¶ Observation

Every slot in AMS lite has a feeder. The gears in the feeder squeeze the material line and load or unload the filament into or out of the toolhead under the drive of the brushed motor. As shown in the following figure:

When the filament is too thin or the gear is damaged, the gap between the gear and the filament becomes larger, causing the gear to slip and ultimately leading to a failure in loading and unloading the material.

¶ Troubleshooting

The following troubleshooting process and actions aim to solve the most frequent issues, which are:

- The head area of the material line is thin.

- The specification of the material line is not standard, the diameter is thin.

- The feeder gear is damaged.

If the issue you met is not listed in this wiki, please submit a customer support ticket.

¶ Tools, Equipment, and Materials

- H1.5 /H2.0 Hex wrench

- Vernier caliper

¶ Actions

Operators may use discretion in determining the actual procedures used, and the order in which these steps are applied.

- Check if the head area of the filament is thin

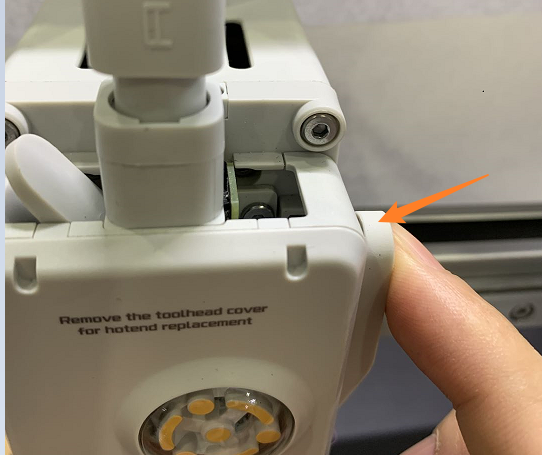

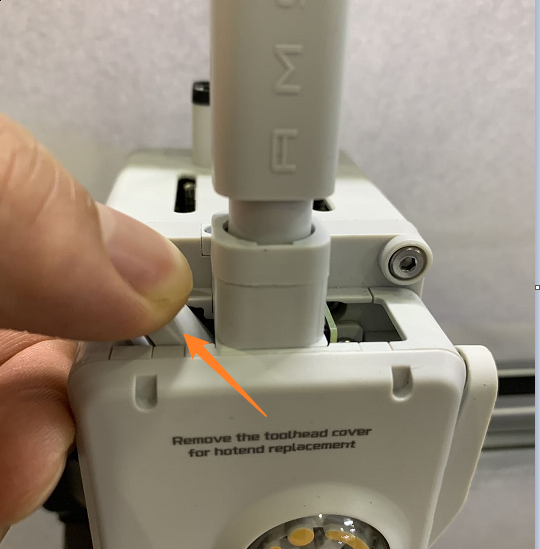

- If the extrusion failure is reported during the feeding process, please manually press the tool head cutter to cut off the filament. If an error occurs during the printing process, go to Step 3.

- Manually press the drive wheel holder of the tool head and pull the filament from the feeder side.

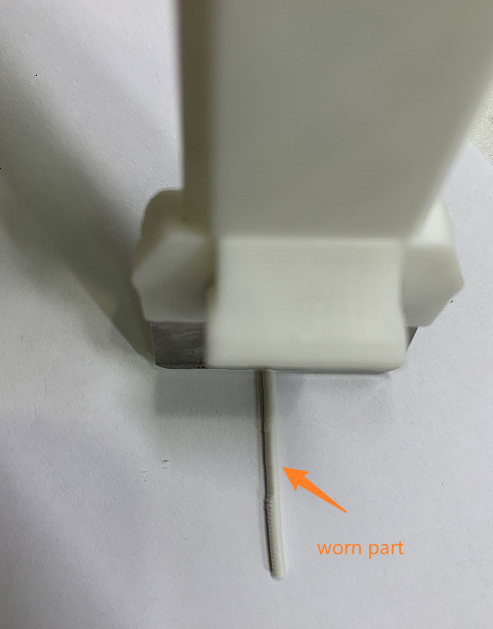

- After pulling out the filament, check if there are any signs of wear on the filament. If so, cut the worn part, insert the filament into the corresponding slot and retry.

- If the extrusion failure is reported during the feeding process, please manually press the tool head cutter to cut off the filament. If an error occurs during the printing process, go to Step 3.

- Check if the filament diameter is too thin

Use a vernier caliper to measure the diameter of the wire at multiple points. The normal diameter of the wire material is 1.75mm +/- 0.03mm. If the wire diameter is too small, you can try to print again after replacing the filaments. - Check if the feeder gear is damaged.

Visually inspect the feeder gear for serious wear, gear offset, and other defects. If the gear is damaged, please replace the loader and unloader.

AMS lite Feeder Unit Installation Tutorial

If the issue persists after troubleshooting, please submit a customer support ticket.

¶ Equivalent Codes

The following HMS codes represent the same type of fault. 12[XX][YY]0000010001 represents the extrusion wheel in YY slot of XX AMS that has the issue.

1200100000010001

1200110000010001

1200120000010001

1200130000010001

1201100000010001

1201110000010001

1201120000010001

1201130000010001

1202100000010001

1202110000010001

1202120000010001

1202130000010001

1203100000010001

1203110000010001

1203120000010001

1203130000010001

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.