¶ Video Guide

¶ Operation Steps

¶ Take out the AMS 2 Pro

- Open the carton and take out the AMS 2 Pro.

|

|

|

|

- Remove the two black foams on the left and right.

|

|

- Remove the tape and take out the AMS 2 Pro.

|

|

|

¶ Take out the accessories

- Remove the instruction manual.

|

|

- Remove the protective film.

|

|

|

|

- Open the top cover and take out the black foam and cable bag.

|

|

|

- Remove the sticker and take out the desiccant.

|

|

¶ Place the desiccant

Remove the packaging and place the desiccant in the AMS 2 Pro.

|

|

|

|

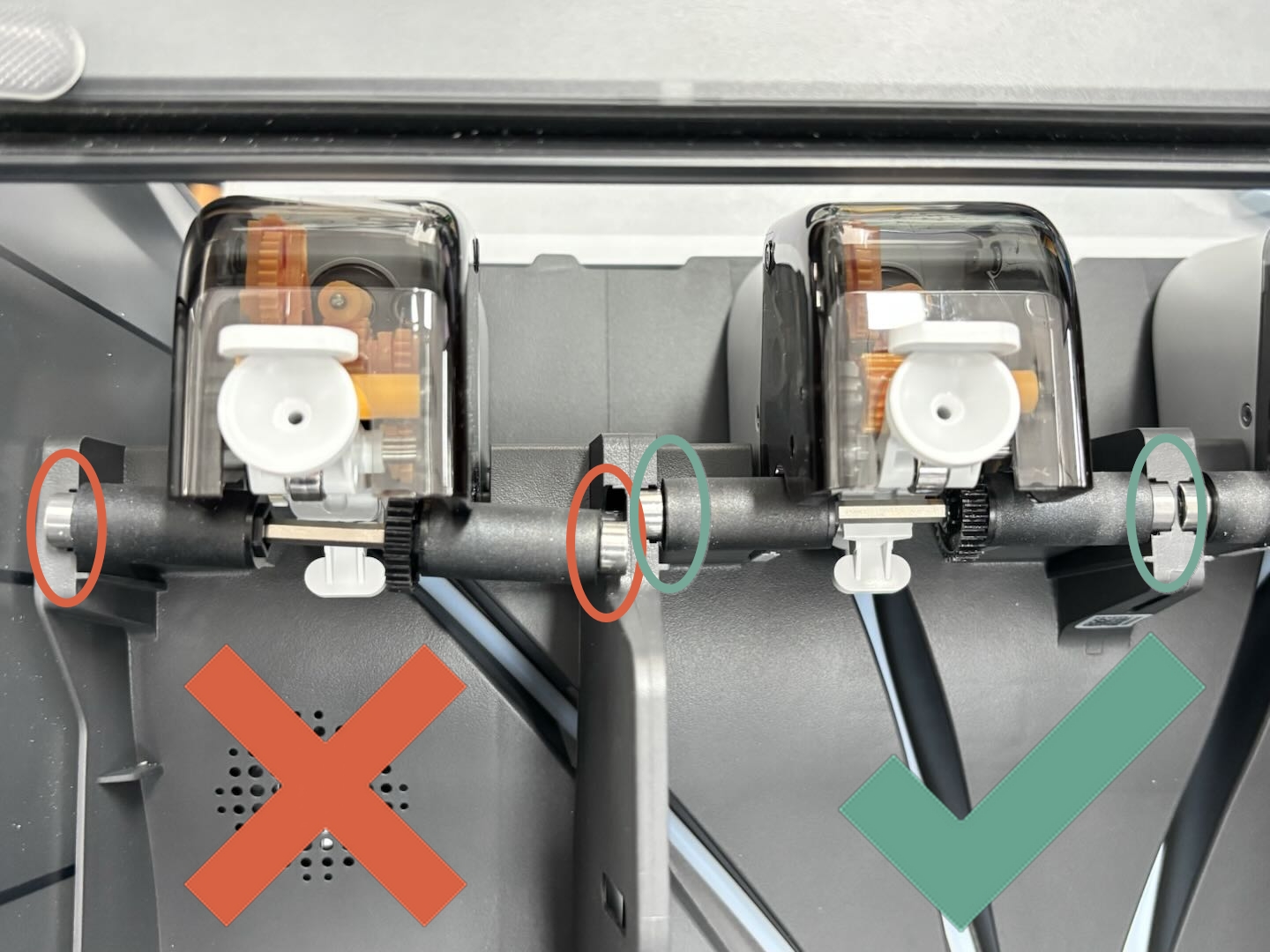

¶ Check the active drive shafts

Vibrations during transportation may cause the drive shafts on the slots to dislodge. Please check and ensure each shaft is properly assembled to prevent filament disarray due to failure to turn the spool to rewind it.

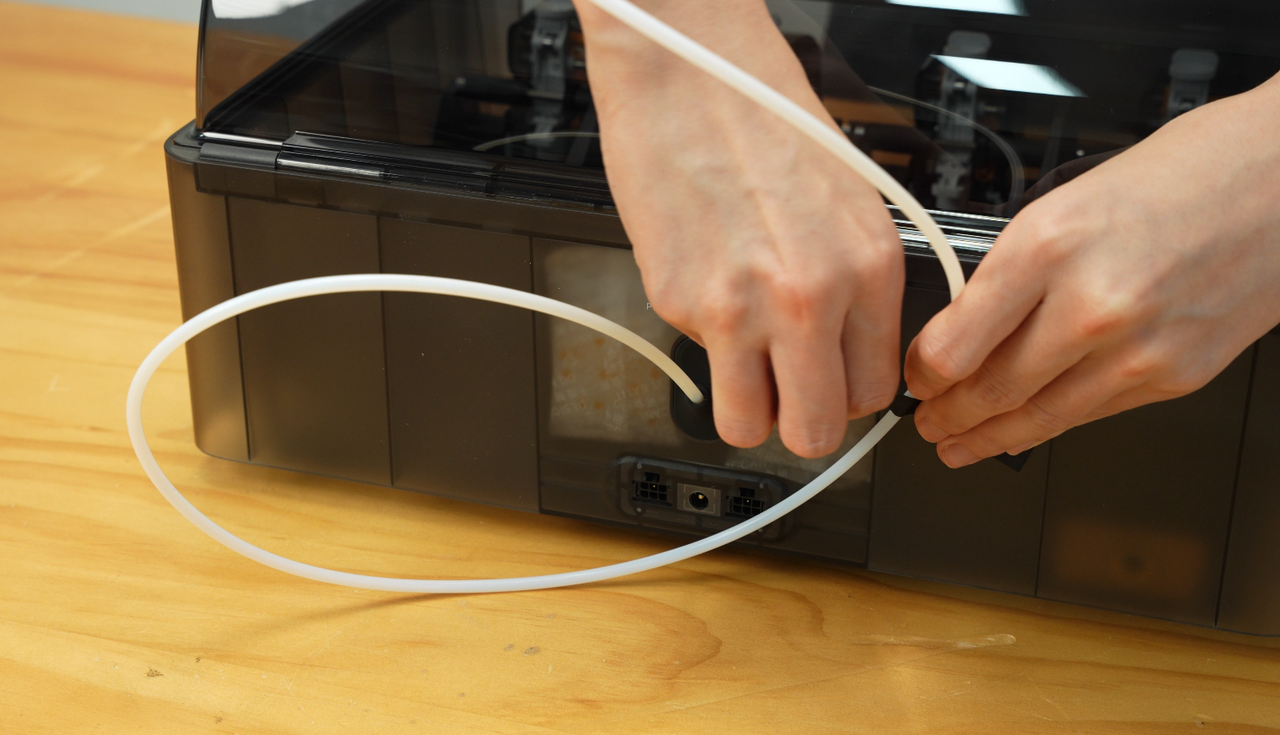

¶ Connect the tube

- Remove the tape and remove the tube.

|

|

- Insert one end of the tube into any coupler of the printer and push the tube forward until it can no longer move forward.

Note:

Due to the differences in the length of the tube in different batches and versions of the whole printer configuration, under the premise of ensuring that the loading resistance meets the requirements, appropriately shortening the length of the tube can effectively reduce the printing time.

After testing and verification, the length of the tube from the AMS to the H2D is recommended to be no less than 600mm to ensure the best working condition of the equipment.

¶ Connect the 6-pin cable

Insert the 6-pin cable into any port of AMS 2 Pro and the other end into the printer.

|

|

Note: Be sure to use the new 6-pin cable included with AMS 2 Pro and AMS HT. Using the 6-pin cable from the previous generation AMS may cause unstable communication between the AMS and the printer, while the previous generation AMS is compatible with the new 6-pin cable.

¶ Turn on the printer

Turn on the printer and you can view the connection between the printer and AMS 2 Pro on the "Filament" page.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!