¶ When to clean

If you frequently print with ABS or ASA filaments, volatile substances can build up in the printer and on the carbon rods. This accumulation leads to an increase in resistance of the carbon rods, resulting in a decline in printing quality.

It is advisable to clean the carbon rods after every 5 rolls (5 kg) of ABS or ASA printing. However, if you notice a decrease in print quality or observe ribbing/vibration artifacts on the external walls of the prints, it is recommended to clean the carbon rods at that time as well.

It must be emphasized that lubricating oil and grease cannot be used on the X-axis carbon rods of the X1 and P1.

¶ Safety warning

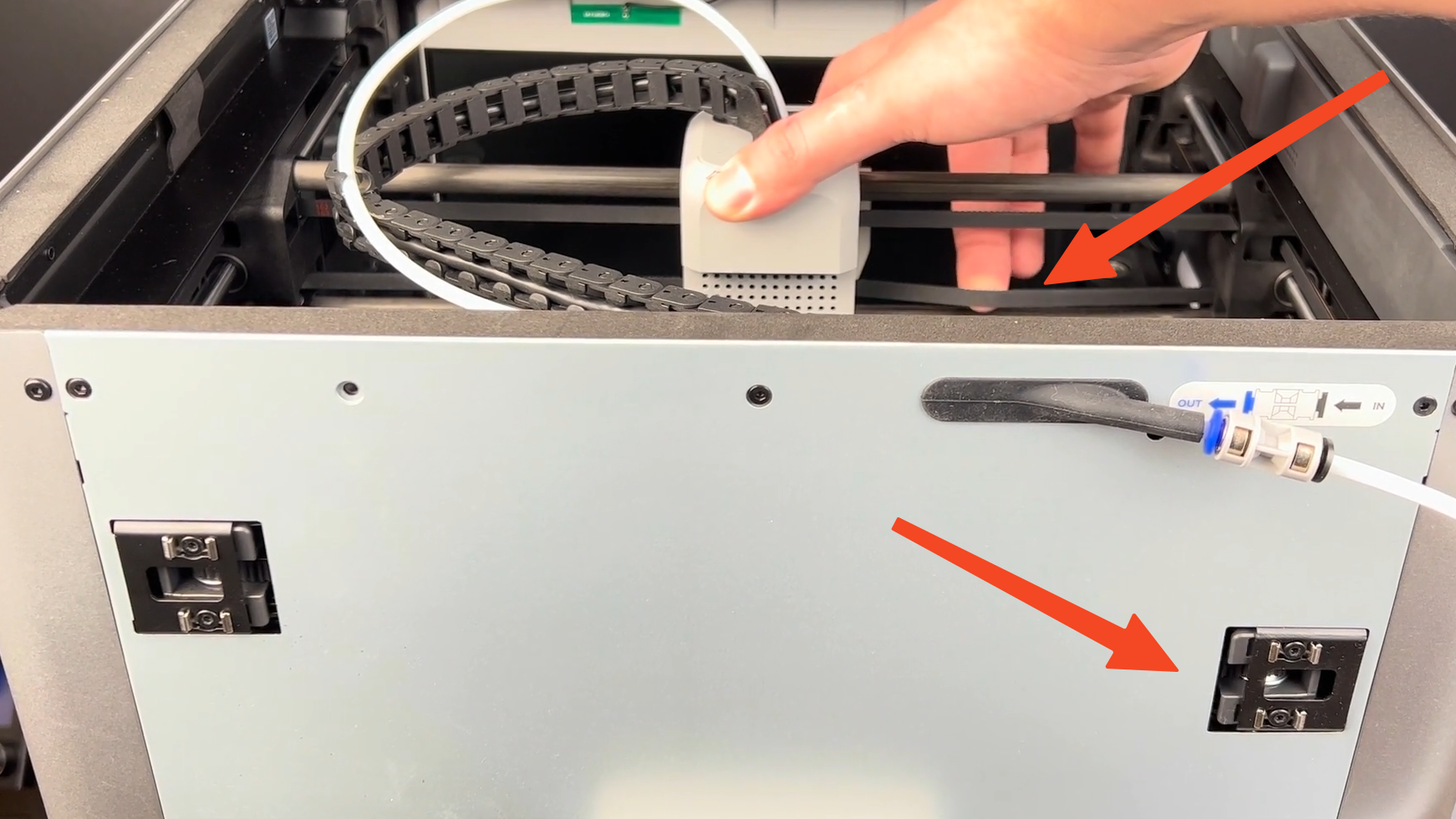

To ensure safety while manually moving the tool head and applying the cleaning agent, it is necessary to disconnect the power supply beforehand.

¶ Tools and materials needed

- IPA-Isopropyl alcohol (70% concentration) (Or ethanol)

- Clean cloth

¶ Video of the procedure

Note:During the belt tension adjustment, before tightening the screws, please move the axis to the end as shown below.

¶ Steps for cleaning the carbon rods

¶ Loosen the belt tensioners

The first step in cleaning the carbon rods for your Bambu Lab printer is to loosen the four screws at the back of the printer that hold the belt tensioners in place.

This step is important as it facilitates easier movement of the print head during cleaning and helps equalize the belt tension in the process.

¶ Check if the belt tensioners move as expected

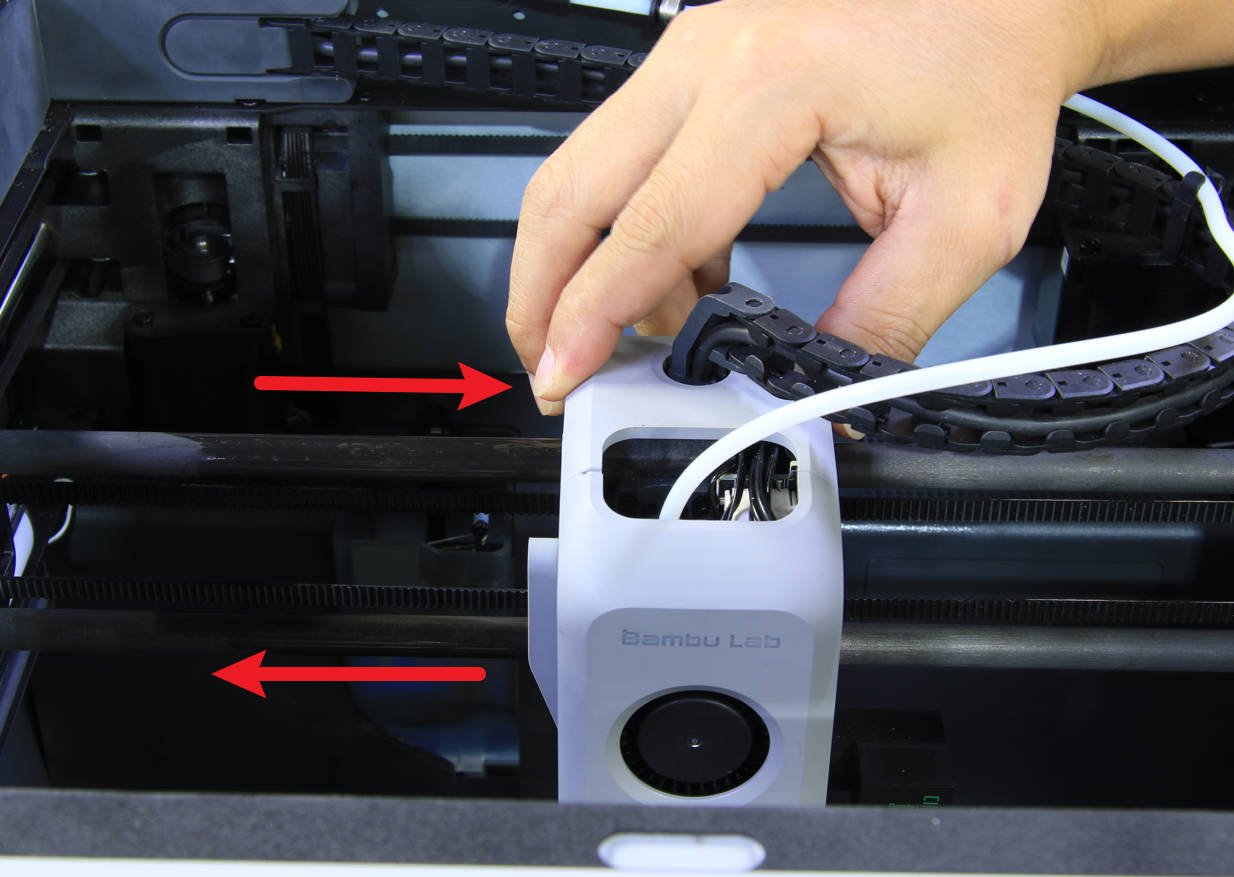

After loosening the belt tensioner screws, you should be able to apply pressure to the belts next to the tool head, causing the tensioners to move on the side.

If the belt tensioners do not move as demonstrated in the video, it is crucial to investigate the reason for this issue. Maintaining equal belt tension is vital for achieving good printing results.

¶ Apply IPA to the carbon fiber rods

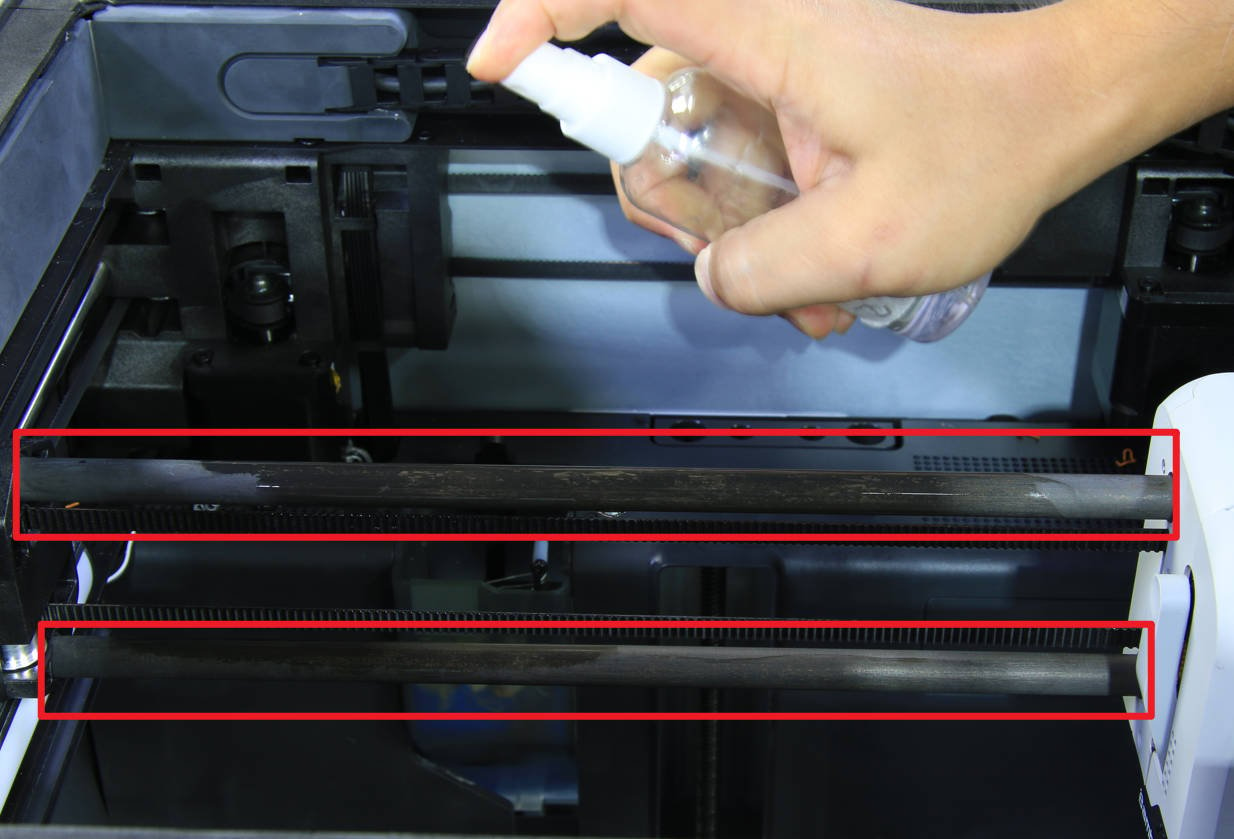

We recommend using IPA (Isopropyl Alcohol) to clean the carbon fiber rods. You can either apply IPA using a spray or use a microfiber cloth soaked in IPA.

Apply a generous amount of IPA onto the carbon rods. While the rods are still wet with IPA, move the print head from left to right along the entire length of the rods.

Continue moving the print head until the IPA starts to evaporate. Afterward, you can use a microfiber cloth to wipe the rods clean.

Repeat this process three times or continue until there is no debris visible on the microfiber cloth when wiping.

When cleaning the rods, it is important to try to get some IPA inside the bearing simultaneously. This can happen automatically if the rods are soaked in IPA during the movement.

Ensure that the IPA reaches inside the bearings during the cleaning process. In certain conditions, volatile substances or debris can enter the bearings, resulting in resistance and reduced movement across the carbon fiber rods, which ultimately leads to decreased print quality.

You'll notice a change in the sound when moving the print head once the rods and the inside of the bearings are clean.

The cleaning is only considered thoroughly done when the white dust-free cloth has no black stains on it. If you frequently print with filaments like ABS and ASA, it is recommended to apply a bit more force when wiping during the cleaning process.

¶ Move the print head for lubrication

Bambu Lab printers utilize self-lubricating bearings. However, after the cleanup process is complete, it may take some time for the lubrication to reach the desired level.

To ensure proper lubrication and calibration of the printer, perform an additional 10-20 movements of the print head along the entire length of the dry carbon fiber rod. This step guarantees that the lubrication functions as intended and allows the printer to adjust itself according to the new resistance encountered.

Usually, this step is not necessary for every operation, but it can be beneficial in certain situations.

¶ Tighten the belt tensioners and perform the calibration

Now that the carbon rods are clean, position the print head in the center of the printer and proceed to tighten the belt tensioners. Be cautious not to overtighten them as it could result in damage, and excessive tension does not contribute to the calibration process.

If you have relocated the printer from its initial position, ensure that you install it in its final location before initiating the calibration. This step is crucial to ensure that the calibration data accurately corresponds to the printer's intended usage location.

¶ Important Notes

- Frequent cleaning of the carbon rods before each print or doing it too often is not advisable. The self-lubricated coating that forms on the rods will be wiped away, causing the printer to use a calibration value stored in the firmware that may not accurately reflect the changed resistance. This can result in poor print quality.

- A slight amount of play in the bearings is normal. If the tolerances were tighter, the bearings would bind and hinder smooth movement along the carbon rods.

- If the print quality remains unchanged even after completing the cleaning procedure, please contact our customer support. Inform them about the steps you have taken so far, and we will provide further assistance in resolving this issue.