¶ 1. Introduction to Laser

Laser (Light Amplification by Stimulated Emission of Radiation) is a type of light emitted through stimulated radiation, characterized by its monochromaticity, strong directionality, high brightness, and good coherence. The principle involves using a specific optical medium (such as gas, liquid, or solid) to amplify light signals, ultimately releasing a strong, concentrated beam of light. Laser technology is widely applied across various fields. Among these applications, laser engraving/cutting equipment utilizes high-energy concentrated lasers to vaporize the material's surface, allowing for the engraving of patterns or cutting materials into desired shapes. The Bambu Lab laser module uses blue laser light at 455 nm ± 5 nm to precisely engrave patterns on surfaces or cut materials to meet diverse needs.

Although lasers have a wide range of applications, their high-energy characteristics also pose certain safety risks. Intense laser beams can cause irreversible damage to the eyes, potentially leading to blindness, especially when they are directly or indirectly exposed to the eyes. Additionally, laser radiation at high power can cause skin burns and, in specific situations, may lead to fires or explosions. Therefore, the correct use of laser equipment is crucial, and safety measures should not be overlooked. In response to the potential hazards of lasers, organizations such as the International Electrotechnical Commission (IEC), the American National Standards Institute (ANSI), and the European Committee for Electrotechnical Standardization (CENELEC) have established strict laser safety standards, mandating that laser equipment of different power levels must be equipped with corresponding safety protection measures.

¶ 2. Laser Classification

Laser Beam Hazards

Laser beams can be hazardous because the energy of the laser can damage the eyes and skin. This can cause damage to both eyes and skin. Red and infrared lasers mainly cause thermal damage to the cornea. Blue light and UV light are more dangerous because they can penetrate the cornea and lens to reach the retina, potentially causing long-term damage like macular degeneration and retinal burns.The risk is higher if the laser is more powerful if it is more focused, and if it stays in one place for a longer time, so all of these factors are considered when assessing safety. Direct laser exposure, specular reflection, and diffuse reflection can result in varying degrees of injury. It is imperative to adhere to the standard operating procedures outlined in the instructions.

Laser GeneratedAir Contaminants

When using a laser to process materials, various potentially harmful air contaminants may be generated. Please follow the user manual to ensure that all exhaust is either filtered through an air purifier or discharged outdoors where it can safely dissipate.

| Classfication | Laser power | Discription | Application | Protective Measurement |

|---|---|---|---|---|

| Class 1 | Very low | Safe under reasonably foreseeable conditions of operation, including the use of optical instruments for intrabeam viewing | Laser printers Compact disc players | Non-hazardous |

| Class 1M | Very low | Safe under reasonably foreseeable conditions of operation, but may be hazardous if the user employs optics within the beam | Fibre-optic communication systems | |

| Class 2 | <1 mW | Amusement laser guns Laser pointers Barcode scanners | ||

| Class 2M | <1 mW | level and orientation instruments for civil engineering applications | ||

| Class 3R | 1-5 mW | Alignment lasers | ||

| Class 3B | 5-500 mW | Immediate skin hazard from direct beam and immediate eye hazard when viewed directly. | Lasers for physiotherapy treatments | Wear eye and skin laser protection equipment |

| Class 4 | >500 mW | Laser projection displays Laser surgery devices Laser cutting devices | Wear eye and skin laser protection equipment |

*Any laser device can be reclassified as a Class 1 with proper enclosures installed and safeguards in place.

¶ 3. Laser Warning Label

(To be updated)

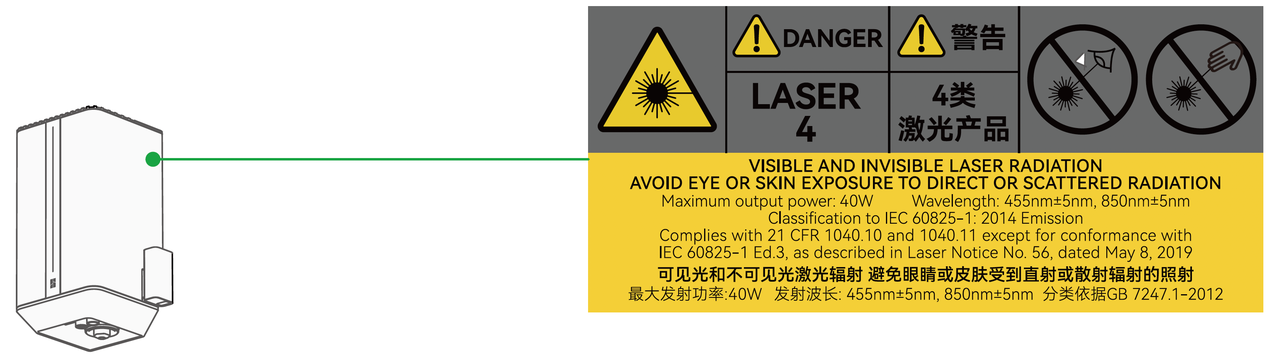

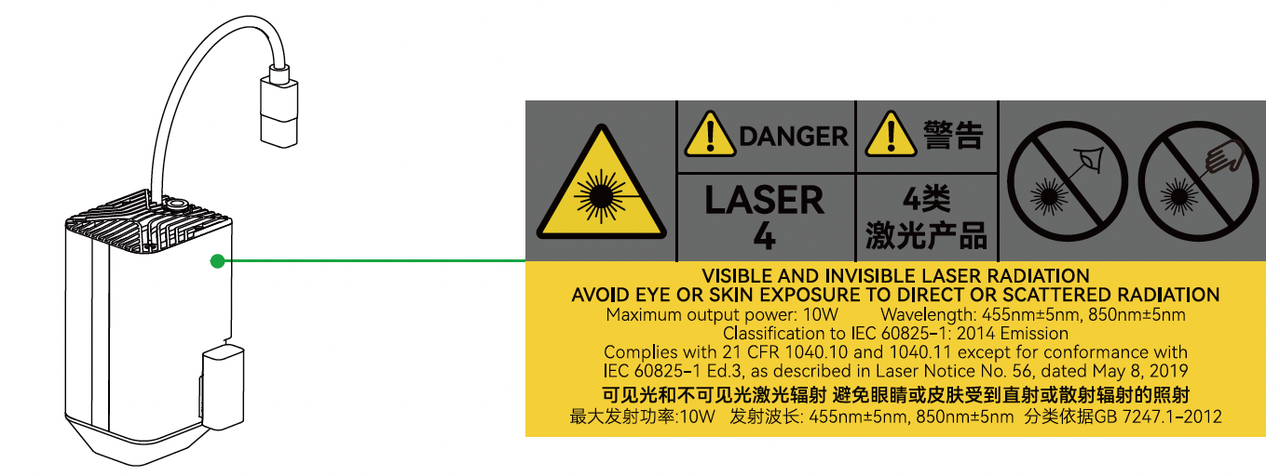

Printer body marking style;

- 10 W:

- 40 W:

Location on the printer;

10 W:

40 W:

Information on the emergency stop button

¶ 4. Laser technical specifications

| Item | Specification |

|---|---|

| Laser Type | Semiconductor Laser |

| Laser Wavelength | 455 nm ± 5 nm Blue Light 850 nm ± 5 nm Infrared Light |

| Laser Power | 10 W ± 1 W |

| Laser Spot Dimension | 0.03 mm * 0.14 mm |

| Working Temperature | 0 ℃-35 ℃ |

| Max Engraving Speed | 400 mm/s |

| Max Cutting Thickness | 5 mm (Basswood Plywood) |

| Laser Safety Class for Laser Module | Class 4 |

| Overall Laser Safety Class* | Class 1 |

| Engraving Area | 310 mm * 270 mm |

| Processing Height Range | 0 mm-280 mm |

| XY Positioning Method | Visual Positioning |

| XY Positioning Accuracy | < 0.3 mm |

| Z Height Measuring Method | Micro Lidar |

| Z Height Measuring Accuracy | ± 0.1 mm |

| Flame Detection | Supported |

| Temperature Detection | Supported |

| Door Sensor | Supported |

| Laser Module Installation Detection | Supported |

| Engraving Timelapse | Supported |

| Safety Key | Included |

| Air Pump | Built-in; 30 kPa, 30 L/min |

| Ventilation Pipe Adapter Outer Diameter | 100 mm |

| Supported Material Type | Wood, rubber, metal sheet, lether, dark acrylic, stone, and more |

* When the printer's protection is complete and properly working, the printer and laser module work as a class 1 laser product.

¶ 5. Safety instructions and protection

¶ 5.1 Laser safety guideline:

¶ 5.1.1 Training:

All personnel working with lasers should receive appropriate training on laser safety, including understanding the classification system and handling procedures.

Especially make sure that you have completed laser safety training before working with either a class 3B or 4 laser.

¶ 5.1.2 Warning Signs:

Clearly mark laser-controlled areas with appropriate warning signs indicating the class of laser and potential hazards.

¶ 5.1.3 Eyewear using:

Match eyewear to laser device with laser wavelength and OD value;

Inspect the lens, to see if any blemishes, pits/digs, surface scratches, coating tack;

Inspect the frame, to see if any broken, cracked, loosed strap;

Evaluate the fit with gaps between frame and face;

Place and store the eyewear properly in accordance with the manufacturer's requirements.

¶ 5.1.4 Emergency Procedures:

Make a plan in place for handling laser-related accidents in advance, including first aid and emergency contact information.

Disabling machine (Emergency Off, shut-down, unplug)

Seek medical attention (if needed)

Contact Radiation Protection for an incident review

¶ 5.2 Safe Work Practices

Do not intentionally look directly into laser light;

Use the laser strictly in accordance with manufacturer’s instructions;

Do not fight the eye’s blink or aversion response;

Never direct the beam toward people;

Operate lasers only in the area designed, never allow a laser beam to escape its designated area of use;

Remove all unnecessary reflective objects from the area near the beam path, including watches, jewelry, or tools;

When not in use, the laser module should be stored to prevent unauthorized use.

¶ 6. Read before use

Before using the laser module, please read and follow these safety guidelines to ensure safe and proper operation.

General safety:

Keep your workspace clean and organized, ensuring that tables, shelves, and any structures holding the device are stable and secure.

Inspect the device thoroughly for any signs of damage before use. If damage is detected, stop using the device immediately.

Always ensure a person is present to supervise the laser module in operation to promptly address any fire hazard.

This device is not recommended for operation by minors. Please place the device in a location inaccessible to them to prevent accidents.

Do not operate the laser module without proper guidance.

When the laser module is working, ensure the area near the device is free from bystanders, children, and pets.

After each task completes, remove all debris from the laser platform to prevent the risk of fire hazards.

Do not disassemble or alter the device's structure, parts and operating methods unless directed by Bambu Lab support.

Operate the laser module within a temperature range of 0°C to 35°C and store it between -10°C and 40°C. Avoid operating or storing the laser module outside these specified temperatures to prevent damage.

Laser safety:

The laser module operates within a closed casing equipped with safety interlocks, which prevents direct contact with the laser. The laser module stops working if the front door, top glass cover, or safety window is opened. For safe use, please read and follow these safety precautions.

Never operate the device with any part removed to avoid harming your health and damaging the device.

Please make sure that the smoke exhaust system is correctly installed and secured, including the ventilation pipe adapter, ventilation pipe, and other related parts. If smoke or unusual odor occurs, please immediately check and adjust the smoke exhaust system.

Do not engrave or cut materials that could release harmful gases. Please note that if you engrave or cut materials that you do not know about the properties, or that could release harmful gases, such as PVC, it may damage your health or the device.

Please ensure the exhaust system is correctly installed and operate the device in a well-ventilated environment to avoid the risk of smoke causing respiratory issues. If any symptom occurs, stop using the device immediately and seek medical attention.

Do not operate the laser module unless it is correctly installed with all safety locking and detection mechanisms active.

Always fully close the front door and top glass cover while the laser is in use, and do not change any part related to safety.

For your safety, avoid looking directly at the laser emission point if any protective plate is open and the module is powered on.

Under any circumstances, do not look at the laser spot or reflected light through the front door, laser safety windows, or other openings for prolonged periods to eye discomfort. If any symptom occurs, stop looking immediately, and close your eyes, or look into the distance to rest. If symptoms persist, please seek medical attention immediately.

Read and follow our safety guidelines, including notes on the printer and the safety document. Also, refer to these laser safety standards for additional guidance: EN 60825-1:2014 + A11:2021 (Europe), IEC60825-1:2014 (International), ANSI Z136.1-2022 (US), and GB 7247.1-2012 (China).

Fire safety:

Familiarize yourself with fire safety protocols and have fire extinguishing equipment on hand, including sprinklers and CO2 fire extinguishers, that are properly and regularly maintained.

Keep flammable, explosive or volatile substances like paper, alcohol and gasoline away from the device to prevent accidental ignition.

Organic materials, such as basswood and acrylic, have a high likelihood of producing open flames. Always monitor the interior of the printer closely when working with these materials, and use a CO2 fire extinguisher or other measures immediately if flames occur.

Ensure the smoke exhaust system is properly working during operation to dissipate smoke. At the same time, we recommend ensure proper ventilation in your work area.

Regularly clean the device and workspace to remove any debris to prevent fire risks.

Warning sign:

This page will be continuously updated. Please visit at any time for the latest information.

Video guidance

https://public-cdn.bblmw.com/wiki/H2D/safety-guidelines/Laser-safety-guidelines-EN.mp4

¶ 7. LSO

(To be updated)

LSO is short for Laser Safety Officer. The LSO is the person who has responsibility for the management of risk, and the authority to ensure compliance with all applicable standards and rules. This person should be competent to assess all systems, and validate the knowledge and skills of all personnel involved in the laser practice.

The LSO can be a risk manager, an Occupational health and safety officer, or other properly qualified person.The LSO is the contact person and spokesperson for the laser program, should there be an audit, a medical-legal situation, a compliance inspection, or questions from accrediting bodies.

There must be only one LSO but in his or her absence from the facility during any use of the laser, there should be someone designated as a deputy LSO, (DLSO) who has equal levels of authority, responsibility, and knowledge. The duties of the LSO will vary depending on the size and scope of the laser facility. However, standards do require the LSO to be responsible for:

¶ 8. Program control

(To be updated)

¶ 9. Disclaimer

¶ Disclaimer and Warning

Thanks for purchasing a Bambu Lab product. The information in this document affects your safety and your legal rights and responsibilities. Read this entire document carefully to ensure proper configuration before use. Failure to read and follow instructions and warnings in this document may result in serious injury to yourself or others, damage to your Bambu Lab product, or damage to other objects in the vicinity. This document and other collateral documents are subject to change at the sole discretion of Bambu Lab.

By using this product, you hereby signify that you have read this disclaimer and warning carefully and that you understand and agree you are solely responsible for your own conduct while using this product, and for any consequences thereof. You agree to use this product only for purposes that are proper and in accordance with all applicable laws, rules and regulations, and all terms, precautions, practices, policies, and guidelines Bambu Lab has made and may make available. Bambu Lab accepts no liability for damage, or injury or any legal responsibility incurred directly or indirectly from the use of the product. The user shall observe safe and lawful practices including, but not limited to, those set forth in this document.

Bambu lab is a trademark of Shenzhen Tuozhu Technology Co., Ltd. and its affiliated companies. Names of products, brands, etc., appearing in this manual are trademarks or registered trademarks of their respective owner companies.

¶ Before You Start

The following documents have been produced to help you safely operate and make full use of your

Bambu Lab H2 Series Laser Module:

Bambu Lab H2 Series Laser Module Disclaimer and Safety Guidelines

Bambu Lab H2 Series Laser Module Quick Start Guide

Check that you have all the included parts. Please review the entire Quick Start Guide before operating the laser module.

Read the Disclaimer and Warning above to understand your legal rights and responsibilities. If you have any questions or problems during the installation, maintenance, or use of this product, please contact a Bambu Lab authorized dealer.

¶ Safety Guidelines

The product shall be used by personnel with necessary training, knowledge and experience.

The product must be properly assembled with Bambu Lab H2 series printers for use.

The product must be disconnected from the power supply before carrying out any installation or maintenance work.

Installation and maintenance must be carried out by a skilled worker in compliance with the manufacturer’s instructions and local safety regulations.

Do not touch the product with any wet part of the body and do not operate it while barefoot.

Do not reach inside the product while it is in operation.

Do not open any access panels of the product, including front door, top cover and side covers when the laser is working.

Do not operate the product when any parts of it are removed or missing.

Do not leave the product unattended when the laser is working.

The product is not allowed to be used by children. Please place the product out of the reach of children.

This product is designed solely for indoor use. It should be kept in a dry environment, the recommended humidity level is under 85%.

The recommended operating temperature for the product is between 10℃ to 30℃ (50℉-86℉).

The product should be positioned on a clean, stable and flat workbench.

The product should be kept in a well-ventilated location.

¶ Compliance Information

FCC Compliance Notice

Supplier’s Declaration of Conformity

Product name: Bambu Lab Laser Module 10W

Model number: SL001

Responsibility Party: Shenzhen Tuozhu Technology Co.,Ltd.(Bambulab USA Inc)

Responsibility Party Address: 8000 Centre Park Drive, STE 330, Austin, TX, 78754

Website: www.bambulab.com

We, Shenzhen Tuozhu Technology Co.,Ltd.(Bambulab USA Inc), being the responsible party, declares that the above mentioned model was tested to demonstrate compliance with all applicable FCC rules and regulations.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) This device must accept any interference received, including interference that may cause undesired operation. Warning: Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

ISED Compliance Notice

This device contains license-exempt transmitter(s)/receiver(s) that comply with Innovation, Science and Economic

Development Canada’s license-exempt RSS(s). Operation is subject to the following two conditions: (1) This device may not cause interference. (2) This device must accept any interference, including interference that may cause undesired operation of the device.

¶ Notice

VISIBLE AND INVISIBLE LASER RADIATION

DO NOT STARE INTO BEAM

Max. Output Power: 10W

Emission Wavelength: 455nm±5nm, 850nm±5nm

CLASS 4 LASER PRODUCT

Classification to IEC 60825-1: 2014, EN 60825-1: 2014+A11:2021, GB 7247.1-2012, BS EN 60825-1:2014+A11:2021 and AS/NZS 60825-1:2014.

Complies with 21 CFR 1040.10 and 1040.11 except for conformance with IEC 60825-1 Ed.3, as described in LaserNotice No. 56, dated May 8, 2019.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!