¶ Z-belt for A1

The Z belt is a closed belt installed at the bottom of the Z-axis. It connects the Z motor and Z-axis lead screw, and moves the toolhead up and down along the Z-axis.

¶ Applicable models of printers

Bambu Lab A1.

¶ What to use?

The Z belt should be replaced if the following situations happen:

- It is broken.

- The belt cannot work properly from wear and tear. This will affect the functions of the printer.

¶ Safety warning

Important!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance.

For any concerns or questions about following this guide, please open a new ticket in our Support Page and we will do our best to respond promptly and provide the assistance you need.

¶ Tools and materials needed

- Z belt for Bambu Lab A1

- H2.0 hex wrench

- H1.5 hex wrench

¶ Removal steps

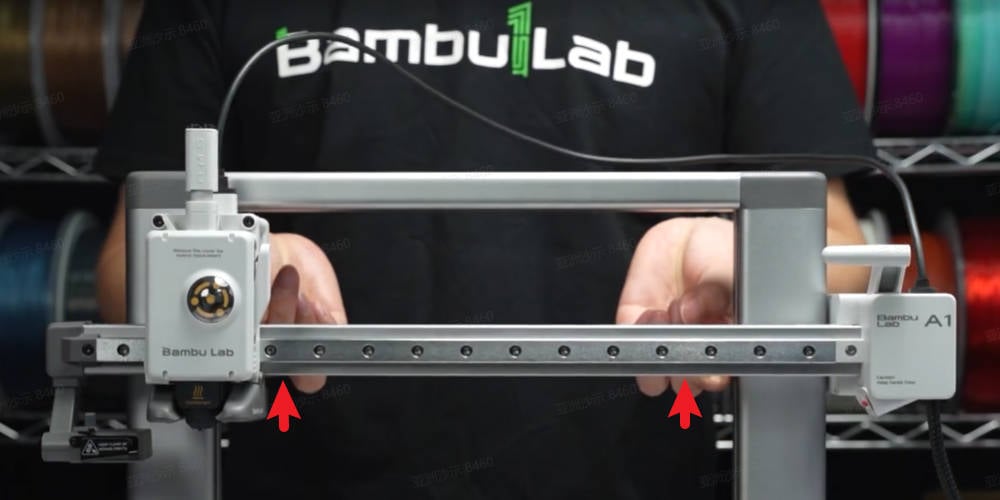

¶ Remove the Y-axis cover

Step 1: Turn off the printer.

Step 2: Place the printer on the table, and move the X-axis to the top.

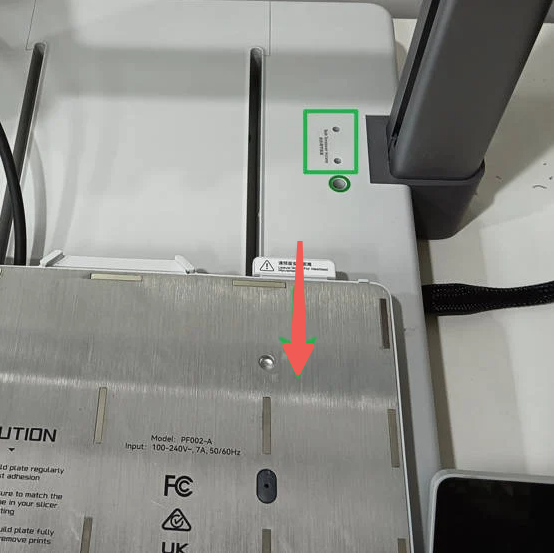

Step 3: Move the heatbed to the end towards the screen, and then remove the Y-axis cover.

|

|

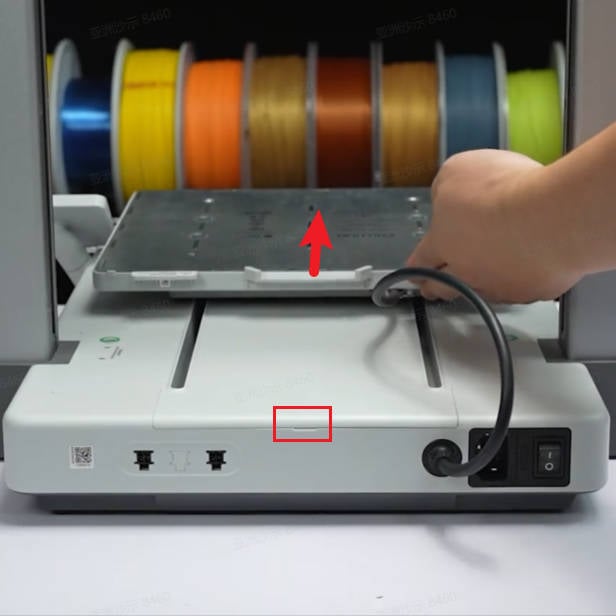

¶ Remove the Z-axis cover

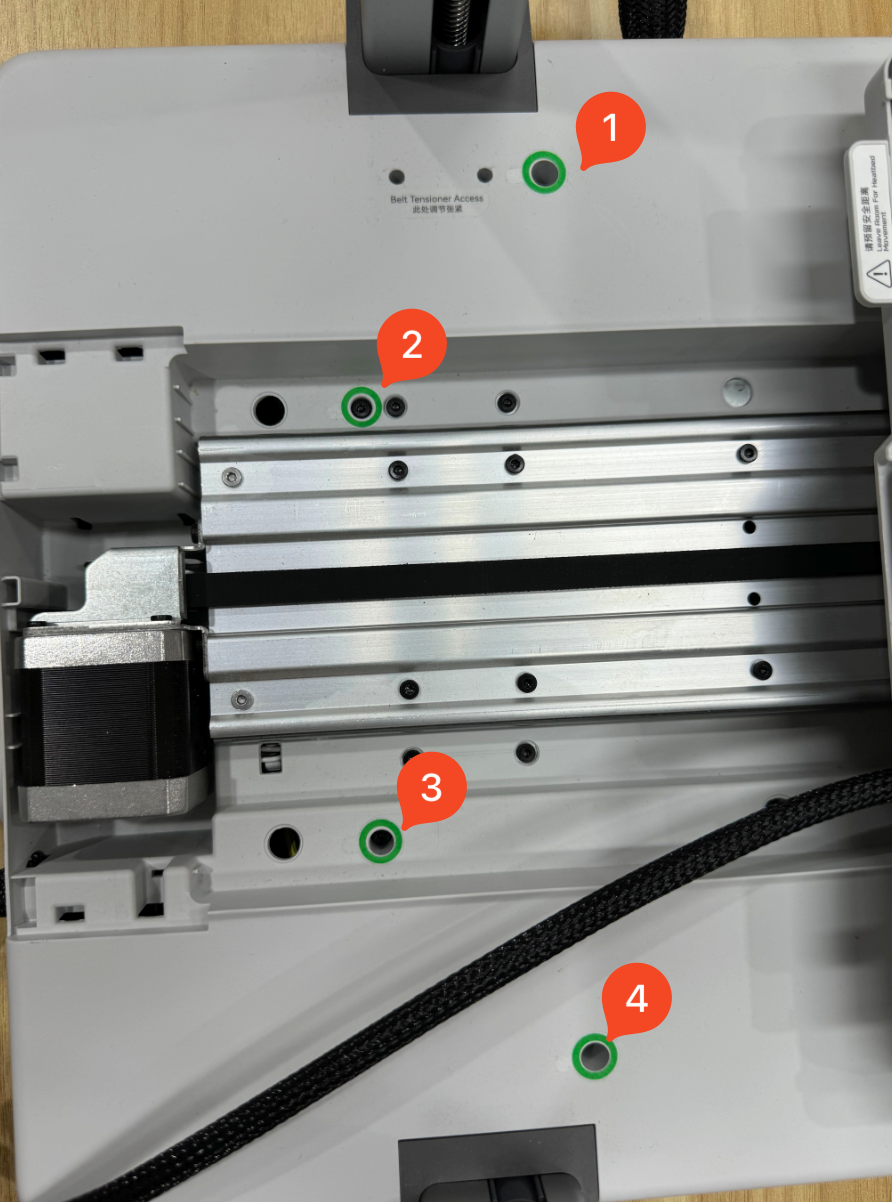

Step 1: Use the H2.0 hex wrench to remove the 4 screws highlighted in green.

Step 2: Use the H2.0 hex wrench to loosen the two screws by one full rotation (do not loosen them entirely).

The tension screws for the Z -axis belt are near the right pillar. You can see them after moving the heatbed towards the screen.

|

|

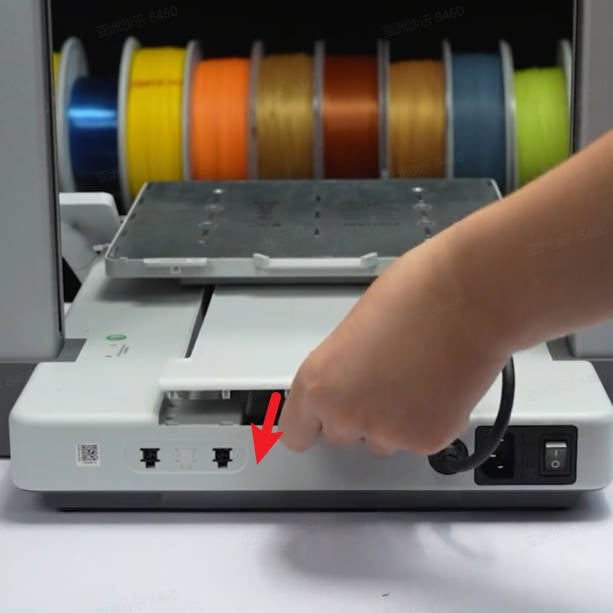

Step 3: Move the heatbed to the end towards the opposite of the screen, and then place the printer on its back on the table.

We recommend that you cover the table with cardboard first to protect the printer. Also, please put the heatbed on the table, to prevent it from suddently dropping when you turn over the printer.

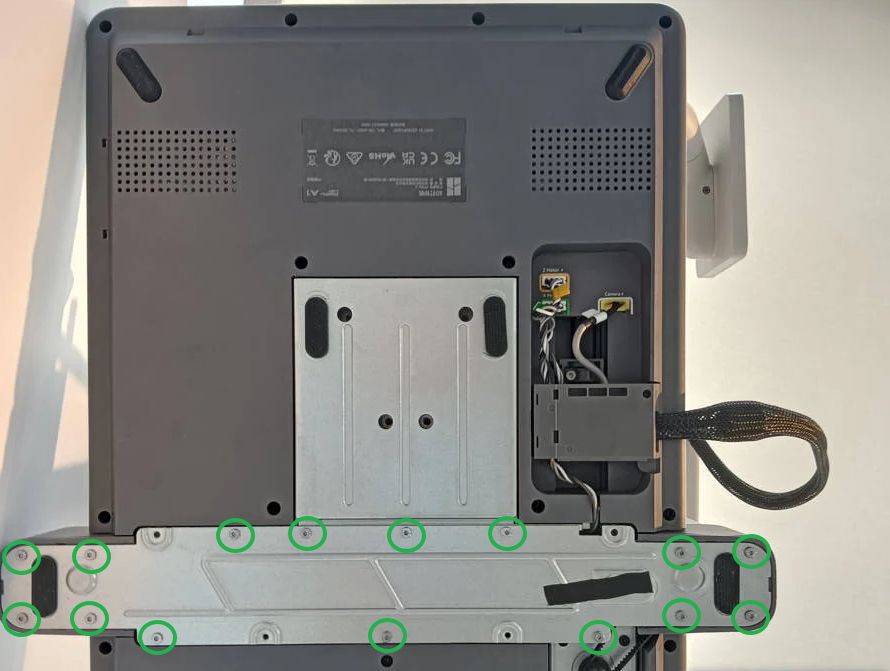

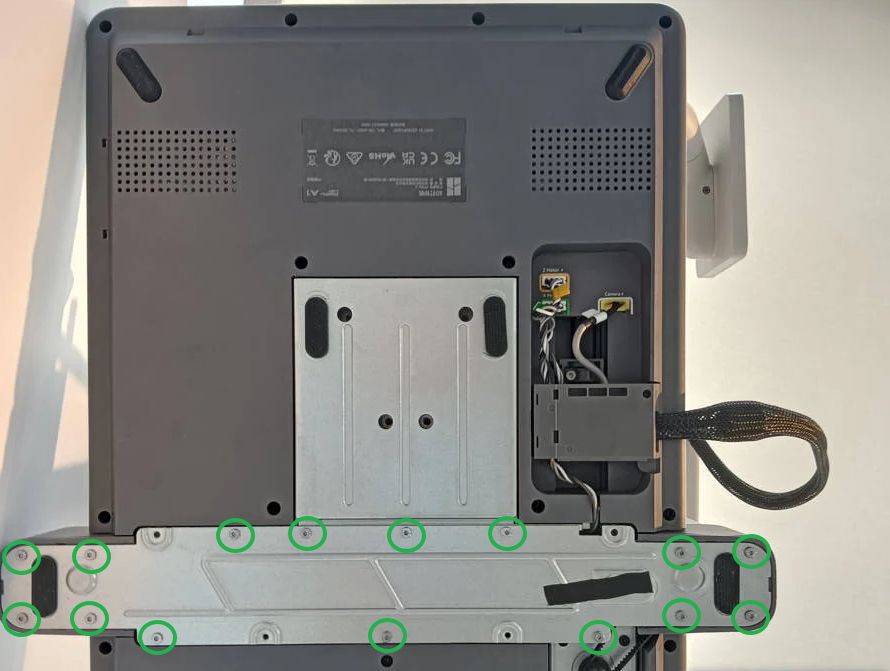

Step 4: Use the H2.0 hex wrench to remove the 15 screws highlighted below. Then you can remove the Z-axis cover.

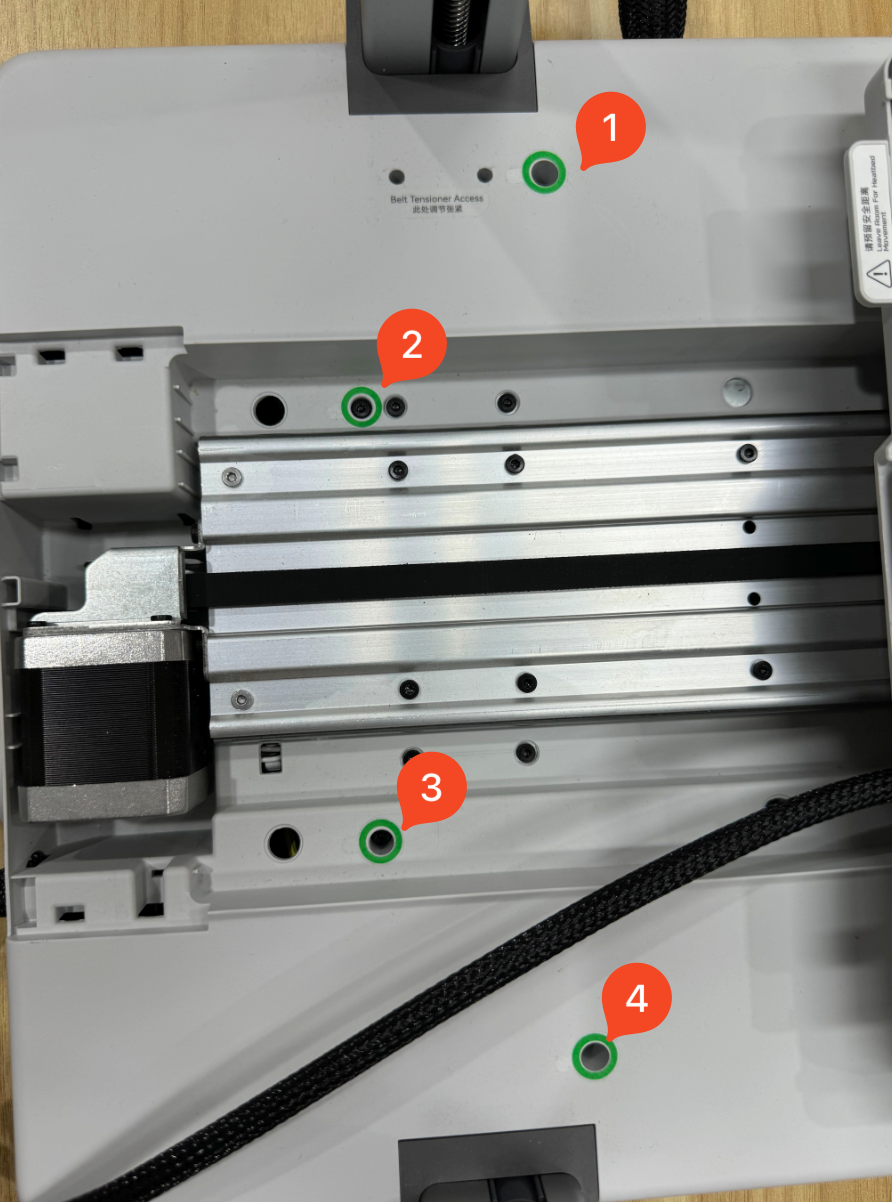

¶ Remove the Z belt

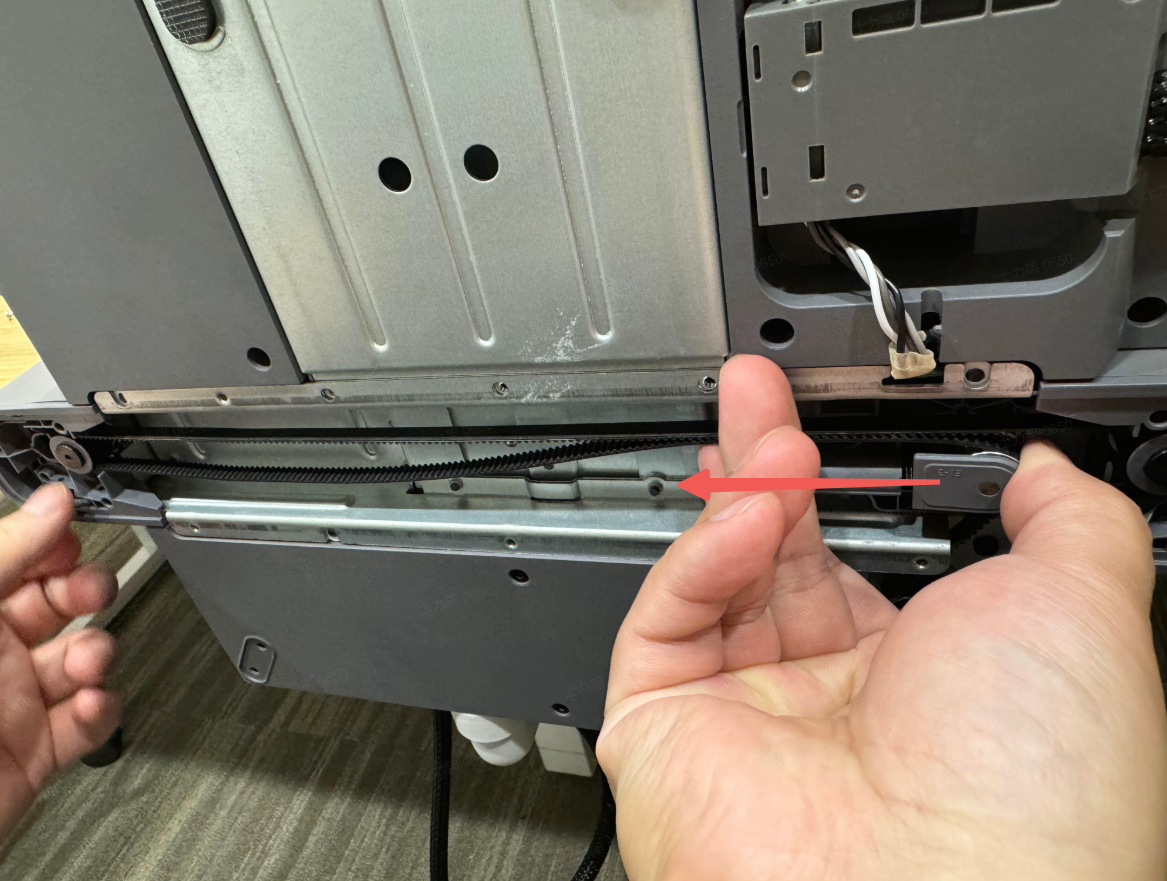

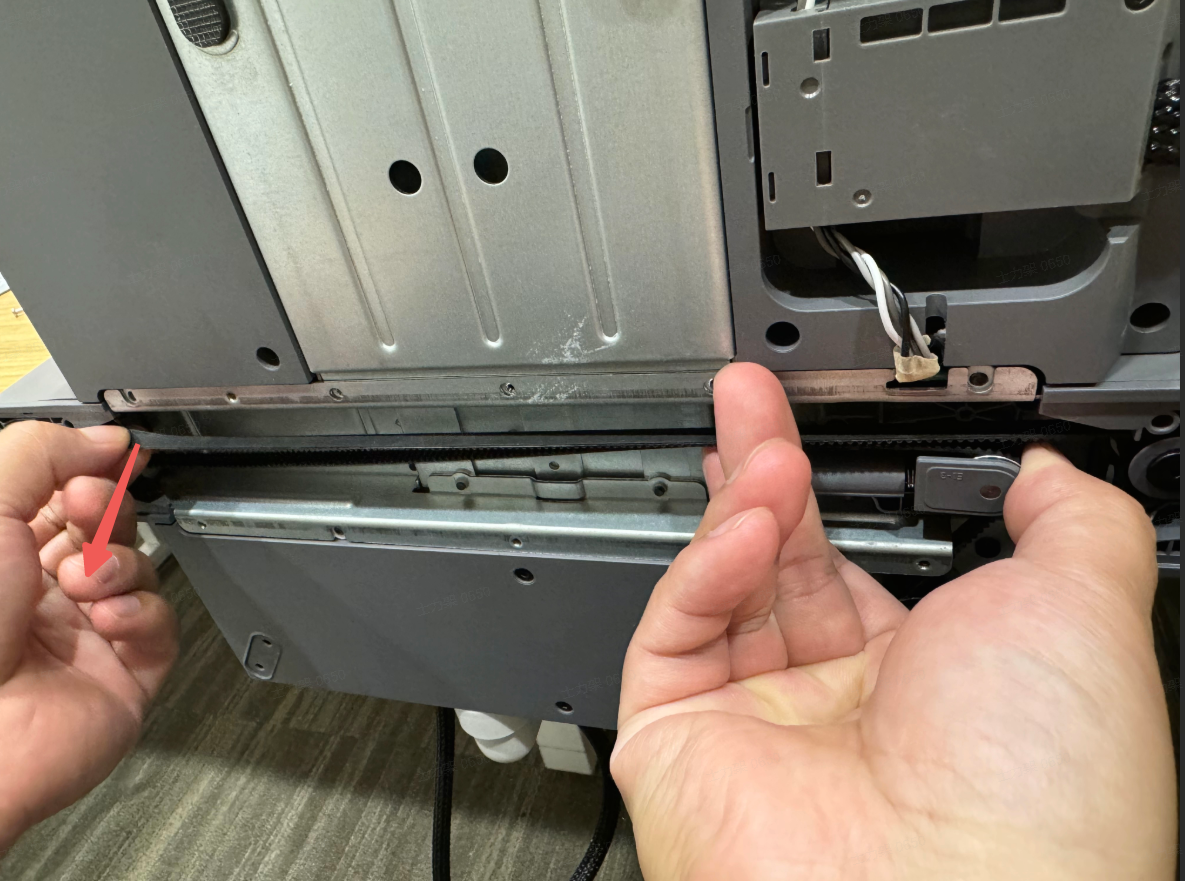

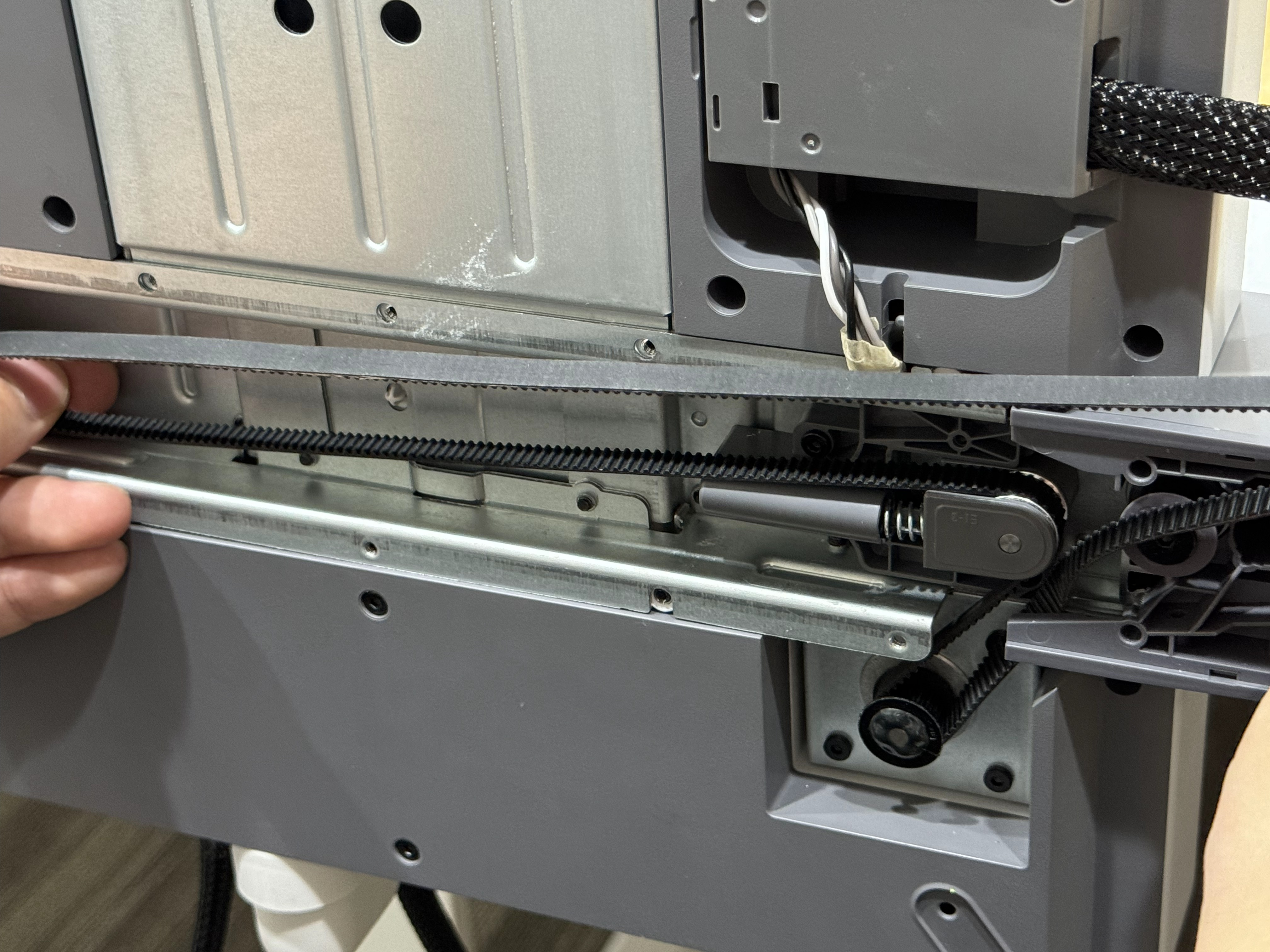

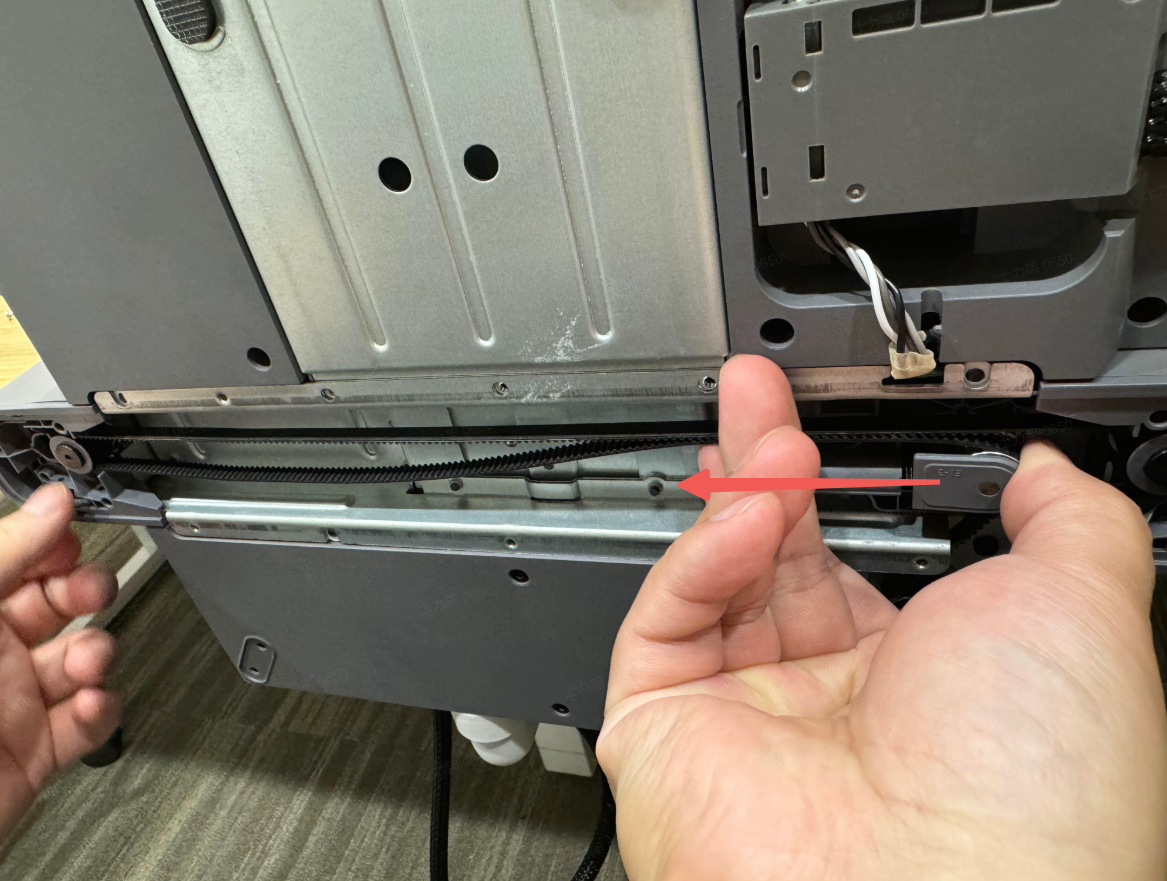

Press and hold the tensioner to the left, and then pull the belt towards you to remove it.

|

|

¶ Installation steps

¶ Install the Z belt

Step 1: Check if the X-axis is parallel to the top. If they are not parallel, manually push the X-axis to the top until they are parallel.

The X-axis is nor parallel to the top. The X-axis is nor parallel to the top. |

|

Step 2: Install the belt to the timing pulley and tensioner in the lower-right corner.

Step 3: Press and hold the tensioner to the left, and then install the belt to the timing pulley on the left.

|

|

Step 4: Drag the belt to check if it can move smoothly.

If not, please check if the belt is correctly installed and whether the lead screw is stuck.

¶ Install the Z-axis cover

Step 1: Place the cover, and then use the H2.0 hex wrench to tighten the 15 screws highlighted in green.

Step 2: Place the printer on the table, and then use the H2.0 hex wrench to tighten the 4 screws highlighted in green.

Step 3: Put back the Y-axis cover.

¶ Tension the Z belt

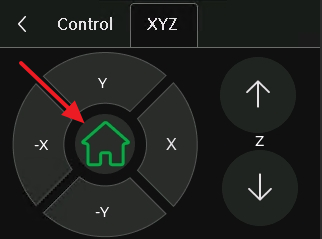

Step 1: Turn on the printer. Go to the screen below, and then perform a homing process.

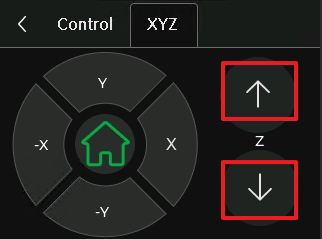

Step 2: After homing completes, press the up and down buttons on the right only once respectively, to move the X-axis up and down once.

Before moving the X-axis down, please make sure the nozzle will not touch the heatbed!

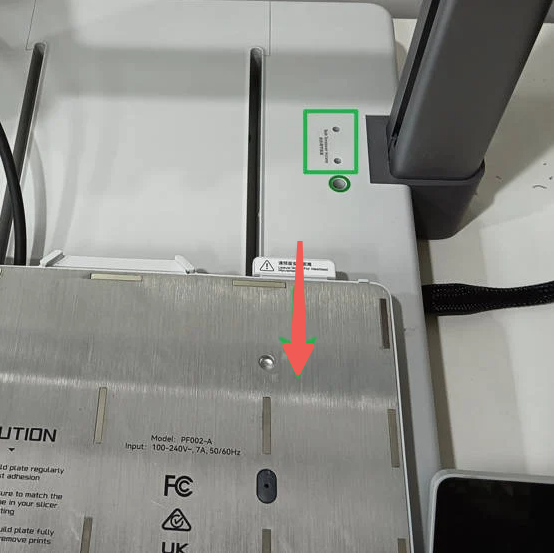

Step 3: Use the H2.0 hex wrench to tighten the 2 tension screws.

|

|

¶ Calibration step after the operation

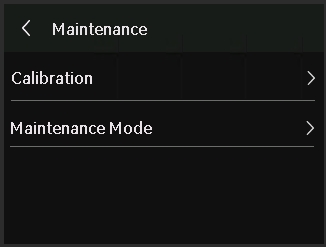

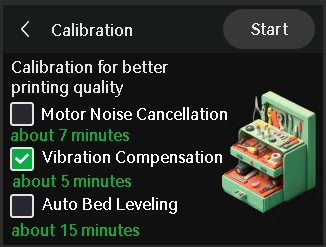

In the Calibration screen, select only Vibration Compensation,and then tap Start.

The calibration will confirm the printer is running as expected.

|

|

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.