¶ What is the variation in print shine / gloss?

During printing, the filament can change its aspect from a shiny surface to a matte surface depending on multiple factors like temperature, speed, layer height, minimal layer time and cooling.

¶ Different shine on the printed part

¶ Why is it happening?

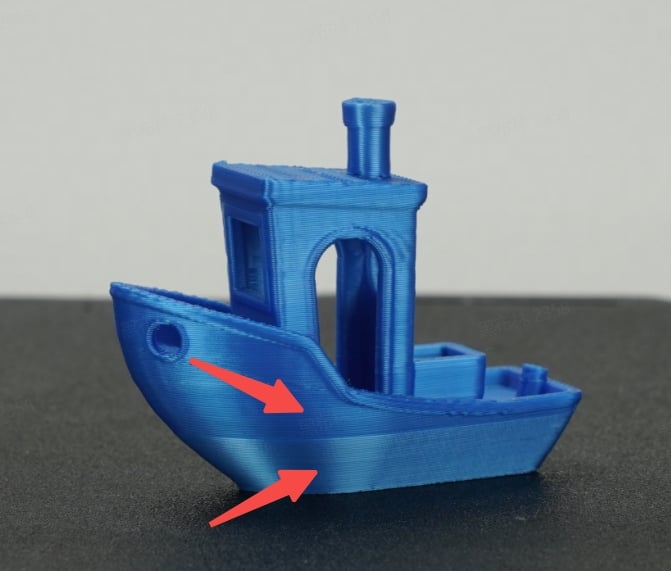

Most of the time, some sections turn from matte to glossy because the print speed slows down and the filament spends more time in the hotend.

This effect is easily seen on more shiny filaments like Silk PLA filament, or PETG basic filament.

¶ Potential causes and solutions

1. The printing speed of different model sections is significantly different

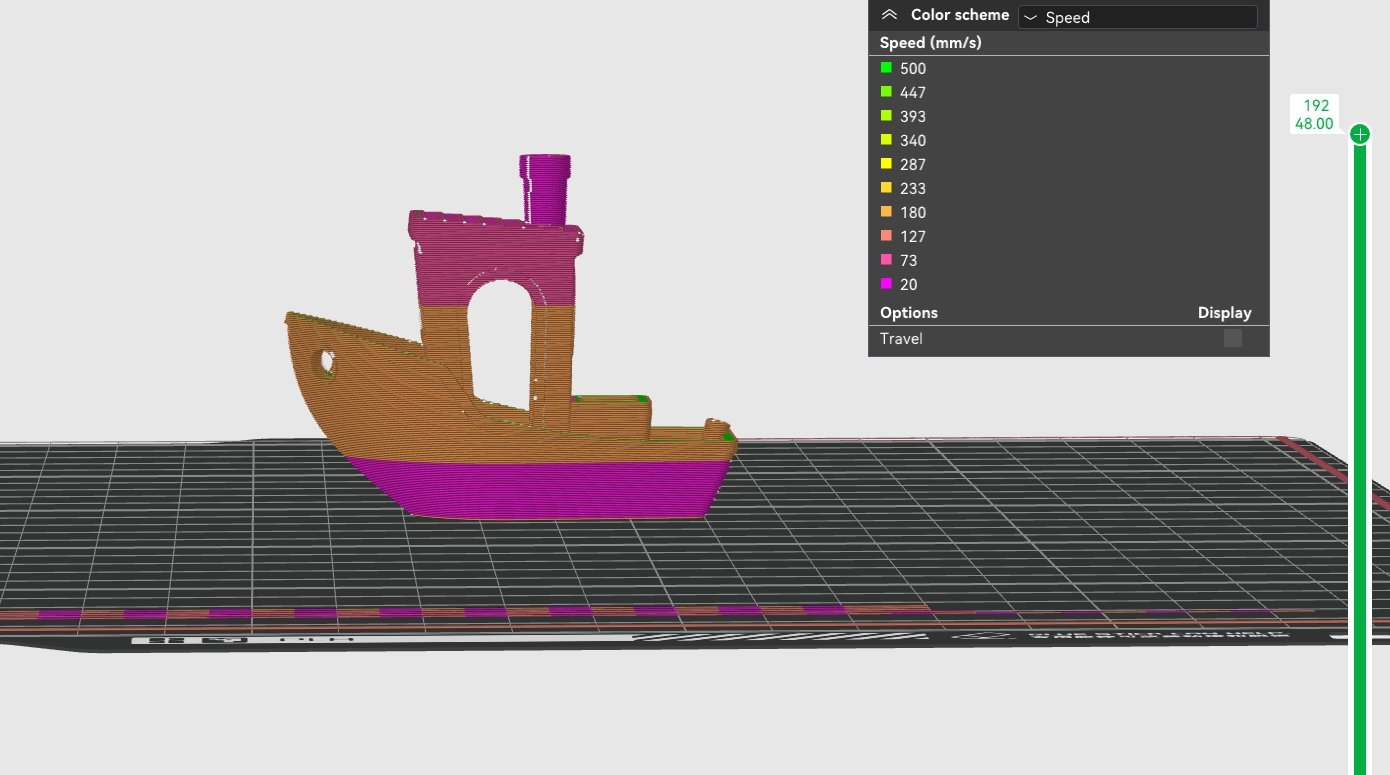

In the example below, you can easily see the purple section in the slicer having a much slower speed compared to the rest of the model.

- For the lower section, this occurs due to the slowdown in print speed caused by the overhanging section

- For the top section, this occurs due to the slowdown in print speed caused by the minimum layer time value, and the need to decrease speed to ensure adequate cooling.

To solve this problem, and avoid this issue in the future:

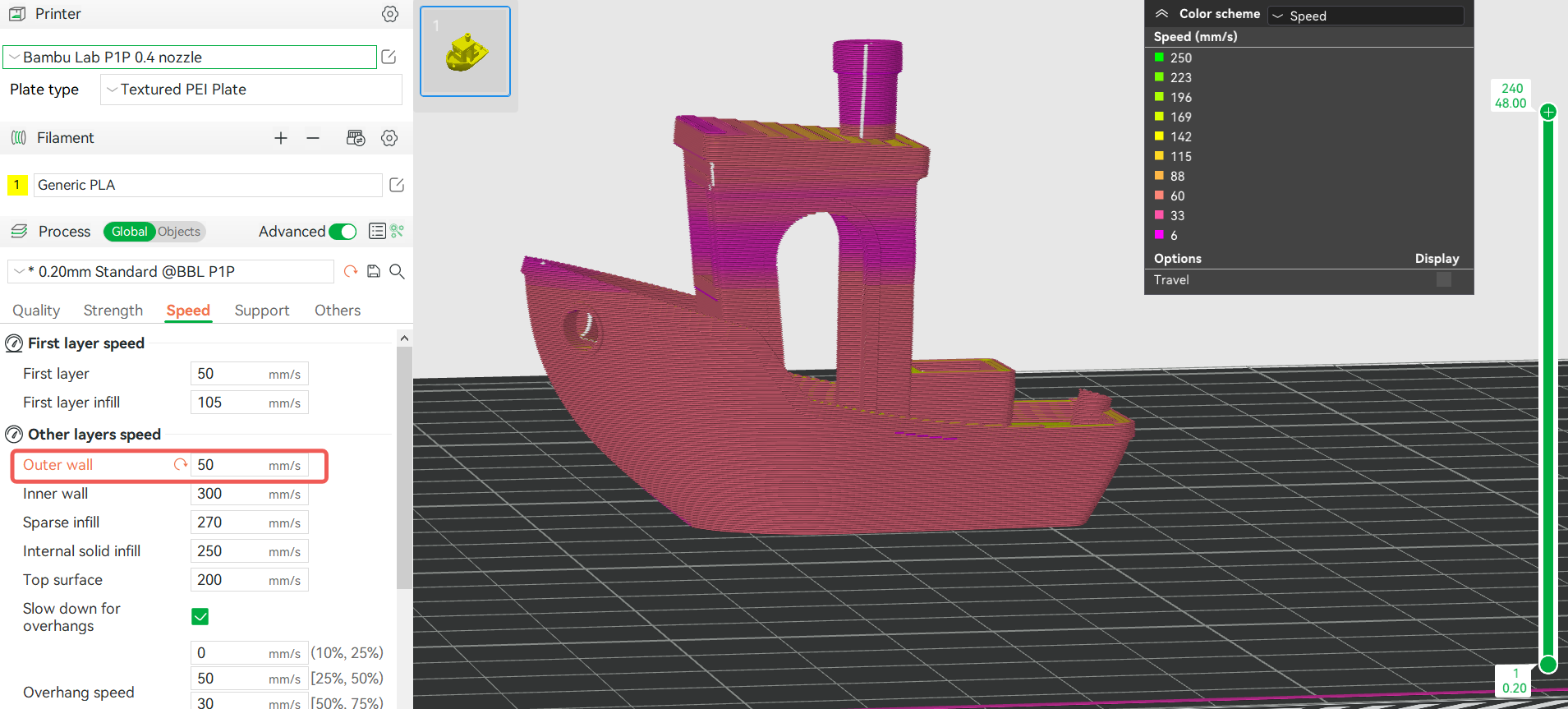

- Adjust the Outer Wall speed to a value that is not very different to the slowest speed shown on the Speed graph in the slicer

- Use a lower layer height of 0.16 mm which can help with the shine difference, as the volumetric speed can be lower and the filament spends more time in the hotend

- Print multiple objects at the same time, to avoid slowdowns caused by cooling requirements

The speed reduction can be made from the Outer Wall setting, under the Speed tab

A community blog post explains this issue in more detail, and it is available here: Bambu Studio Fine Tuning: Tips and Tricks

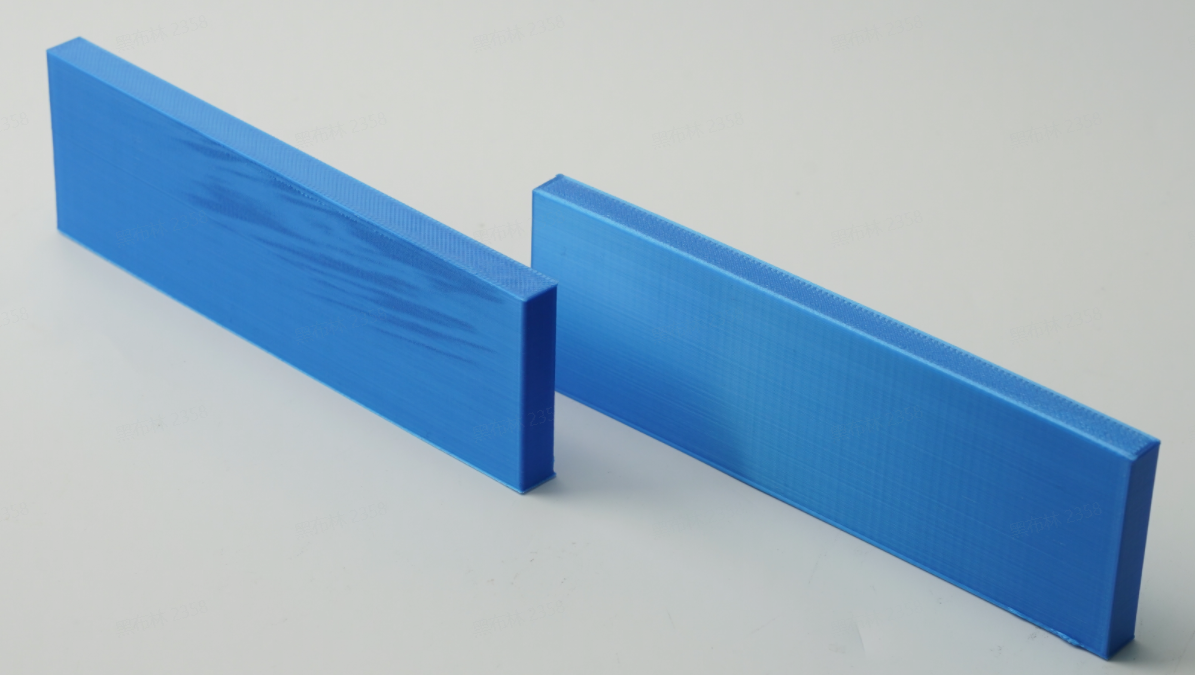

2. Inconsistent finish when fast printing at very low layer height

When printing models with a very low layer height (such as 0.08 mm) at high speed, you might see that the model generates a fish scale effect as the one shown in the images below.

This occurs due to a combination between low layer height and the forces applied on the filament when printing very fast that shear the filament.

To solve this problem, and avoid this issue in the future:

- Change the slicer settings to a larger layer height, ranging from 0.12mm to 0.16mm or 0.20mm. We recommend 0.16mm as a good option for fast print speed and good quality prints.

- Reduce the printing speed with 20-30% and increase the printing temperature by +5-10C

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.