¶ Purpose

This article provides guidance on how to use PETG HF filaments in a wet state and set the appropriate parameters.

¶ Basic rule: the drier the filament, the higher the print quality

Each filament will absorb moisture from the air to a greater or lesser extent and become damp. During printing, these water vapors will quickly vaporize after being heated in the high-temperature nozzle, causing the filament melt to expand, flow faster, and produce pores, which will cause the printed parts to have problems such as stringing, oozing, holes, rough surface, and low strength. The more severe the filament is damp (the higher the ambient humidity and the longer the exposure time), the more serious these problems are. Therefore, it is strongly recommended that before printing the model, especially those models with high requirements for appearance, if you are not sure that the filament is dry enough, dry the filament first, and seal and dry the filament during use. If the filament is found to be damp, it is recommended to use Generic PETG HF printing parameters.

¶ Comparison of Printing with Dry and Wet Filament Using Generic PETG HF Parameters

Generic PETG HF can be printed without the need for drying.

Boat and test piece printed under Generic PETG HF parameters in dry state |

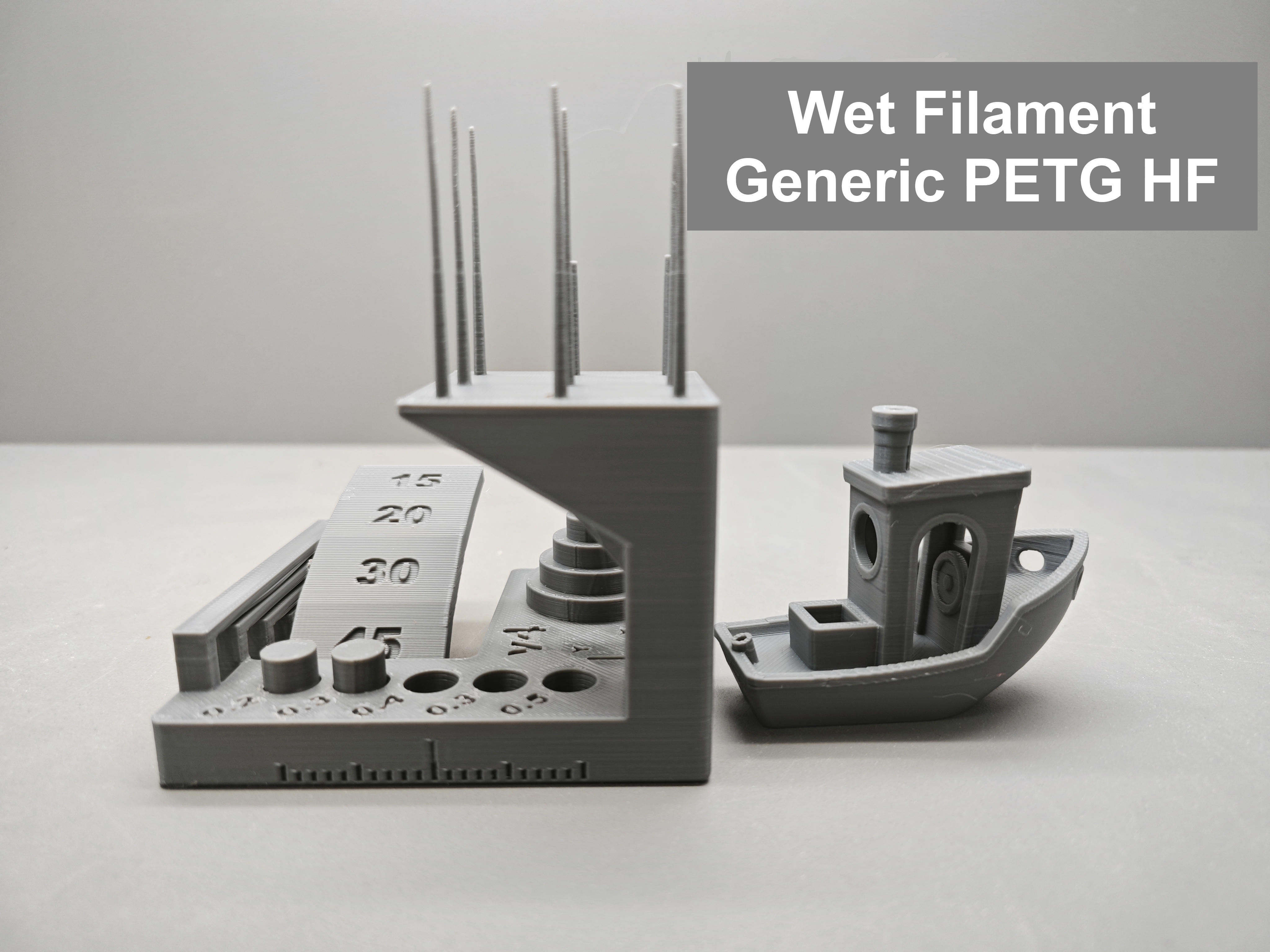

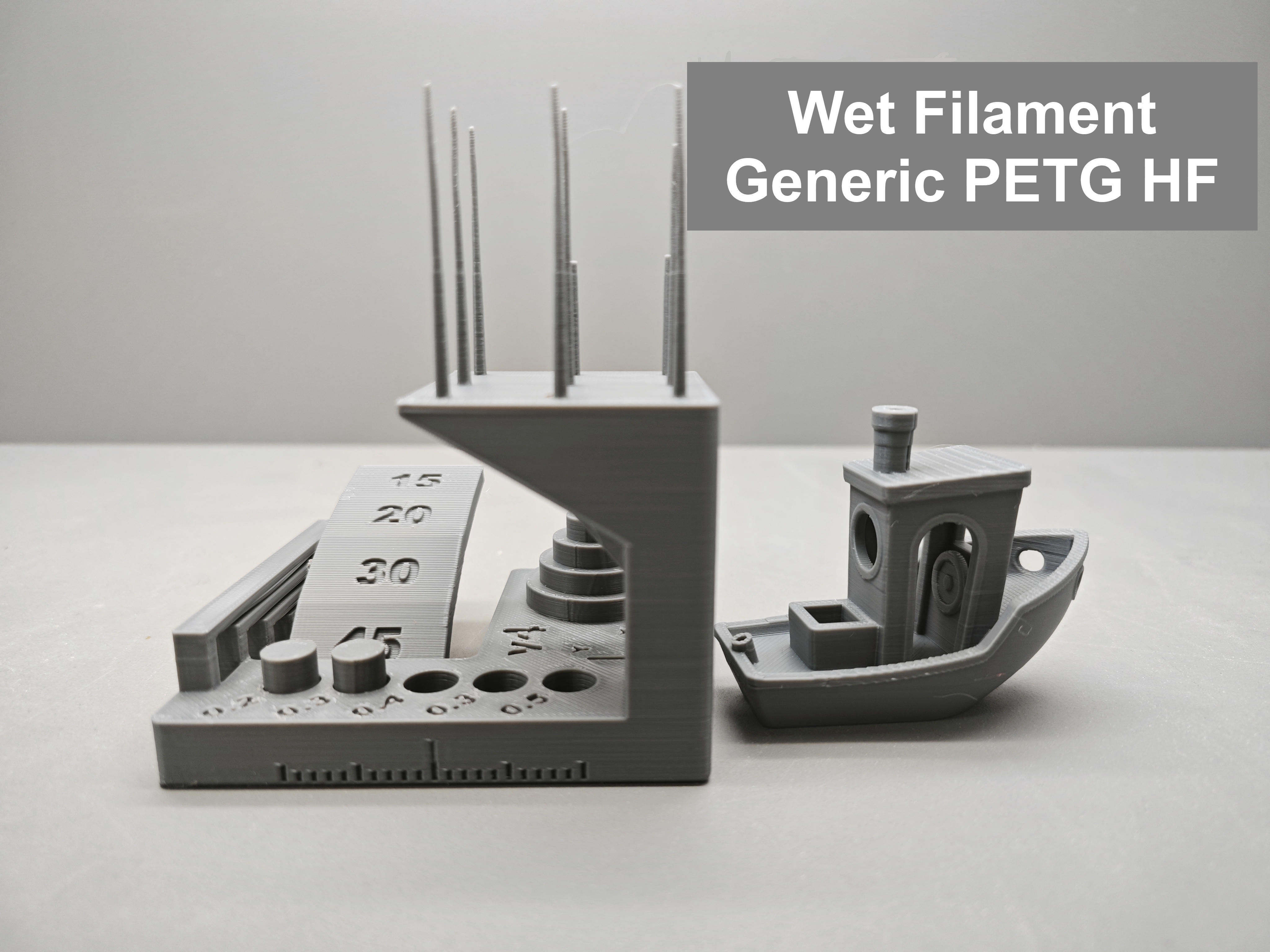

Boat and test piece printed under Generic PETG HF parameters in wet state |

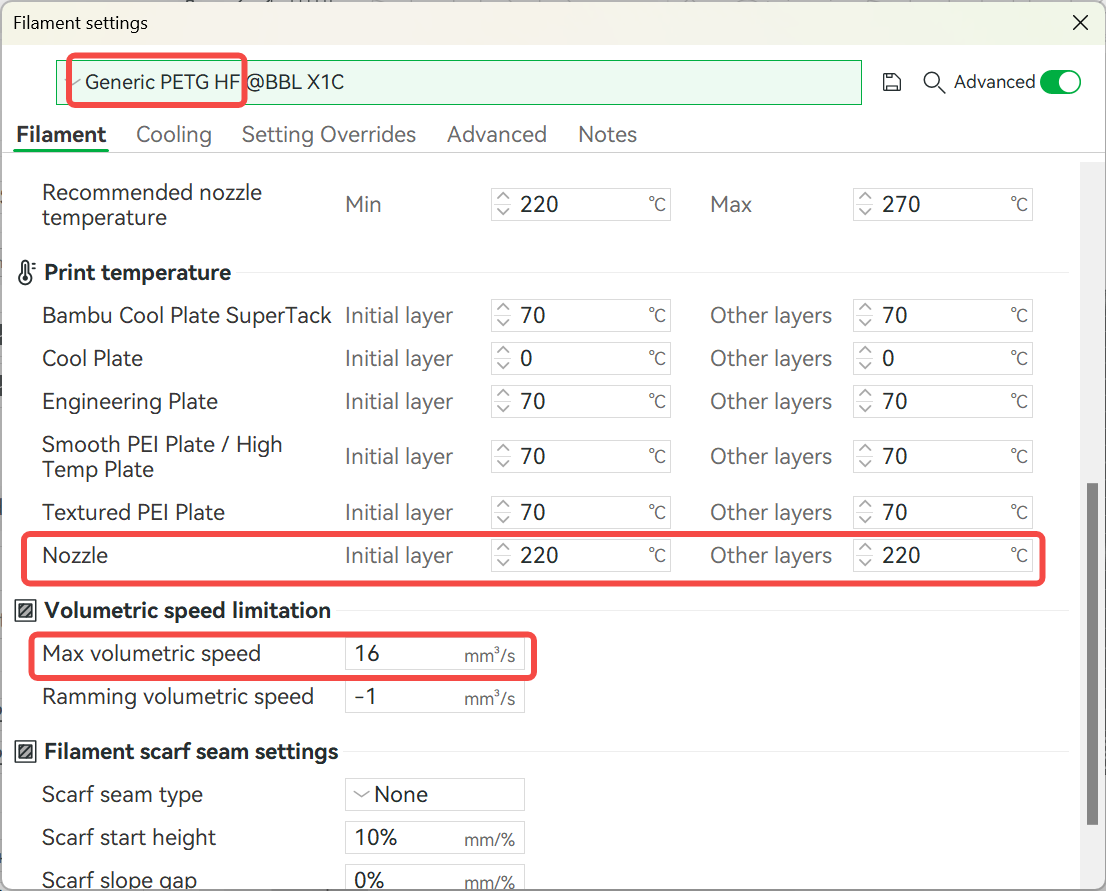

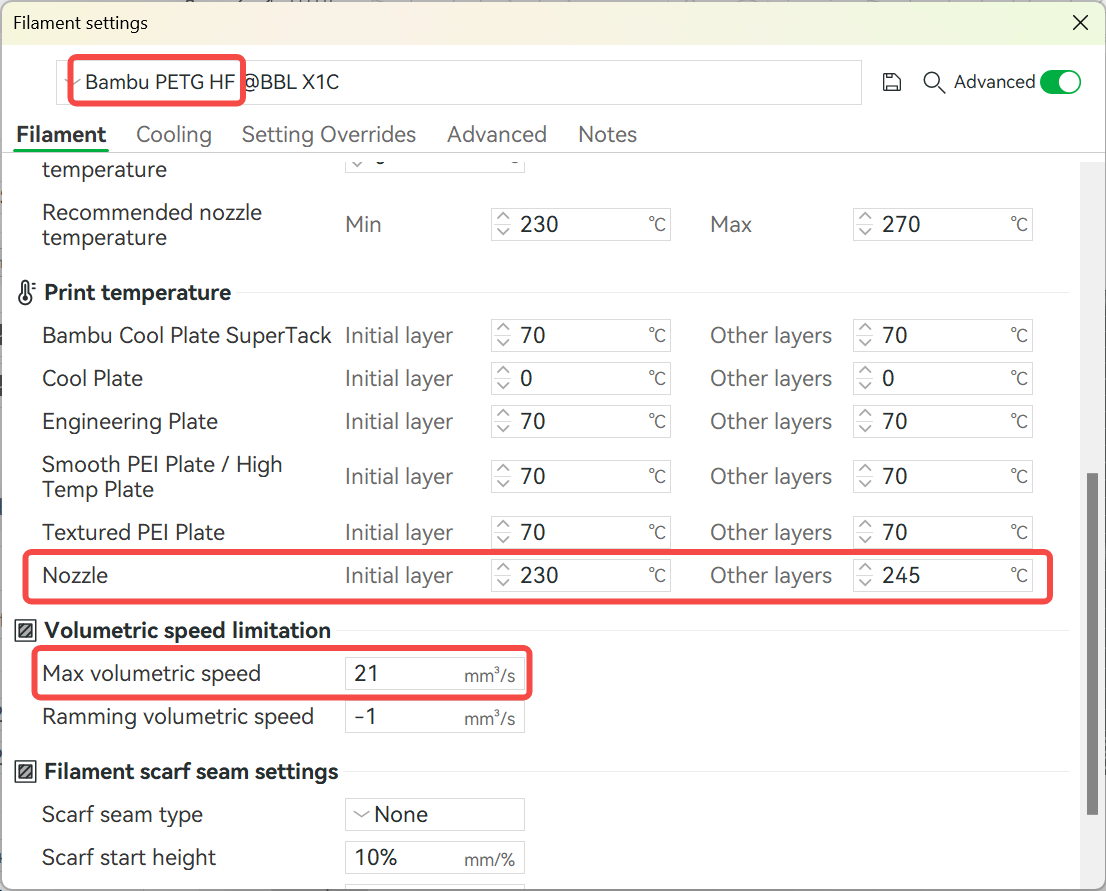

Note: In order to print PETG HF in a wet state, the printing temperature of Generic PETG HF is set to 220℃ and the volume speed is 16mm³/s, which is lower than the printing parameters of Bambu PETG HF. It is not recommended to increase the print speed when printing at this temperature, which may cause risks such as clogging and extrusion failure. After the filament is dried, it is recommended to use the default Bambu PETG HF printing parameters, which will provide faster printing speed, better performance, and more stable prints.

Default printing parameters of Generic PETG HF |

Default printing parameters of Bambu PETG HF |

¶ Notes

-

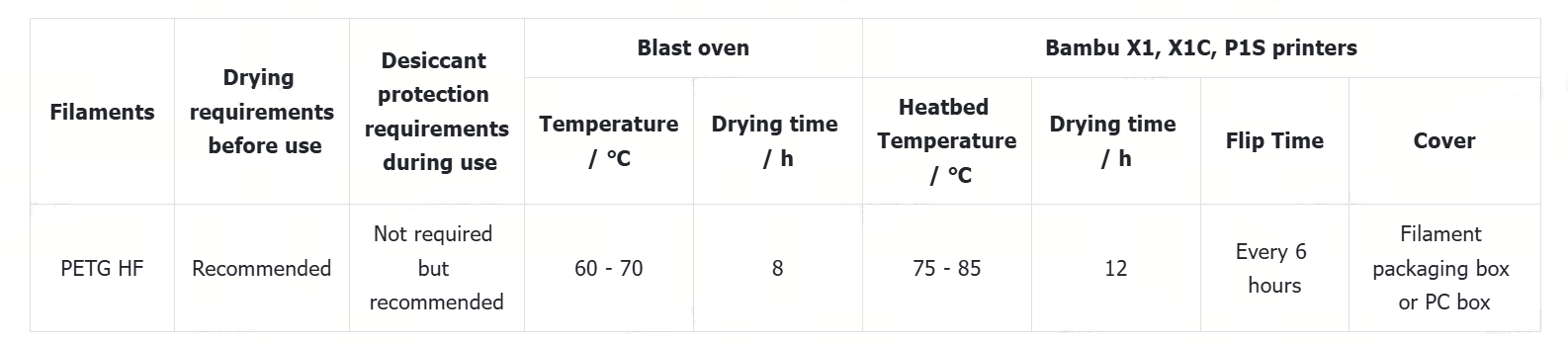

Dry the filament before printing: PETG HF needs to be dried before use (dried in a blast drying oven at 65°C for 8 hours) to avoid moisture causing bubbles and holes in the extruded lines.

-

Use a drying box: Desiccant needs to be used during use to prevent moisture absorption.

-

If the filament has been damp and there is no protection: It is recommended to reduce the printing temperature and speed. It is recommended to use Generic PETG HF printing parameters (this parameter is specially optimized for the case where the filament has been damp. The printing quality changes with the moisture level of the filament. If the printing quality is still poor, it is recommended to continue to reduce the printing speed).

¶ Dry the filaments to be used according to the correct operation, temperature, and duration

If you purchased filaments without spool, please install the filaments on the spool before drying. You can refer to this Wiki for installation methods: Refill Filament with Bambu Reusable Spool / Refill

When using X1 or X1C to dry filaments, you need to cover the roll with the filament packaging box or the self-printed PC box, and keep the top cover and front door tightly closed throughout the process to ensure that the temperature of the space where the roll is located reaches a high value; in addition, the spool needs to be turned over during the drying process to ensure that the entire filament is dried. For specific operations, please refer to: How to Dry Filament on the X1 and P1 Series Heatbed

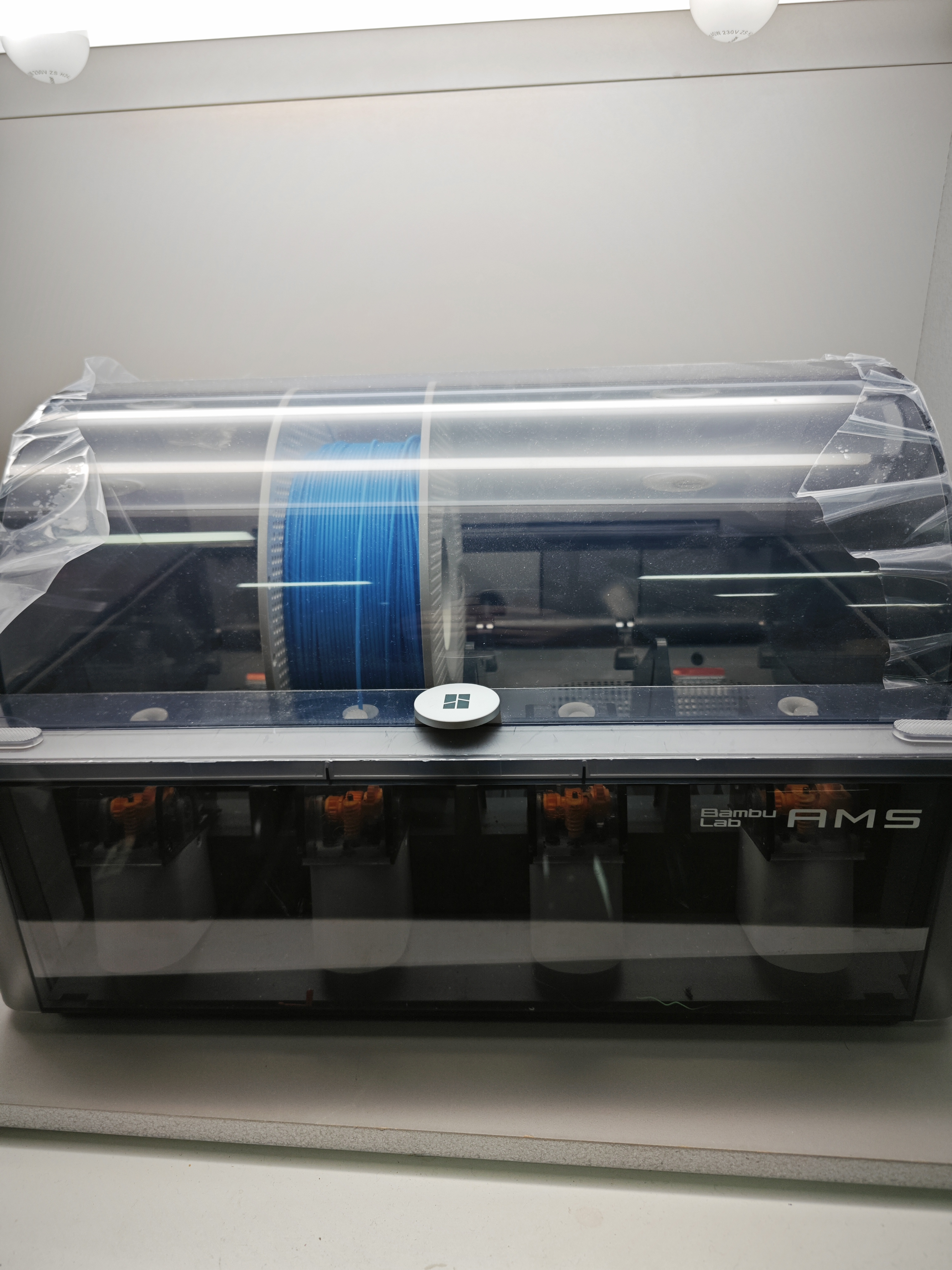

When ready to print, place filament in an AMS or sealed box and place desiccant in it for protection.

|

|

¶ Comparison of Printing with Dry and Wet Filament Using Bambu PETG HF Parameters

When printing using Bambu PETG HF parameters, please make sure to dry the filament.

Boat and test piece printed under Generic PETG HF parameters in dry state |

Boat and test piece printed under Generic PETG HF parameters in wet state |

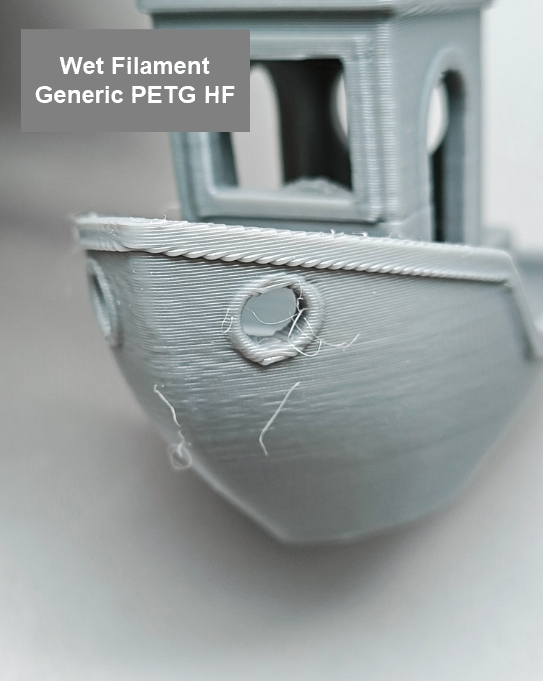

Wet filament printing under Bambu PETG HF parameters has the risk of stringing and ozzing |

Wet filament printing under Bambu PETG HF parameters has the risk of stringing and pores on the surface |

When the filament is wet, if the filament is not dried and the Bambu PETG HF printing parameters are used, obvious stringing and ozzing will occur. In severe cases, a large number of pores may appear, affecting the quality of the model.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!