¶ Stringing and oozing

Cause: excessive nozzle extrusion or abnormal expansion and flow of molten filament.

1. Damp filament - It is recommended to dry the filament first and then use it in an airtight container with desiccant. You can refer to this wiki to dry filament: Procedure and 3mf file for drying filament with the X1C heatbed | Bambu Lab Wiki

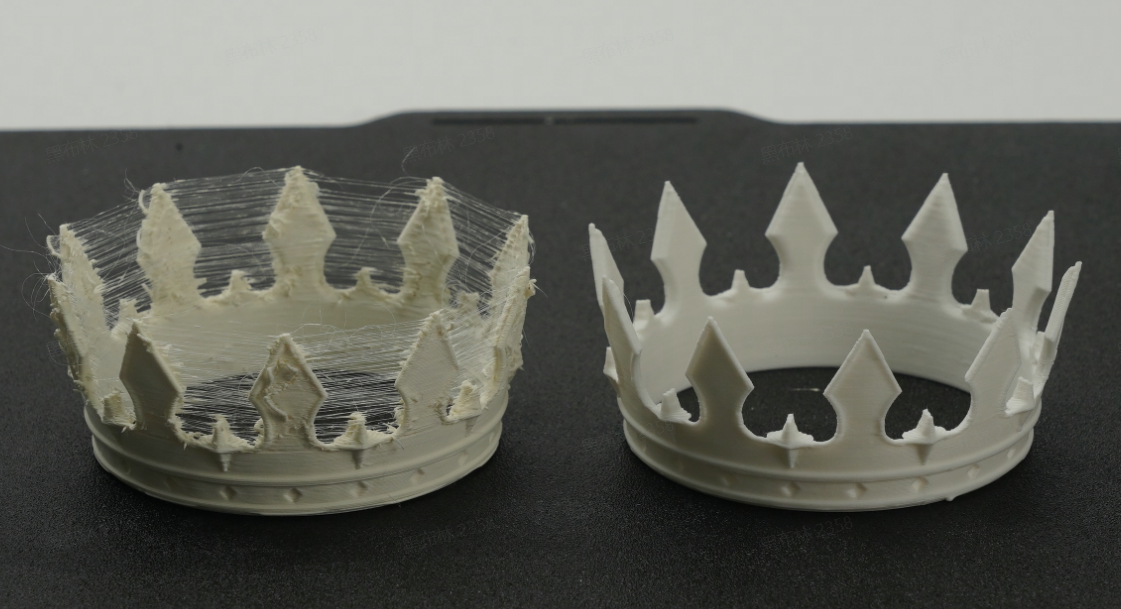

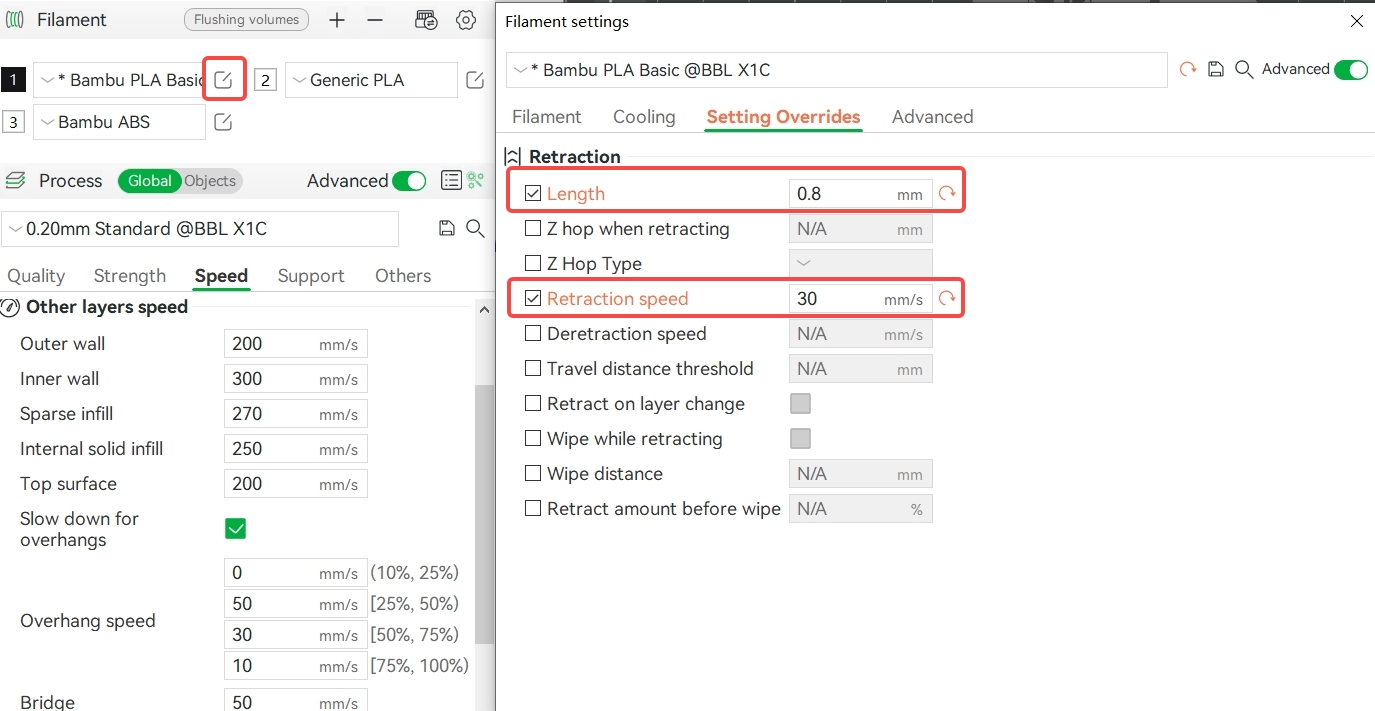

2. The model has a long travel distance and a small retraction length, which causes the filament to flow out of the nozzle during travel - when printing multiple models, reduce the spacing between the models, and appropriately increase the retraction length or retraction speed.

Note: When the retraction length is set too large, it is easy to cause the plug, and it is generally recommended not to exceed 2 mm.

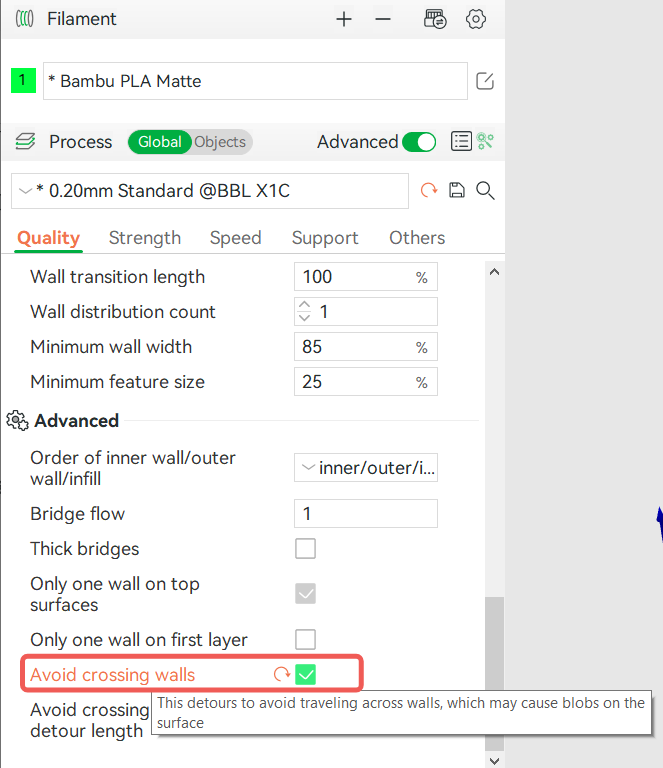

3. The model has special structure or improper placement. When there are more discontinuous structures in a single model and the spacing between the models is large, there will be long-distance traveling in the printing, so the melted filament will drip down during traveling, resulting in defects such as stringing and ozzing. In this case, the placement distance between models can be reduced. You can also enable "Avoid crossing walls" to reduce the probability of stringing.

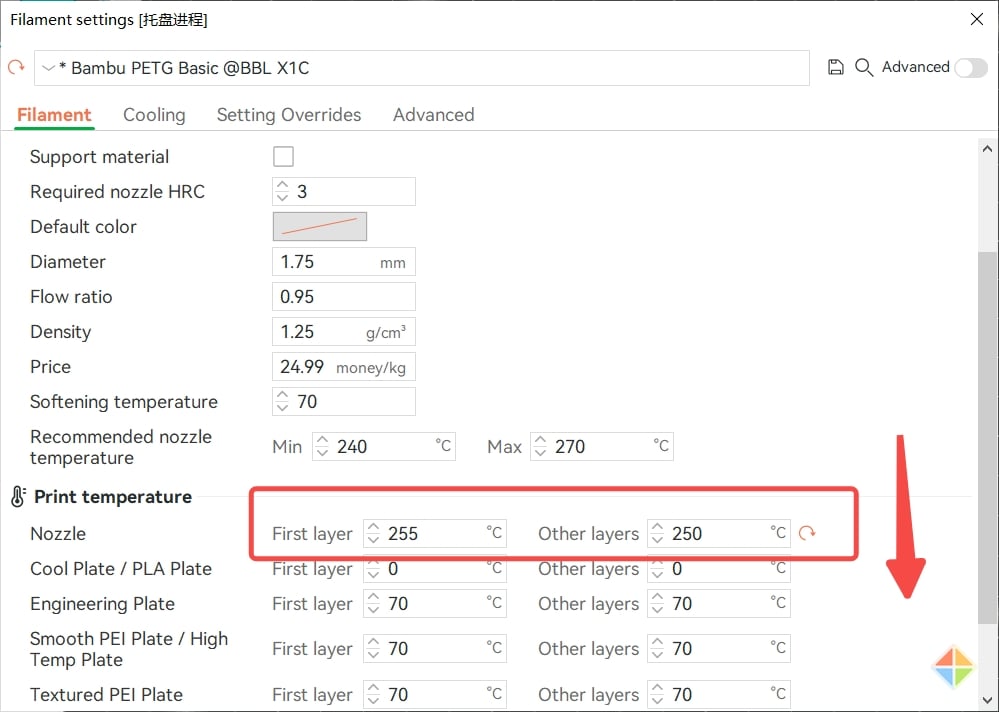

4. The nozzle temperature is too high, resulting in the viscosity of the molten filament being too small - properly reduce the nozzle temperature.

5. When using low-density filaments (such as LW- PLA), the print temperature or flow ratio is not properly set - it is recommended to properly reduce the print temperature and set the flow ratio between 0.5 and 0.7. Low-density filament, such as LW-PLA, there are more holes and gas (water) in the interior, and the printing process will produce gas, which will cause the molten filament to produce a large expansion, so it is recommended to dry the filament before printing and set a lower flow ratio when slicing.

6. The nozzle aperture is too large, resulting in more filaments flowing out of the nozzle.

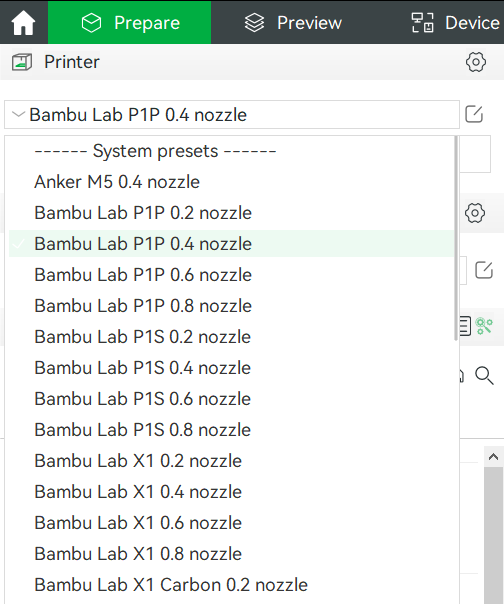

- Choose the wrong nozzle size when slicing, or use a larger diameter nozzle when printing - before printing, make sure that the selected configuration is the same as the actual nozzle size.

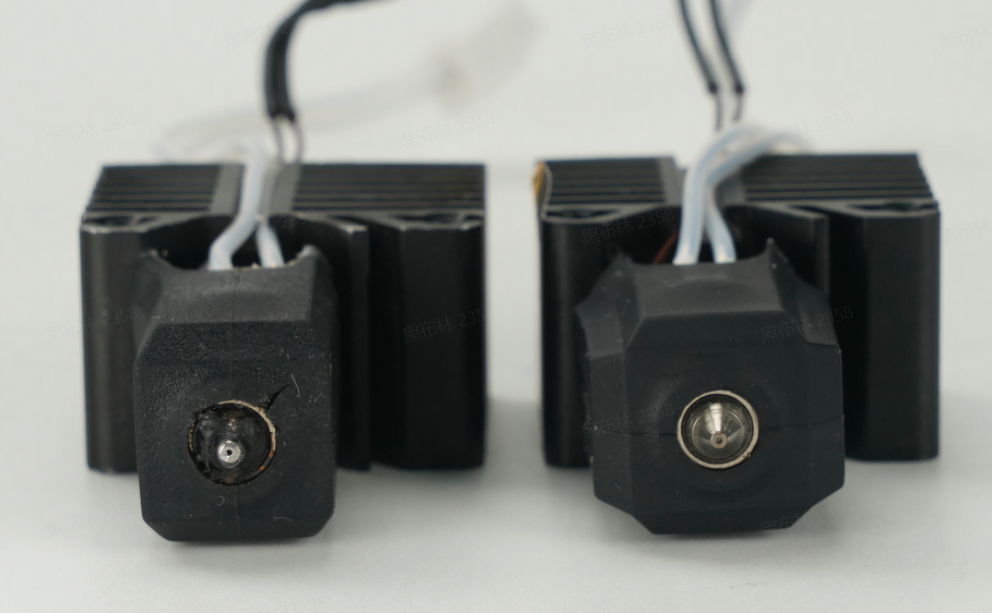

- Nozzle has been used for a long time, there is obvious wear - replace the nozzle.