¶ Introduction to high-temperature plate

Bambu High Temperature Plate consists of two parts: the High Temperature plate sheet and the Engineering Plate. You can print on both sides of the plate.

The high-temperature sheet is made of PEI, featuring a smooth surface and a fine matte texture. It's attached to the engineering plate using 3M high-heat-resistant double-sided tape. Unlike the PC sheet used in the Cool Plate, PEI material offers better heat resistance and is less likely to deform under high temperatures. This makes it more compatible with various filaments.

Except for the PLA filament, When printing with other filaments, it's highly recommended to use adhesive (Bambu glue stick or liquid glue is recommended) to ensure proper adhesion between the filaments and the build plate. This is crucial to prevent the risk of cracking the high-temperature sheet.

¶ Introduction to smooth PEI plate

The Smooth PEI Plate is obtained by adhering a carefully selected PEI sheet to a spring steel using a highly heat-resistant 3M adhesive. The Smooth PEI Plate provides a flat surface for printed objects and is suitable for scenarios that require a level bottom surface.

The PEI sheet on the surface of the Smooth PEI Plate allows for printing with various filaments.

Only PLA filament does not require glue, while printing with other filaments requires the use of gluing to prevent the PEI sheet from tearing.

The thicker 0.5 mm spring steel helps reduce the risk of warping in the printing plate.

¶ Troubleshooting bed adhesion issues

The surface of the Bambu Lab High-Temperature / Smooth PEI Plate is made of customized PEI material, compatible with a wide range of popular filaments, offering a highly smooth print surface. Over time, users might face issues with inadequate build plate adhesion. Here are some recommended steps for troubleshooting adhesion problems with the Bambu Lab High-Temperature Plate.

|

|

¶ Clean the printing surface

Periodically, we recommend cleaning the Bambu Lab High-Temperature / Smooth PEI Plate to ensure that the printing surface is free of debris, old glue stick, or fingerprints. The natural oils from your hands can transfer to the printing surface, impacting the sheet's adhesion properties

We suggest cleaning the printing surface with warm water and regular soap. You can use a basic sponge and dishwashing detergent, wash it with water, and dry it with a regular paper towel.

¶ Slightly raise the heatbed temperature

The adhesion between the filament and the build plate is significantly influenced by the heatbed temperature; higher heatbed temperatures result in stronger adhesion. If you feel the adhesion force is inadequate, you can slightly increase the bed temperature to enhance adhesion.

Note: For PLA and PETG materials, excessively high temperatures may lead to clogging and elephant foot problems.

¶ Add brim and support structure

The force between the print and the build plate is roughly proportional to their contact area. When printing small objects, adding a brim enhances the pressure between the print and the build plate, preventing warping or detachment. Thin and tall items are more prone to nozzle scraping at high speeds. It's advisable to use proper support when printing such objects to optimize the force structure and minimize the risk of warping or detachment.

¶ Double-check the heatbed temperature and the filament used

Most filament types come with a default preset in Bambu Studio. If you customize your profile, we recommend double-checking the temperatures set for the heatbed. Sometimes, you might need to adjust the temperature based on the type of filament used and its properties.

¶ Adjust the first layer settings in the Bambu Studio

You can adjust slicer settings for the first layer to enhance adhesion. The slicer profiles in Bambu Studio come pre-configured with values that were performed best during testing. However, if issues arise, we recommend starting the print with a 0.5mm line width and a 0.25mm layer height for optimal results. These settings establish a solid foundation for the rest of the model and increase the chances of success.

¶ Ask for help

If you still encounter adhesion issues after following the steps described in this article, feel free to create a ticket, and our support team will assist you.

¶ Troubleshooting when the build-plate/sheet is damaged(scratches/bubbles/exfoliation)

Apply a thin layer of glue stick to prevent models from adhering too strongly to the print surface.

Additionally, allow the plate to cool down before removing prints.

Following these guidelines ensures the plate's longevity and reduces the likelihood of bubbles forming under the sheet for new replacement plates.

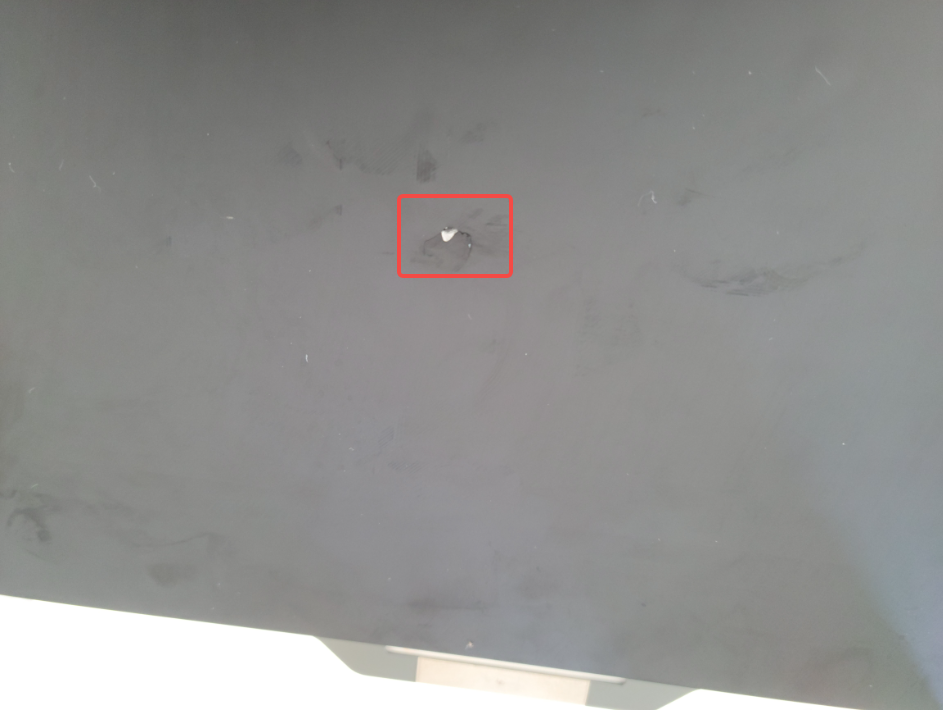

¶ Case 1: If the surface of the build plate is broken(scratches or exfoliation)

The problem can only be fixed by replacing the sheet. How to replace the Bambu Lab Plate sheet | Bambu Lab Wiki

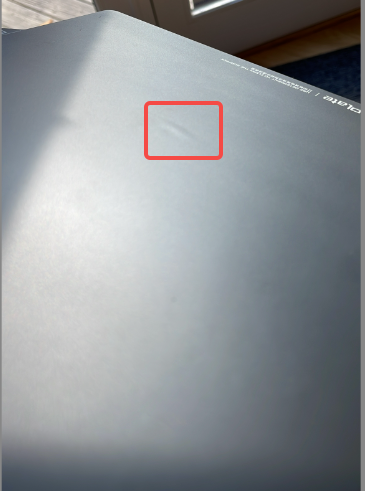

¶ Case 2: If there are bubbles on the plate

Attempt to remove bubbles using the following technique:

1. Place the sheet with the sticker side down onto the heatbed.

2. Heat the bed to 100 ℃.

3. Once the bed reaches the temperature, turn off the heat and let it cool.

4. Once cool to the touch, inspect the sticker side for any remaining air bubbles.

If the above steps cannot remove the bubbles, the only solution is to replace the sheet. How to replace the Bambu Lab Plate sheet | Bambu Lab Wiki

¶ Note

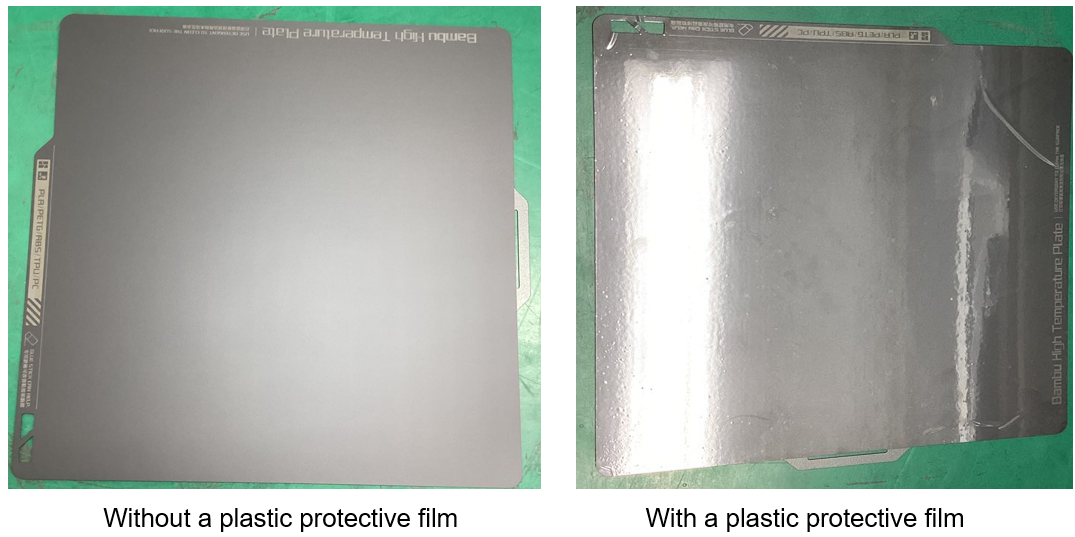

If your high-temperature plate comes with a plastic protective film on the surface, please remove it before using it.