¶ AMS HT Feeder Unit

¶ When to Use

- Feeder unit is damaged

- Recommended by Bambu Lab support

¶ Required Tools and Materials

-

H2.0 Hex Wrench

-

H1.5 Hex Wrench

-

AMS HT Feeder Unit *1

-

Active Extrusion Wheel *1

-

692ZZ Ball Bearing *1

-

BT2-8 Screw *4

¶ Safety Warning

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide the assistance you need.

¶ Removing the Old Feeder Unit

¶ 1. Remove the PTFE Tube from the Back of the AMS HT

Press the PTFE tube release button on the back of the AMS HT to unlock the connector, then pull out the PTFE tube.

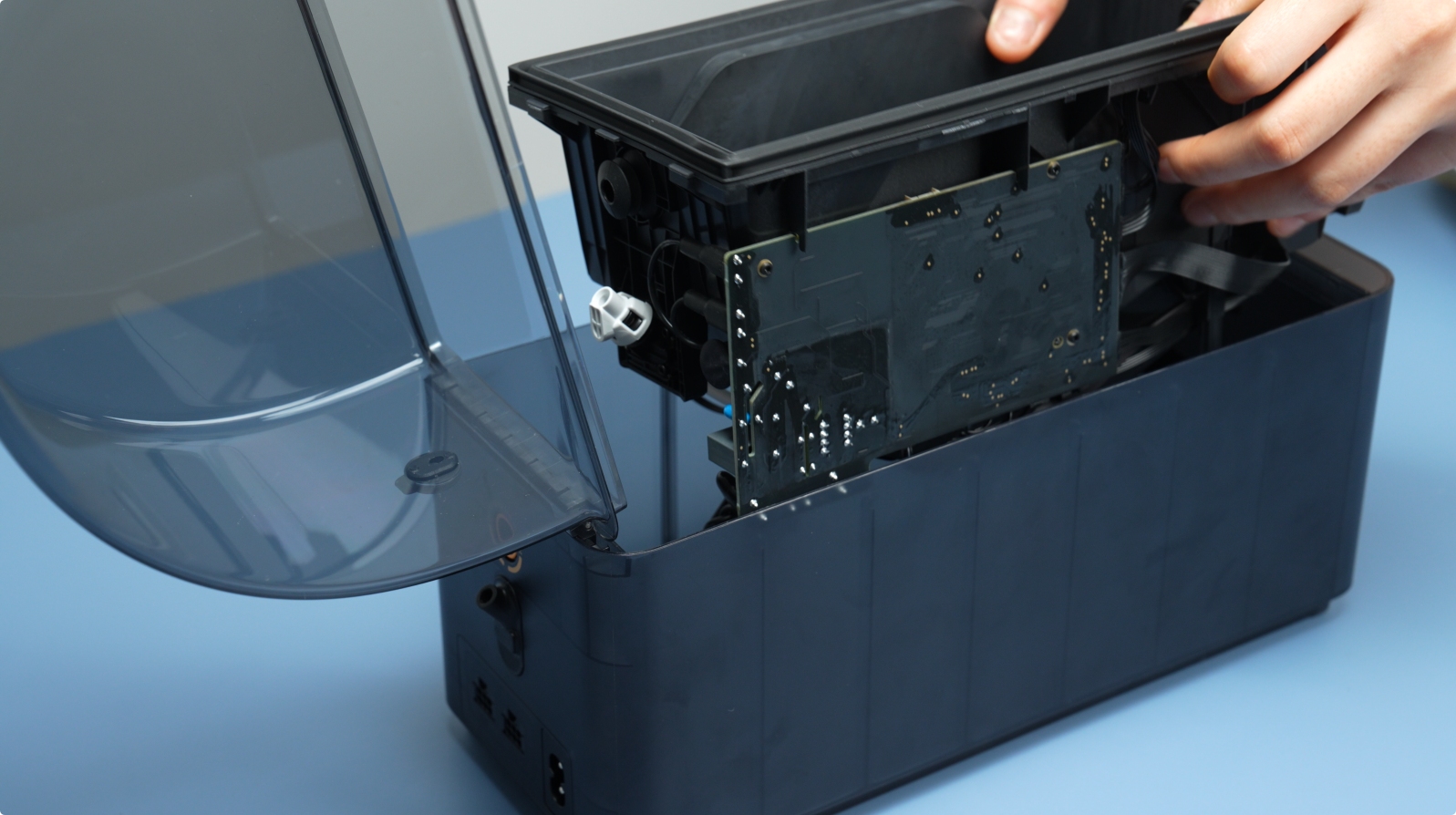

¶ 2. Remove the AMS HT Main Frame

Remove the two bottom screws (BT3*8).

After removing the screws, slowly pull the main frame assembly upward.

|

|

Lift the main frame assembly upward after creating a gap, noting that cables are connected, so avoid forceful handling.

Unlock the connector latch and disconnect the front display cable.

Next, disconnect the signal and power cables from the AMS HT power board.

|

|

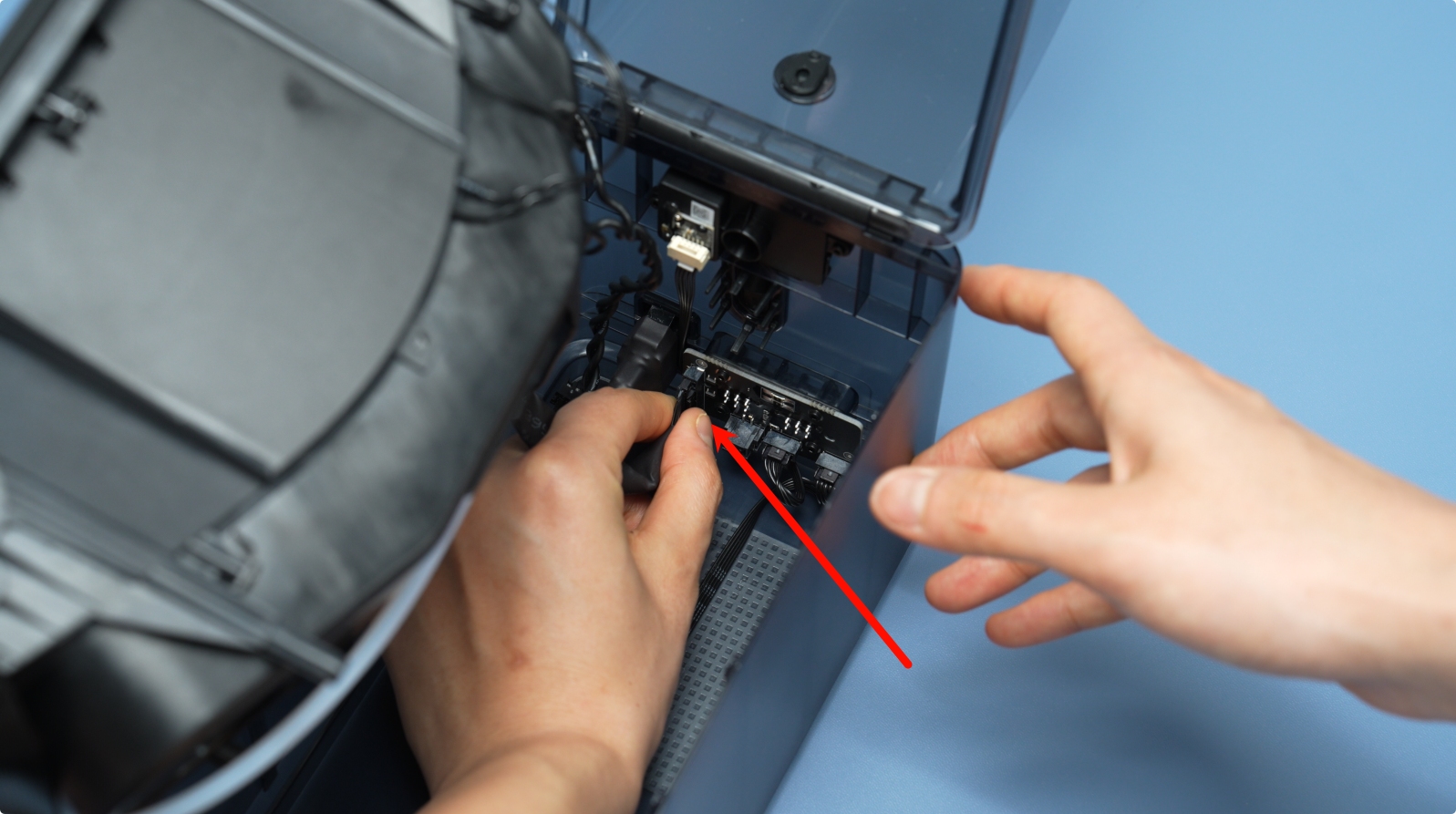

Remove the power socket to mainboard cable by pressing the unlock latch and pulling out the cable connector with the insulating rubber sleeve.

|

|

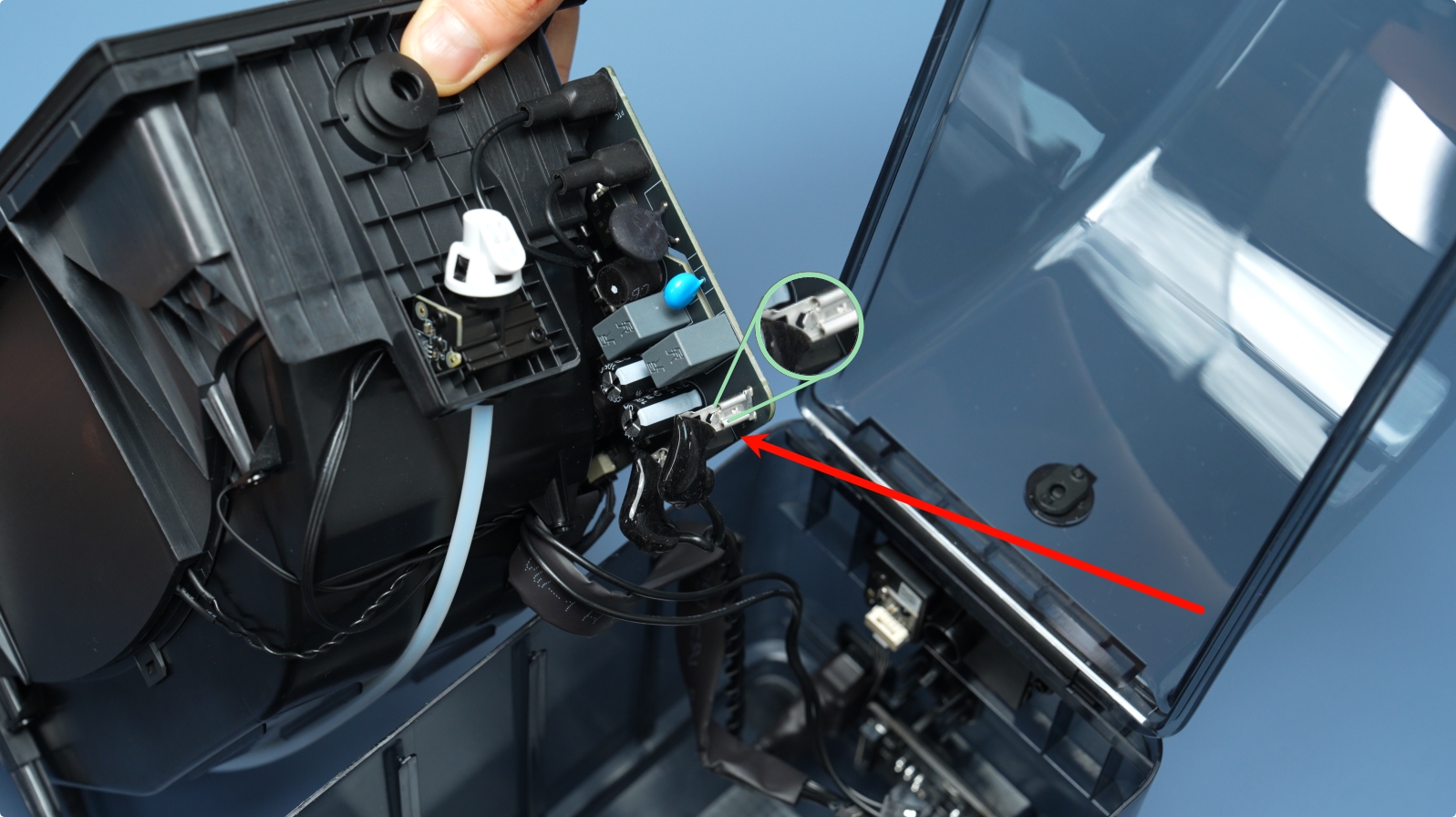

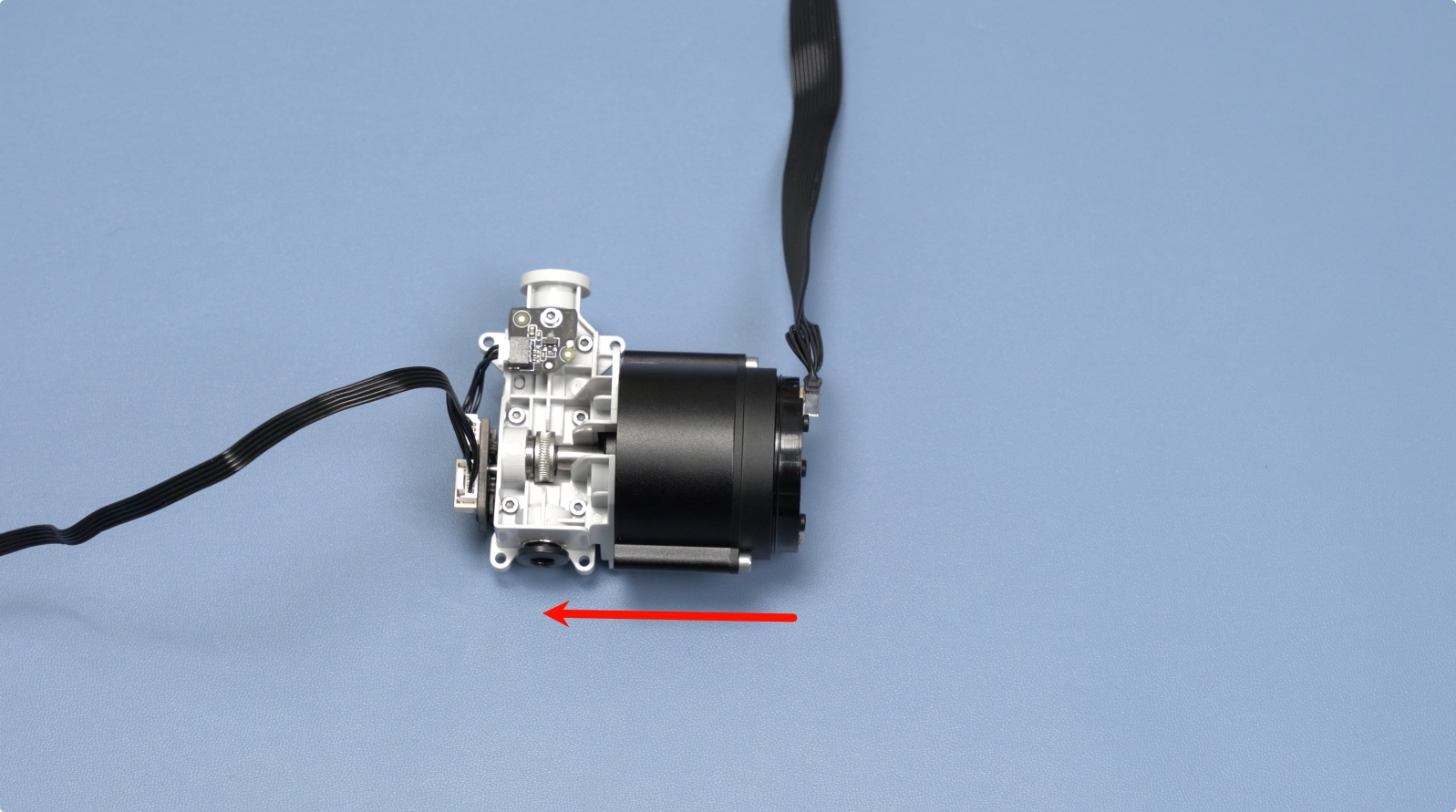

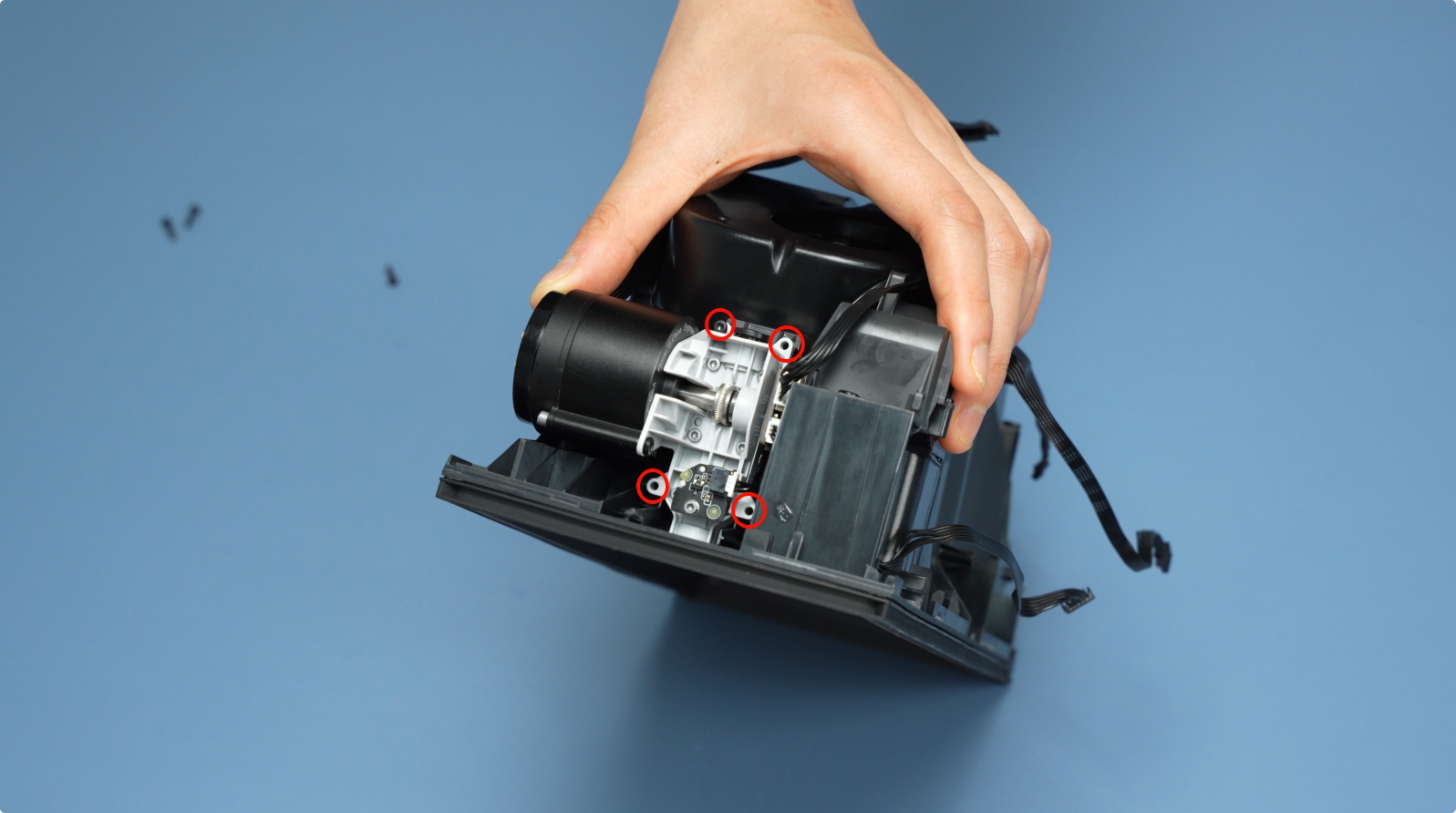

¶ 3. Remove the Feeder Unit

Remove the PTFE tube between the feeder unit and the outlet.

Remove the four fixing screws (BT2*8) of the feeder unit and take the feeder unit cable out of the cable management slot.

Replacing the feeder Unit does not require removing the mainboard.

|

|

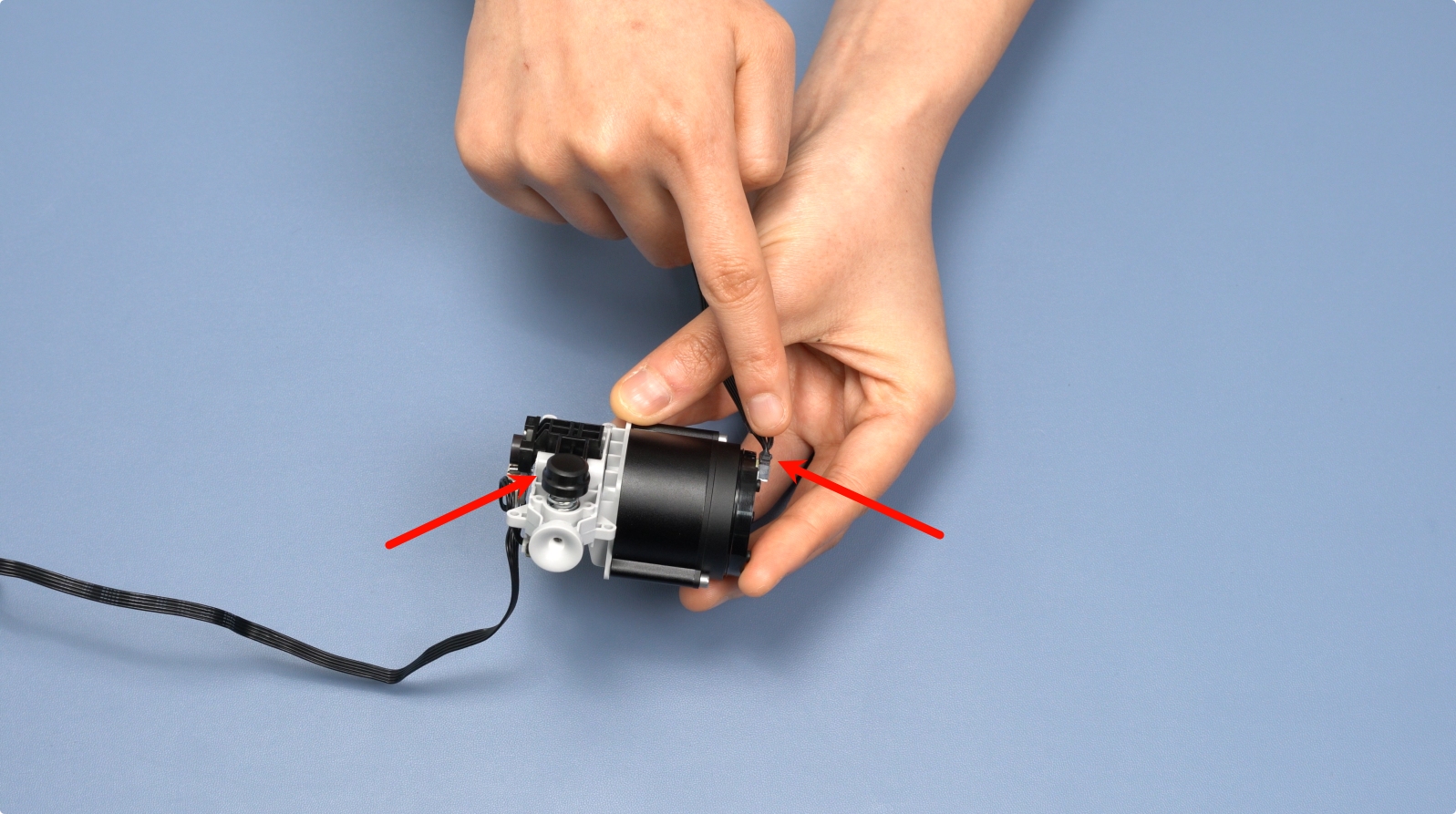

Press the filament release button to push out the feeder unit.

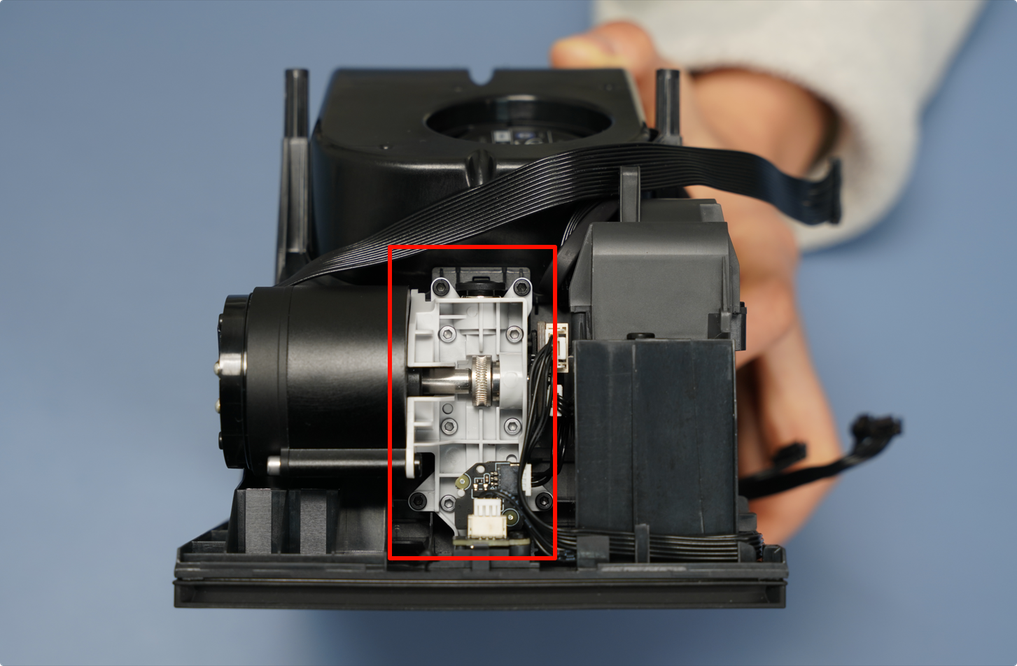

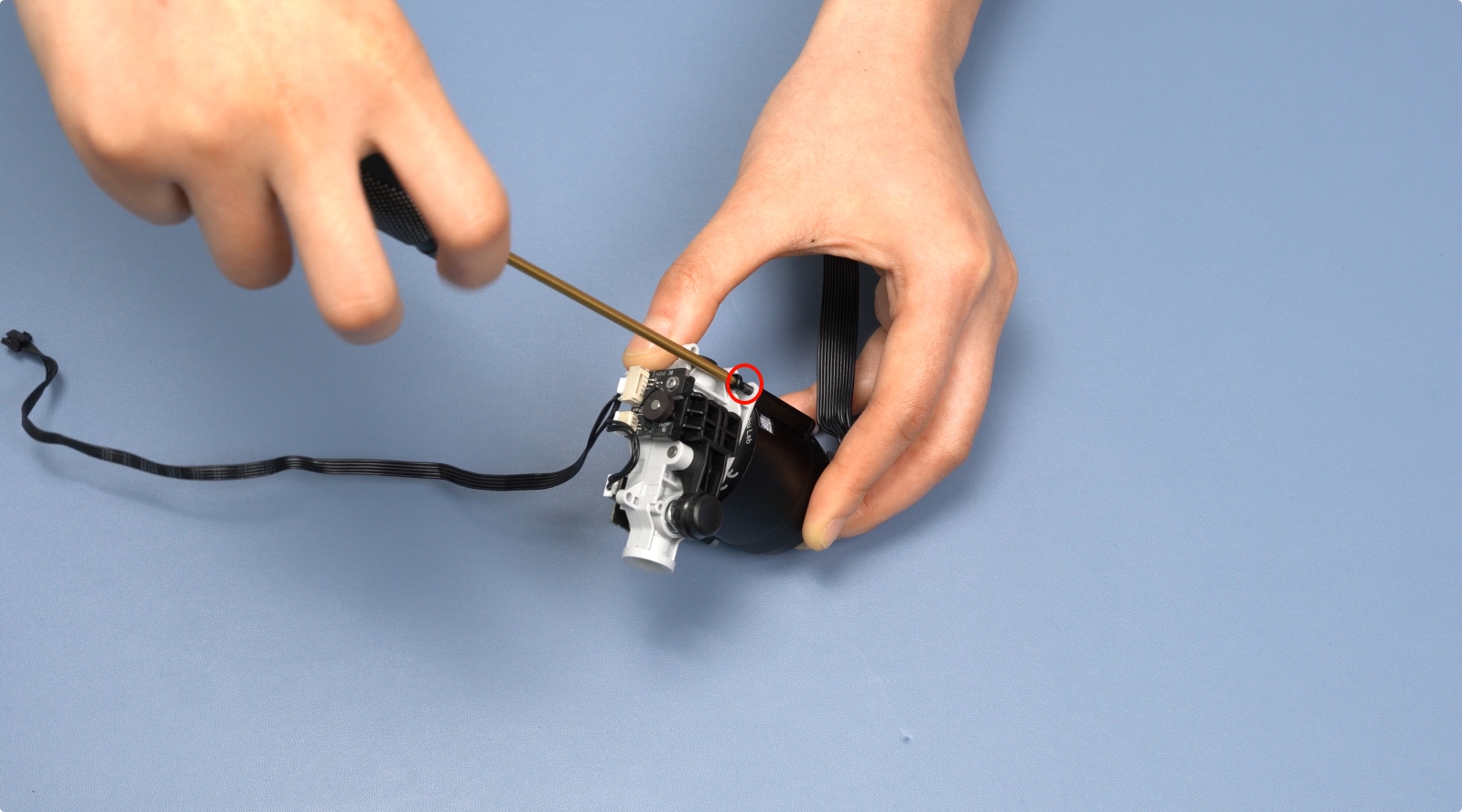

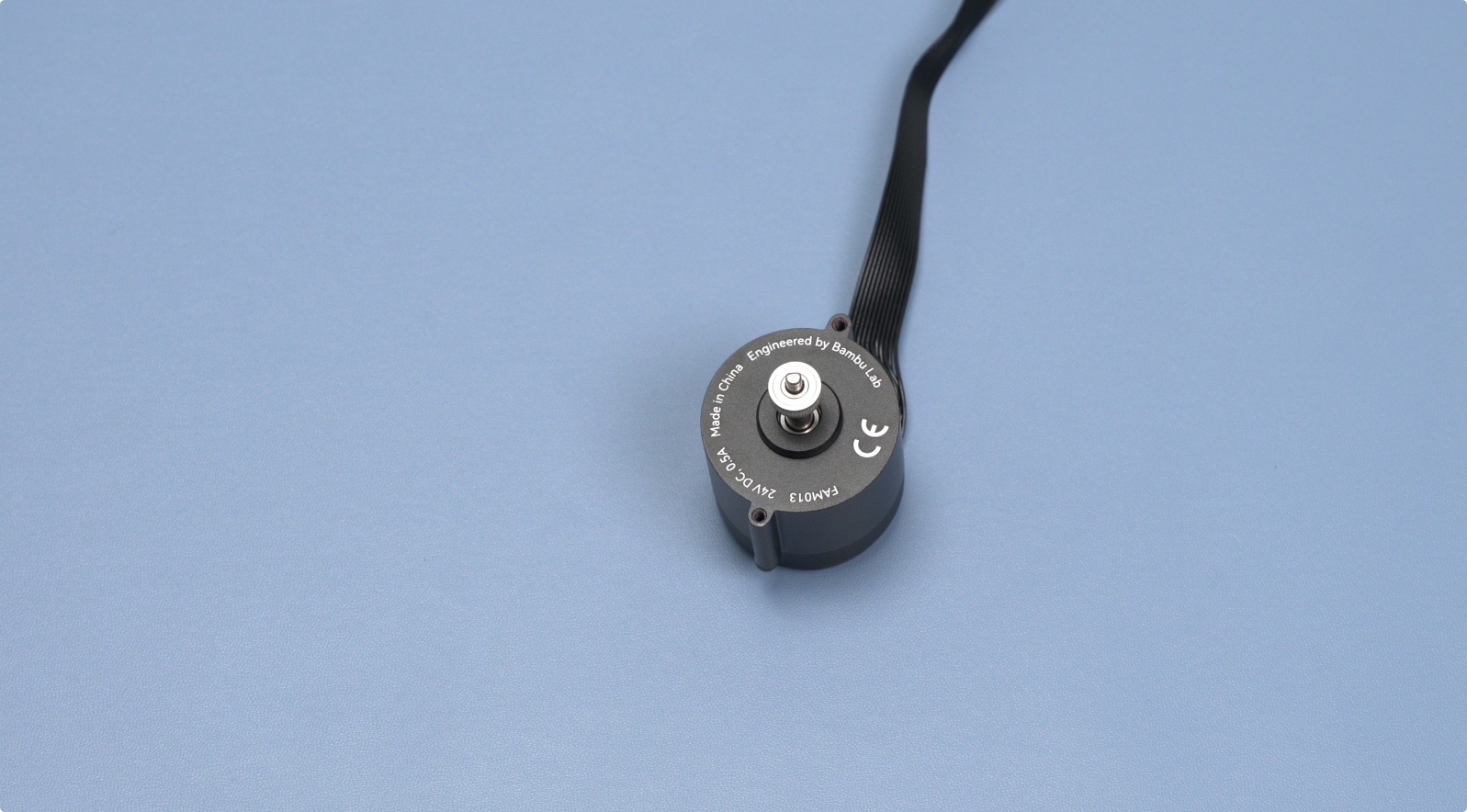

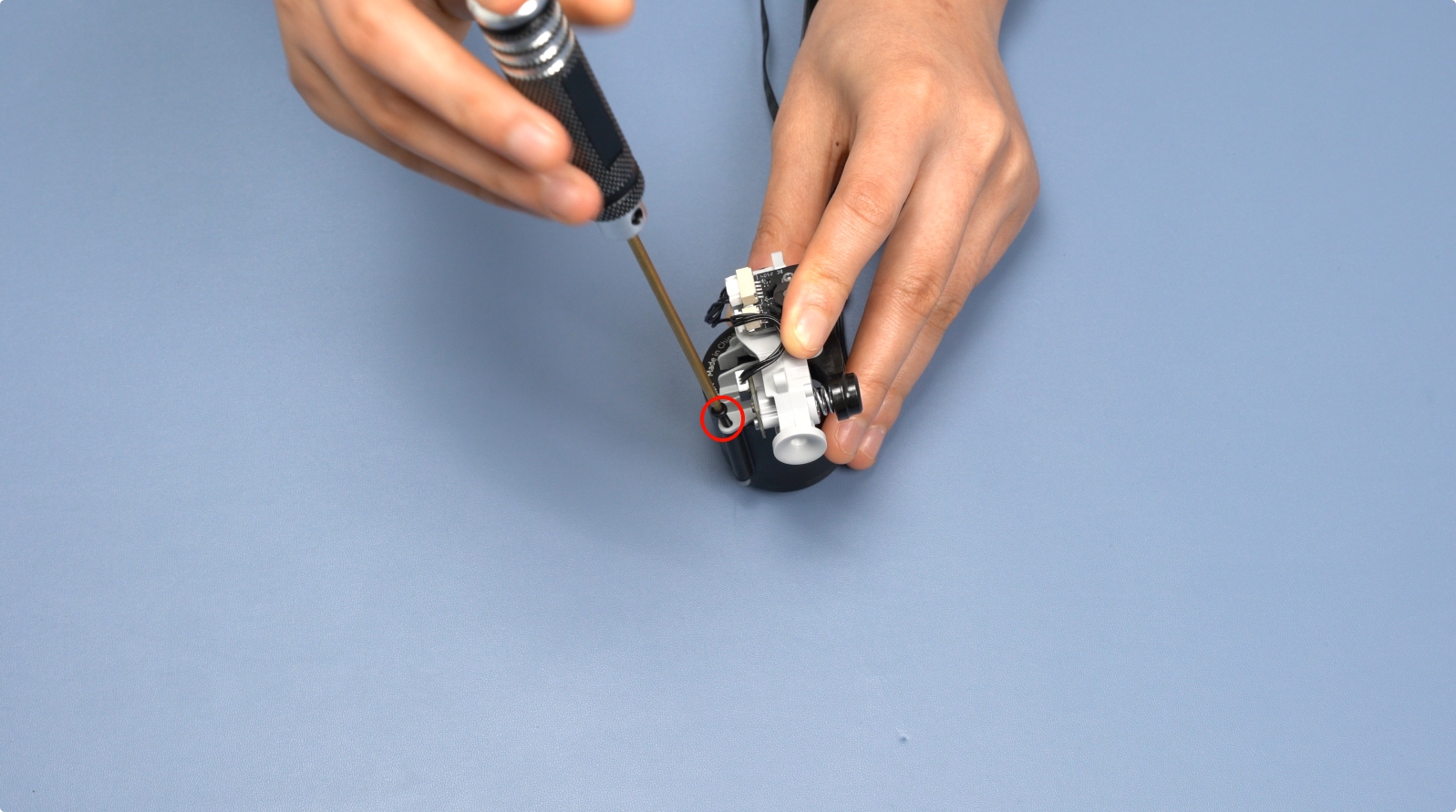

¶ 4. Remove the Feeder Motor

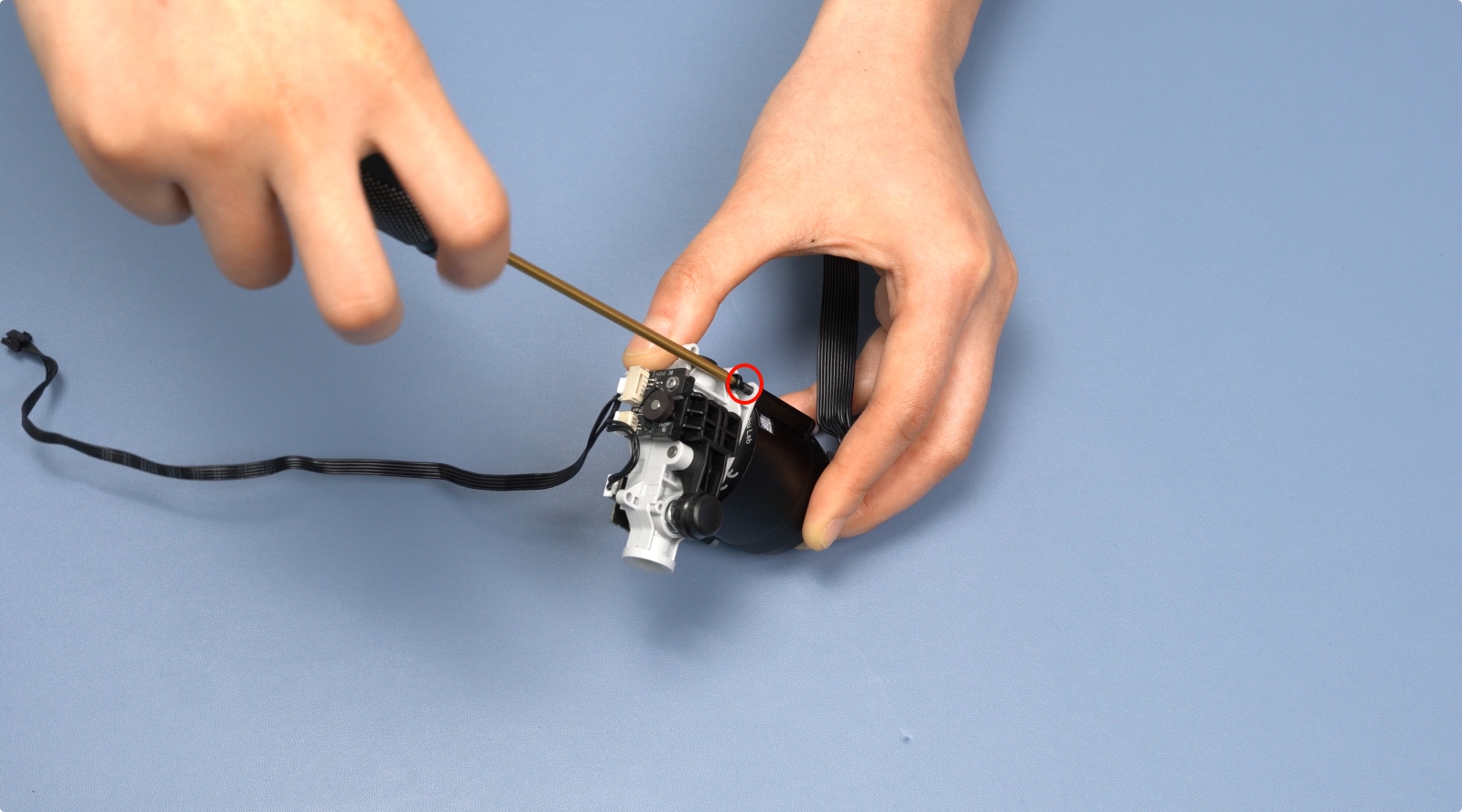

Remove the two fixing screws (M2.5*8) of the feeder motor.

|

|

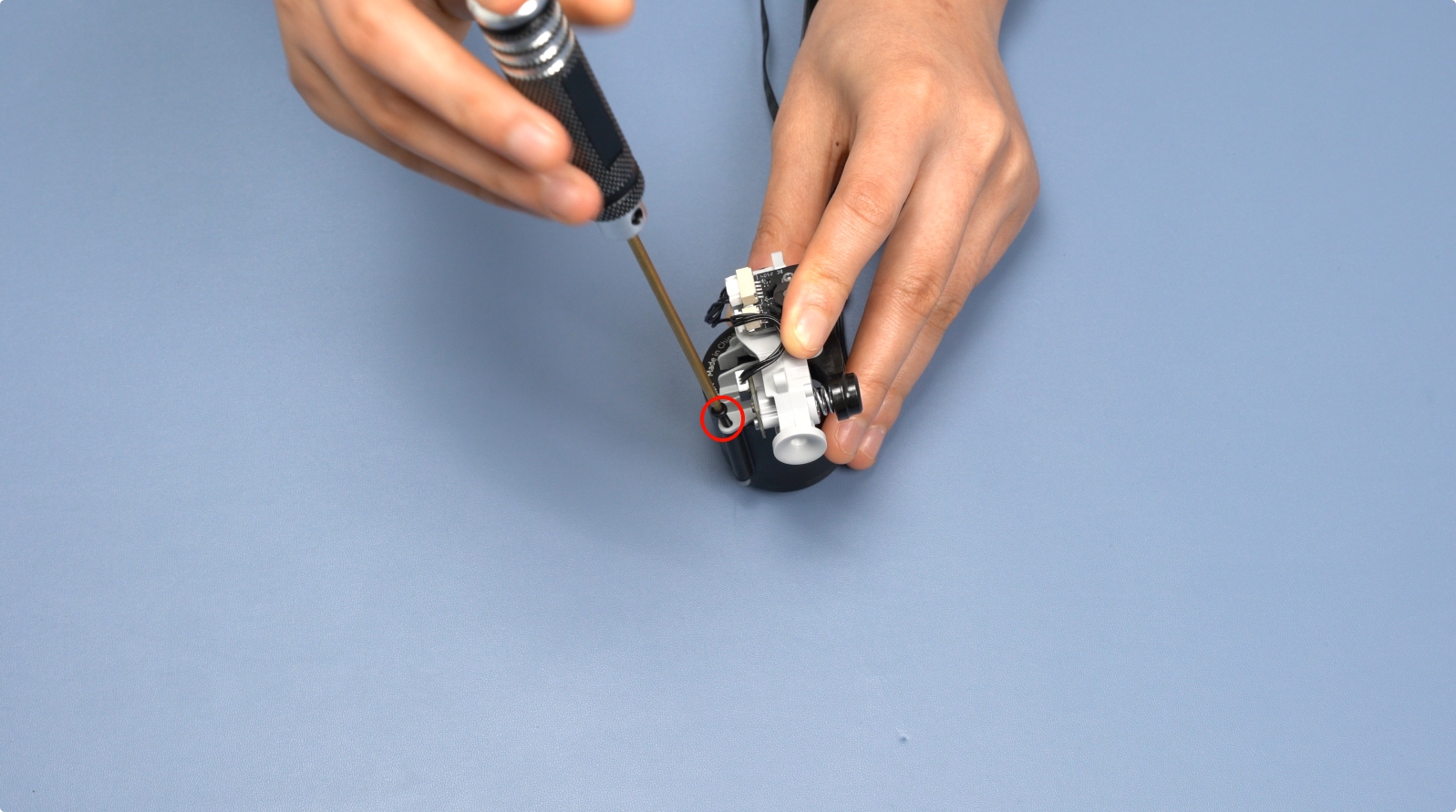

Remove the feeder motor and drive gear, ensuring the drive gear is preserved to avoid loss.

|

|

¶ Installing the New Feeder Unit

¶ 1. Install the Feeder Motor

Install the drive gear onto the feeder motor.

|

|

Insert the motor into the feeder unit, ensuring the filament release button and motor cable are oriented in the same direction.

|

|

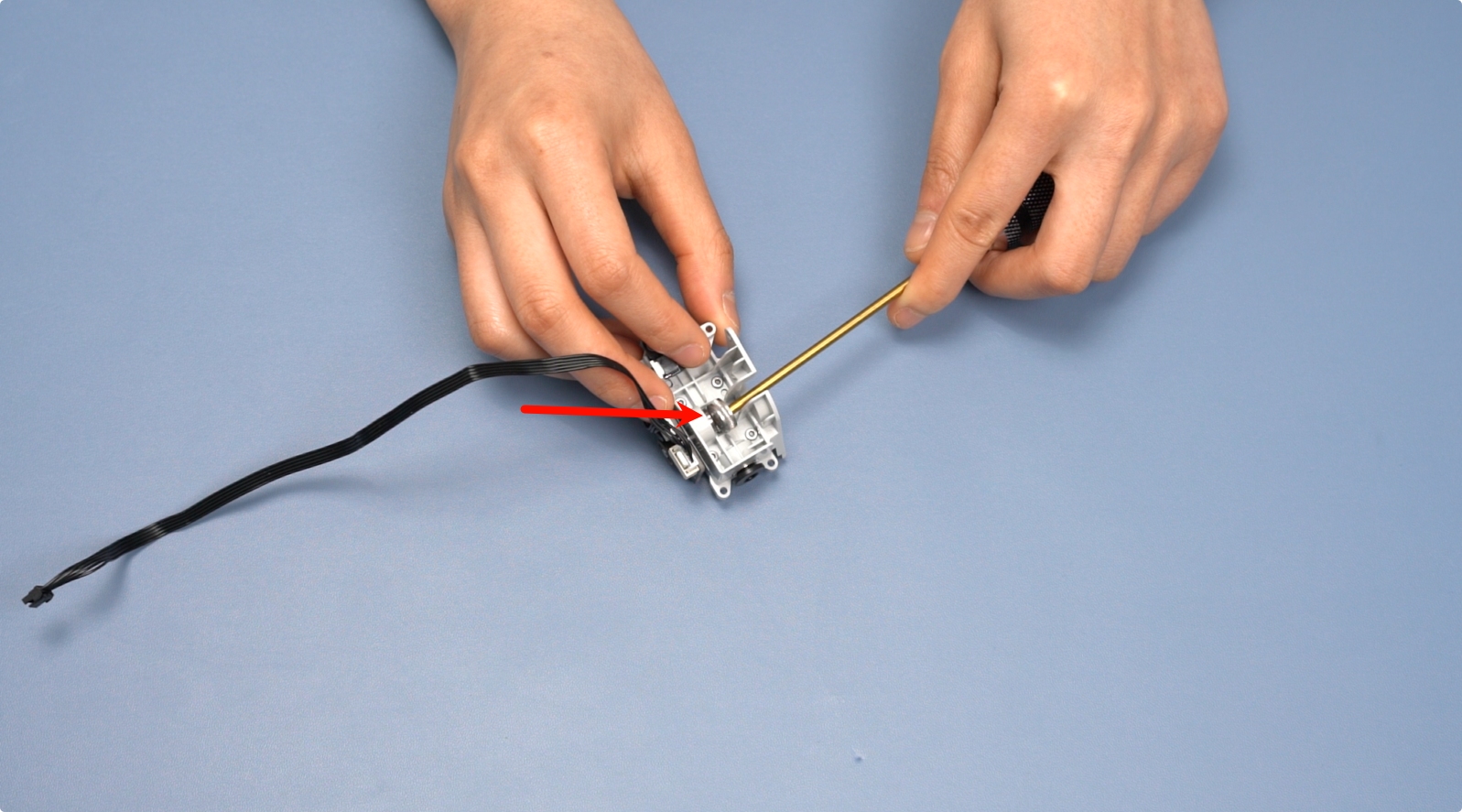

Secure the motor with the two fixing screws (M2.5*8).

|

|

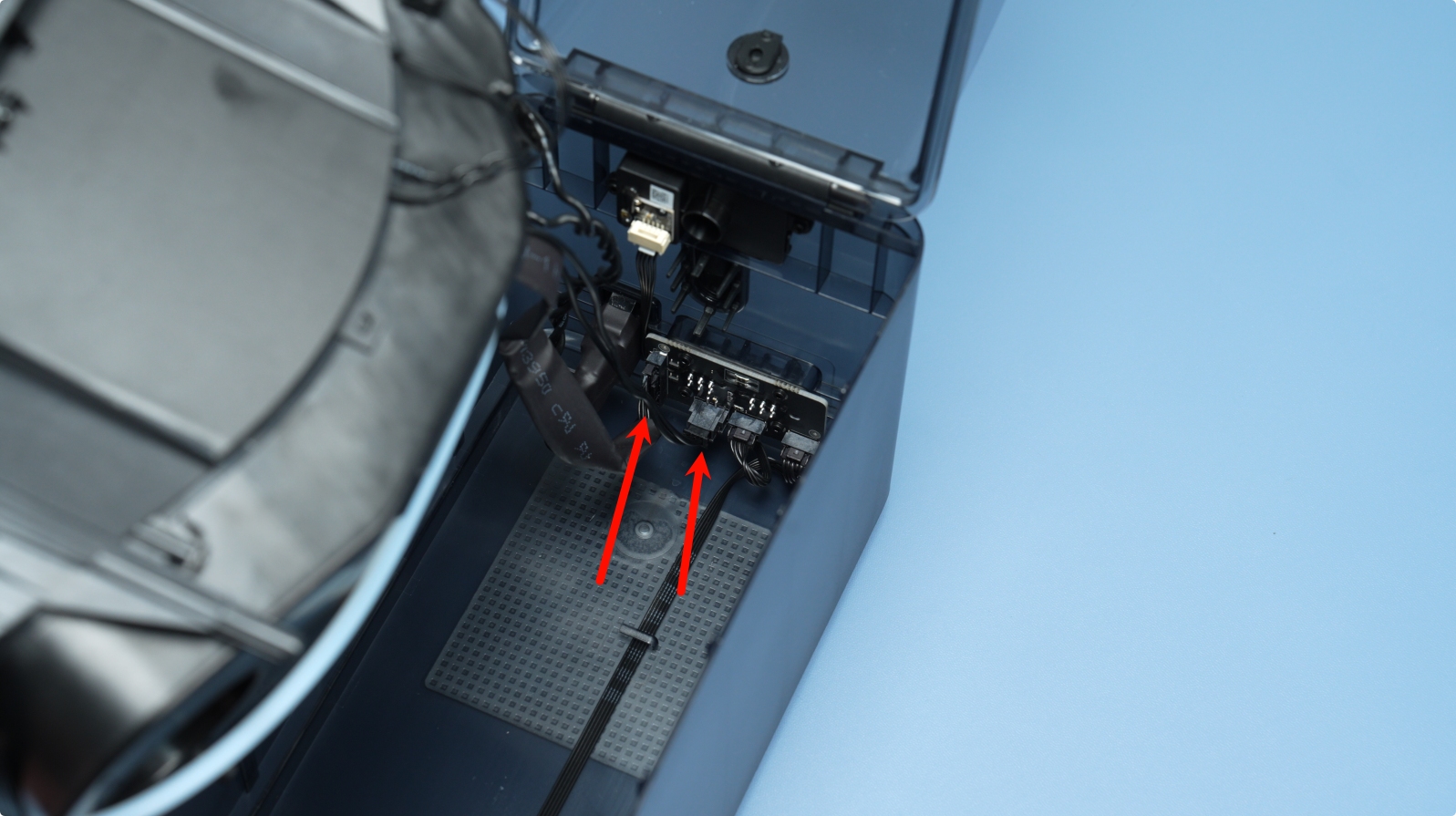

¶ 2. Install the Feeder Unit

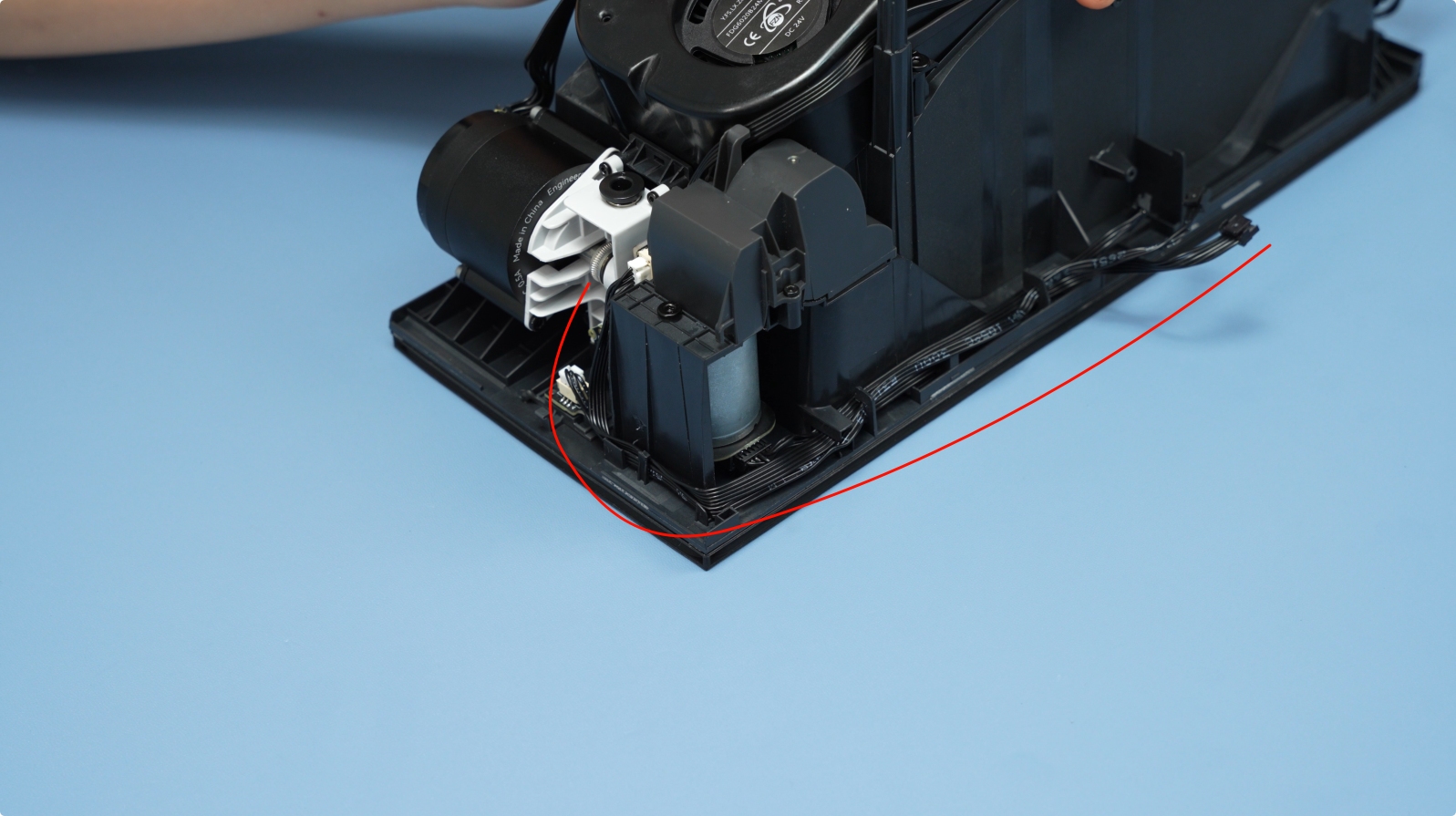

Install the feeder unit onto the main frame and secure it with the four fixing screws (BT2*8).

After installing the feeder unit, organize the cables into the cable management slot.

|

|

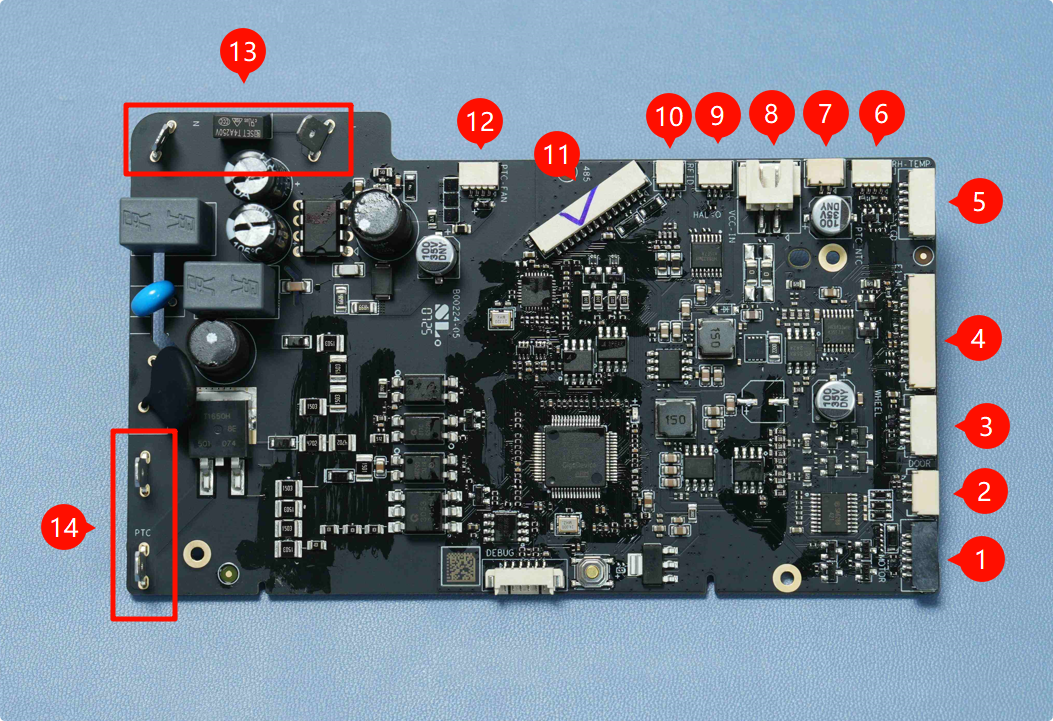

Mainboard Connection Diagram

| 1. Filament Retraction Motor | 2. Lid Status Hall Sensor | 3. Odometer Board |

| 4. 3520 AMS Internal Assist Motor | 5. LCD Screen | 6. Temperature & Humidity Sensor |

| 7. Heating Unit Thermistor | 8. Mainboard Power Connector | 9. Feeder Hall Sensor Assembly |

| 10. RFID Coil | 11. Mainboard Communication Connector | 12. Heating Unit Fan |

| 13. Mainboard AC Input | 14. Heating Unit AC Input |

¶ 3. Install the AMS HT Main Frame

Connect the PTFE tube between the feeder and the outlet.

Connect the cables at positions 1 and 2, where position 1 is the mainboard communication cable (14-pin) and position 2 is the mainboard power cable (2-pin).

Connect the power socket cable to the mainboard and install the insulating rubber sleeve.

Note: The connection here does not distinguish between positive and negative poles.

Connect the AMS HT front display cable and ensure the cable is secured in the cable management slot.

|

|

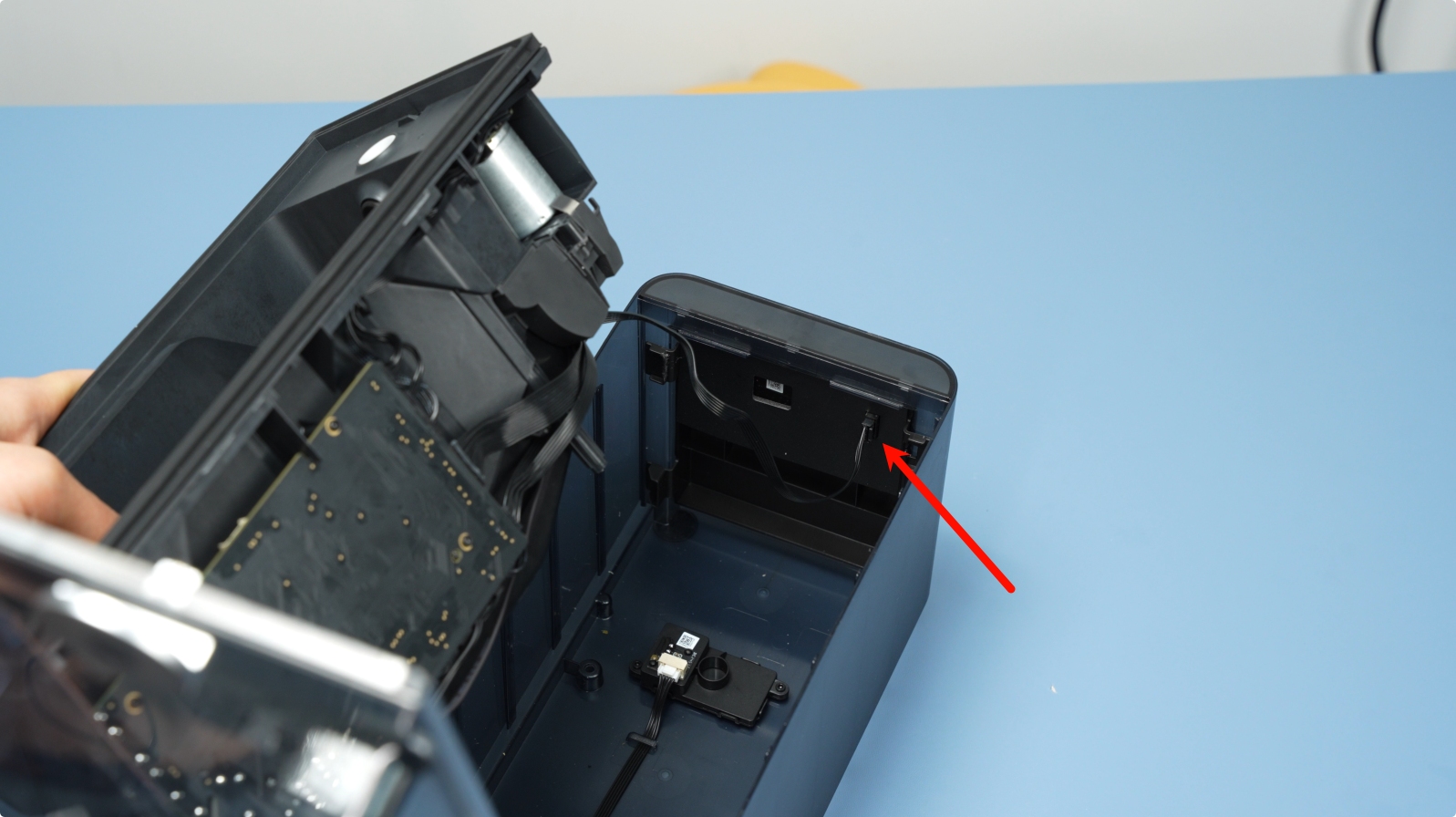

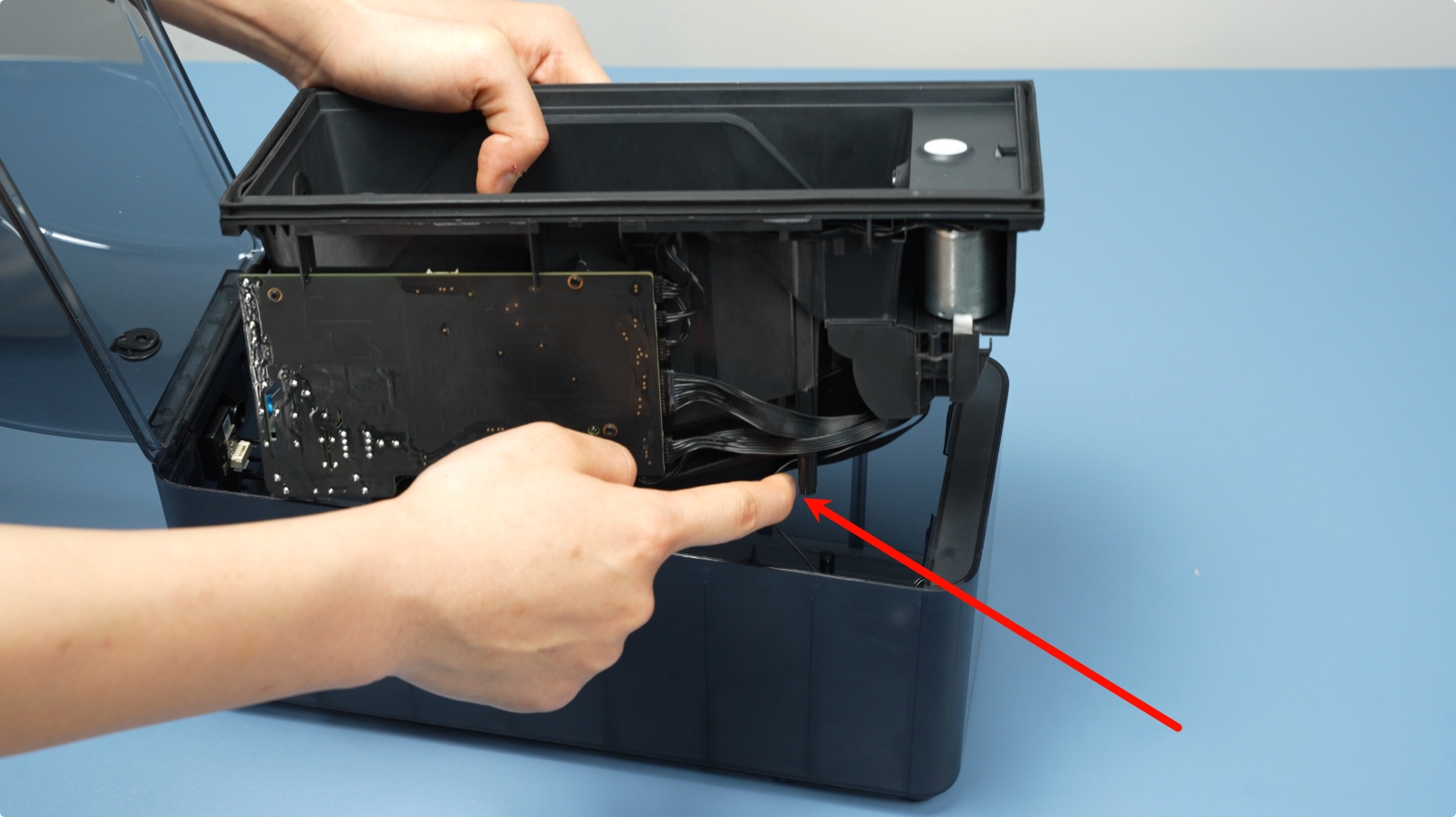

Hook the protruding cable with your finger and install the mid-frame assembly into the bottom shell assembly.

|

|

Ensure the main frame assembly is fully pressed into the bottom shell assembly without any front or rear tilting, and secure it with the two bottom fixing screws (BT3*8).

|

|

¶ 4. Insert the PTFE Tube into the Back of the AMS HT

Push the PTFE tube into the back of the AMS HT. After installation, tug the PTFE tube to confirm it is securely fixed.

¶ Verify the functionality

After replacement, connect the AMS HT to the printer. Load filament and test the load and unload functions. If both functions operate without issues, the replacement is successful.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!