¶ Video guide

¶ 1. Printing Preparation

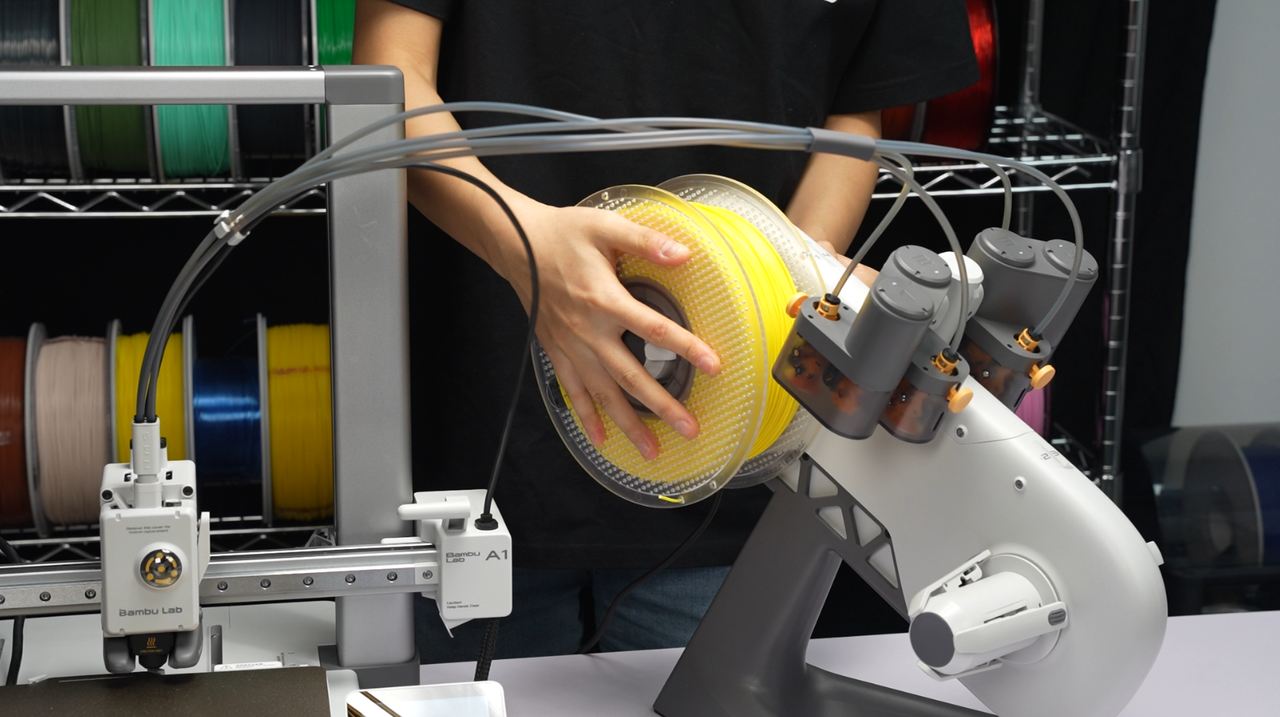

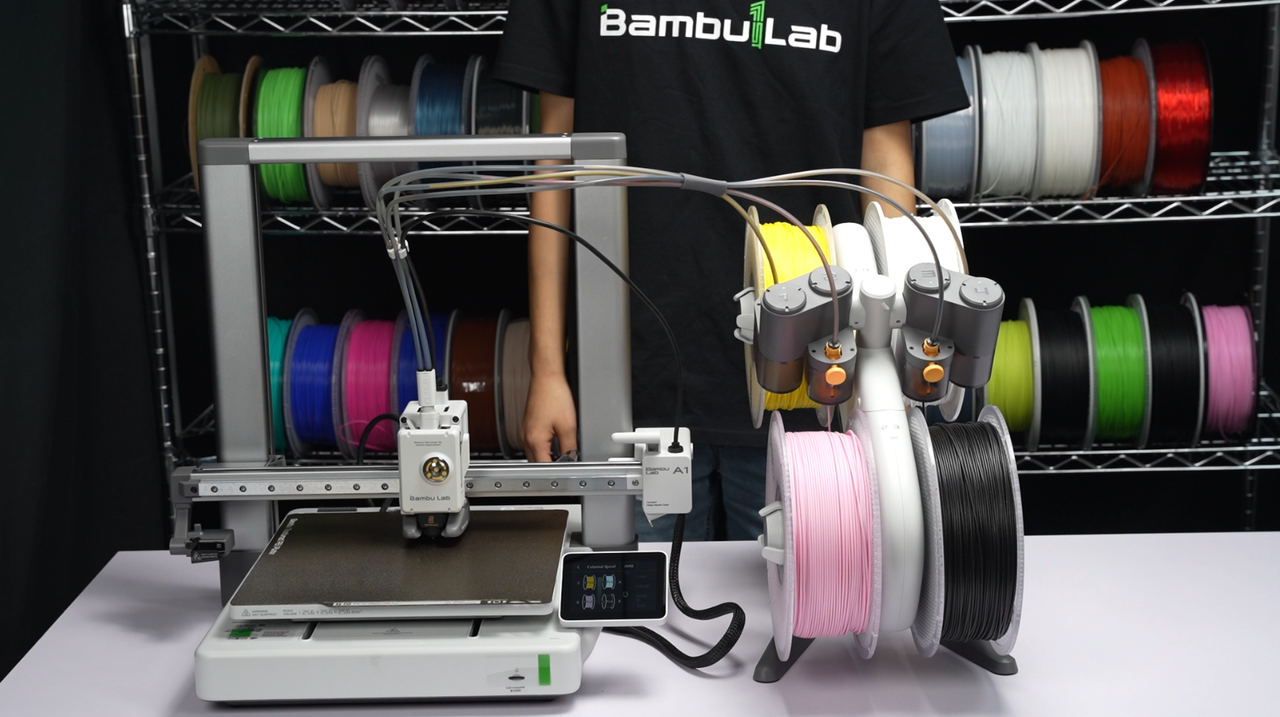

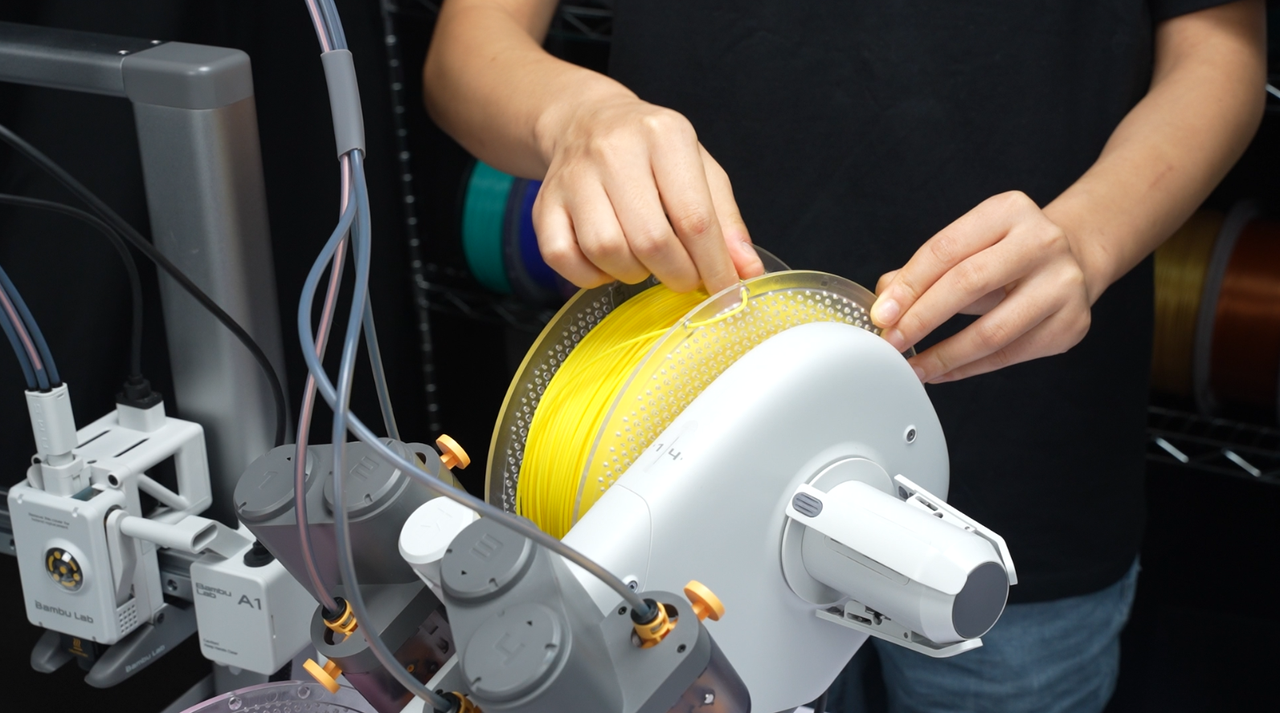

¶ 1. Spool loading

|

|

|

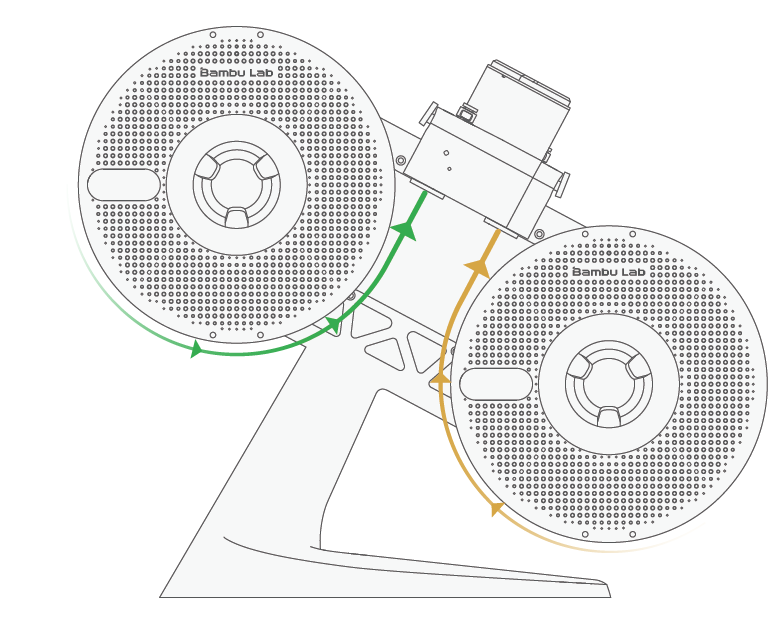

Orient spool installation according to the filament winding direction. (as shown in the diagram). The correct installation orientation for the filament spool is where the filament can be inserted from below the feeder, following the direction of the filament path.

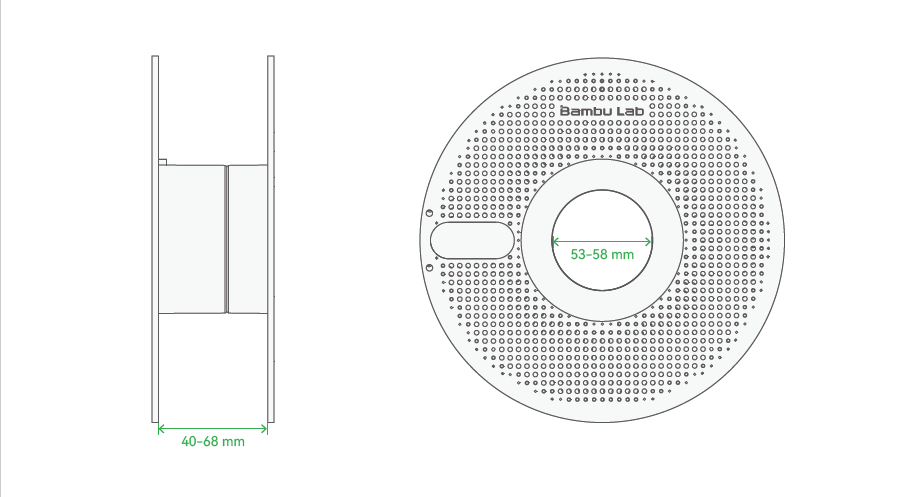

The AMS lite supports spools with a 40-68 mm width and an inner diameter of 53-58 mm.

Avoid using AMS lite to print flexible materials, including TPU (except AMS for TPU), TPE, or absorbent PVA. Avoid using materials that are too hard (too high modulus) or too brittle (not enough toughness), including third-party fiber reinforcement materials(PA-CF/GF, PET-CF/GFPLA-CF/GF, etc.). Please use external spool placement to print these filaments.

¶ 2. Insert the filament into the feeder inlet of the AMS lite

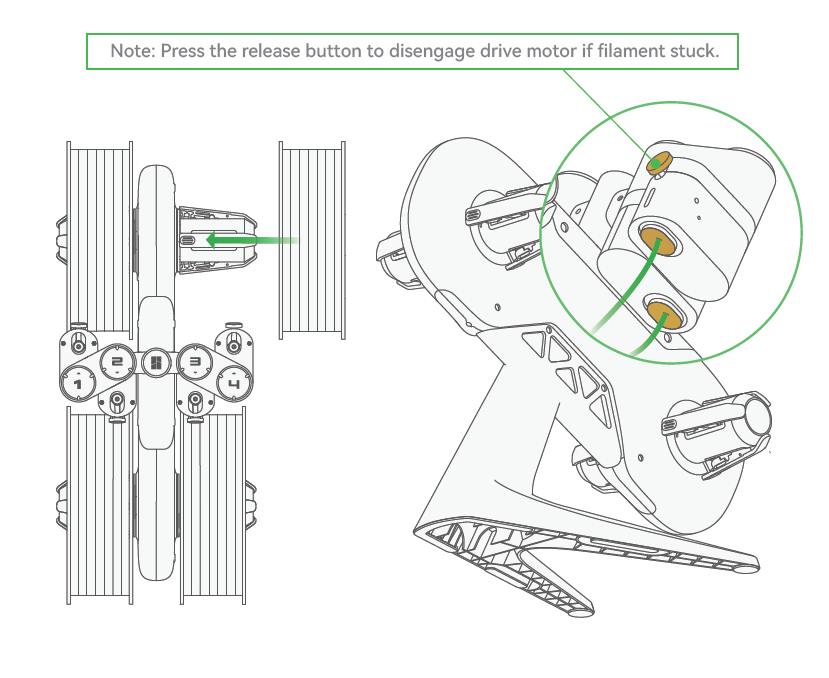

After ensuring that the filament spool axle is securely fastened, you can begin inserting the filament through the feeder inlet. Please align it accurately with the insertion port to avoid improper insertion. If the filament gets jammed, you can press the release button to disengage the drive motor. After inserting the filament, the feeder will automatically feed the filament into the PTFE tube, about 40 cm。

|

|

¶ 2. Start printing

After ensuring that the filament is loaded and the build plate is in place, you can proceed with printing.

Note: When unpacking the printer, the heatbed may have been stationary for a long time, which can increase friction during the first layer of printing. This may lead to misalignment and potential damage to the build plate if printing is started directly. To prevent this, it is recommended to manually move the heatbed to its maximum position to ensure smooth printing.

¶ 1. Initiate a print job using Bambu Studio

¶ Install the Bambu Studio:

Click here to download Bambu Studio: https://bambulab.com/en/download/studio

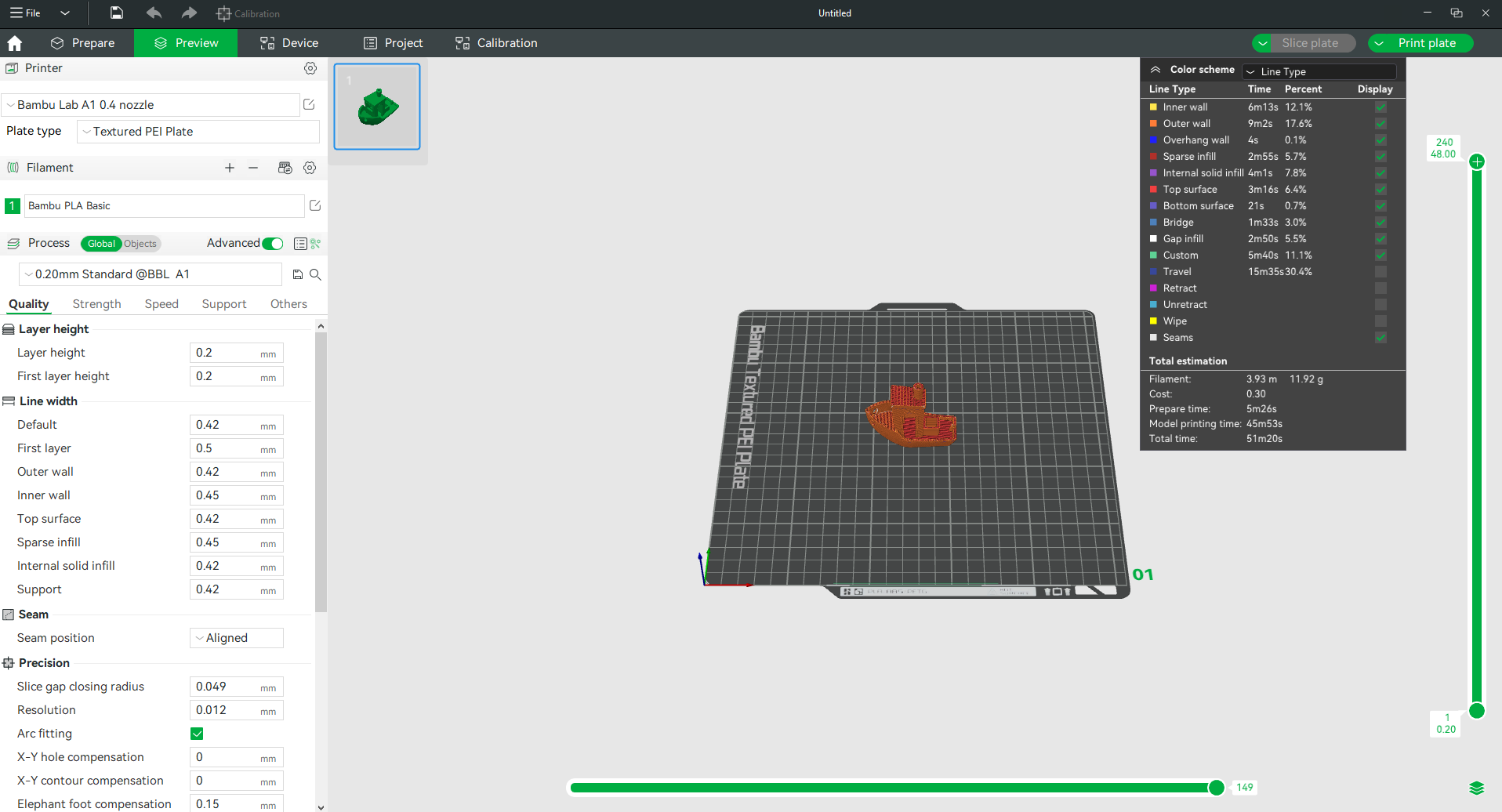

¶ Slice and send the print

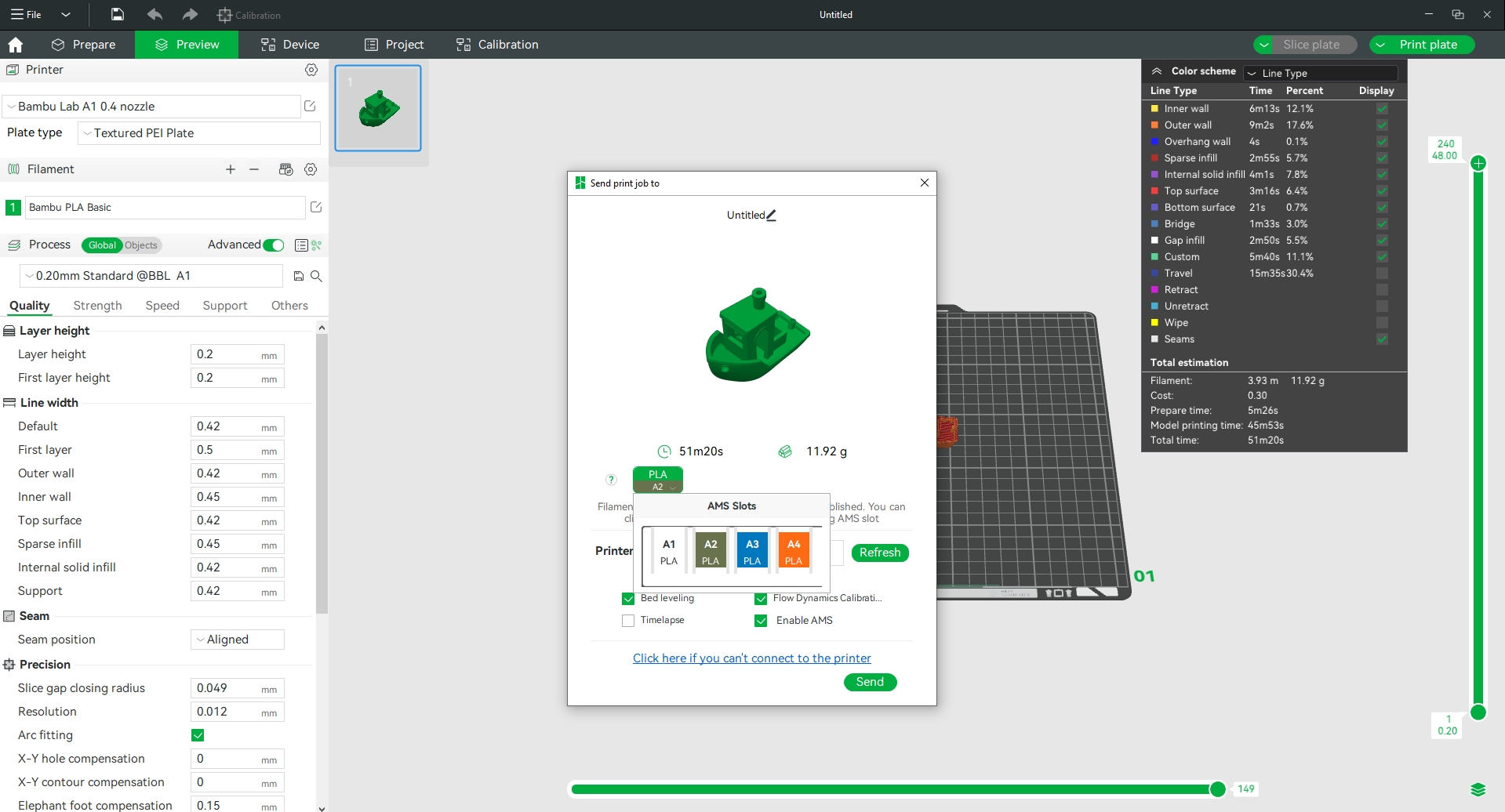

Select the model you want to print, click Slice Plate in the upper right corner, and then click Print Plate in the upper right corner.

|

|

¶ 2. Initiate a print using the built-in file

¶ 1. Click "Print files" on the home page to access the built-in files on the micro SD card.

¶ 2. Select the model you want to print.

¶ 3. Enable "Use AMS," and enabling the bed leveling and flow dynamics calibration functions is recommended.

¶ 4. AMS filament Mapping

Map the actual filament used in the AMS lite to the filament specified in the print file. If no filament matches the color specified in the file, you can either place the specified filament in the AMS lite or choose another filament with the same properties and a close color match.

¶ 5. Click "Print"

¶ Appendix: Remove the Filament Spool

¶ 1. Unload the filament

After the filament is retracted from the tool head, rotate the filament spool while pulling back the filament. Press the release button to disconnect the drive motor if the filament gets stuck. When the filament is close to the coupler connector, hold the filament by hand and insert the filament end into the hole in the filament spool.

|

|

After a print job is completed successfully, the filament will automatically retract back into the AMS lite. However, if the print job is canceled or interrupted midway, you will need to click "unload" on the screen to allow the filament clamped by the toolhead to retract back into the AMS lite; in other words, manually control filament unload before proceeding with the aforementioned unloading tray operation.

|

|

¶ 2. Remove the spool

When removing the filament spool, please use both hands to grasp the entire spool instead of just one side. Also, place your thumb near the center of the rotating axis and pull the spool outward.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue.

Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.