¶ Belt Tensioning

The correct belt tension is essential to a core XY motion system. A loose belt or belt slop, can cause lots of issues in 3D printing, such as circles looking like ovals.

The belt and the gantry form a mass-spring system, with the belt being the spring (k) and the gantry being the mass (m). The natural frequency of the system is f = sqrt (k/m). Having a loose belt reduces the k, and the f, which in turn affects vibration compensation.

H2D monitors belt tension through this equation f = sqrt (k/m). During calibration, the motors will generate vibrations at various frequencies and look for the resonance, which happens when the input frequency is equal to the natural frequency. We call this operation frequency sweep, and it generates quite some noise with an increasing pitch.

When the H2D finds that the natural frequency has changed, it is time to tighten the belt. It is a semi-automatic process and can be done with a simple operation.

¶ Belt Tensioning Steps

IMPORTANT: Power OFF the printer first.

¶ XY-Belt Tensioning

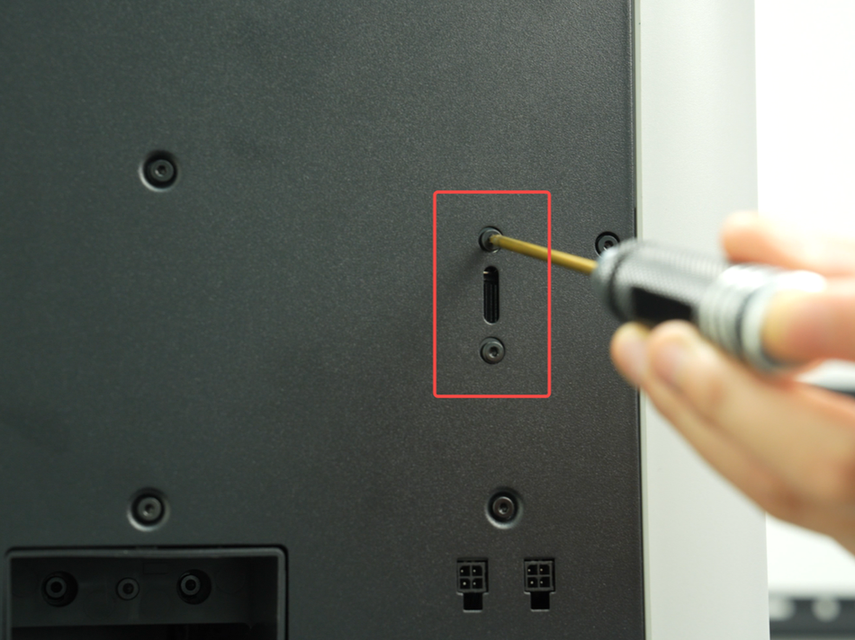

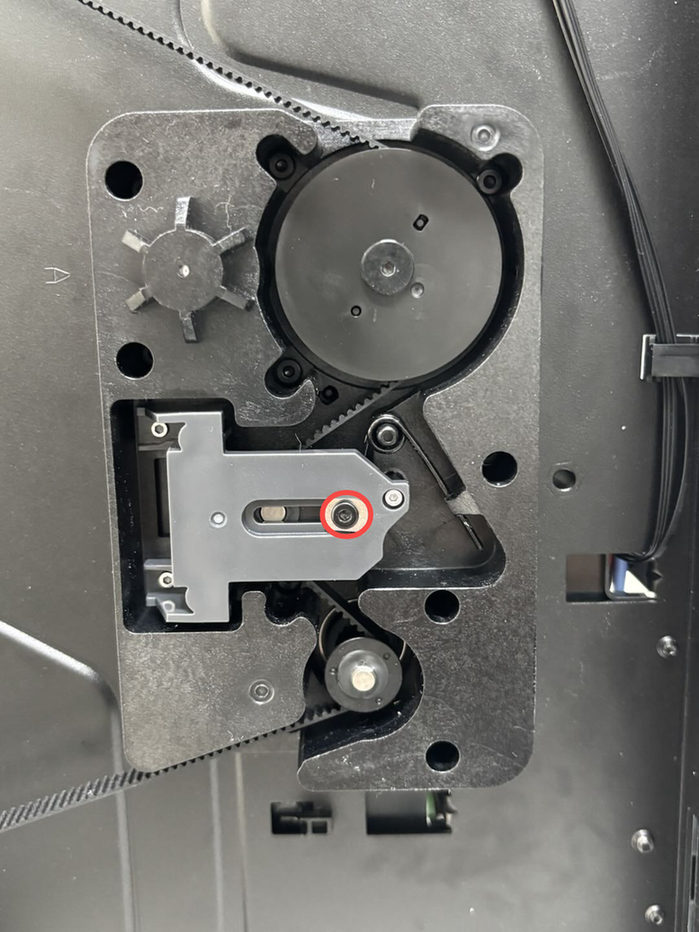

- Loosen the 4 screws of the belt-tensioner. Loosen the screw 1-2 turns; do not remove it.

|

|

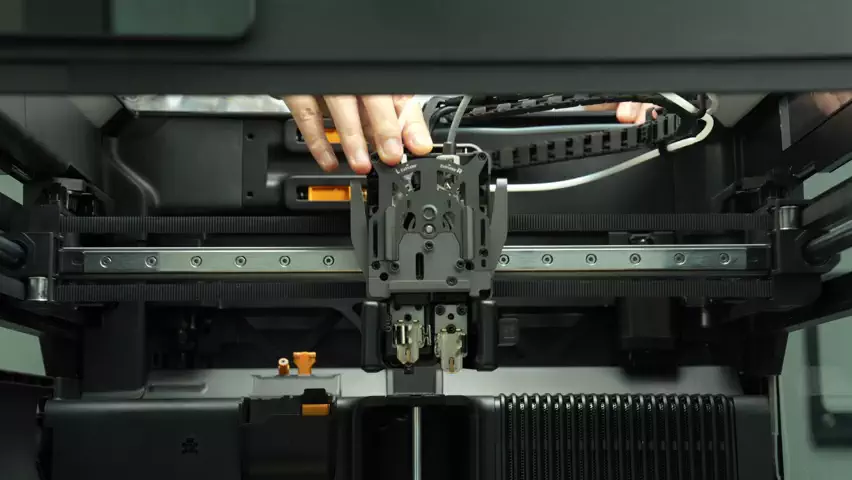

- Gently move the toolhead back and forth several times, and finally move it to the rear end of the printer.

*The diagram illustrates tool head positioning; the hotend does not need to be detached.

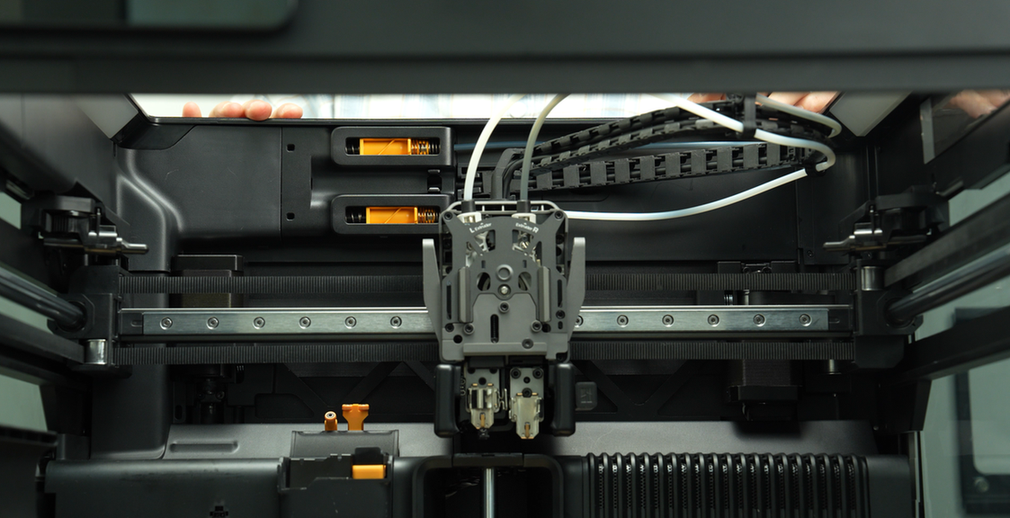

After positioning, ensure the tool head and X-Axis alignment matches the picture below before proceeding.

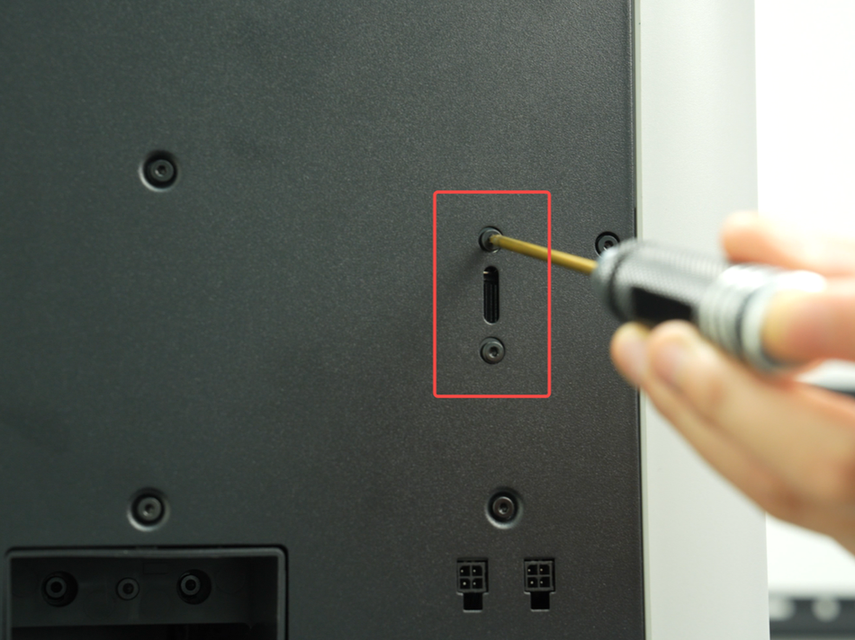

- Tighten the 4 screws again. The spring system in the belt-tensioner will tighten the belt to the correct tension.

|

|

IMPORTANT: DO NOT overtighten the belt tensioning screws. Doing that can cause damage and will not provide better results. Simply tighten both screws like any other screws and don't over-torque them.

¶ Z-Belt Tensioning

Remove the top glass cover, place the printer at an angle, and use an H2.0 screwdriver to loosen the tensioner screw. (Do not remove the screw)

Pull the Z-axis belt back and forth 3-5 times by hand to ensure smooth movement, then use an H2.0 hex key to tighten the Z-axis tensioner slider fixing screw (M3x6).

After tightening, place the printer back upright on a stable table/ground and cover it with the top glass cover.

Since the printer is relatively heavy, it is recommended to have two people operate together to avoid damage caused by this.

¶ Calibration

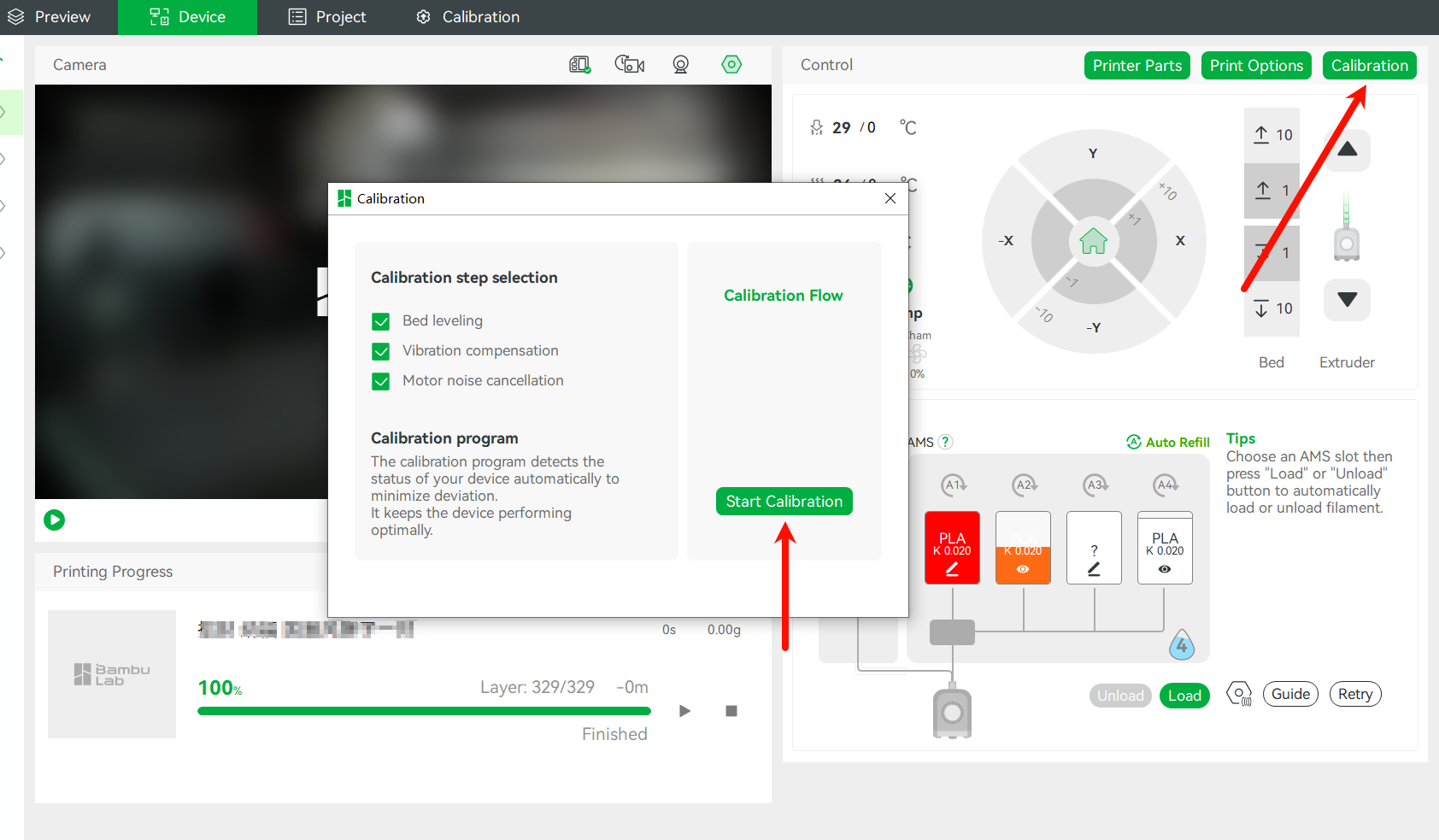

After the belt tensioning operation is completed, the resonant frequency identification needs to be recalibrated to record the new resonance characteristics of the equipment.

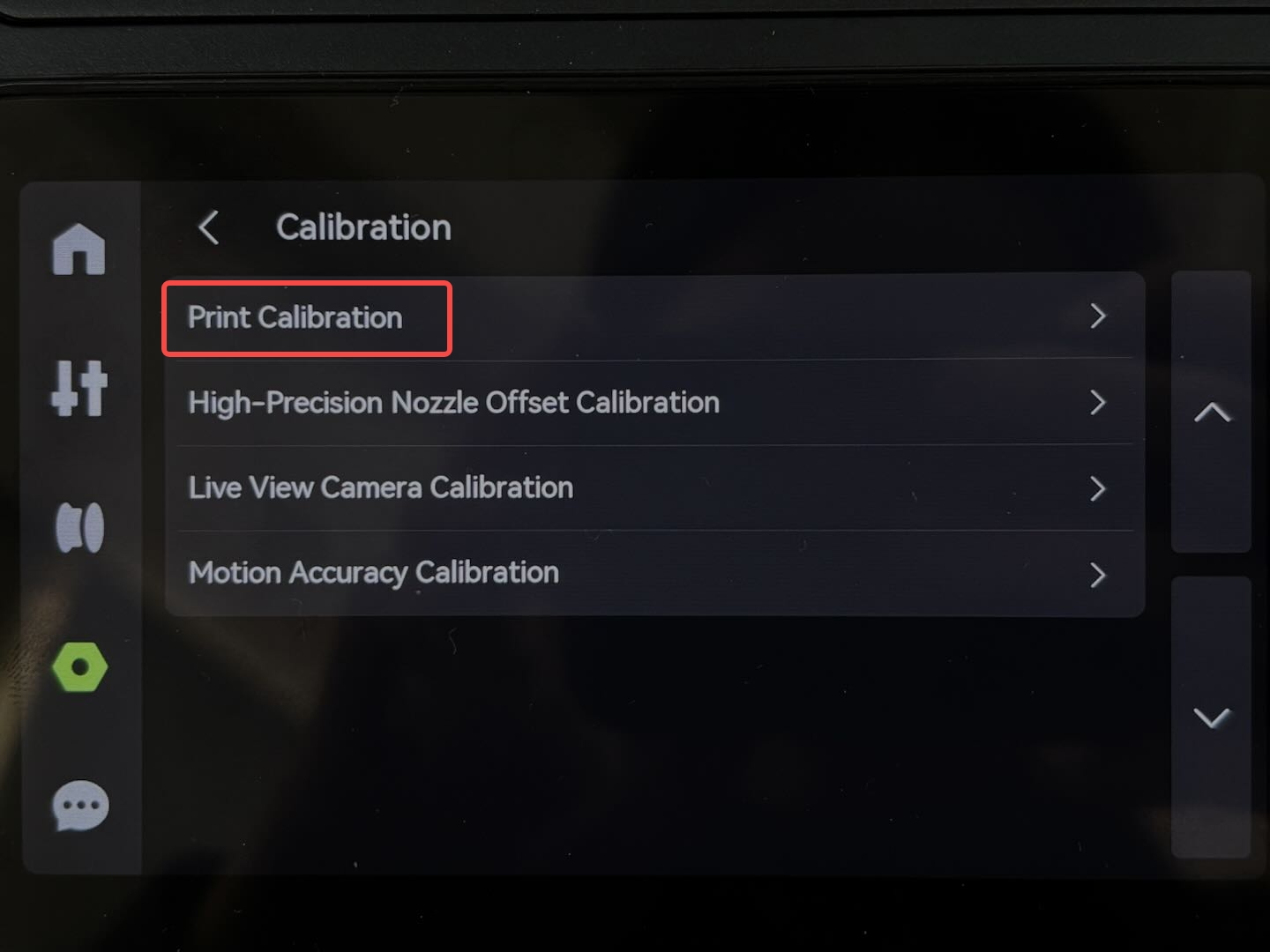

The H2D printer can be calibrated from the screen or Bambu Studio.

|

|

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!