¶ Introduction

The Y-axis of A1 utilizes a full-metal guide wheel, and this guide rail system ensures that users do not need to frequently adjust the motion components of A1. However, regular lubrication and cleaning are required to reduce wear and noise, ensure the accuracy and lifespan of the printer, and effectively prevent rusting of the guide rail. Each printer receives a certain degree of lubrication before leaving the factory, but only a small amount of lubricant is applied to the machine. This is because if an excessive amount of lubricant is applied, it may drip onto the casing during transportation, affecting the appearance.

Therefore, we strongly recommend that you check the lubrication of the Y-axis after unboxing the printer to ensure that the lubricant covers the entire guide rail evenly. If insufficient lubrication is found, please refer to the following A1 Y-axis lubrication guide.

In daily use, we recommend lubricating the Y-axis guide rail once a month. Additionally, when you receive a lubrication prompt, please follow the instructions to lubricate the Y-axis guide rail.

¶ Comparison Before and After Lubrication

|

|

¶ Materials Required

- Non-woven fabric

- Lubricant oil

¶ Supplementary Instructions for Lubricant Oil:

Considering user feedback regarding the stickiness of the lubricant grease and its potential to attract dust and debris, we have conducted extensive verification tests and decided to switch the lubricant for the Y-axis guide rail of the A1 model. Therefore, for the Y-axis guide rail of the A1 model, we recommend using lubricant oil for lubrication. We suggest switching to lubricant oil for future maintenance if you have previously used lubricant grease. During the lubrication process, you can also wipe off the lubricant grease on the guide rail and then follow the guide to applying the lubricant oil.

Friendly reminder: The accessory box provides two types of lubricants, one is lubricant oil, and the other is lubricant grease. The packaging may vary depending on the batch, so please refer to the actual packaging you received. Here is an introduction to their respective applications:

Purposes of Lubricant Oil: Used for X-axis linear rail, Y-axis guide rail, and eliminating noise from idler wheels.

Purposes of Lubricant Grease: Used for lubricating lead screws and extruder wheels. Please note that it is strictly prohibited to use lubricating grease on the X-axis linear rail.

|

|

Besides the lubricant oil in the accessory box, you can also use "WD-40 Multi-Use Product" (both in large and small bottles, which are okay) to lubricate the X-axis linear rail, Y-axis guide rail, and Z-axis lead screw. (Click here to be redirected to the recommended purchase link. ) . Both A1 and A1 mini utilize "WD-40 Multi-Use Product" for lubrication, and their operating methods are the same. Therefore, you can refer to How to lubricate the A1 series Y-axis guide rail (with "WD-40 Multi-Use Product") Take the A1 mini as an example.

Please purchase the authentic "WD-40 Multi-Use Product".

We have not tested other types of lubricant oil and cannot determine if they may adversely affect the Y-axis slide rail (including but not limited to corrosion and wear of bearings and steel shafts).

¶ Video Guide

¶ Guide for Applying Lubricant Oil

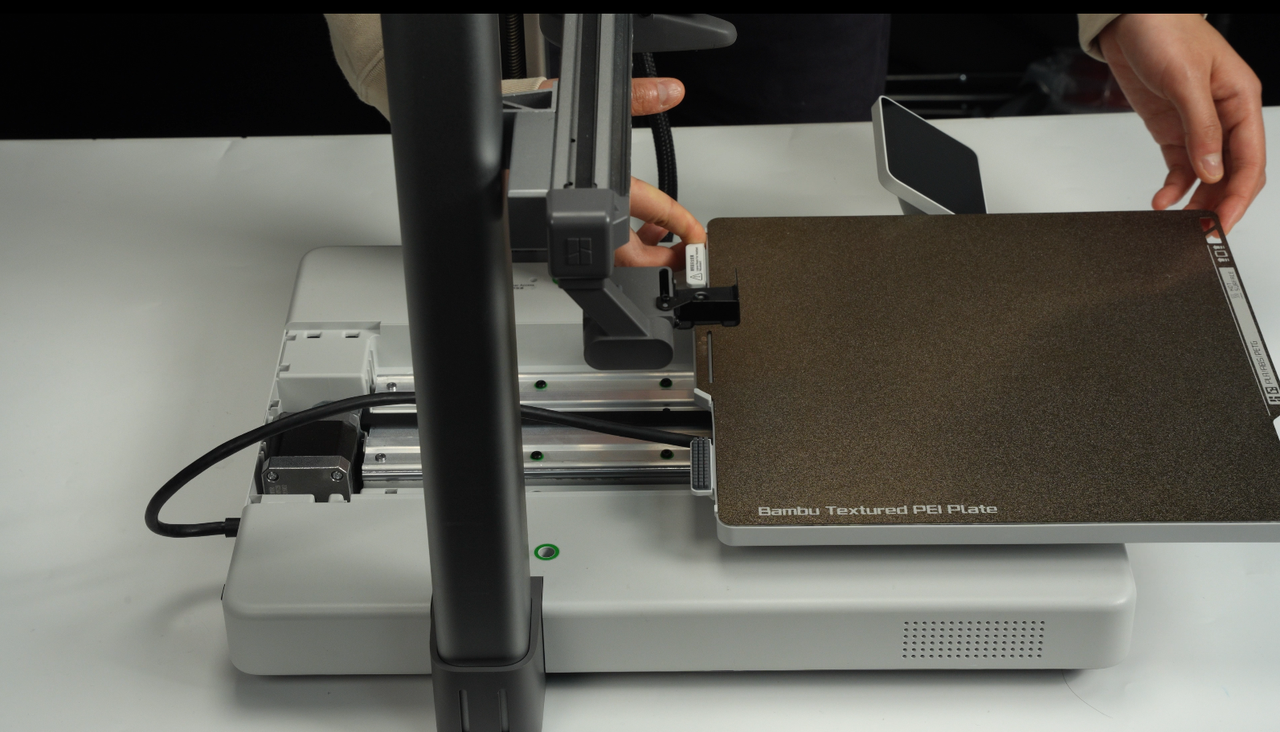

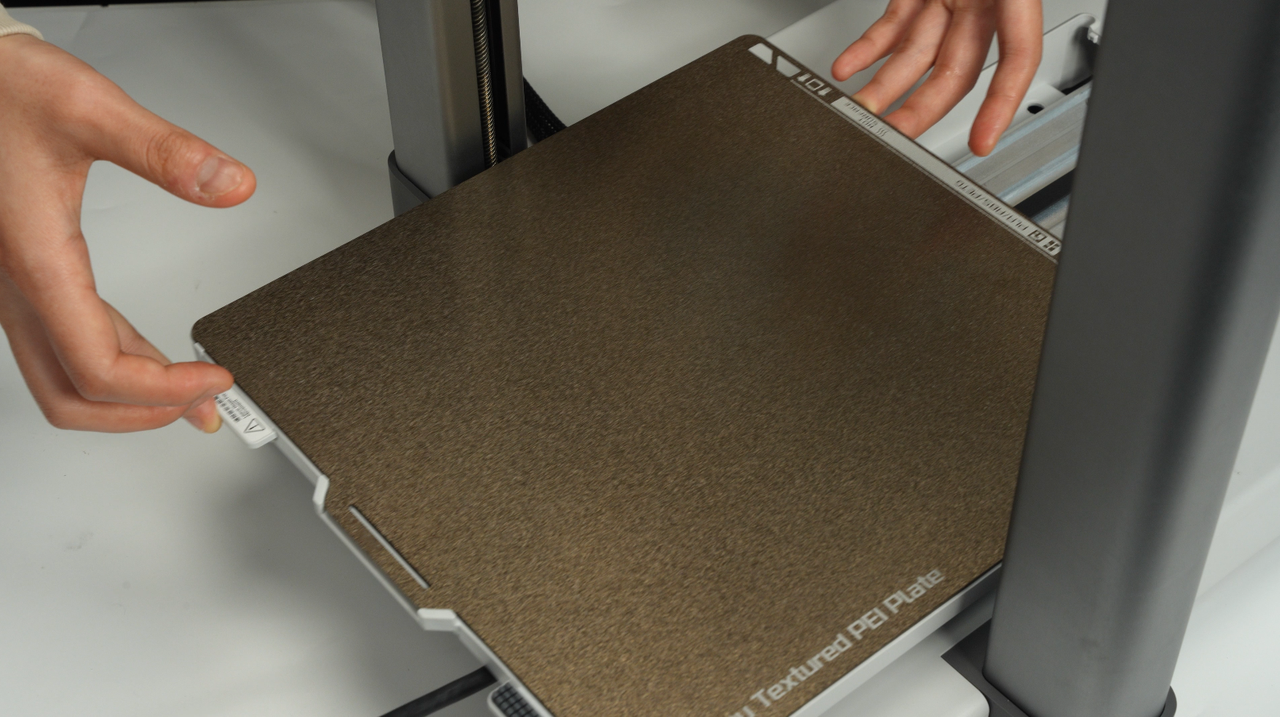

During the operation, please handle with care and ensure that lubricant oil does not come into contact with the surface of the textured plate. If necessary, it is recommended to remove the textured plate from the heatbed during the operation.

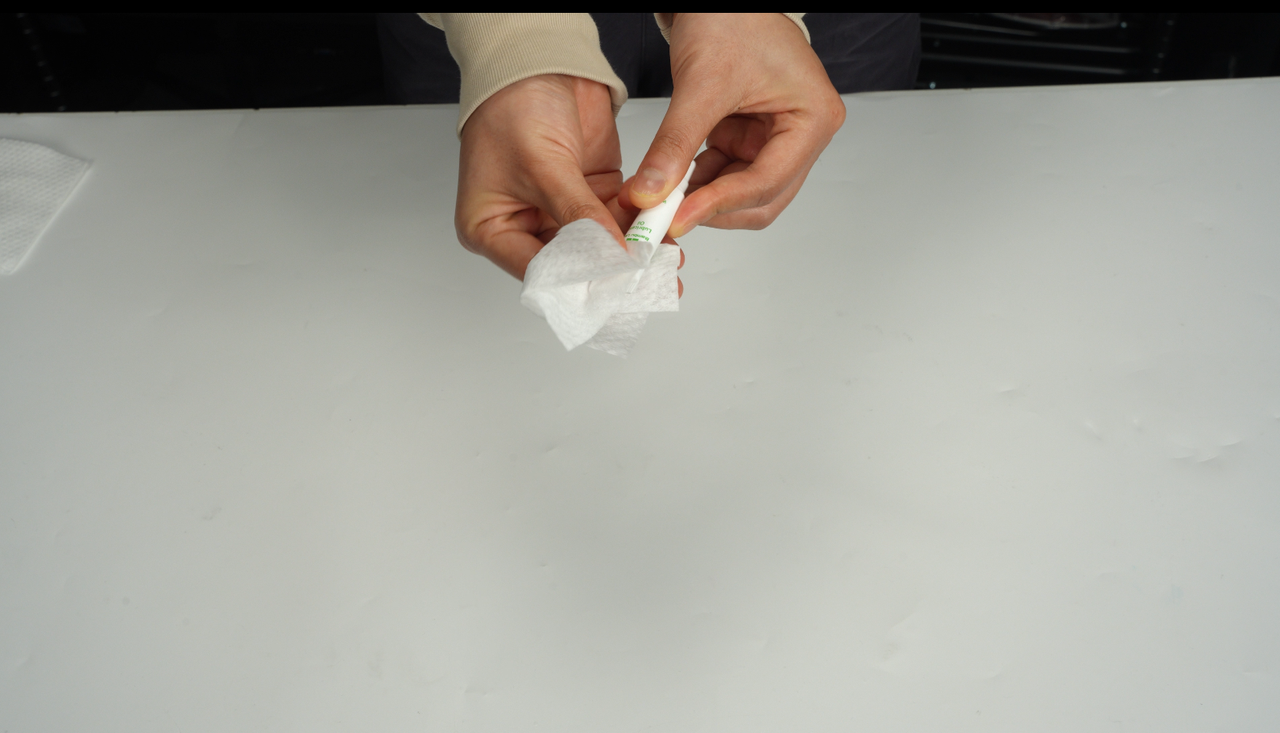

¶ Step 1 : Use a non-woven cloth to lightly wipe it off.

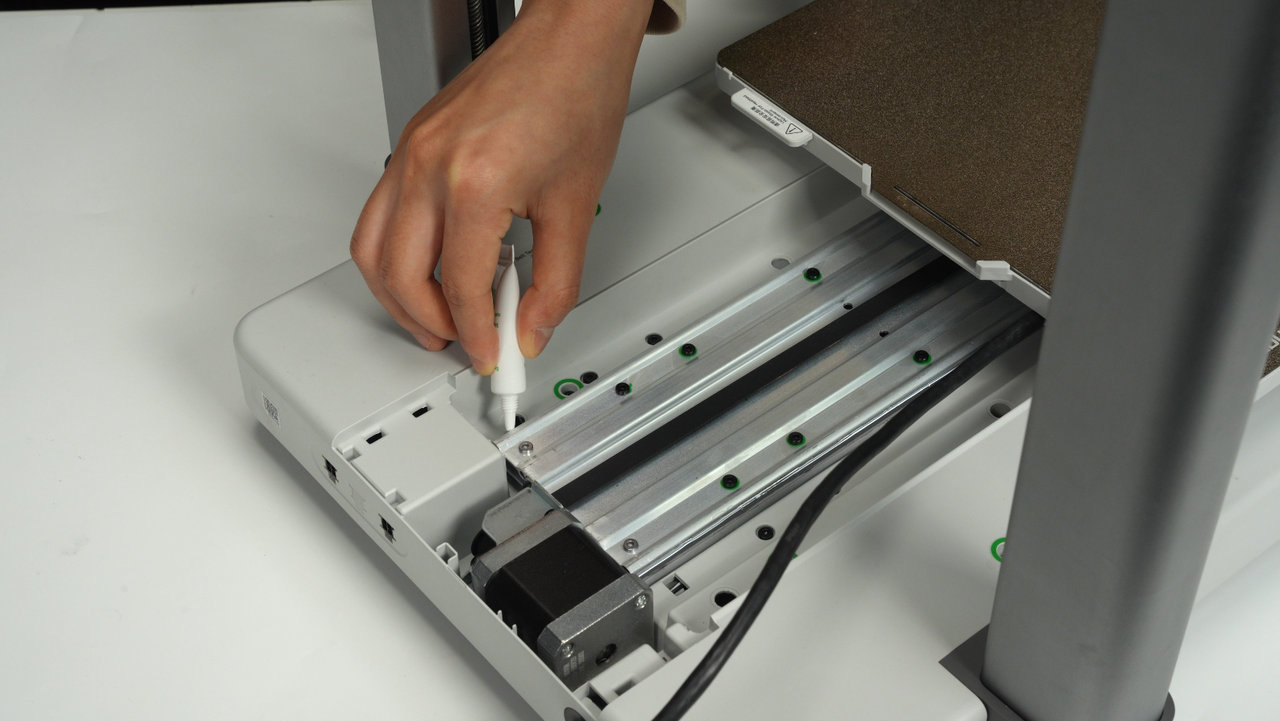

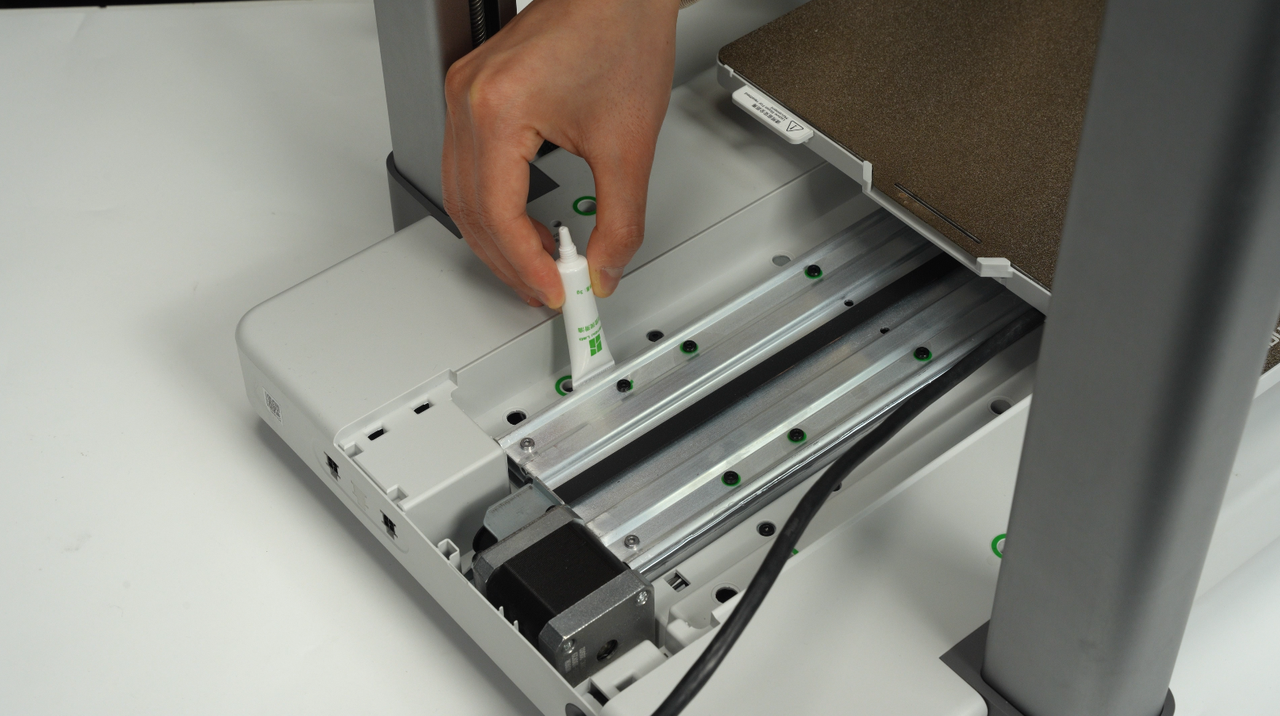

Avoid using tissues that may leave fibers. Rotate and unlock the lubricant oil cap, then create a small hole in the bottle nozzle.

|

|

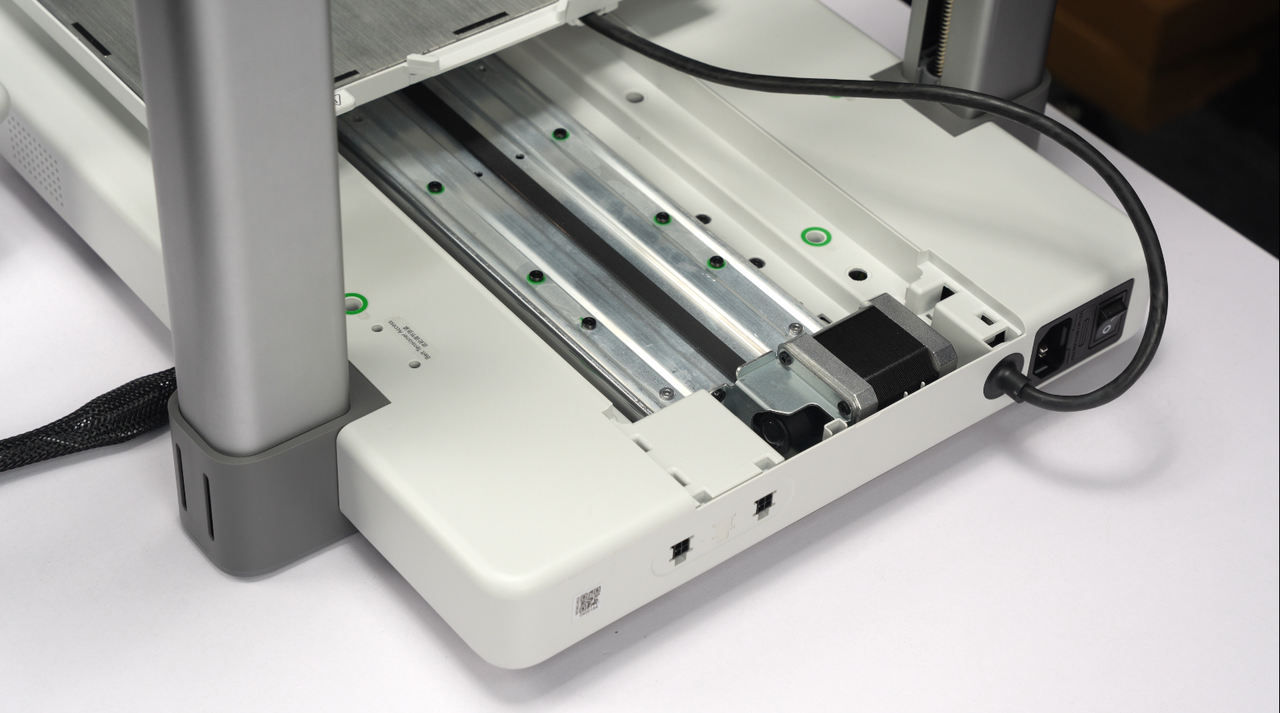

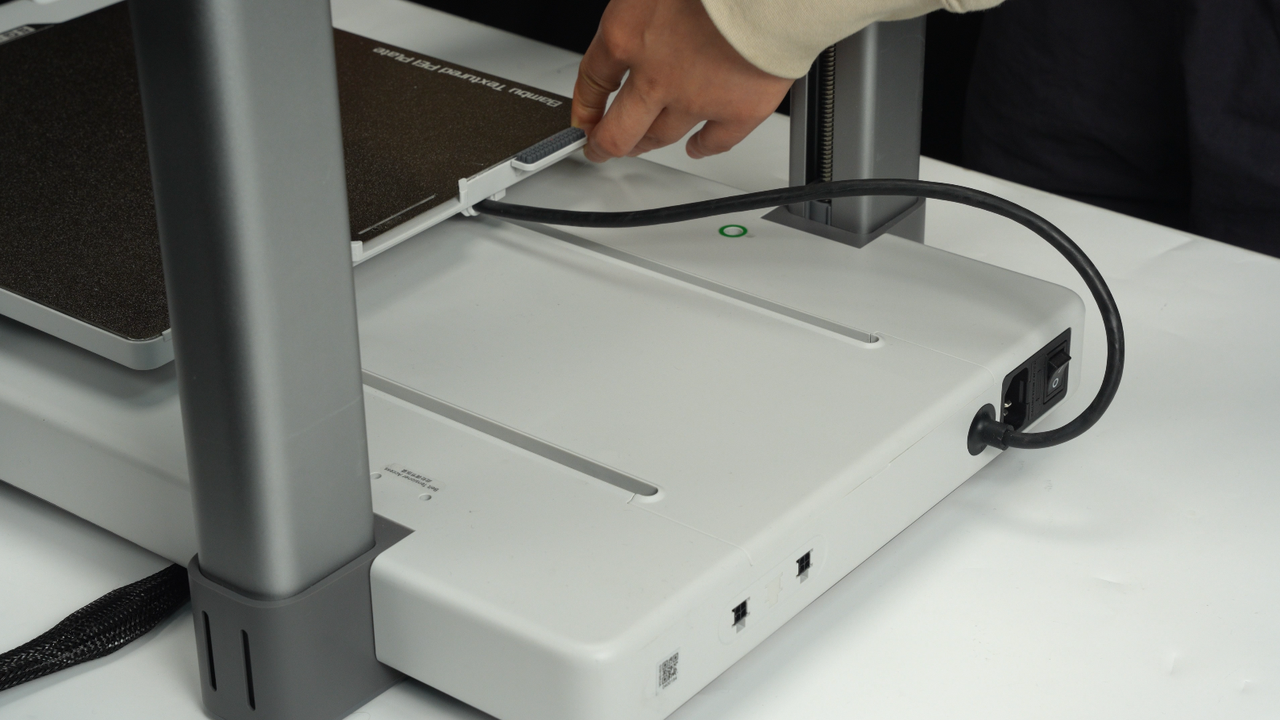

¶ Step 2: Push the heatbed fully to the front end, where the screen is located.

Open the Y-axis rail cover.

|

|

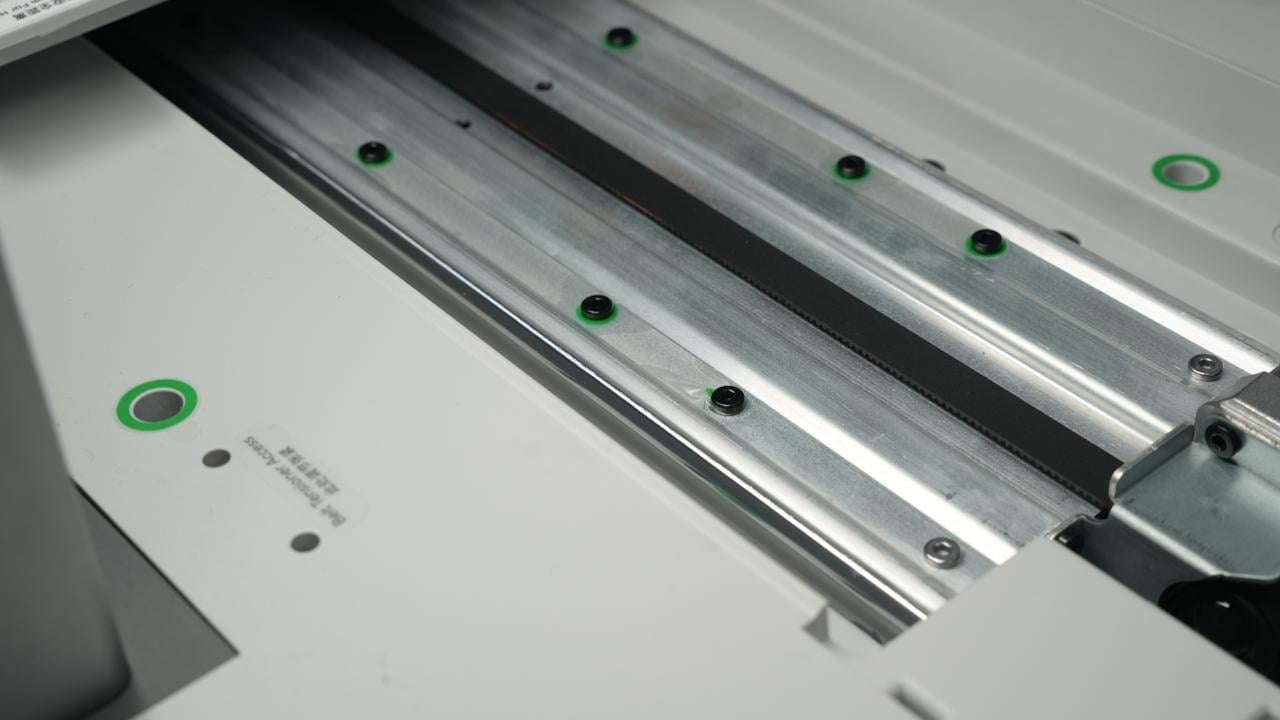

¶ Step 3: Use a clean non-woven cloth to wipe away any remaining lubricant grease on the guide rails, as well as the surrounding dust and debris.

|

|

¶ Step 4:Squeeze the lubricant oil bottle along the upper edge of the Y-axis steel shaft, ensuring even and exclusive application onto the steel shaft.

|

|

¶ Step 5: Apply the lubricant oil onto the curved surface of the steel shaft using the bottle's tail end.

|

|

¶ Step 6:Move the heatbed back and forth to evenly distribute the lubricant oil.

|

|

Following the same method, apply lubricant oil to the remaining sections of the steel shaft.

|

|

|

|

¶ Step 7: Push the heatbed fully to the front end, where the screen is located. Put the cover back.

|

|

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue.

Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.