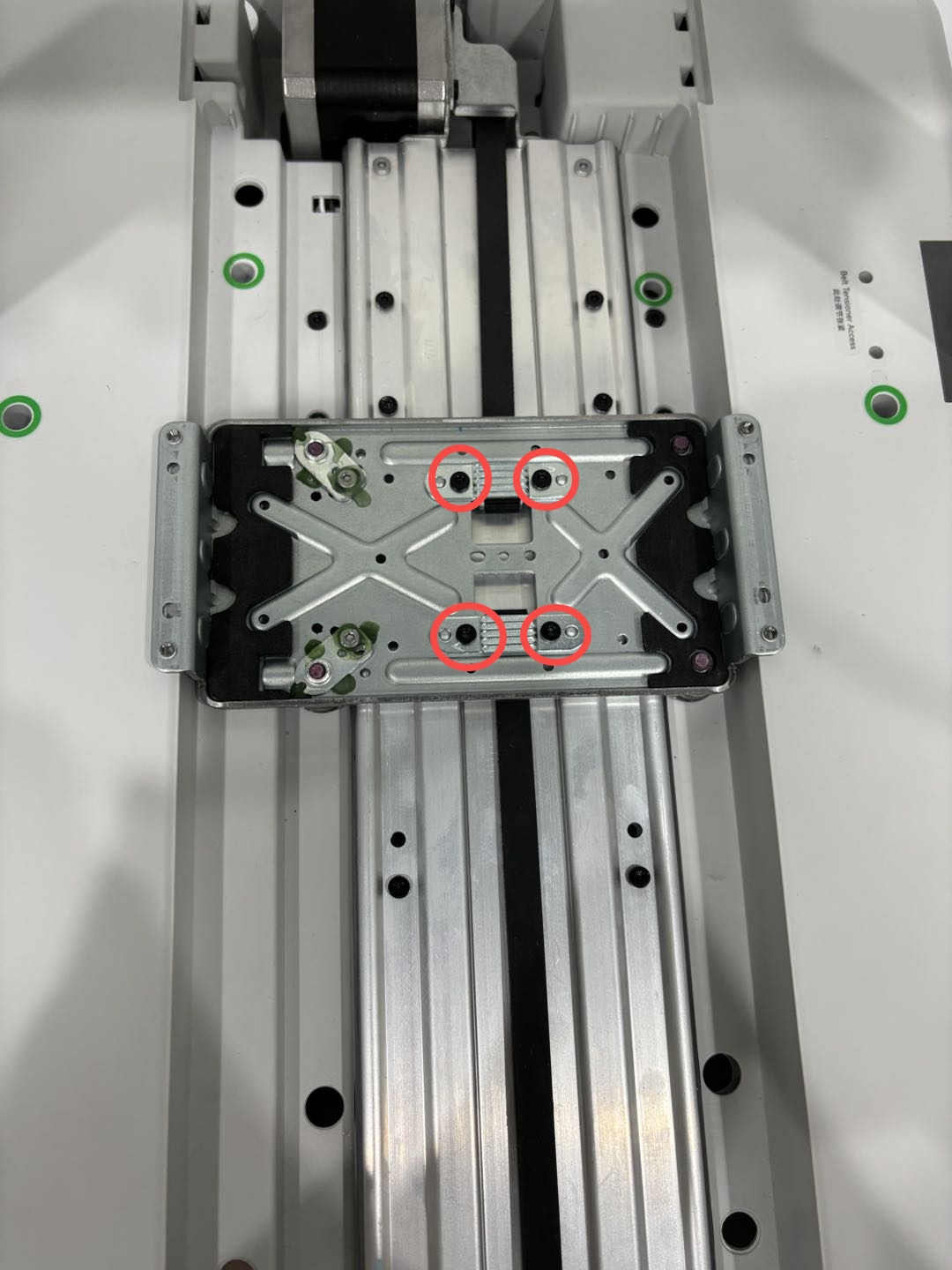

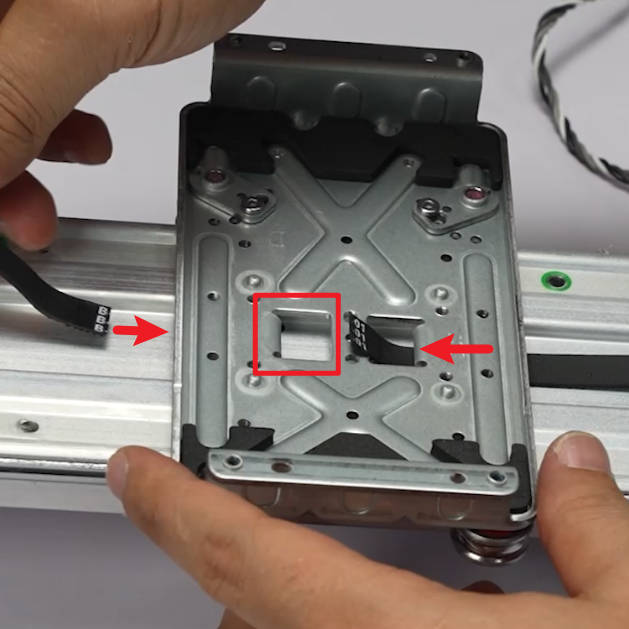

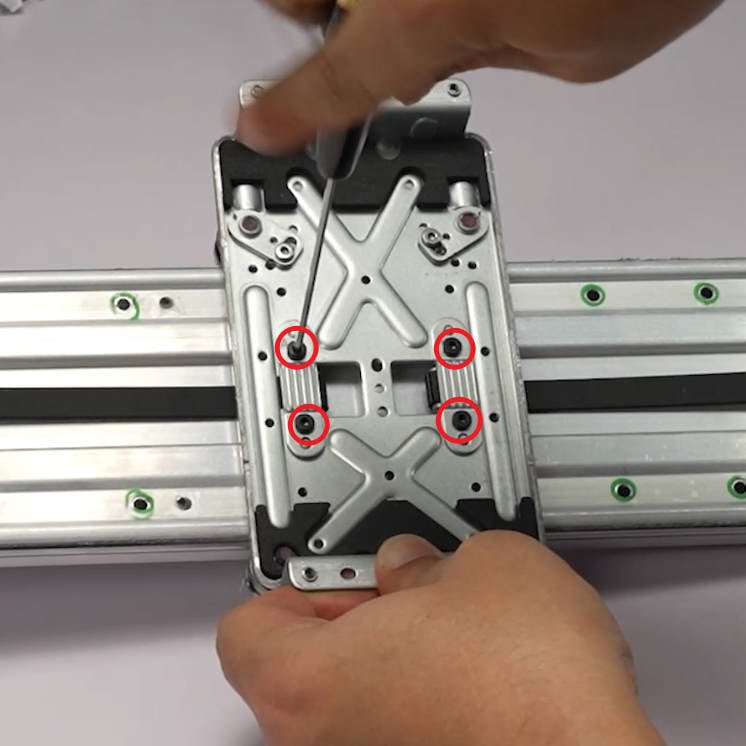

Step 3: Use H2.0 hex wrench to remove four screws, and remove the belt clamp.

¶ Glue the belt

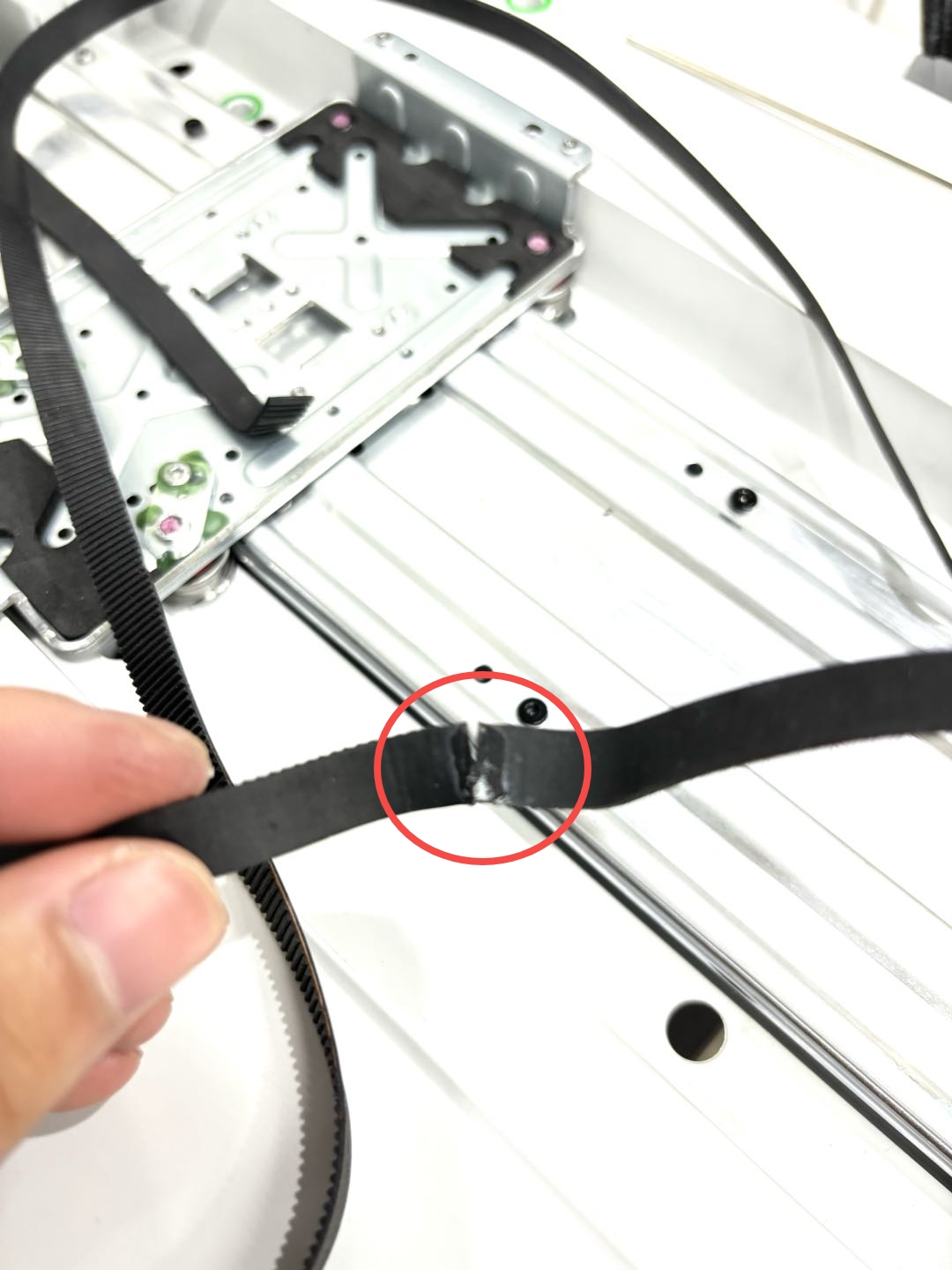

Please glue the new belt to the old belt and ensure the following points:

- The old and new belts have the same orientation, please refer to the orientation of the old belt;

- Taking the pasting method as shown in the figure below as an example, you can paste the end of the new belt with a longer tooth surface and the end of the old belt with a smaller tooth surface;

|

|

¶ Install the Y-belt

¶ Thread Y-belt

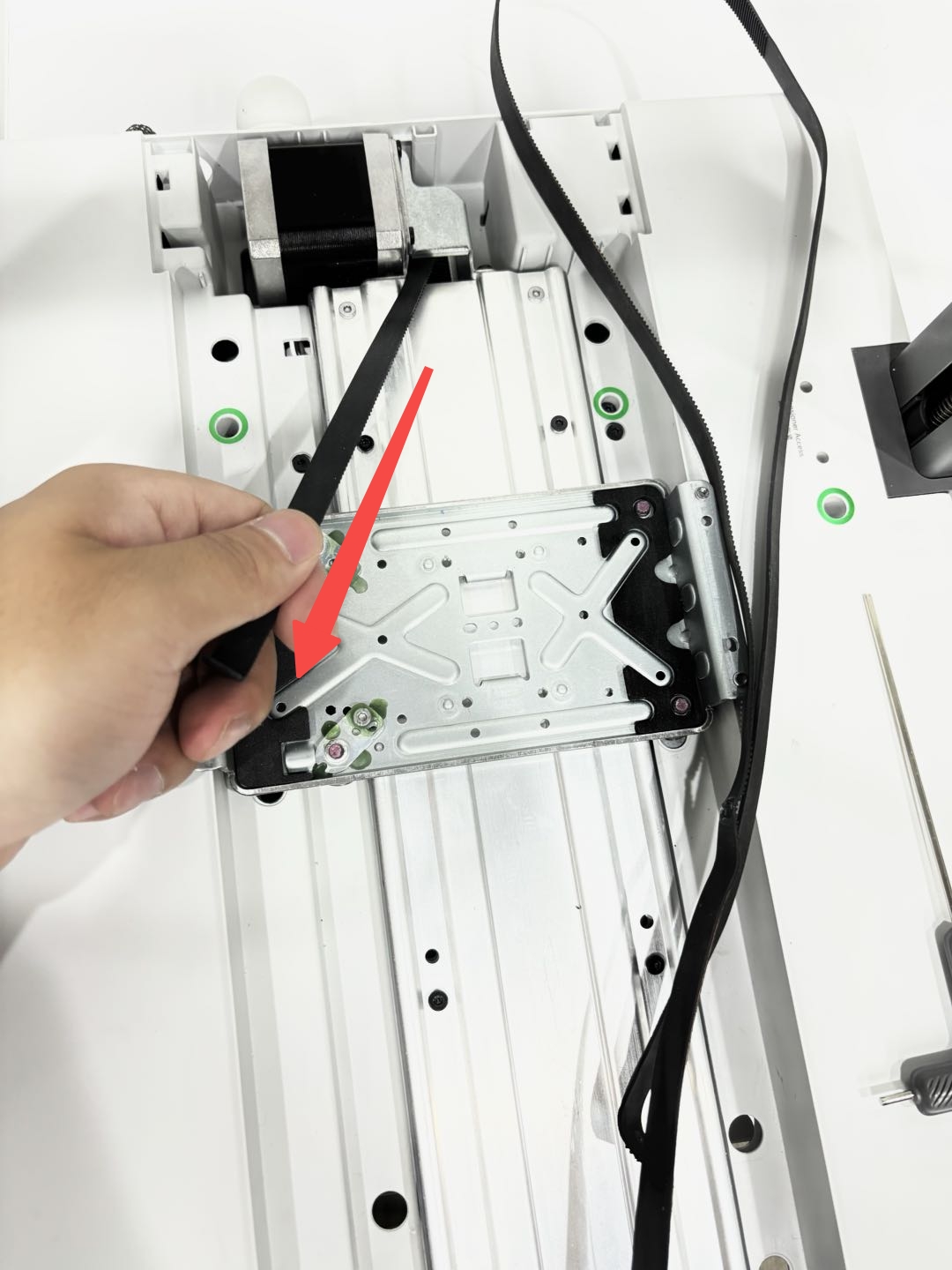

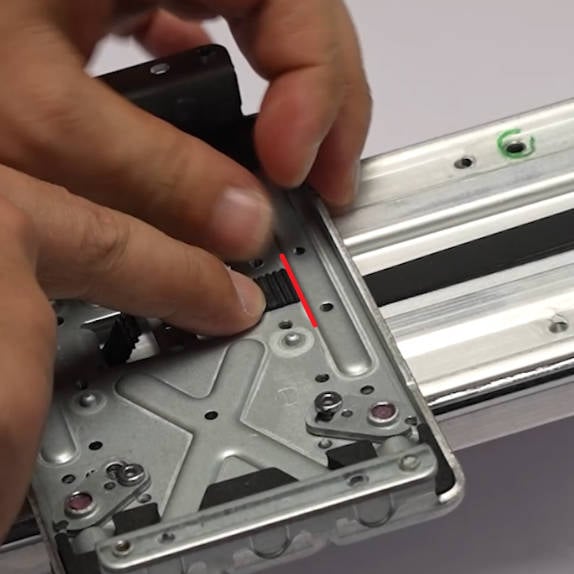

Step 1: After the glue has solified, hold the old belt at the motor end and pull the old belt gently under the guidance of the old belt to thread the new belt through the Y-axis.

Please pull the belt carefully to avoid the old and new belts from breaking at the pasting point.

Step 2: After the new belt passes through the Y-axis, please tear the old and new belts apart from the pasting point.

¶ Fix the Y-belt

Connect both ends of the belt to the heatbed bracket, install the belt clamp, and lock the screws to secure.

|

|

|

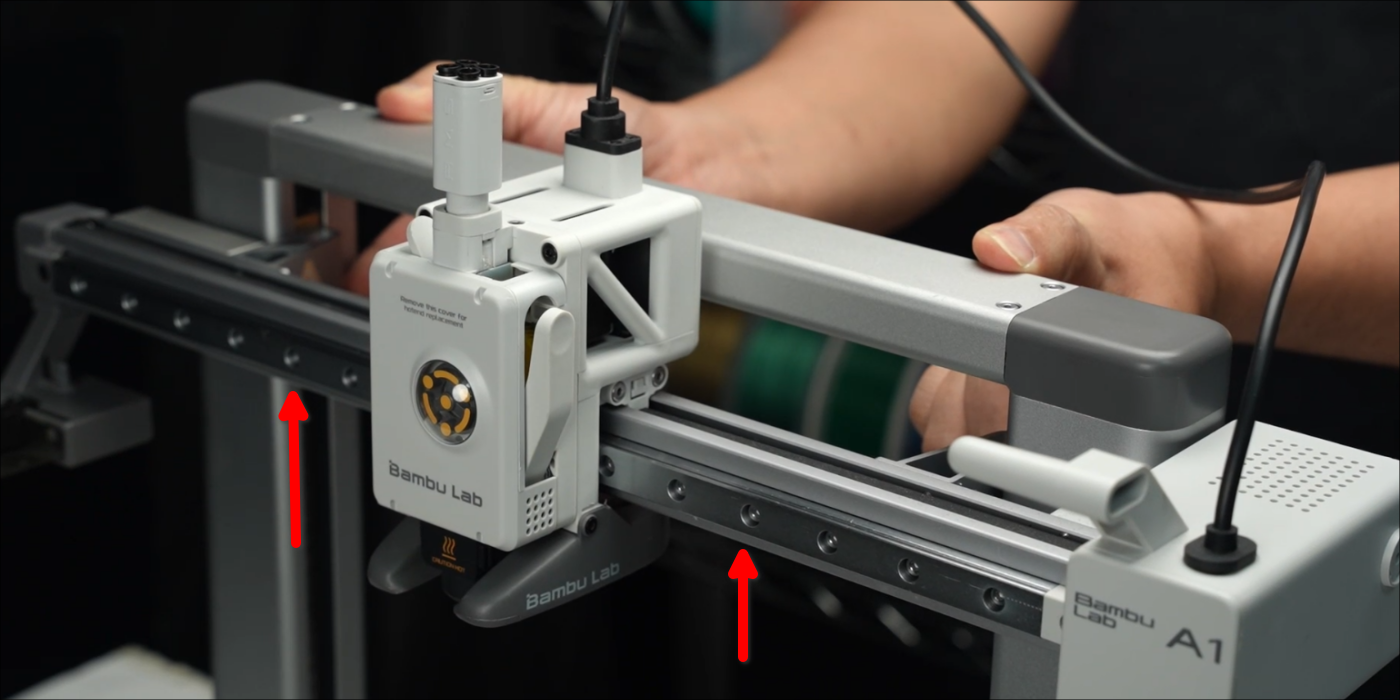

Move the heatbed bracket to confirm that the belt is installed in place, and then install the torsion spring on the fixed base hook.

¶ Install the printer bottom cover

Step 1: Place the printer face down to facilitate access to the bottom of the printer.

Please note the motor cable marked by the red arrow. Be sure to organize this cable before fully depressing the bottom cover.

Snap the bottom cover into place, then tighten ten screws, being careful not to over-tighten.

Step 2: Put the SD card back into the printer.

Step 3: After aligning the cable holder, push down to make sure the USB cable is fully inserted.

Then, tighten the screws shown in the picture to lock it in place. Since this screw goes into the plastic frame, avoid over-tightening.

Reconnect the camera, X-axis motor, and Z-axis motor cables to complete the installation.

¶ Reinstall the heatbed

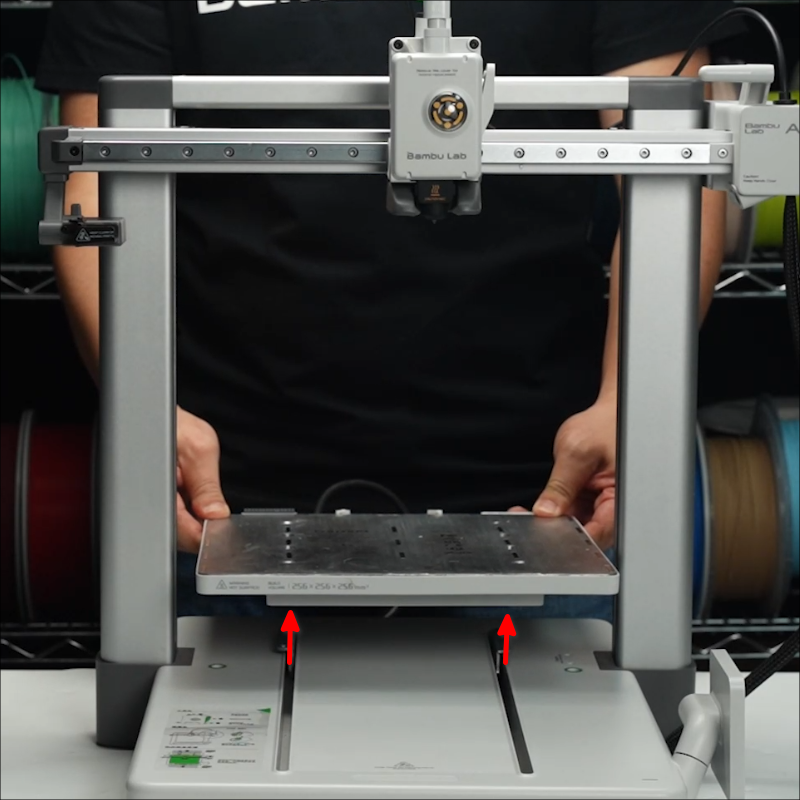

Turn the printer over and place it on a stable table.

Observe the installation position from the left (or right) side of the printer, and place the heatbed on the heatbed holder;

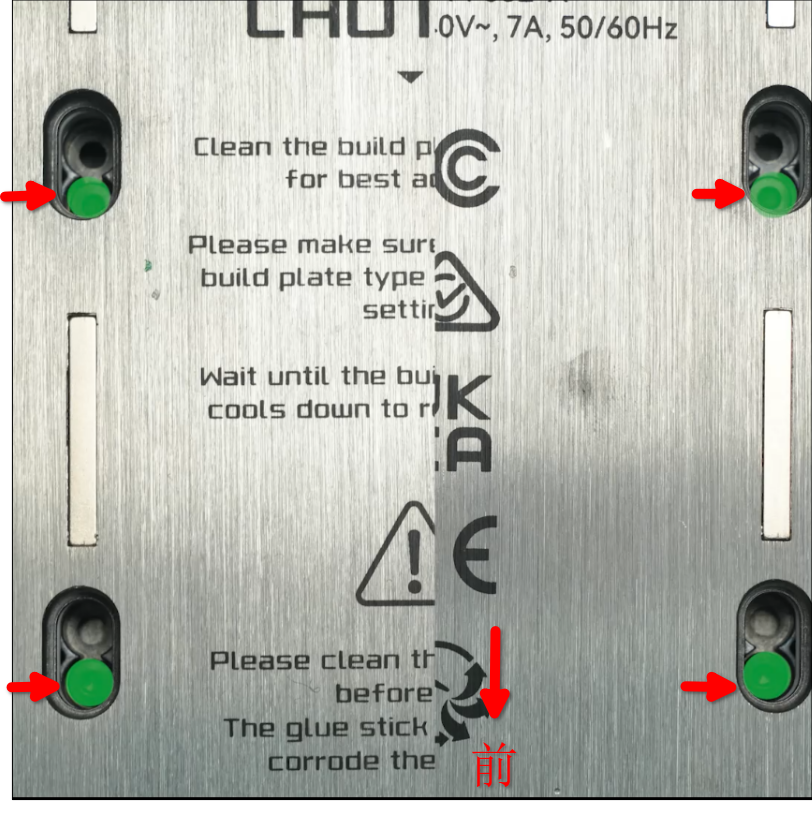

Align the four screw holes, use an H2.0 hex wrench to lock four screws diagonally. Please note that the screws need to be locked in the screw holes away from the silicone nozzle wiper. Install four soft rubber plugs.

|

|

|

¶ Reinstall the Y-axis top cover

Move the heatbed forward to the bottom, insert the Y-axis top cover from under the heatbed, push it forward to the bottom, aim at the buckle, and install the Y-axis top cover to the bottom.

|

|

|

¶ Printer Calibration

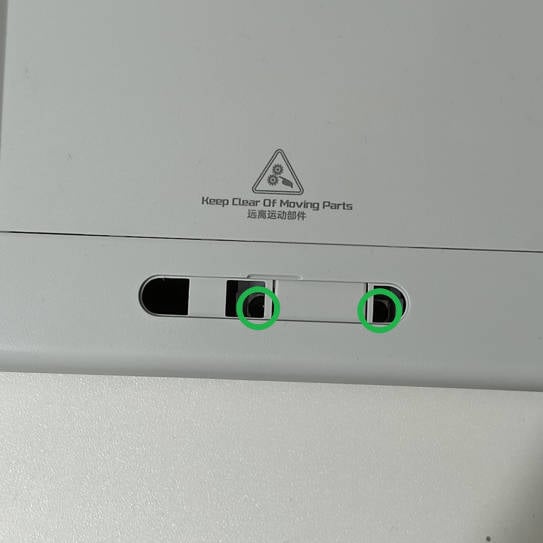

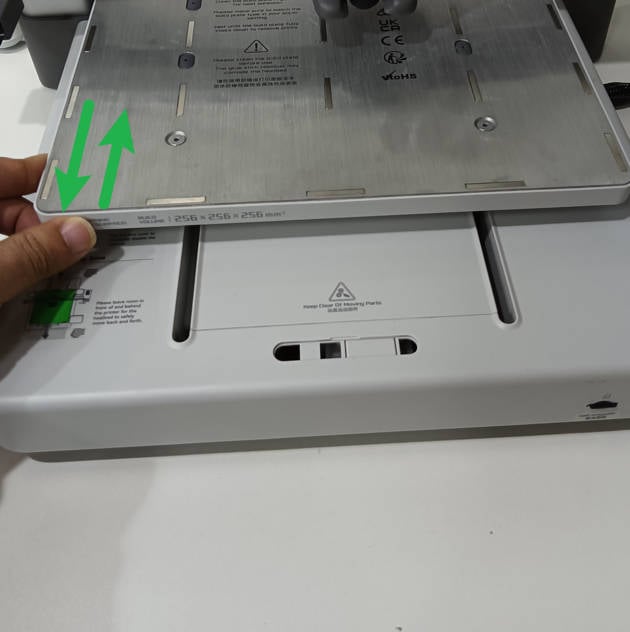

Step 1: Manually move the heatbed back and forth three times along the Y-axis, then re-tighten the tension screws (the tension screws have been loosened one turn when removing the Y-belt), and cover it.

|

|

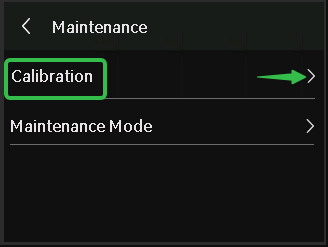

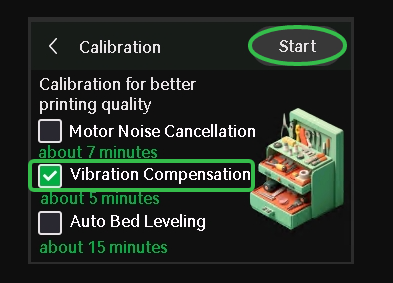

Step 2: Select Vibration Compensation in the calibration menu, and complete the calibration process.

|

|

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.