¶ The filament sticks to the nozzle

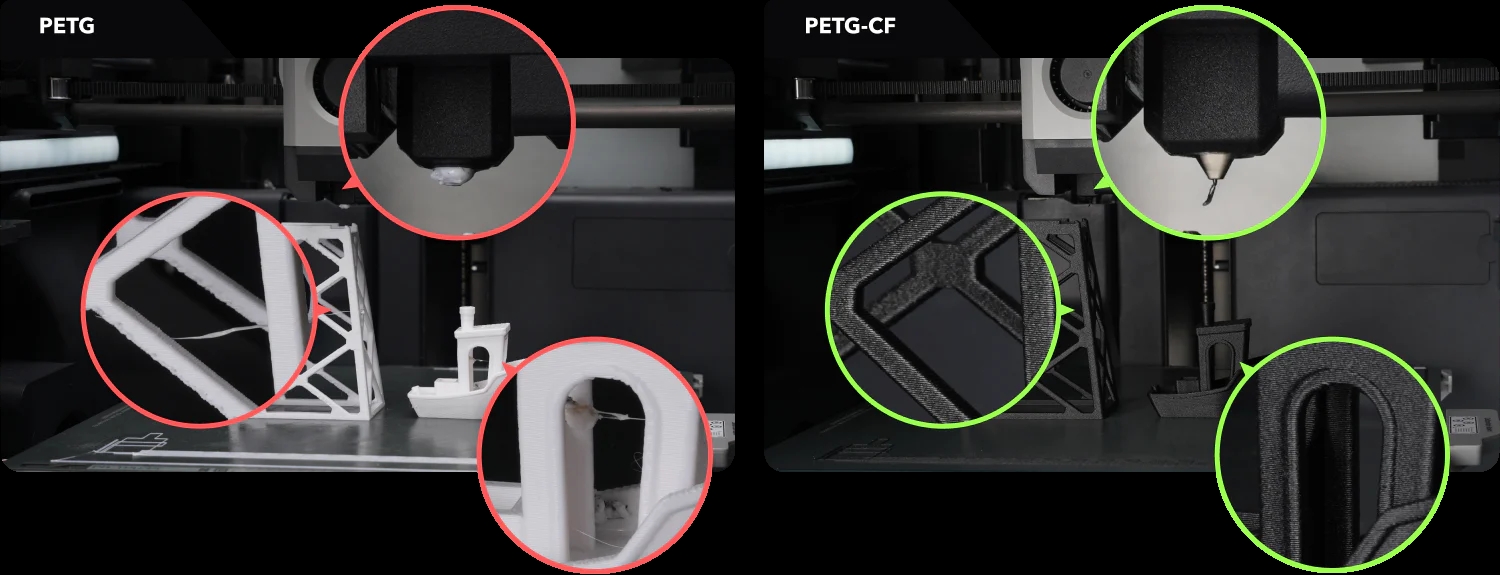

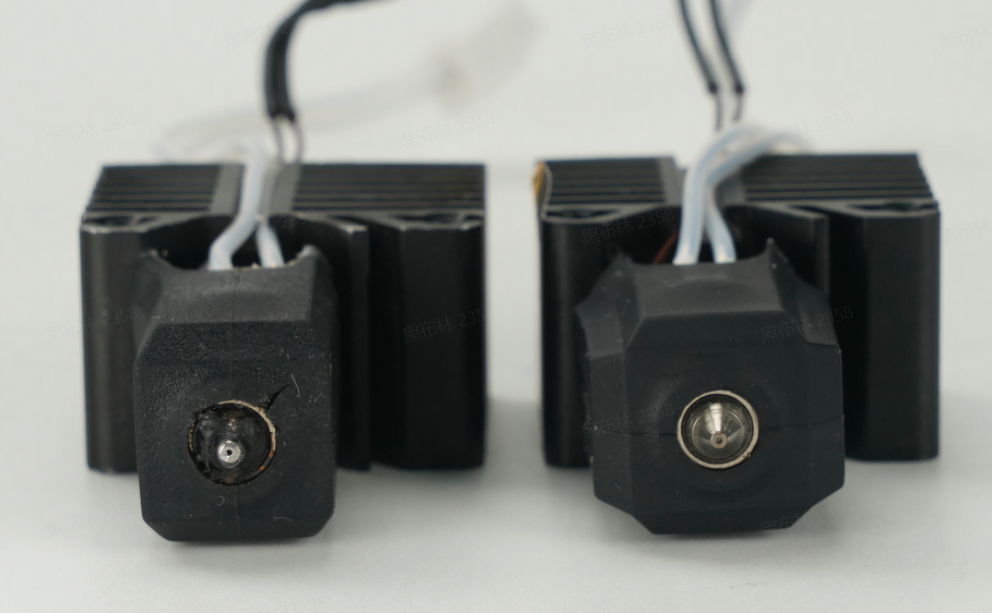

Sometimes, after printing for a period of time, a small part of the extruded filament adheres to the nozzle, resulting in a lack of material, roughness, and other phenomena in the printing model. More seriously, the nozzle will have a large mass of material, resulting in printing failure. The following figure shows a typical filament-sticking nozzle phenomenon. You can solve this problem by heating the nozzle and then carefully removing the stuck filament.

This problem generally occurs when printing PETG filaments, which include ordinary PETG and PETG-CF. Bambu PETG Basic and Bambu PETG-CF are specially formulated and optimized, so the probability of sticking nozzle is much lower than other brands of PETG and PETG-CF in the market. And even if the sticking nozzle occurs, the impact is very slight and rarely leads to defects in the print. However, in some special cases, sticky nozzle problems will still occur, the following are the corresponding solutions.

¶ 1. The filament is damp

Although the water absorption rate of PETG filament is relatively low, after exposure to humid air for a certain time, the filament will still be damp, and the greater the ambient humidity, the faster the filament will be damp, resulting in problems such as sticking nozzle, stringing, oozing, and rough print surface. The reason is that when the water vapor carried by the filament passes through the nozzle, it will expand violently due to the heat, which causes the melt at the nozzle to expand and spread around, and when a part of it adheres to the outer wall of the nozzle, it may cause the sticking nozzle. The corresponding solution is to put the filament roll in a blast oven, dry it at 65 to 75 ° C for about 8 hours, or use an X1C heat bed to dry the filament (please refer to Procedure and 3mf file for drying filament with the X1C heatbed | Bambu Lab Wiki).

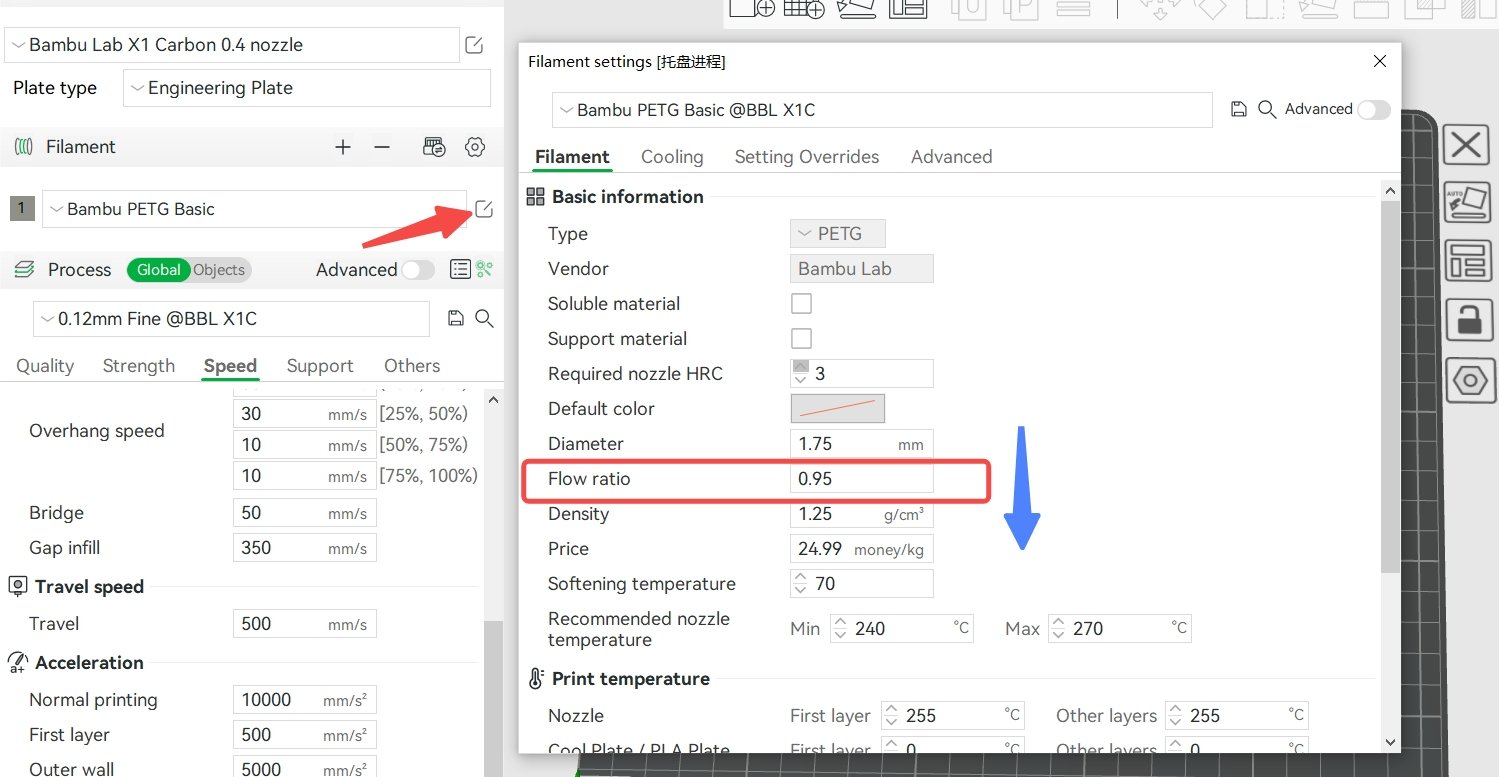

¶ 2. The flow ratio is too large, or the nozzle is worn and the actual ratio is larger than the set one

For PETG filaments, the recommended flow ratio is between 0.93-0.96. If it is lower than 0.93, the risk of material shortage will increase, and the interlayer bond strength of the model will be low. If it is higher than 0.96, the model strength will be higher, but the risk of leakage and sticking nozzle will be increased. The default flow ratio of Bambu PETG Basic and Bambu PETG-CF is 0.95. Do not increase it at will. When you are using these two filaments after drying (very important) to print some models and have a sticky nozzle problem, first check whether the nozzle has been worn, if it has been worn, then replace it; if not worn, please try to slightly reduce this value to between 0.93 and 0.94.

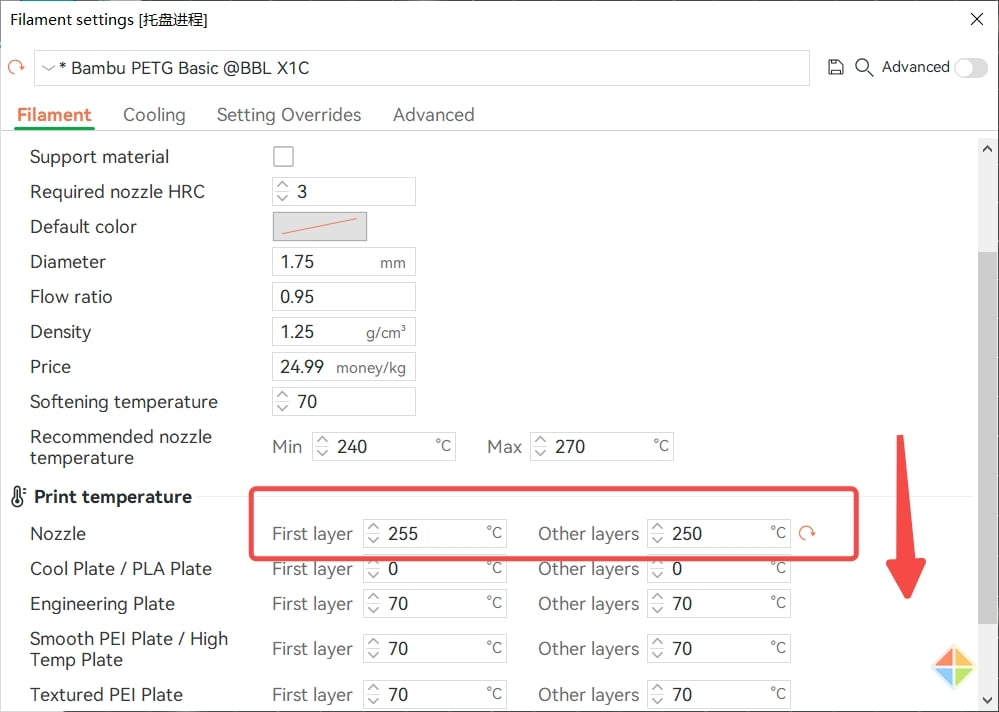

¶ 3. Printing speed is too low or printing temperature is too high

In general, the higher the printing speed, the more filaments need to be melted per unit of time, and the higher the nozzle temperature required. When the printing speed is very high, the nozzle temperature needs to be properly adjusted to avoid insufficient melting of the filament, resulting the material shortage. On the contrary, when the printing speed is very low, the heating time of the filament in the nozzle is longer, the melting is more thorough, and the fluidity of the melt is stronger. At this time, if the nozzle temperature is not properly lowered, it may cause problems such as string, material leakage, and sticking nozzle. Therefore, when you reduce the printing speed and maximum volumetric speed (corresponding to the highest printing speed), please reduce the nozzle temperature appropriately at the same time.

¶ 4. The nozzle wiping part is worn, loose, too small or damaged

After being used for a period of time, the nozzle wiping part may have been worn, loose, small in height or damaged, resulting in poor nozzle wiping effect and filament residues sticking to the nozzle. Please confirm whether these problems exist by visually inspecting, moving the nozzle wiping part by hand, pushing the hotend to the nozzle wiping part to compare the height after power off, and pushing the hotend to hit the nozzle wiping part quickly. If these problems are found, the nozzle parts need to be repaired or replaced.

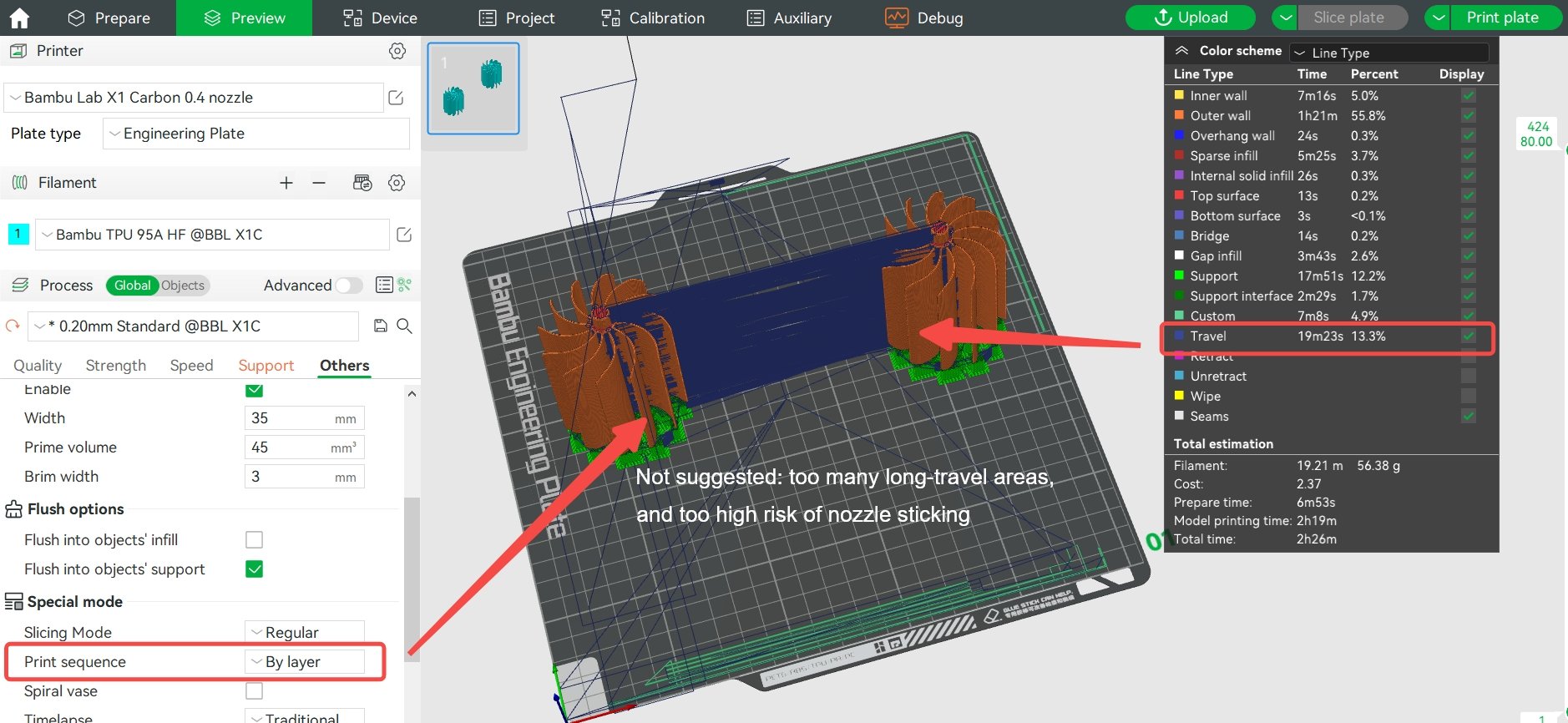

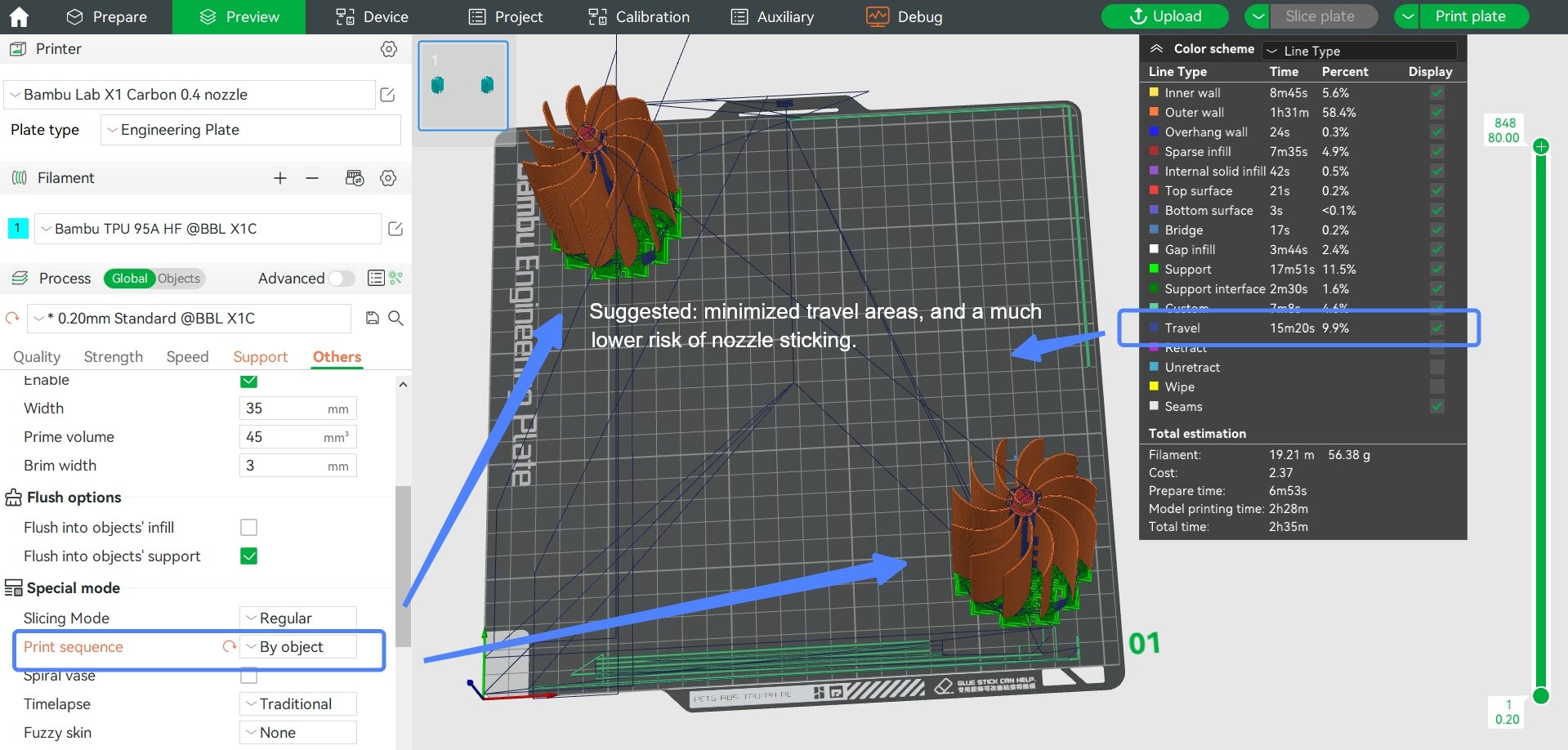

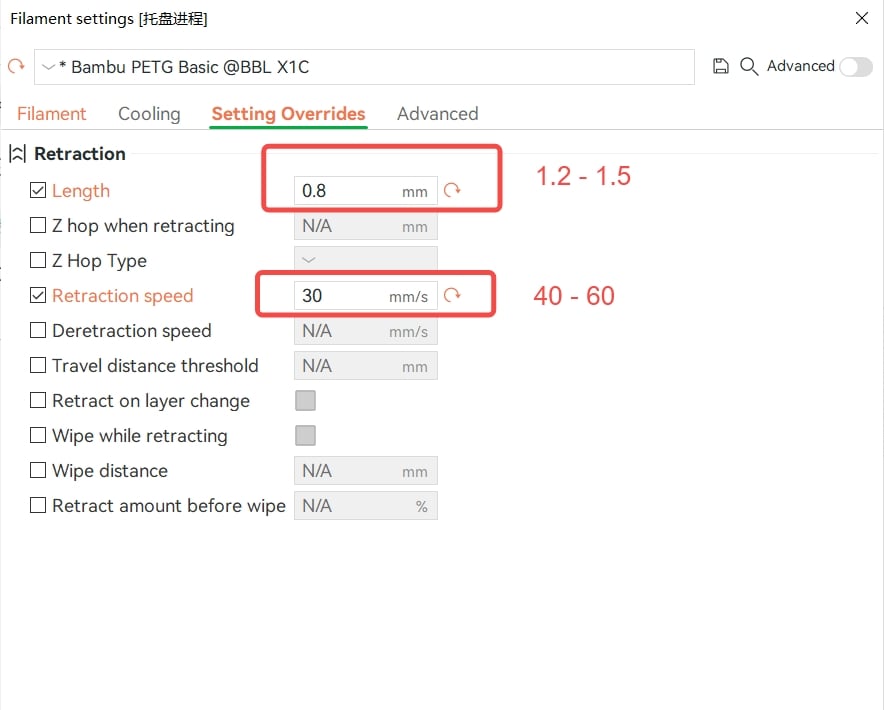

¶ 5. The model itself has too many long jumping areas (discontinuous areas)

If the model itself has many long jumping areas(discontinuous areas), or if the model placement is unreasonable, resulting in many long-distance travel during printing, then the filament melt in the nozzle may ooz out during the travel process during printing and be rubbed against the outer edge of the nozzle during printing and accumulate continuously, causing the nozzle sticking. At this time, a reasonable model placement method should be used to avoid too many long-distance travels. You can also consider appropriately increasing the retraction length and retraction speed. Note: When the retraction length is set too large, it may cause clogging. It is generally recommended not to exceed 2 mm.