¶ Video Guide

Visit YouTube to watch our A1 printer packing video guide.

¶ Disassembly Operation Step

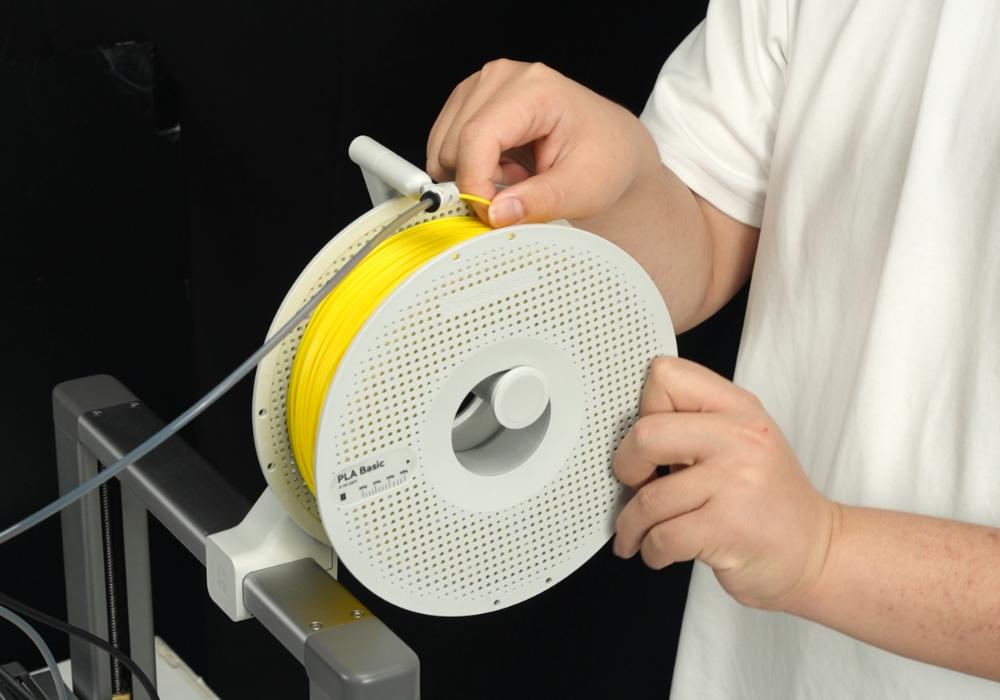

¶ Step 1: Remove the filament spool from the external spool holder

Unload the filament manually from the PTFE tube, insert the filament end side into the filament spool hole, and remove the spool from the spool holder.

|

|

|

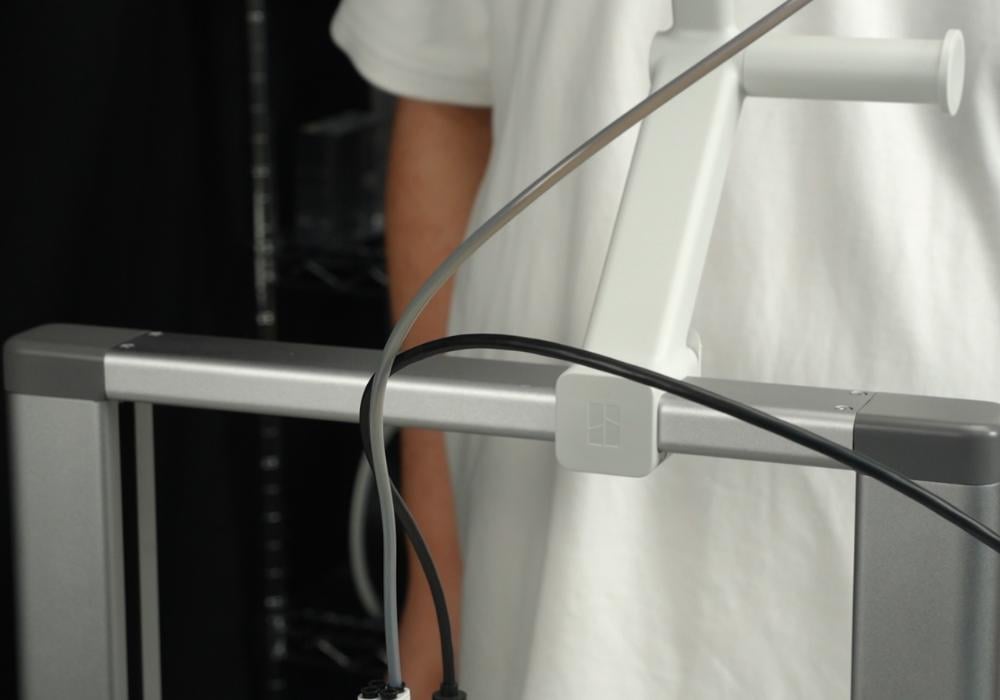

¶ Step 2: Remove the PTFE tubes from the printer, and disconnect the power supply.

1. Remove the cable organizer that secures the PTFE tube and the toolhead connection cable.

|

|

2. Press the toolhead filament inlet connector (by tweezers in the video), and press the filament connector on the spool holder to disconnect the PTFE tube.

|

|

3. Press the switch button to power off the printer and disconnect the power cable.

|

|

¶ Step 3: Remove the purge wiper, take off the build plate, fold the screen, and uninstall the filament spool holder

1. Remove one M3-12 screw located below the purge wiper, and slide the purge wiper backward out of the X-axis end cap slot.

|

|

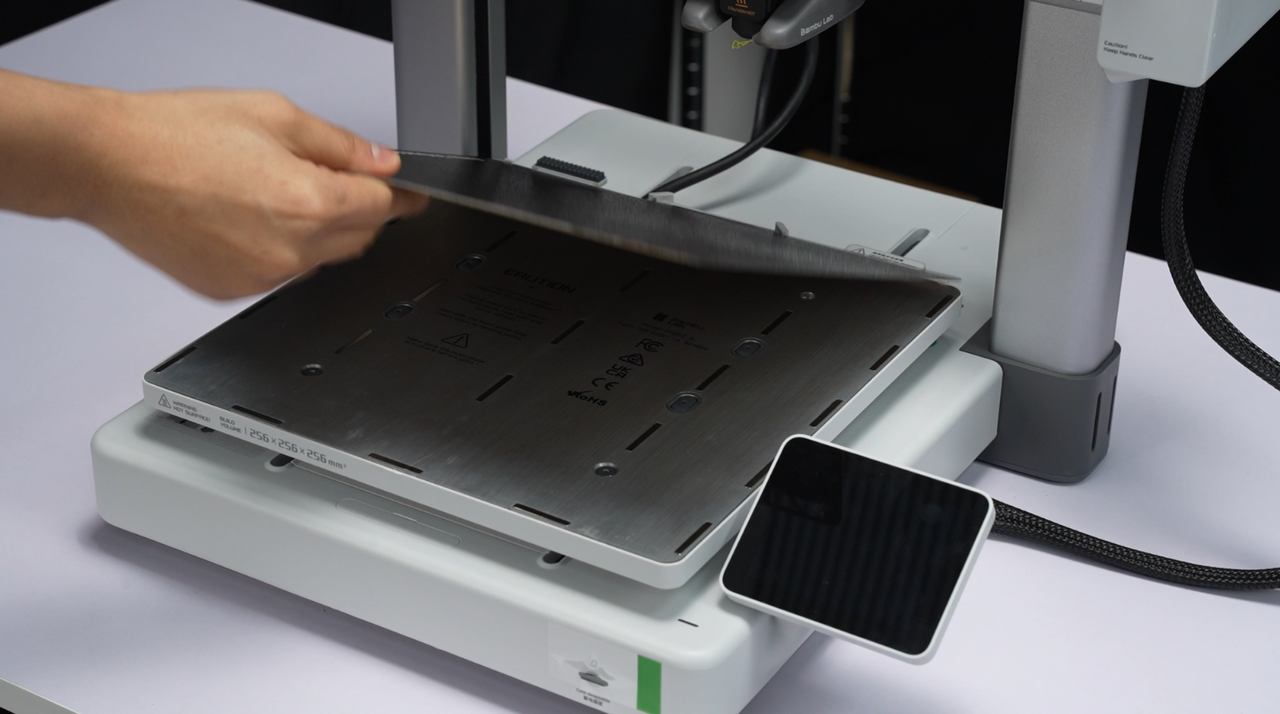

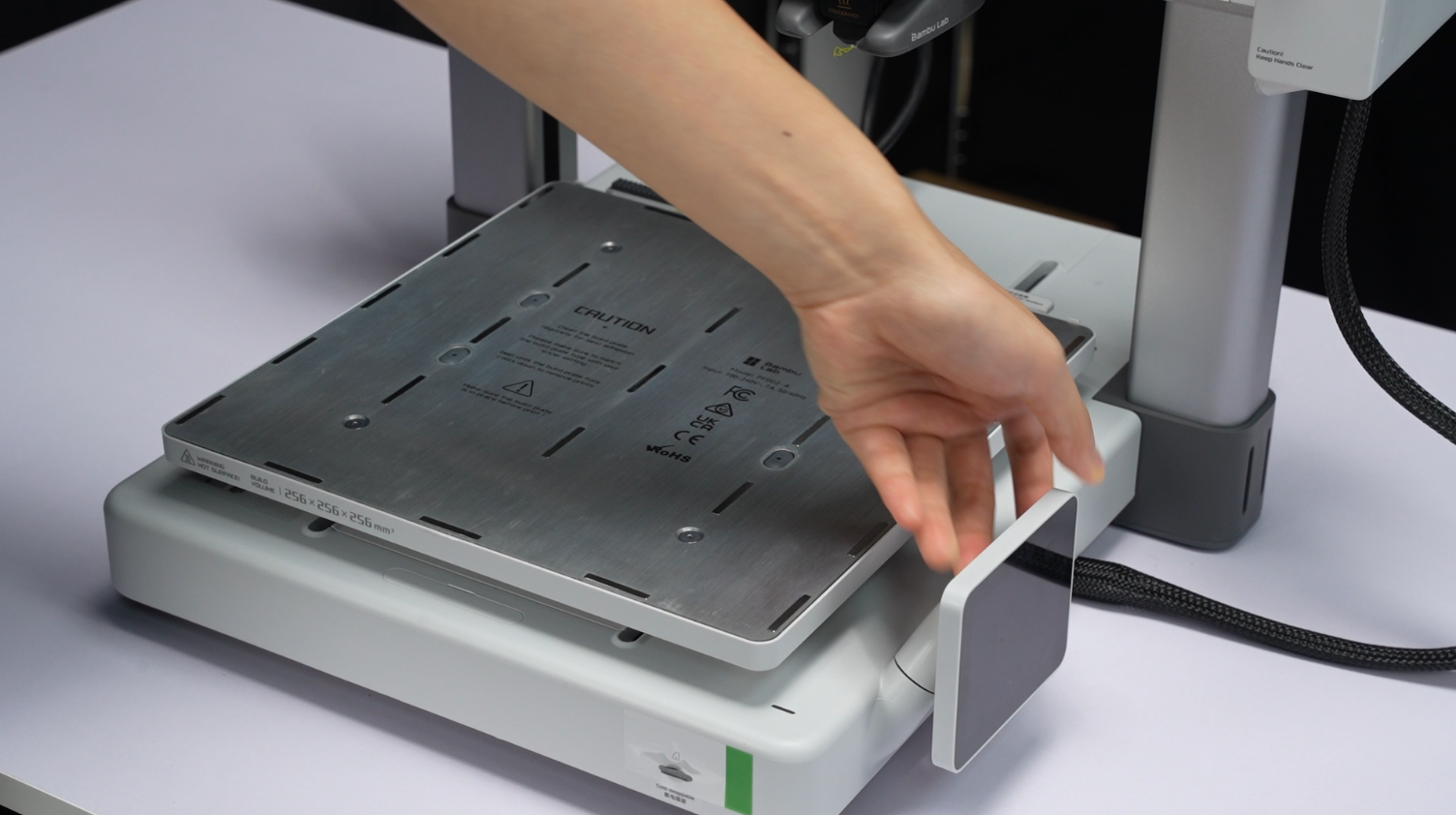

2. Remove the build plate from the heatbed, and flip the display screen on the right side of the printer backward to fold it up.

|

|

3. Open the fastening latch of the spool holder and remove it from the beam of the gantry.

|

|

¶ Step 4: Uninstall the cable box and unplug the three connectors

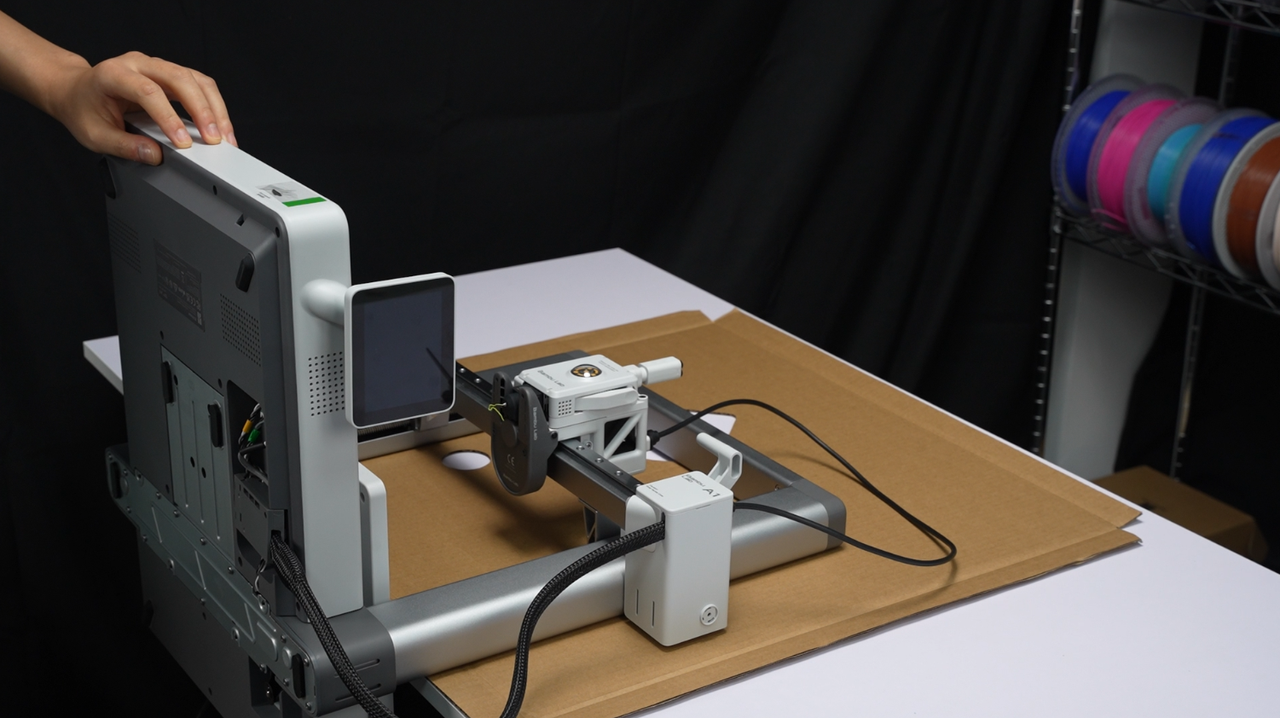

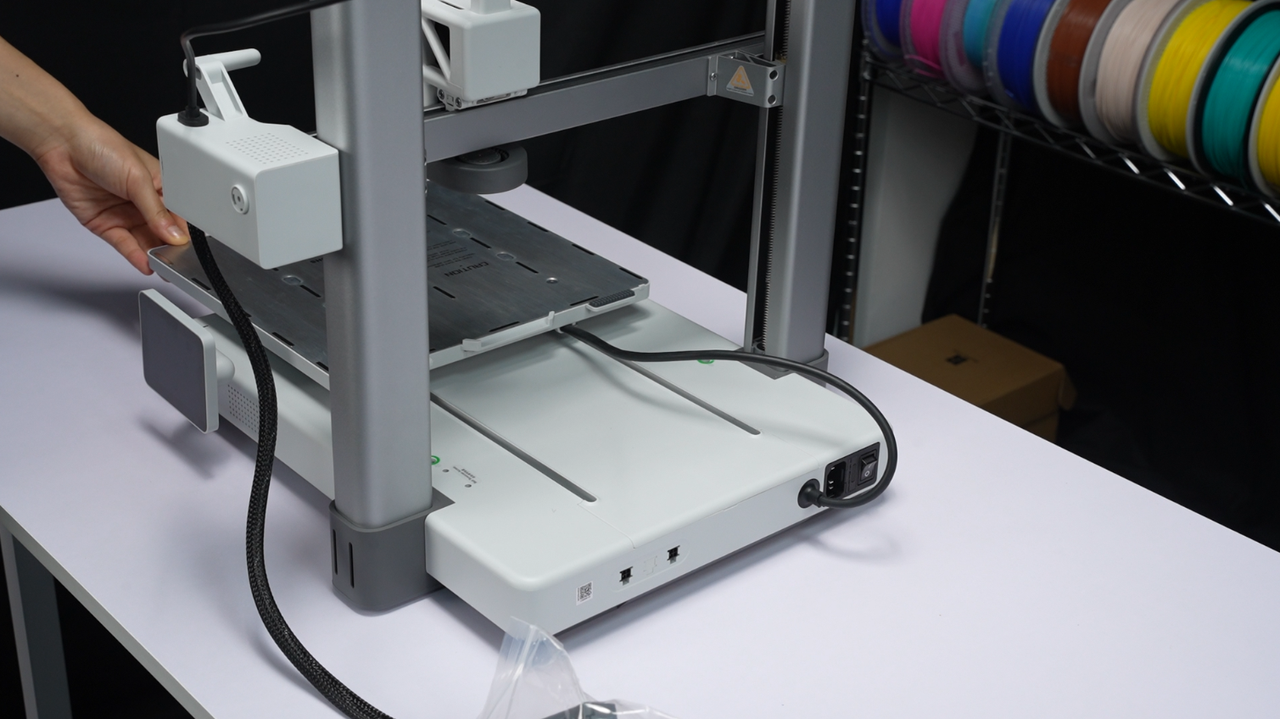

1. push the heatbed to the other end of the screen.

2. Rotate A1 90 degrees backward and place it upside down on the edge of the table (it is recommended to cover the table with a hardboard to protect the printer), with the printer base facing towards yourself, in order to proceed with the removal of the cable box.

|

|

Note: Before proceeding with the following steps, ensure that the printer is stable on the tabletop and support the printer base with your hands.

3. Loosen the pre-installed screws on the cable box at the indicated positions and disconnect the three motor connectors.

|

|

4. After pulling down the cable box, remove the Type-C connector; gently pry open the yellow cable card slot and uninstall the cable box.

|

|

|

|

Note: If you encounter any difficulties during the process, please refer to the operation instructions in the unboxing video. You can use an H1.5 Allen hex to pry open the cable slot to avoid damaging your nails.

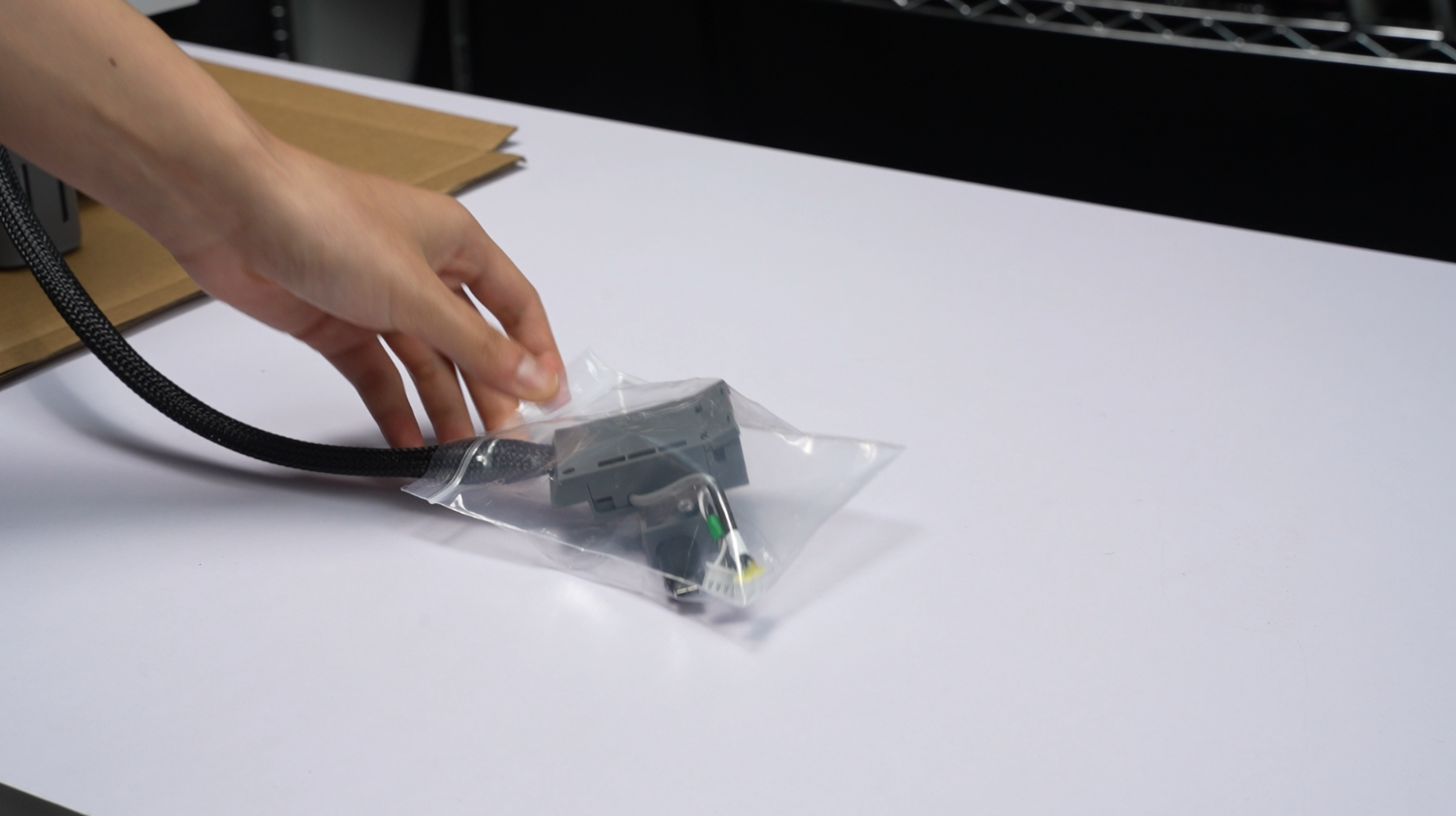

5. Wrap the cable box with a self-sealing bag.

|

|

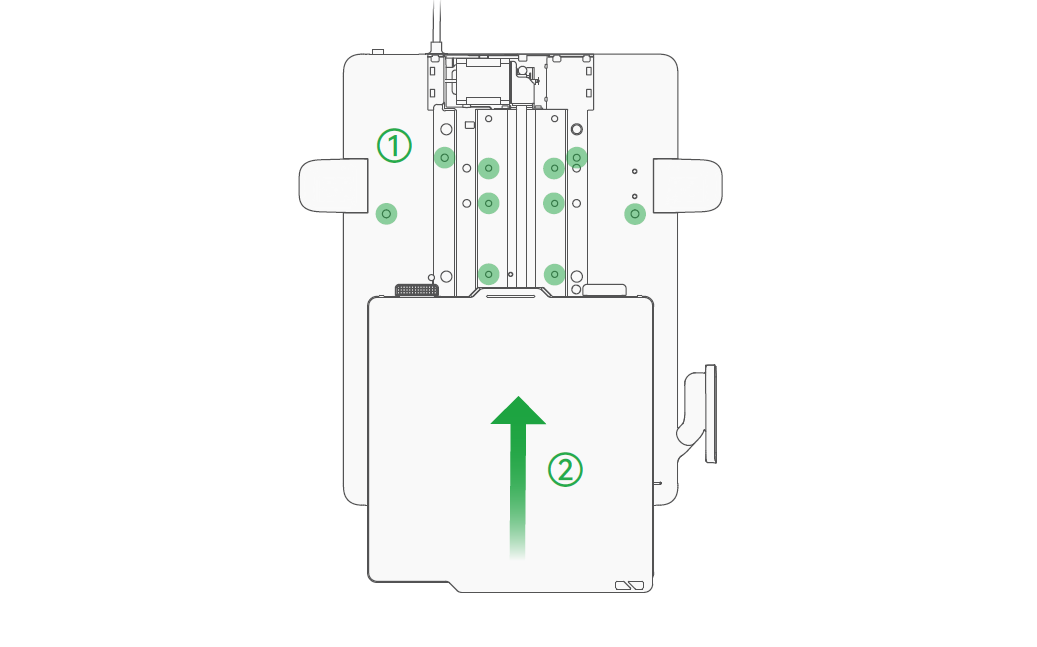

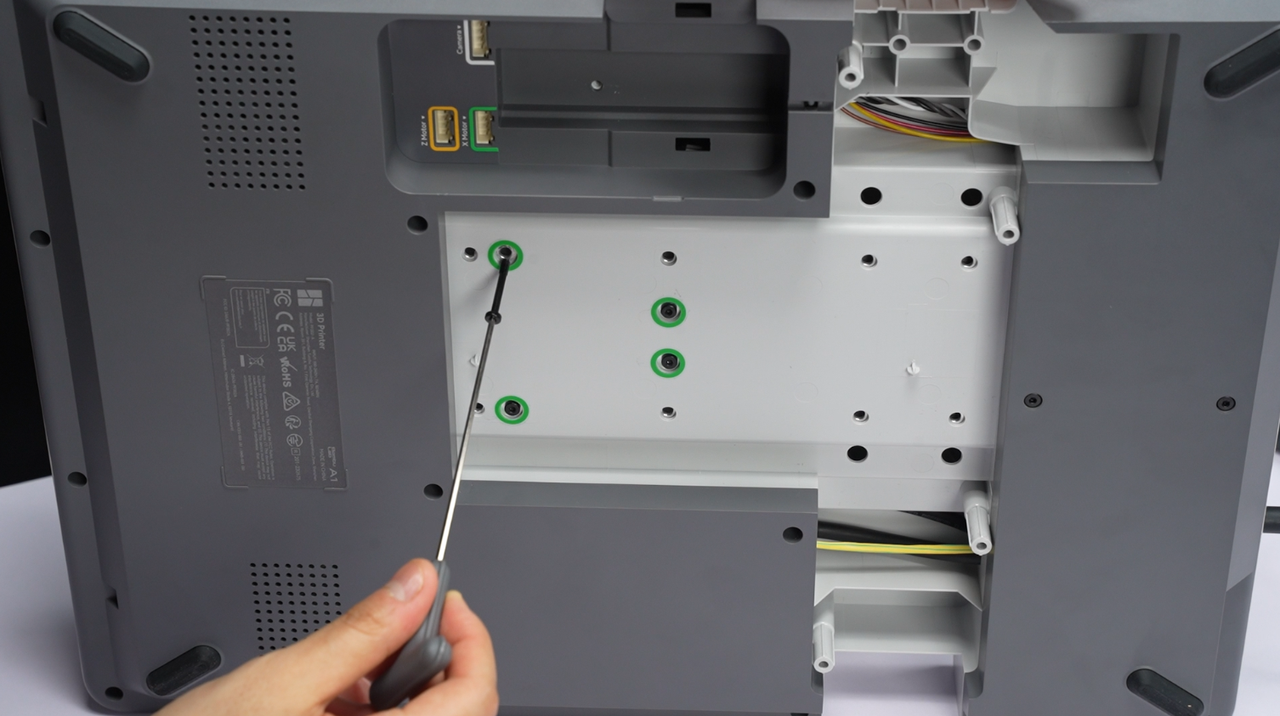

¶ Step 5: Remove the 12 fixed screws between the printer base and the gantry frame

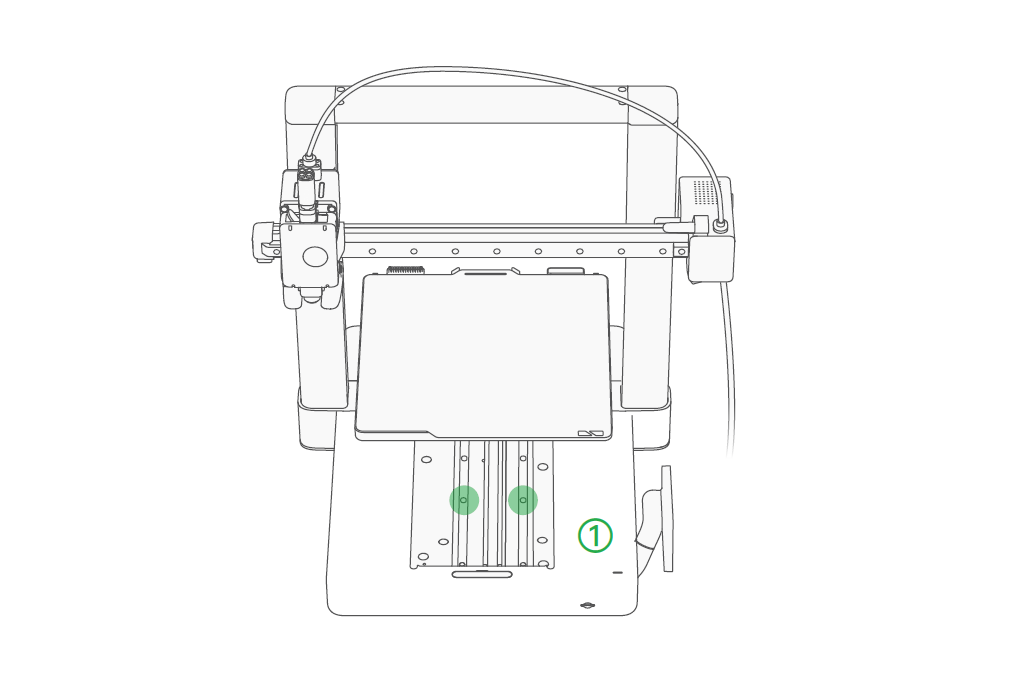

The location of the fixed screws between the printer base and the gantry frame (a total of 12 screws need to be removed) is shown in the diagram below.

|

|

1. Push the heatbed way to the end in the direction of the screen, and remove the Y-axis rail cover.

|

|

2. Unscrew the 12 screws, during which you may need to push the heatbed once to locate the positions of the last 2 screws.

|

|

3. Push the heatbed to the end in the direction of the screen, and then slide the Y-axis rail cover back into place.

|

|

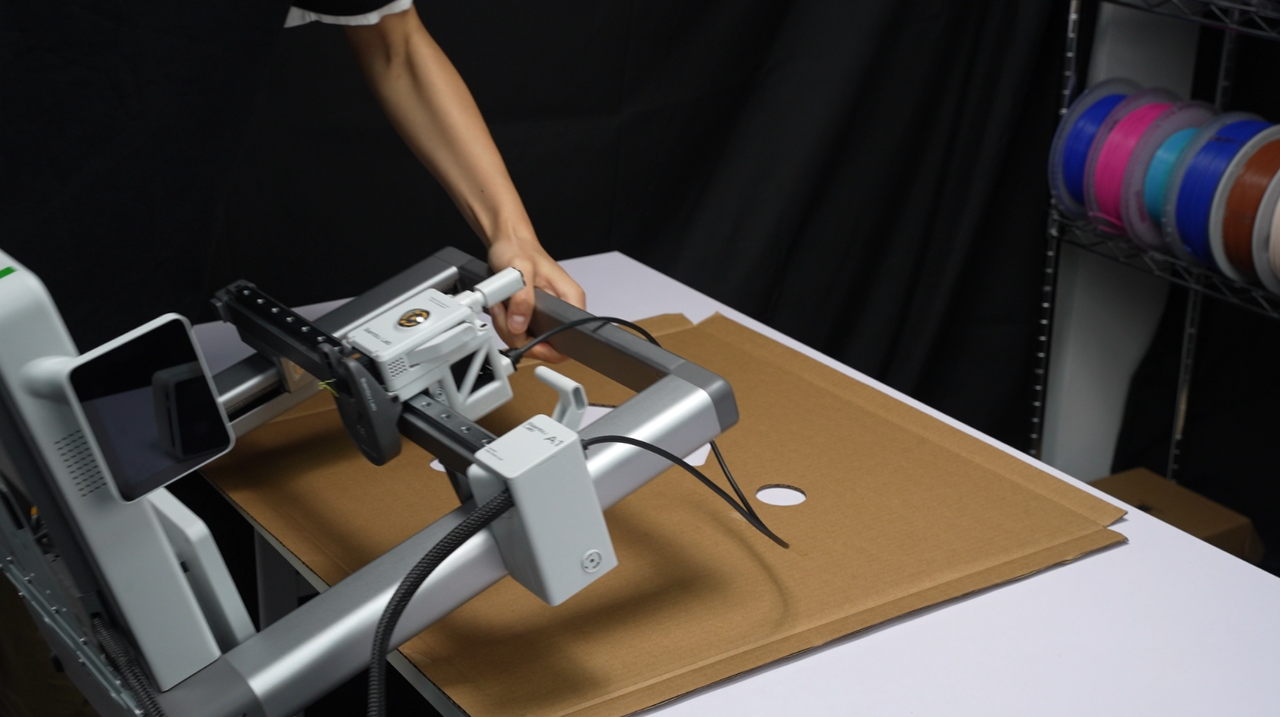

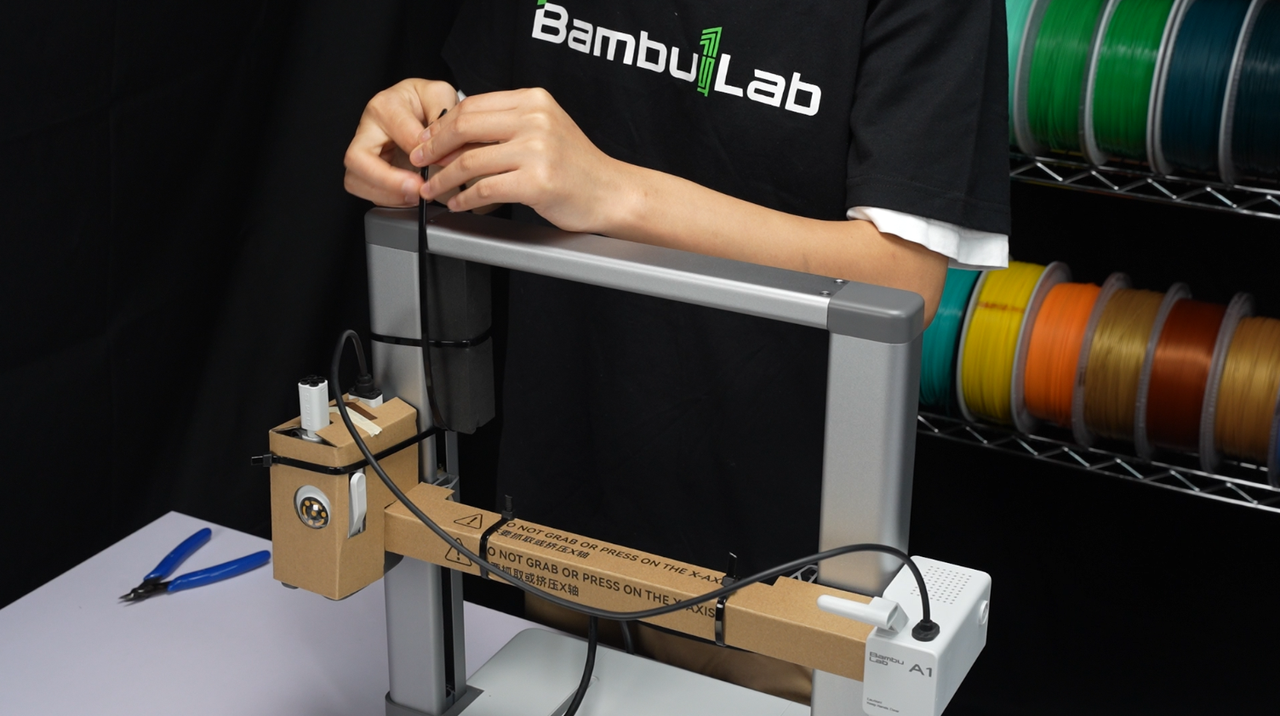

¶ Step 6: Secure the toolhead with zip ties and install protective foam and cardboard

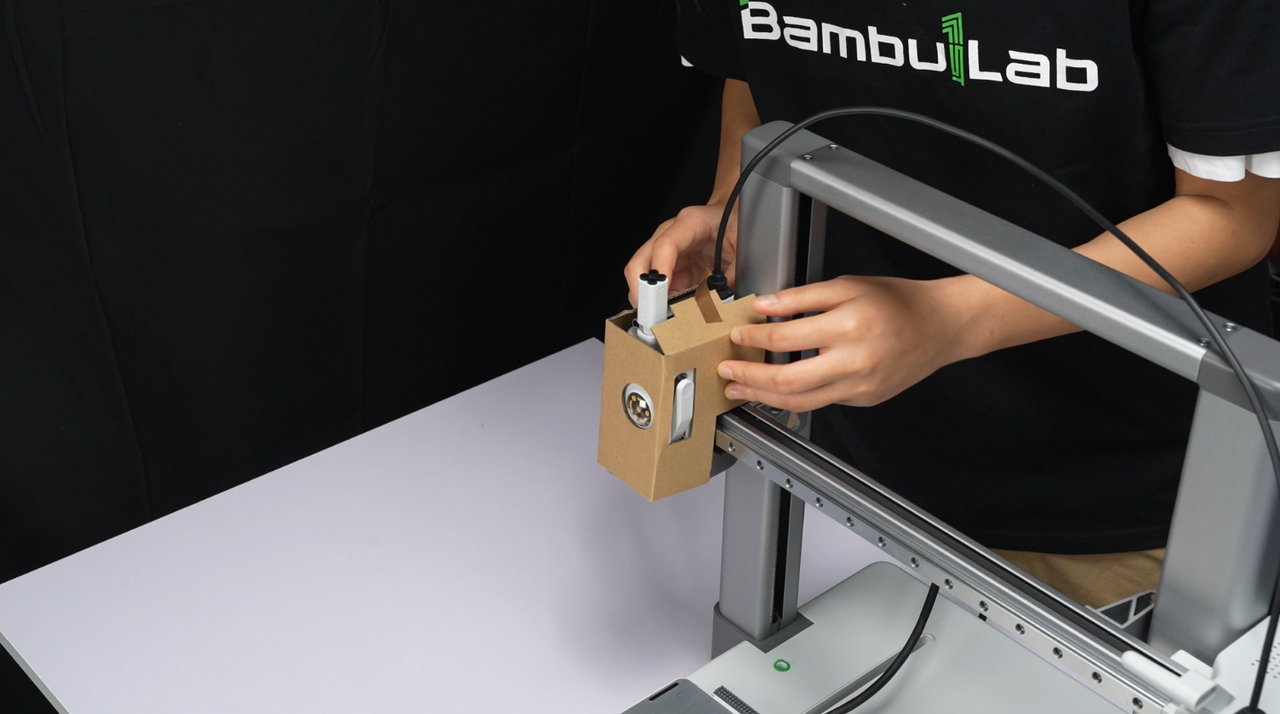

1. Move the toolhead to the end of the X-axis guide rail; Install the protection cardboard for the toolhead; and secure the toolhead and the gantry frame with zip ties.

|

|

2. Install the protection cardboard for the X-axis guide rail; and secure it with zip ties.

|

|

3. Place the foam padding on the inner sides of the gantry frame, and secure them using zip ties respectively.

|

|

|

|

4. Secure the connection cable and the toolhead and the gantry frame with zip ties.

|

|

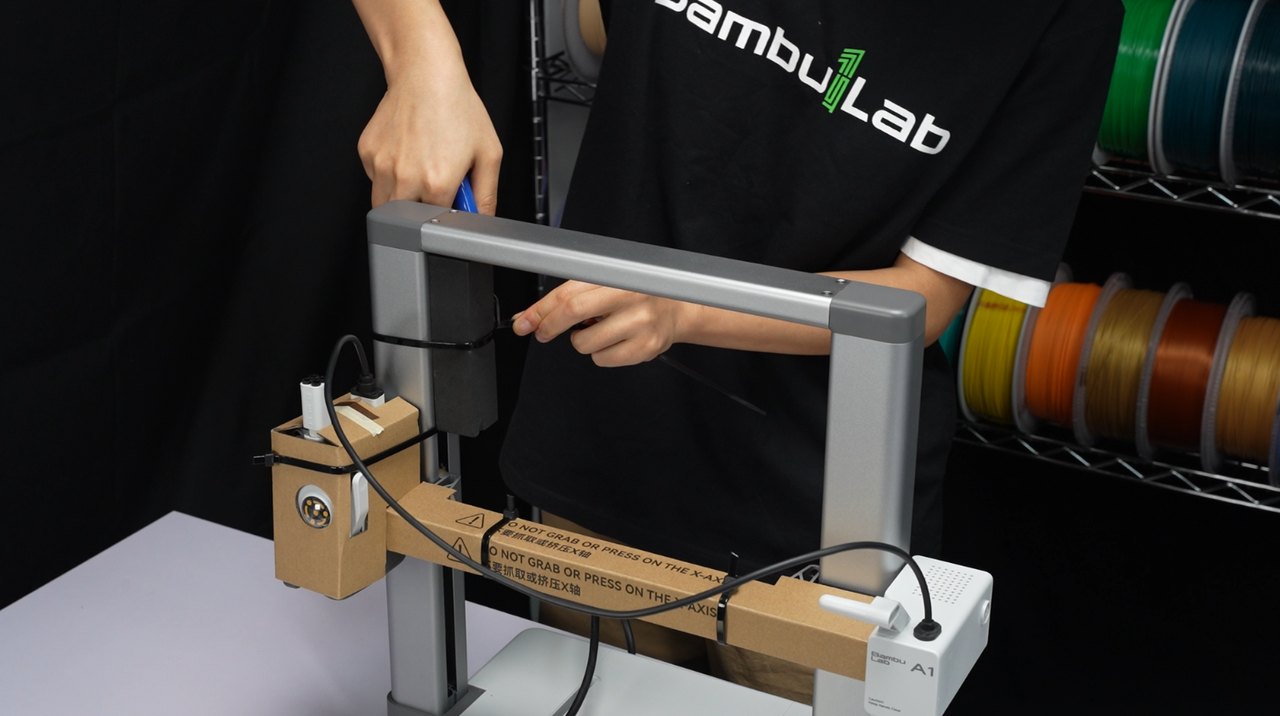

¶ Step 7: Separate the gantry frame from the printer base

Lift the printer base and slightly tilt it to separate it from the gantry frame.

|

|

¶ Step 8: Tighten the four screws on the heatbed to prevent damage to the heated bed unit during transportation.

1. Push the heatbed to align the edge of the nozzle wiper approximately with the groove on the printer base. This will roughly align the four screw holes on the heatbed with the printer base for the next step of screwing them in. Rotate the base 90 degrees so that the screen is positioned directly above.

|

|

2. Tighten the four screws to secure the heatbed. If the screws cannot be tightened, make slight adjustments to align the holes on the heatbed with the corresponding holes on the base.

|

|

3. Check the status of the heatbed and ensure that it is securely fixed and can not be moved after tightening the screws.

¶ Packing Operation Steps

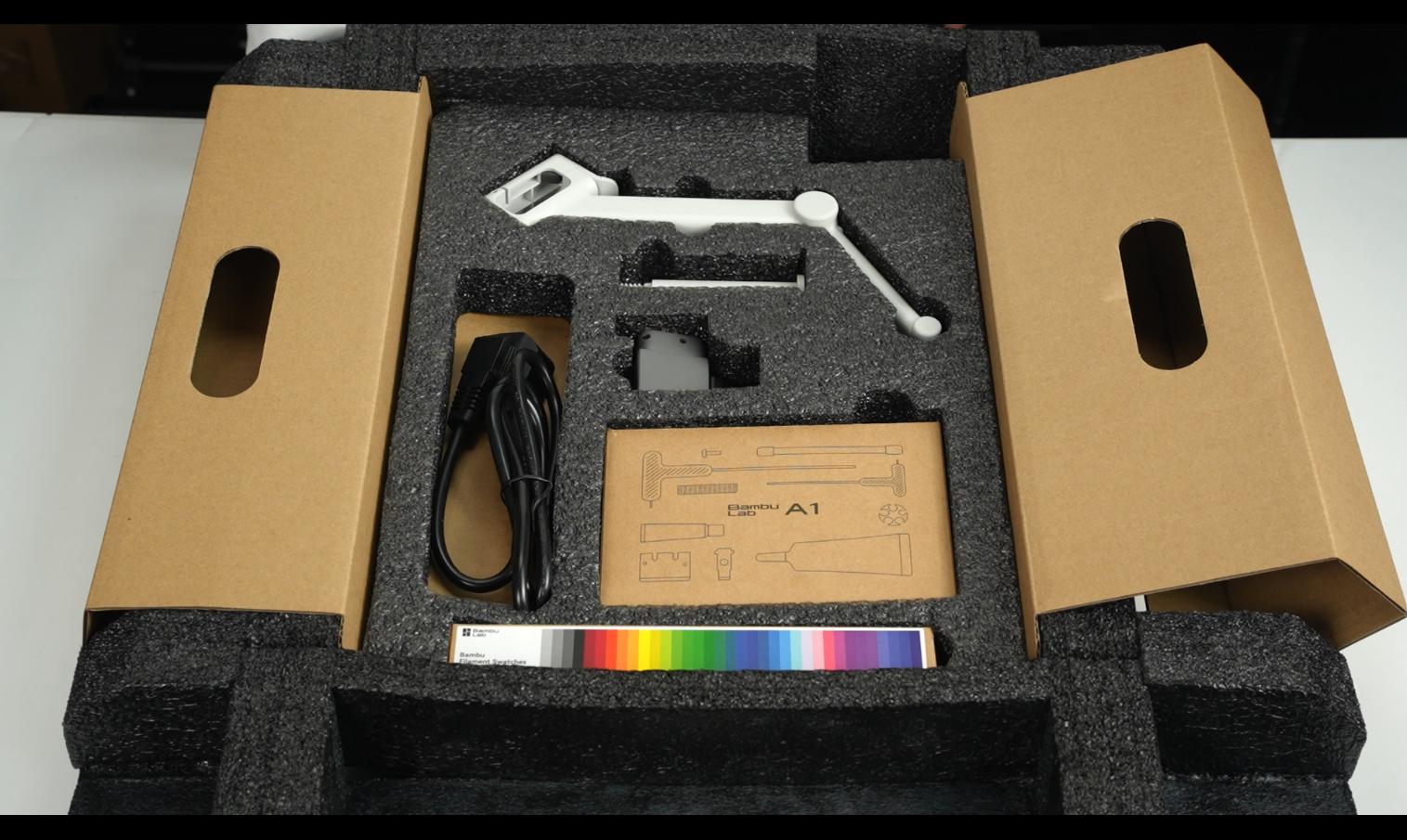

¶ Step 1: Place the components back into the accessories kit and individually place the remaining accessories into protective foam

1. Put the components back into the accessories kit. Lock the spool holder latch and unscrew the spool holder support shaft from the main body.

|

|

2. Place the filament spool holder, extruder assembly, accessories kit, power connection cable, and 3D printing filament swatches one by one into the protective foam.

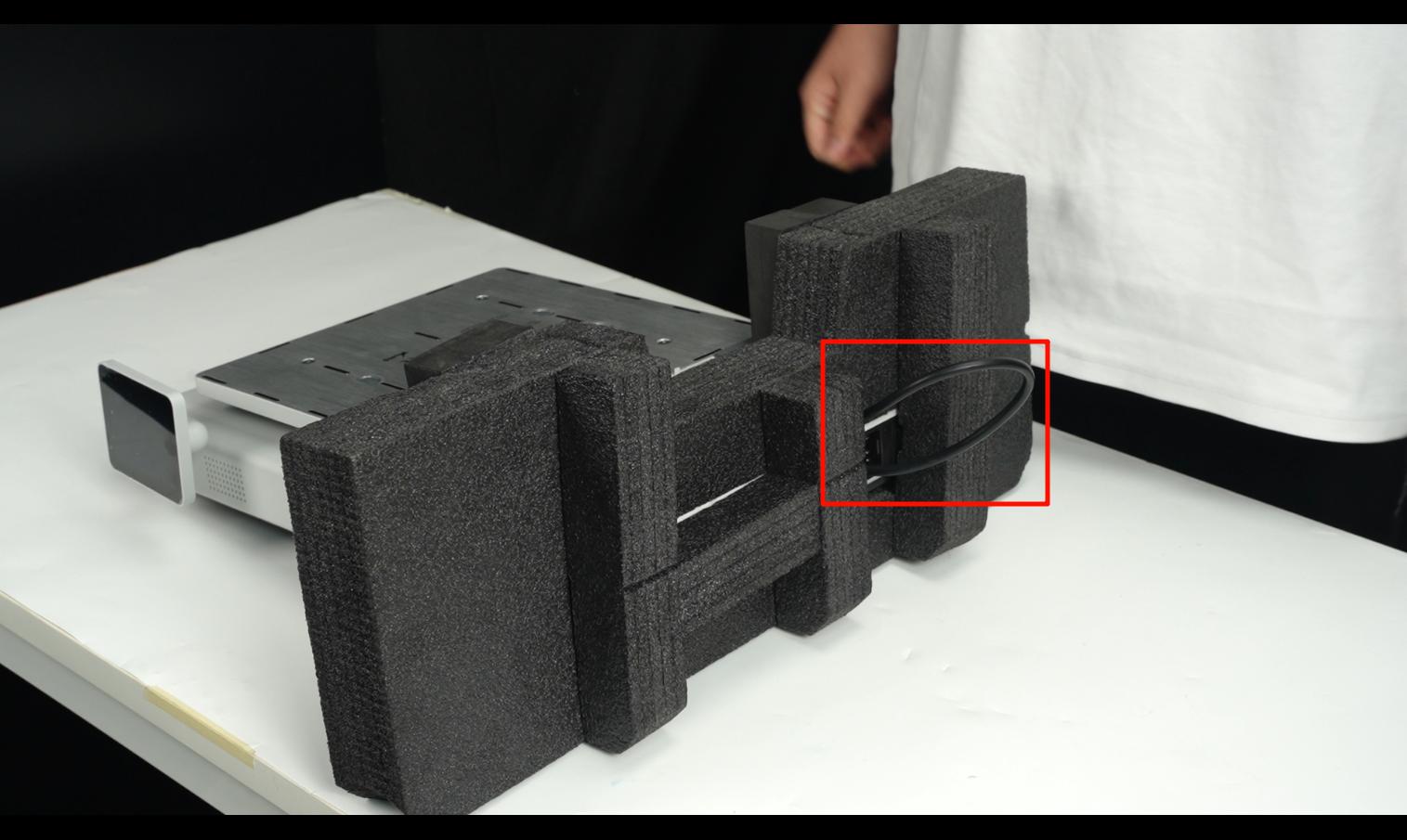

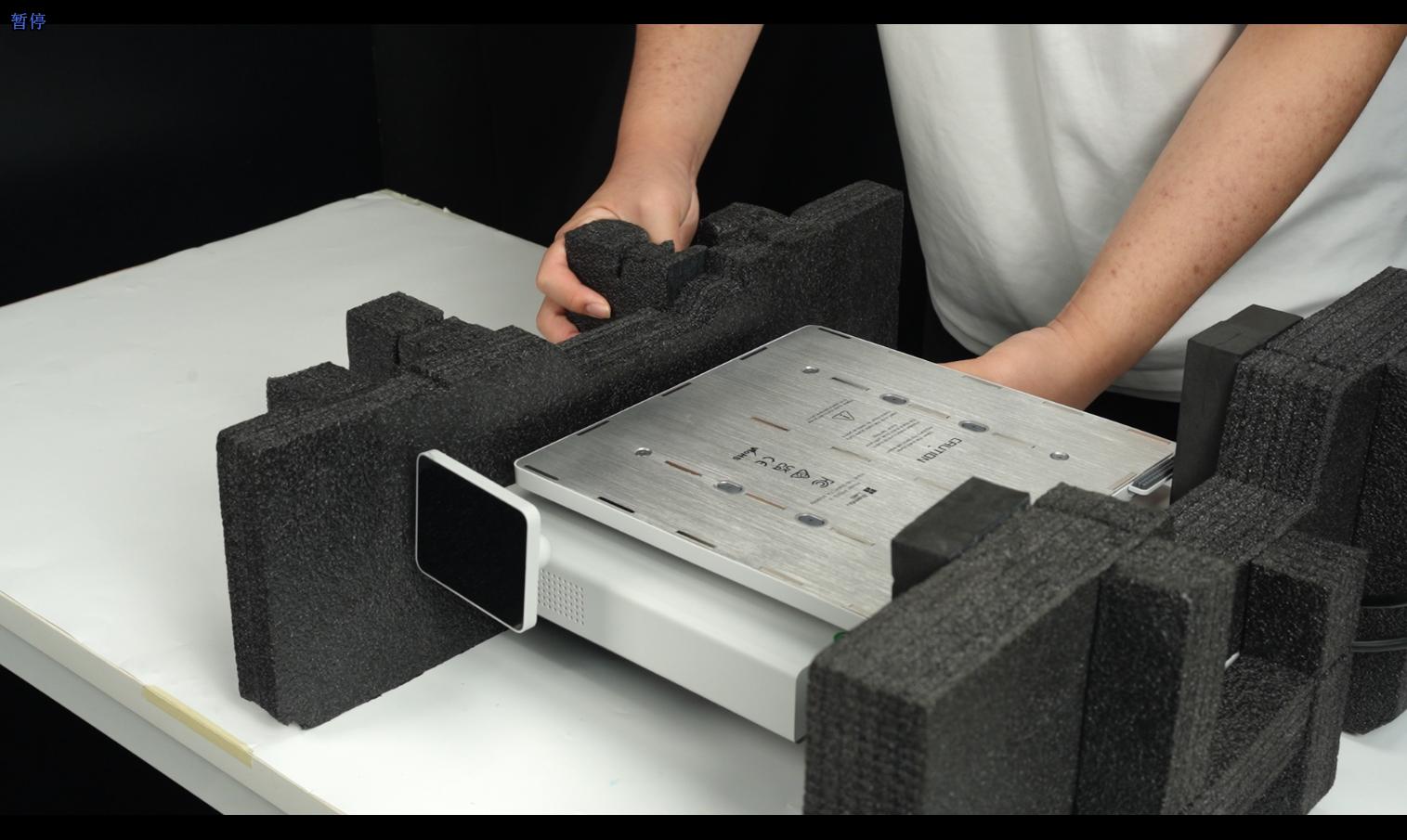

¶ Step 2: Install the protection foam and pack

1. Install protective foam on both sides of the printer base, ensuring that the heat bed cables pass through the holes in the protective foam during installation to prevent any compression.

|

|

2. Place the printer components and their accessories into the packaging box in the following order.

|

|

|

|

|

|

|

|

3. Seal the plastic packaging bag and use adhesive tape to seal the box.

|

|

|

|

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.