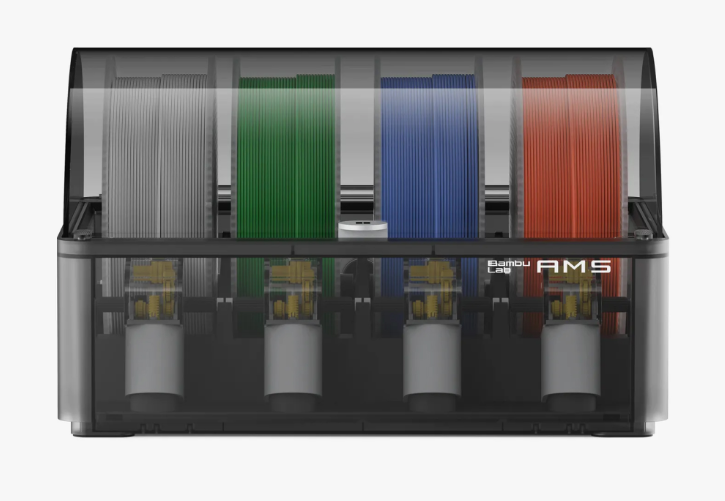

Every generation of Bambu Lab AMS (Automated Material System) is equipped with intelligent humidity detection—your first line of defense against filament degradation.

By continuously monitoring humidity inside the chamber, the AMS helps you avoid moisture-related print quality issues (e.g., surface bubbles, stringing).

Whether it’s PLA, PETG, or PA and other hygroscopic materials, the AMS provides humidity readings so you can always keep track of storage conditions.

¶ Understanding Humidity

¶ Absolute Humidity (ρₐ) — Actual Water Content

Definition: The mass of water vapor per unit volume of air (g/m³).

Plain explanation: Absolute humidity is “how many grams of water vapor are in the air,” directly determined by vapor pressure and temperature.

¶ Relative Humidity (RH) — Percentage of Saturation

Definition: The ratio of the current water vapor partial pressure to the saturation vapor pressure at the same temperature, expressed as a percentage.

Plain explanation: Relative humidity is “how full the air is” compared to the maximum it could hold at that temperature.

Example: RH = 60% means the air contains 60% of the maximum possible water vapor for that temperature.

¶ Temperature’s Effect

Temperature affects relative humidity but not absolute humidity (actual water content remains the same).

- Temperature ↑ → Air can hold more water vapor → RH ↓

- Temperature ↓ → Air can hold less water vapor → RH ↑

This is why RH readings often increase after drying as the AMS cools down.

Everyday example:

- Summer at 30 °C with 50% RH has more water vapor (higher absolute humidity) than

- Winter at 5 °C with 90% RH, which contains less water vapor but may feel damper.

¶ Humidity Display by AMS Generation

¶ AMS — Level Indicator (A–E)

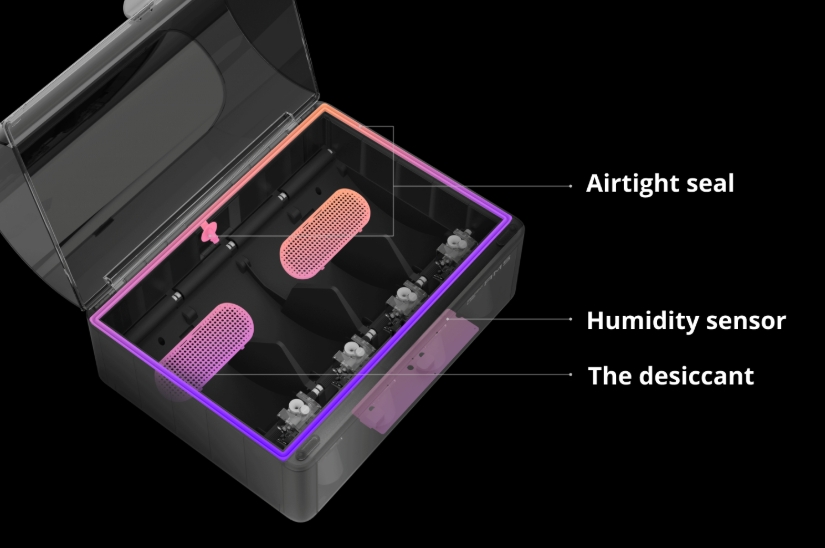

Because the AMS temperature and humidity sensor is located on the mainboard at the bottom, readings can be affected by sensor placement and mainboard heat.

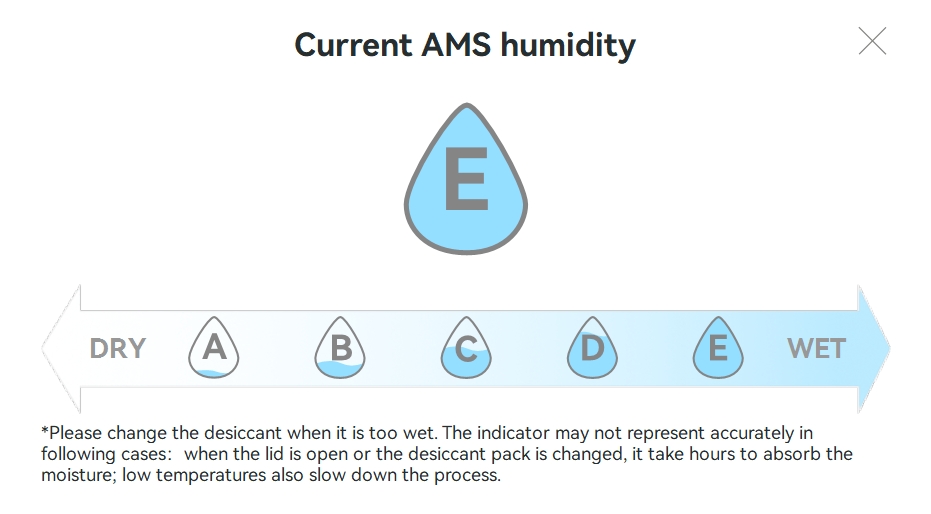

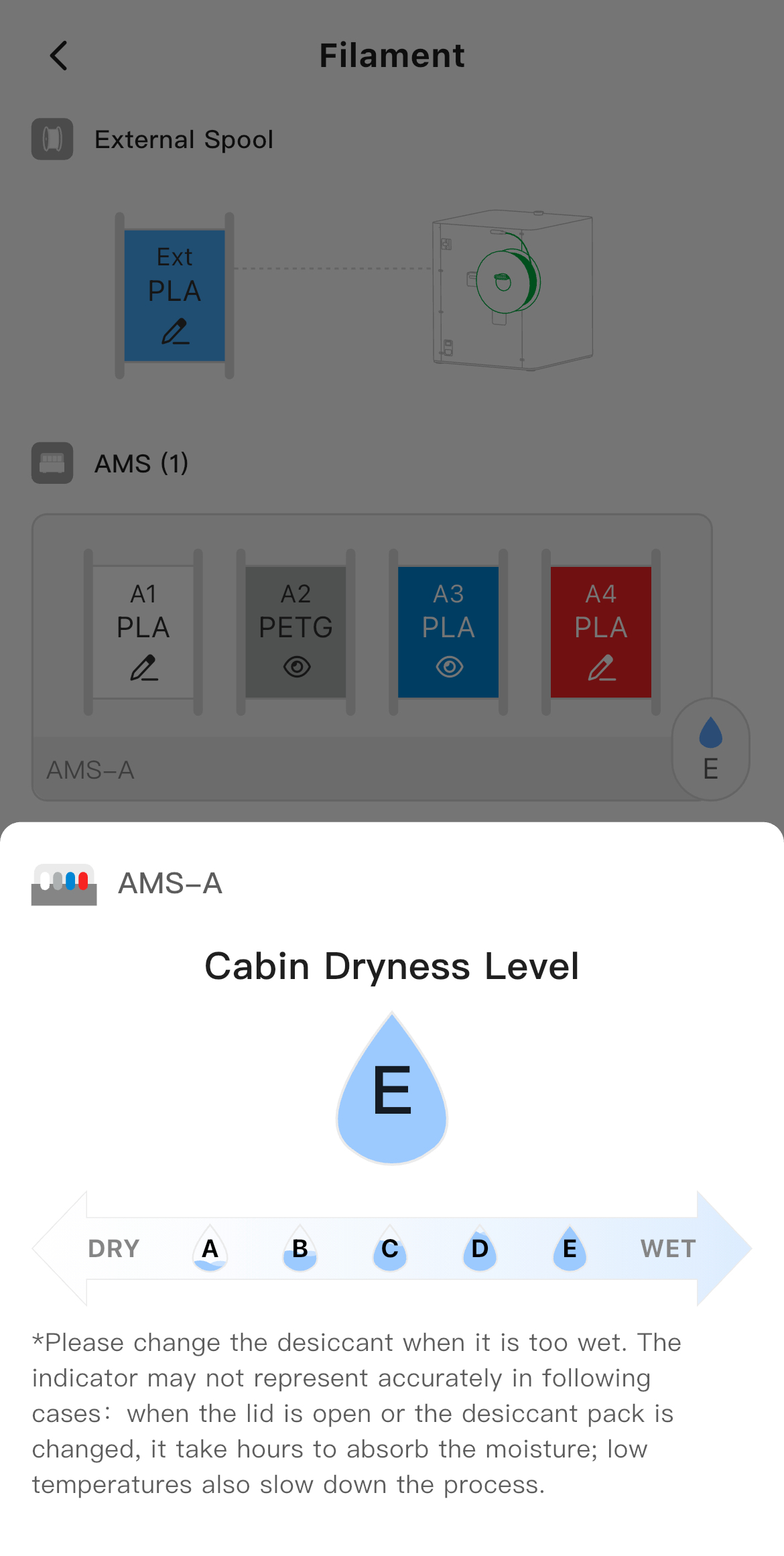

As a result, in the latest firmware/software, humidity is displayed using five levels (A–E):

|

|

-

The humidity level is calculated based on the measured water content and temperature, which are then converted into a relative humidity value and mapped to different curve thresholds. Each humidity level is determined by the water content, temperature, and relative humidity value together. Levels A–E represent humidity from low to high.

-

At the same relative humidity, the higher the water content and temperature → the higher level; At the same temperature, the higher the water content, the higher the relative humidity → the higher level.

For example:- Relative humidity RH = 30% → at around 20 °C, water content is 4.7 g/m³ → Humidity Level A

- Relative humidity RH = 30% → at around 24 °C, water content is 5.9 g/m³ → Humidity Level B

In other words, even at the same relative humidity, the software may classify them as different levels (A or B) depending on the actual temperature and water content.

-

Users should note that when the display shows Level C or above, the AMS chamber is relatively humid, so please ensure proper sealing and replace the desiccant as needed.

Example displays:

|

|

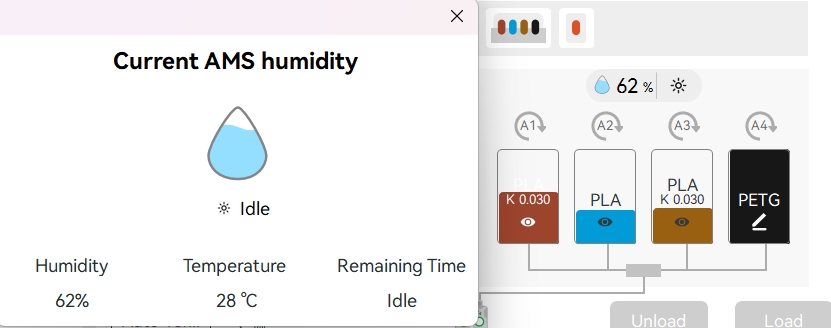

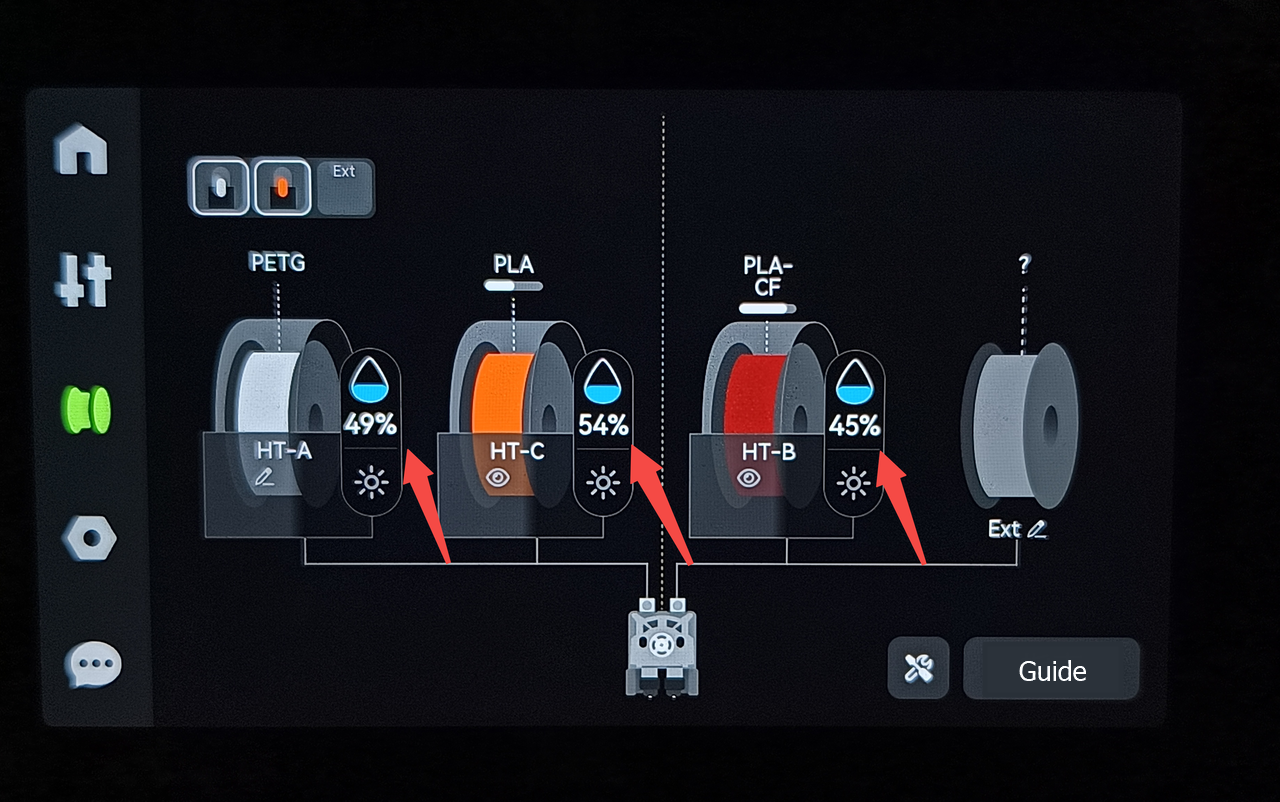

¶ AMS 2 Pro / AMS HT — Percentage Display

|

|

The new AMS models feature optimized sensor placement, allowing direct display of relative humidity as a percentage.

Usage notes:

The latest AMS models use an improved sensor layout that can directly show relative humidity as a percentage.

When using this feature, keep in mind:

-

For best results, use this together with the AMS drying function. If the humidity stays high for a long time, simply run the dryer again to bring the moisture level down.

-

After drying, you may see the humidity number go back up. This is normal—it happens because the chamber cools down after heating, which makes the relative humidity reading rise, even though no extra moisture has been added.

Example displays:

AMS HT onboard display |

Bambu Studio display |

Printer screen display |

¶ Recommendations

When humidity readings are abnormal, check:

1.Desiccant status — Use Bambu official silica gel desiccant and check regularly.

Replace when spent (dark green) with fresh (yellow).

Avoid calcium chloride desiccants, as saturated CaCl₂ can release water and damage electronics.

Please note that the desiccant is a mixture: the orange particles are indicator particles (they change color when absorbing moisture), and the white particles are regular moisture-absorbing particles. When the orange particles change color, it indicates that the desiccant has absorbed enough moisture and needs to be replaced.

Left: Spent desiccant (dark green); Right: Fresh desiccant (yellow)

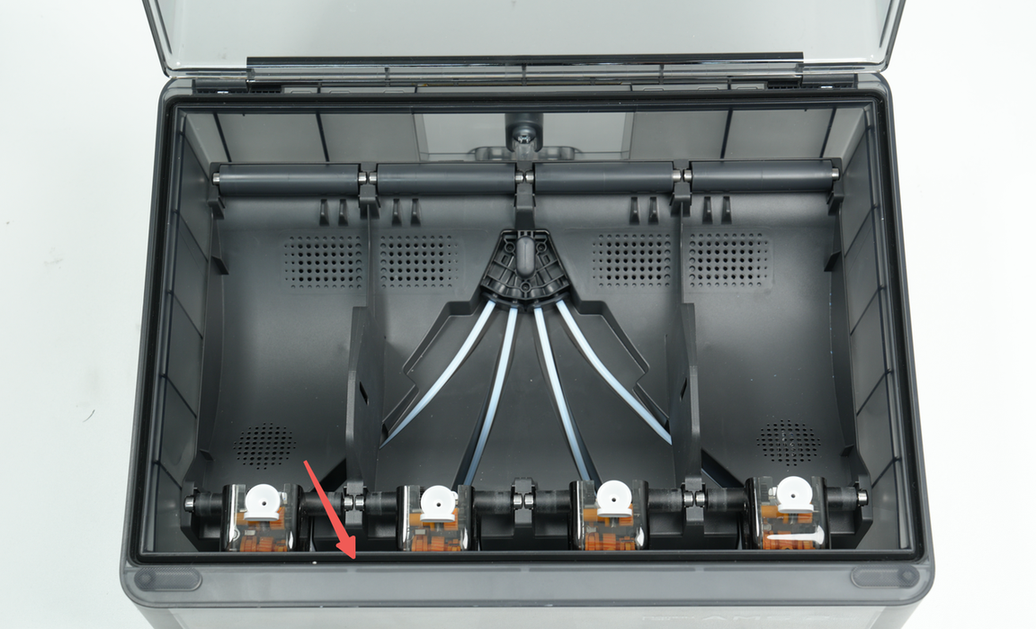

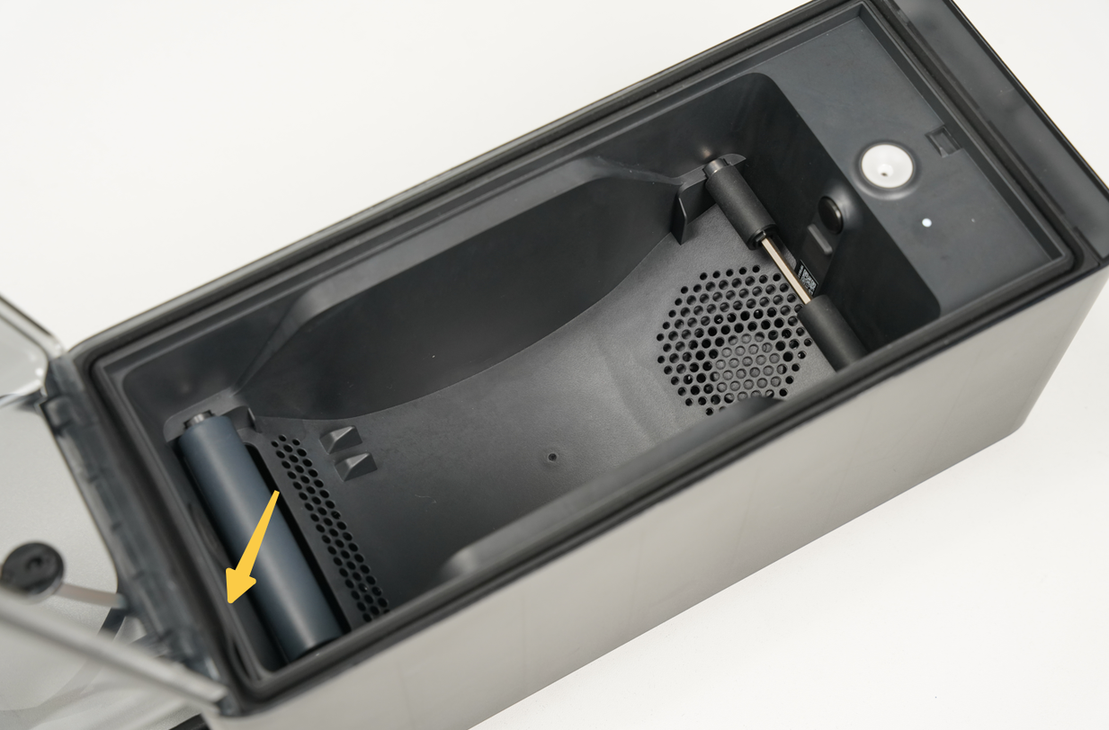

2.AMS seals — Check the lower cover seal strip for tight fit, and ensure the upper cover closes completely without deformation.

|

|

3.Ambient temperature fluctuations — Large changes (e.g., after drying or with big day-night temperature swings) can cause RH readings to vary significantly.

This is normal when actual moisture content remains unchanged.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!