¶ Paper

The cutting module can accurately cut paper, greatly improving the efficiency and accuracy of users when making creative objects such as models and decorations.

¶ Heat Transfer Vinyl

The heat transfer vinyl comes in a variety of color options and is easy to cut, with strong adhesion that withstands multiple washes and stretching. This material needs to be heat transferred to adhere firmly to the object surface. Creators often use it for custom designs on apparel such as T-shirts, hoodies, and backpacks.

¶ Heat Transfer Vinyl Usage Guide

Heat transfer vinyl material introduction

¶ Removable Vinyl

The removable vinyl can be directly pasted on the object surface through the adhesive backing, which is convenient to use. Creators can apply them to DIY scenarios such as daily object decoration and festival layouts.

¶ Removable Vinyl Transfer Guide

When using removable vinyl (such as matte removable vinyl, carbon fiber textured removable vinyl, etc.), after cutting, you can use transfer tape to transfer the work to object surfaces.

Note: Dust, grease and other stains will reduce the stickiness of the surface. It is recommended to clean the surface to be transferred before pasting.

Strip away excess material, using weeding tools such as a hook weeder to help with cleaning if necessary

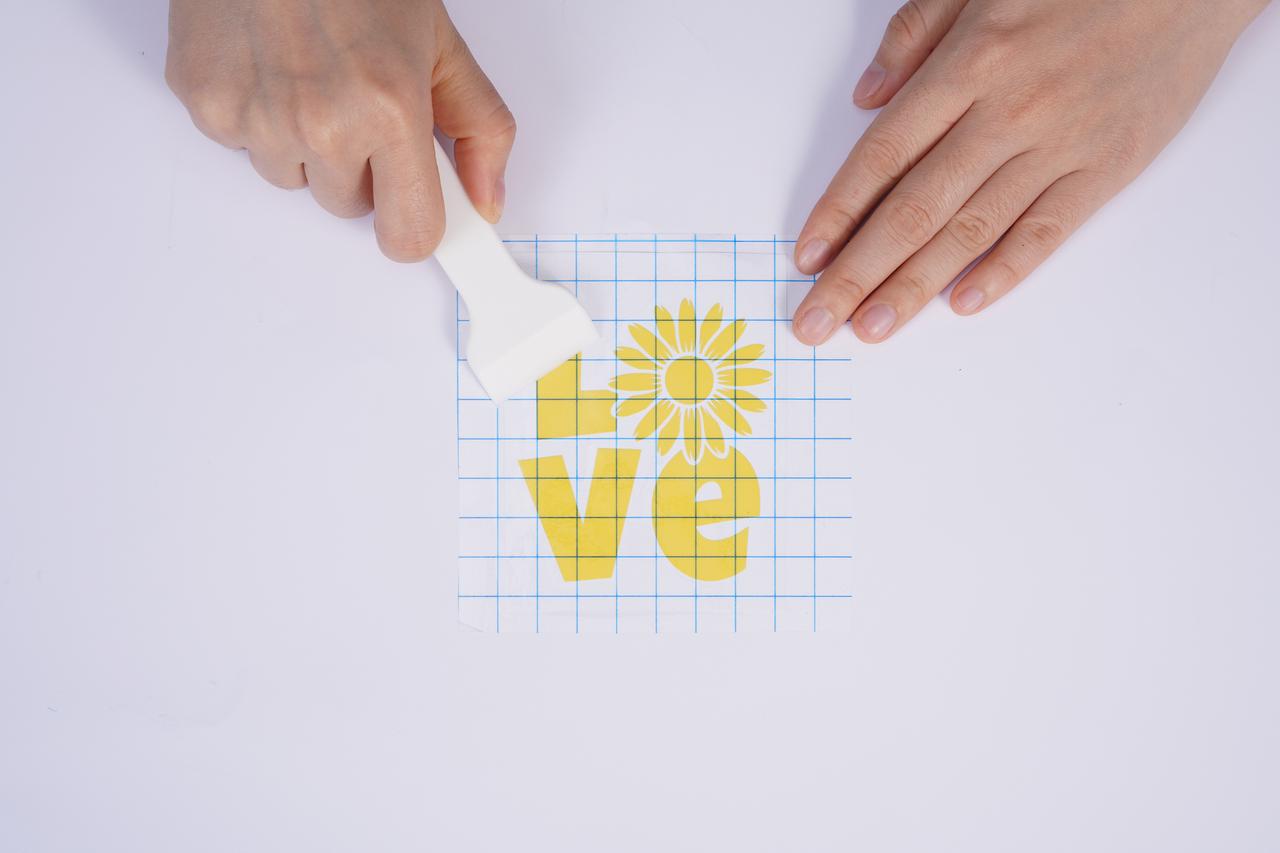

Cut the transfer tape to the appropriate size and press it on the removable vinyl surface

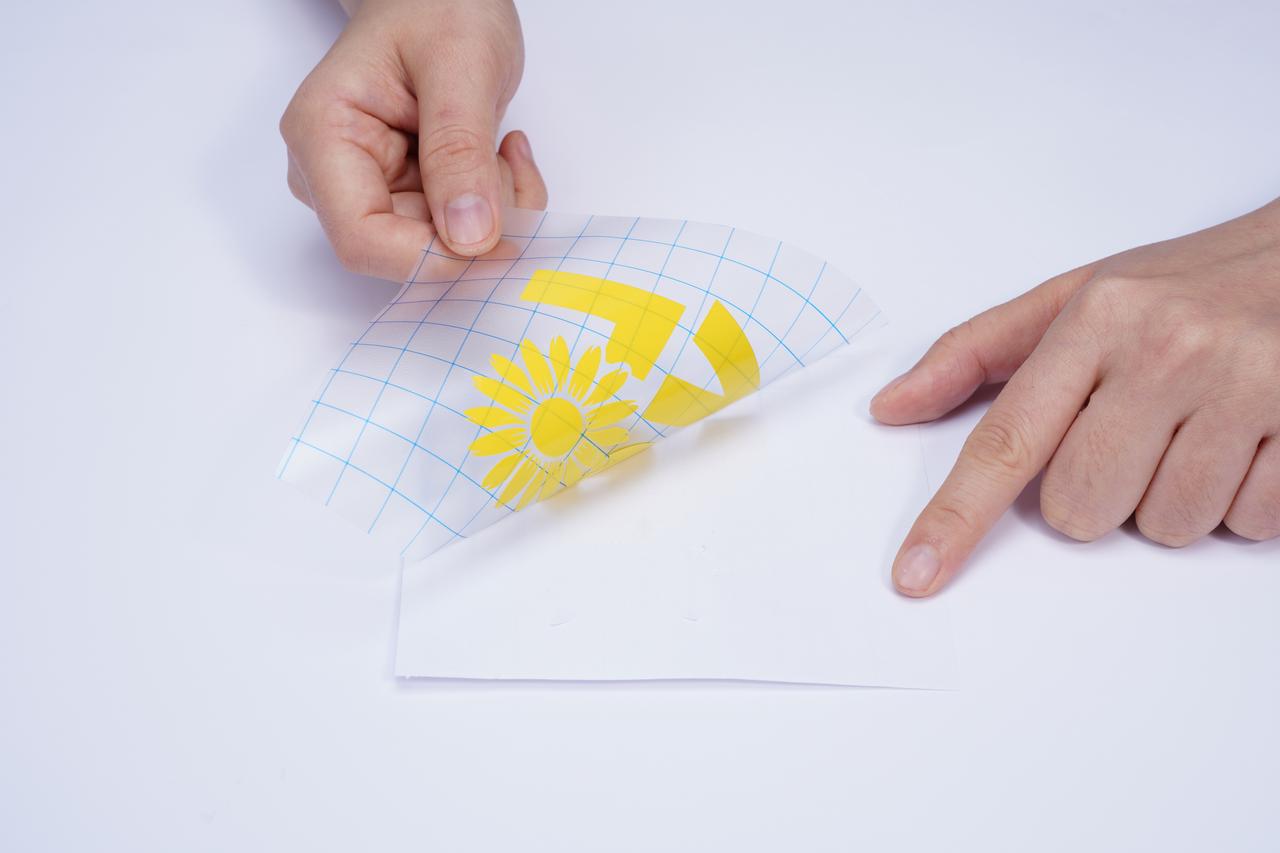

Gently peel off the transfer tape to separate the pattern from the release paper

Align the pattern to the object to be transferred and apply pressure

Gently tear off the transfer tape to complete the work!

¶ Reflective Decal Sheet

The reflective decal sheet can be eye-catching in dim light or at night. Creators can apply them to traffic facilities, clothing design or creative decoration according to actual needs, which can not only provide practicality but also enhance visual effects.

¶ Precautions for basic cut of reflective decal sheet

When cutting reflective decal sheets, please pay attention to the following matters to ensure processing quality and normal operation of the equipment:

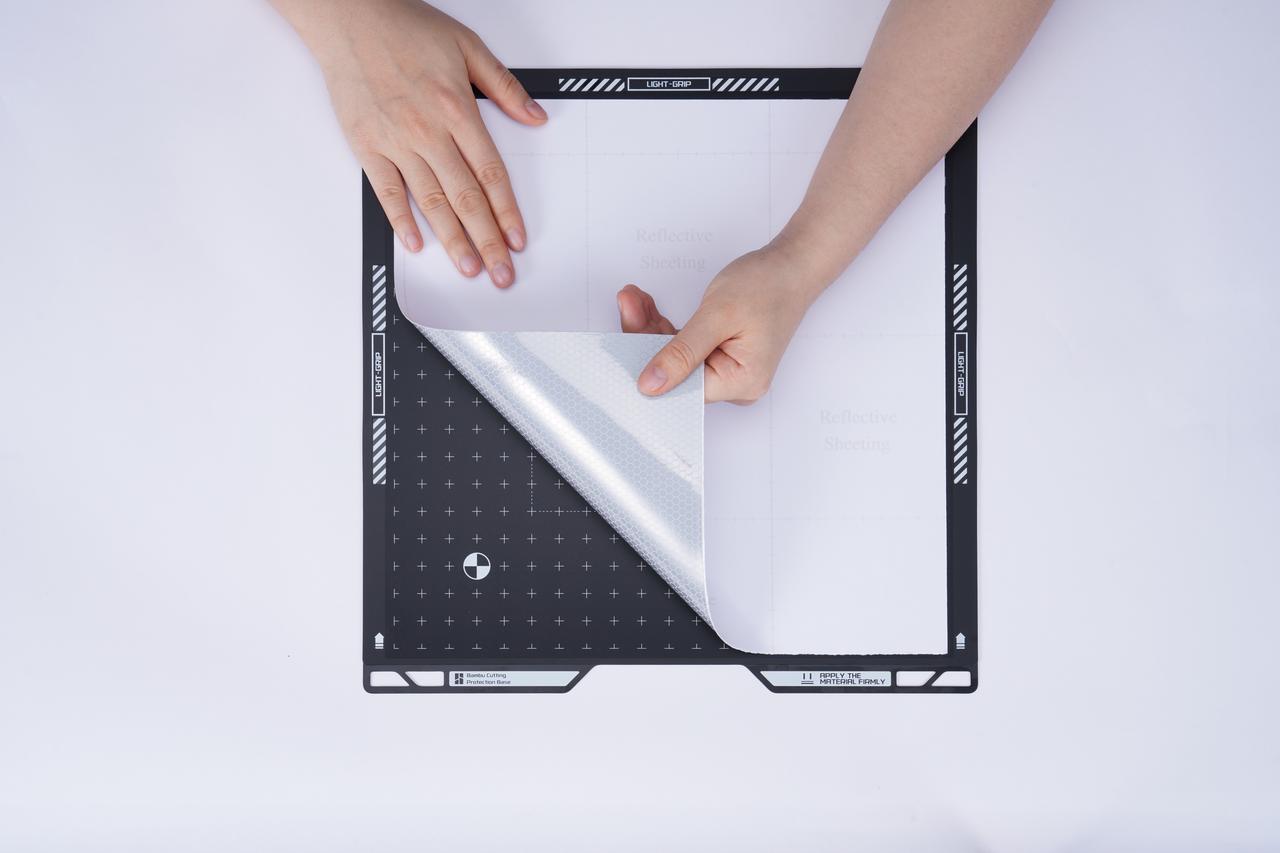

- Attach the material correctly and mirror the image in Bambu Suite

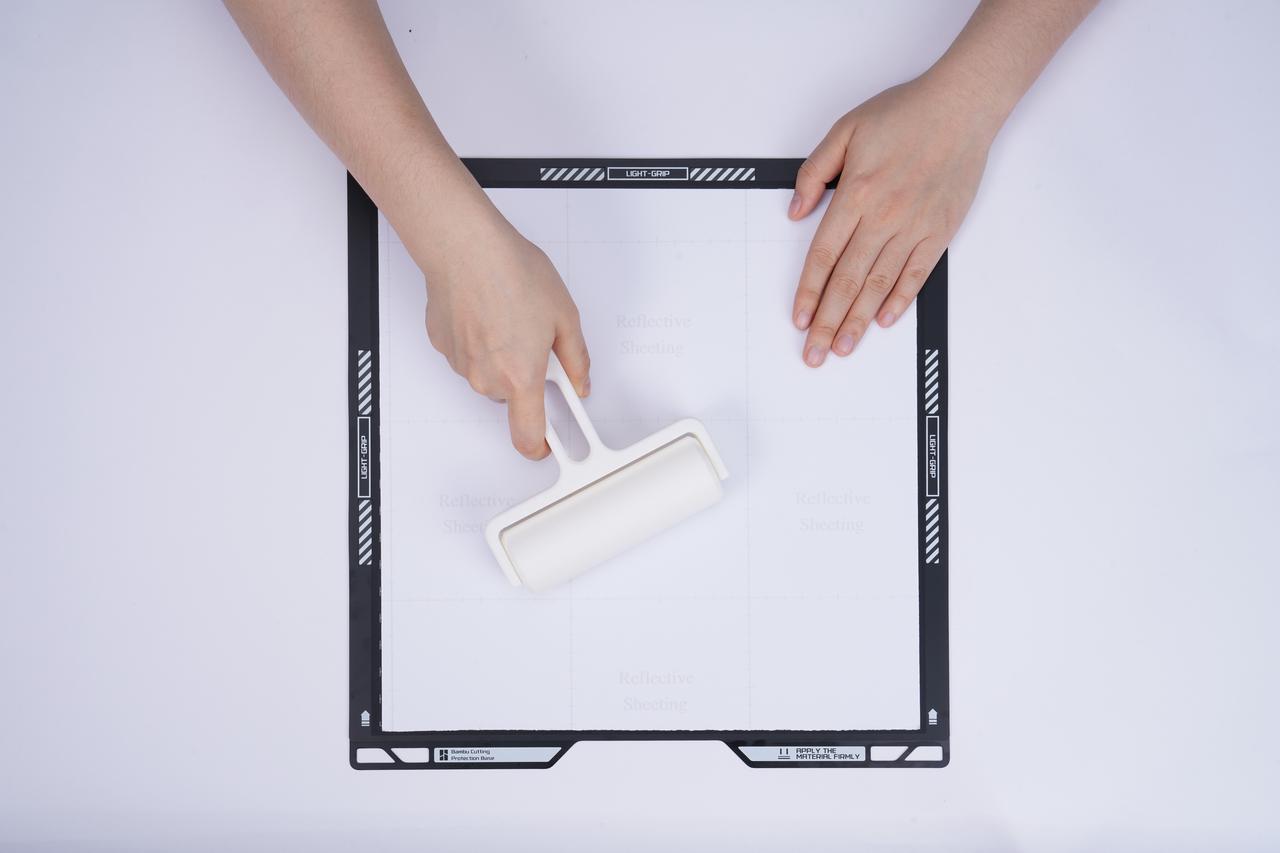

- Use a lightgrip cutting mat and stick the reflective side of the reflective decal sheet down on the mat, cut the release paper side, and use a roller to flatten and compact the material to ensure that the material is stable and does not shift during processing.

- Before processing, please make sure that the processed image has been mirrored to ensure the correct display of the design after cutting.

Why mirror a pattern?

Cutting Module Mirror Function Introduction

- Check and replace the blade in time

- The reflective decal sheet is thick and hard, which causes great wear on the tip of the fine-point blade. To ensure cutting accuracy and smooth processing, please pay attention to regularly checking the status of the blade and replace the blade in time when necessary to avoid affecting the processing effect.

¶ PU Leatherette Fabric

PU leatherette fabric has excellent flexibility, good dimensional stability, and delicate texture, making it an ideal choice for DIY creation. The cutting module can accurately cut it.

¶ Precautions for basic cut of PU leatherette fabric

When cutting PU leatherette fabric, please pay special attention to the following matters to ensure processing quality and normal operation of the equipment:

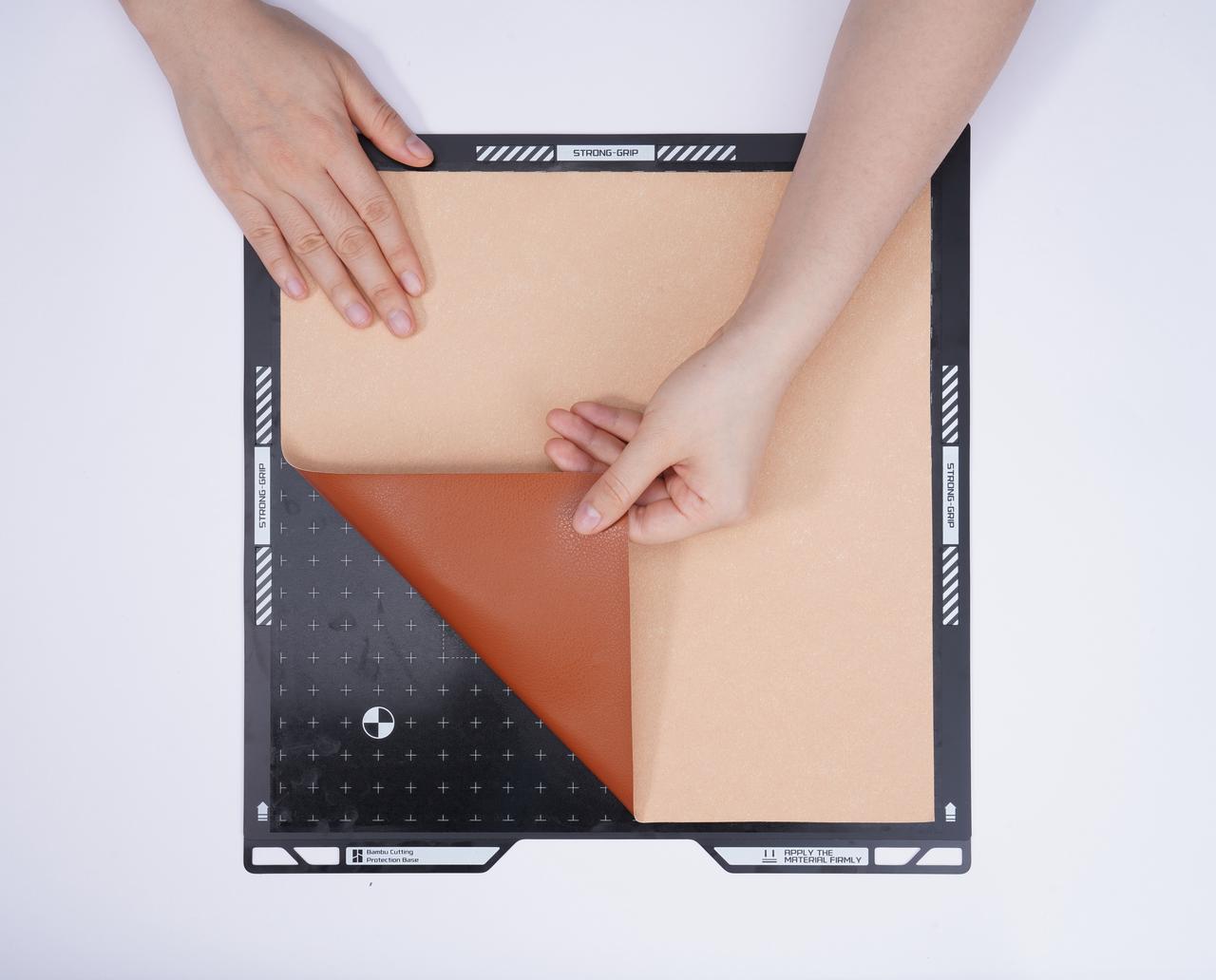

- Material attachment: Since the non-woven bottom surface of PU leatherette fabric has weak adhesion to the mat, it is recommended to use a StrongGrip cutting mat, stick the PU leatherette fabric on the mat with the leather side facing down, and cut the non-woven side. To avoid material displacement, it is recommended to use a roller tool to evenly flatten and compact the material to ensure stability during processing.

- Mirror the Image: Before processing, please make sure that the processed image has been mirrored to ensure the correct display direction of the front pattern after cutting.

Why mirror a pattern?

Cutting Module Mirror Function Introduction

Important Reminder:

If process laser on the leather surface of PU leatherette fabric, please ensure that the leather surface is always facing up and never place it upside down to avoid the laser from accidentally acting on the non-woven fabric, thereby ensuring the processing effect and preventing material damage.