Wiki in additional languages can be found below:

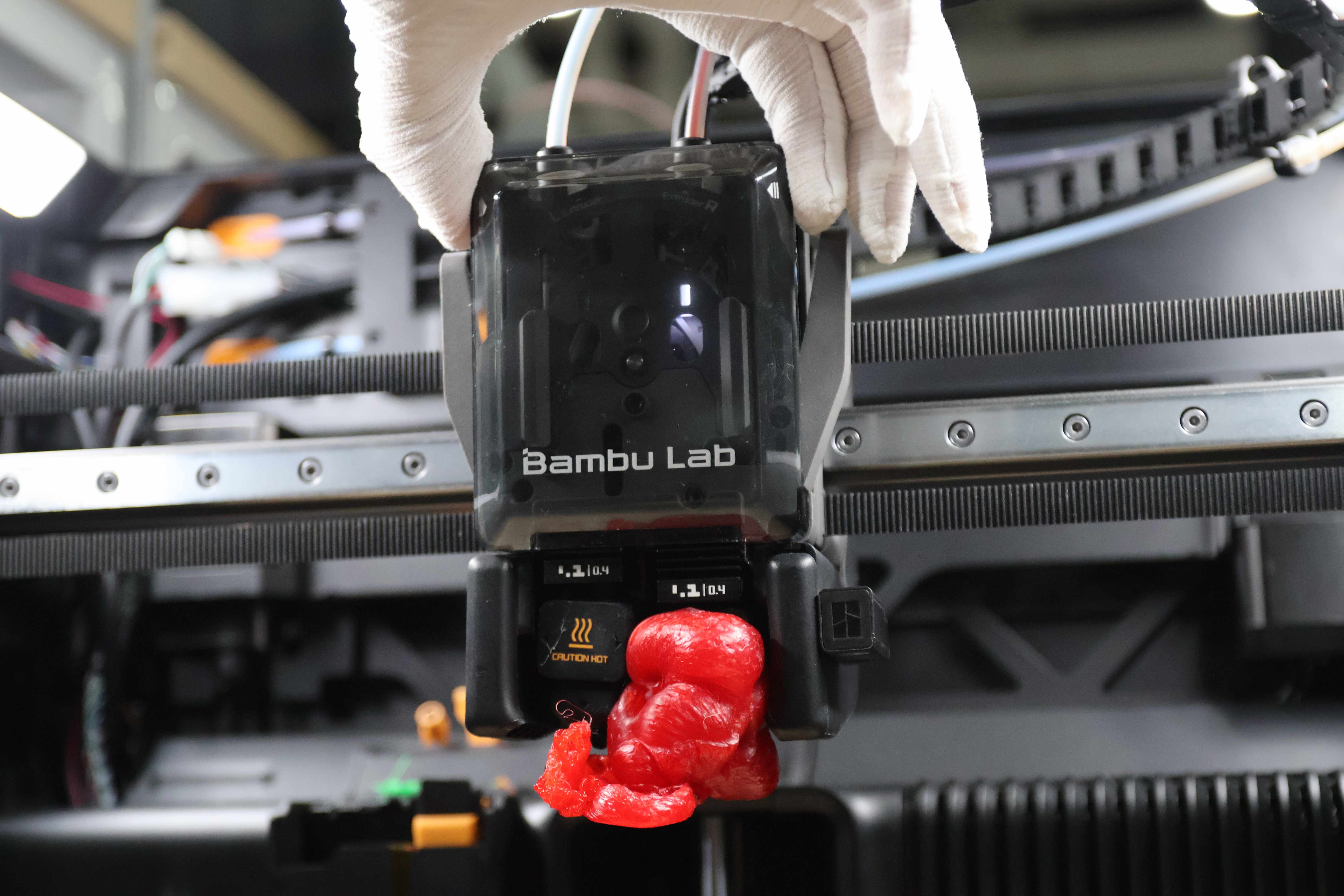

¶ Hotend Clumping

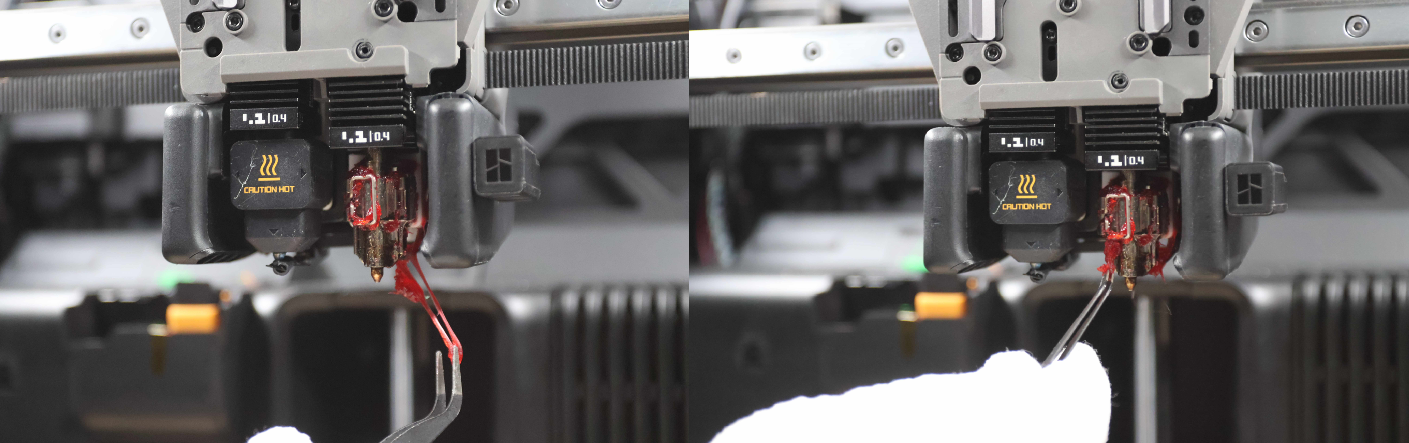

Hotend Clumping, also called Hotend Blob is a mass of plastic accumulated around the hotend. When the model detaches during the first few layers of printing for various reasons, it may adhere to the nozzle. As the nozzle continues to extrude, this can result in a more serious “clumping” issue.

¶ Tools and materials needed

- Hair dryer (High-temperature setting)

- Flat head tweezers

- Tissue paper

- Heat protective gloves

¶ Safety Warning

IMPORTANT!

When you perform maintenance or troubleshooting on the printer, please first confirm the temperature of the hot end and hot bed to avoid operating at high temperatures. If you must operate at high temperatures, please wear heat protective gloves to ensure safe and effective execution.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Operation Guide

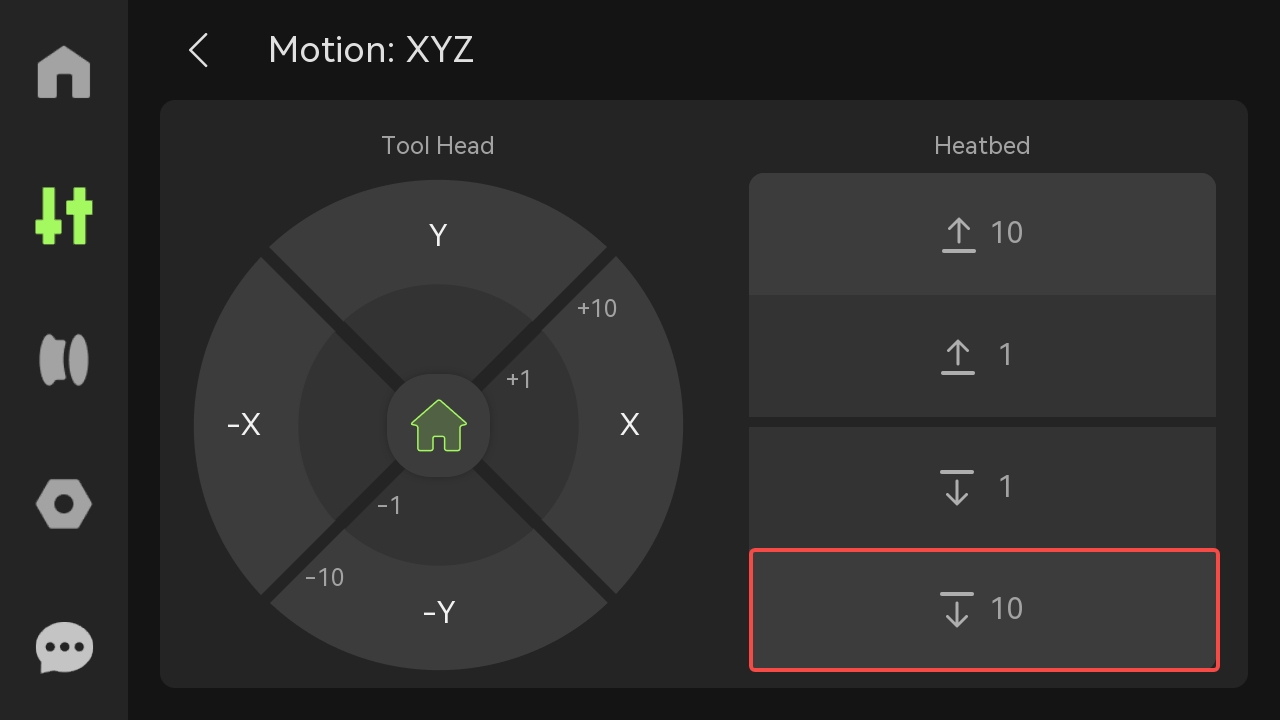

¶ Lower the Heatbed

Click the on-screen button to lower the heatbed to increase operating space.

Note: Do not click the Home button to avoid collision and potential secondary damage.

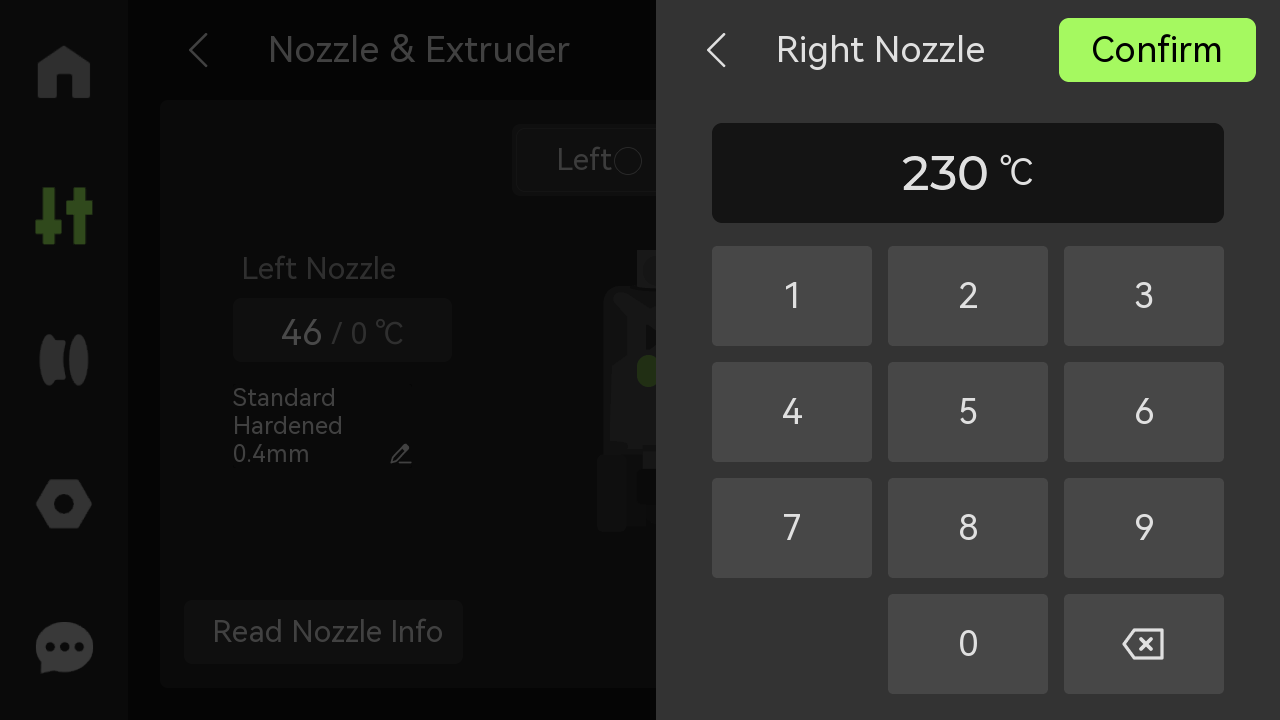

¶ Heat the Nozzle

Set the nozzle temperature slightly higher than the printing temperature of the filament to soften it.

For example, with PLA, heat the nozzle to 230°C. Once the temperature stabilizes, wait for 1 minutes before proceeding to the next step.

Note:For safety reasons, when the printer is not in its normal working condition, the hotend will automatically stop heating after being maintained at a high temperature for a certain period of time. If you have not completed the necessary processing within this time, please remember to reheat the hotend.

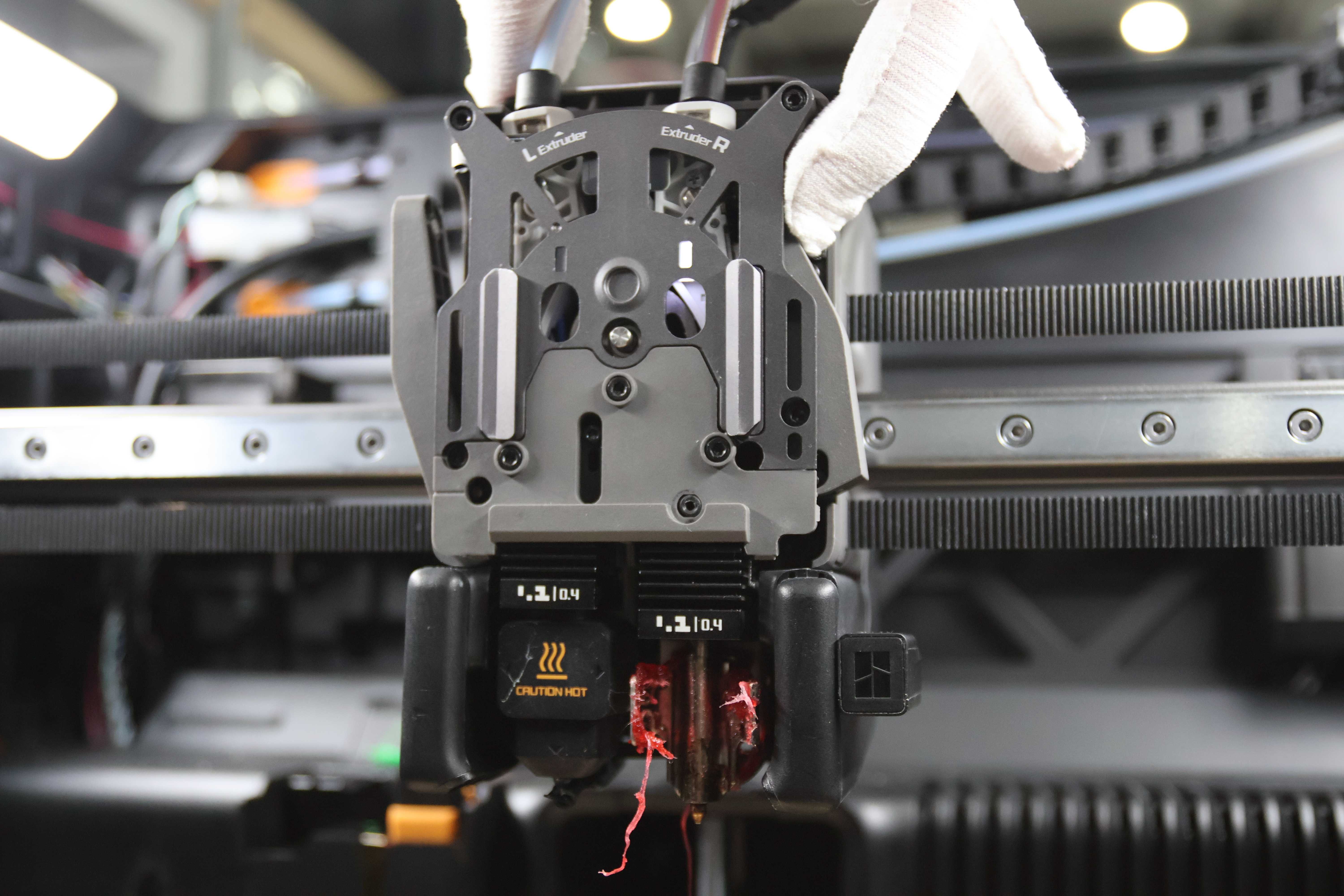

¶ Remove the Toolhead Front Cover

Wearing heat protective gloves, pinch the top of the toolhead front cover to remove it.

¶ Remove the Silicone Sock for Hotend

Gently pull down on the silicone sock for hotend that is covered with filament to remove it from the toolhead.

Note: At this time, since the temperature of the silicone sock is high, you can try to remove the filament from the silicone sock; if you cannot remove it, please refer to the steps in the following "Clean the Silicone Sock for Hotend" to clean it.

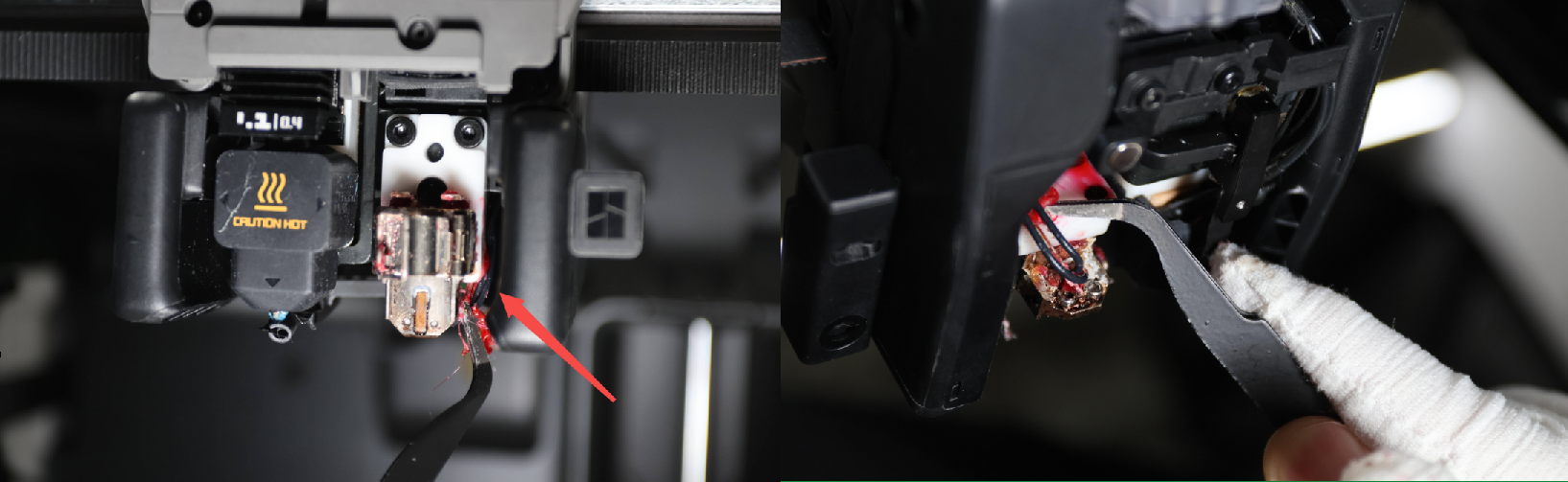

¶ Clean the Hotend Heating Assembly and Hotend

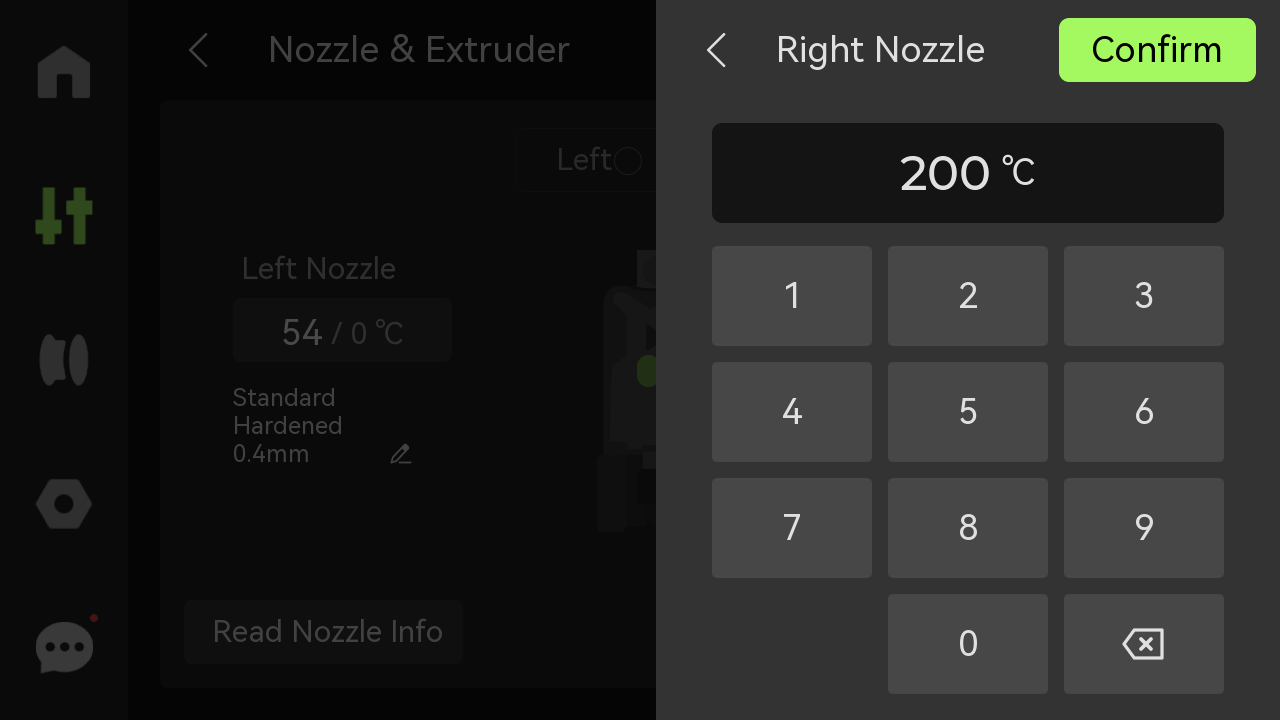

- To prevent the filament from smoking, the nozzle temperature needs to be lowered to 200°C;

- Use tweezers to carefully remove the filaments around the hotend heating assembly;

Note: Be careful not to damaging the heating assembly cable.

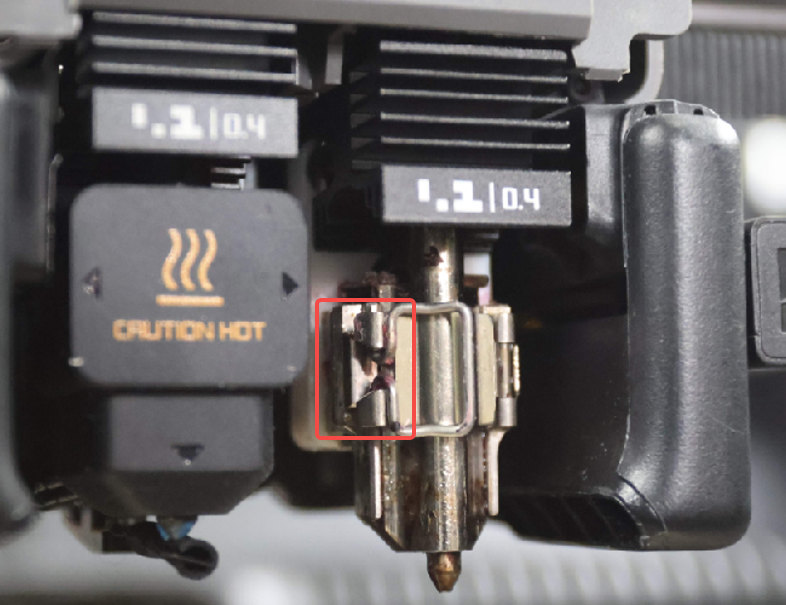

- Press the cutter to cut the filament;

- Open the buckle and pinch the hardened steel part to remove the nozzle;

- Use tweezers to remove large pieces of filament from the hotend. The remaining filament will be cleaned after the hotend is installed.

- Continue to clean the remaining filaments on the hotend heating assembly;

At the same time, carefully clean the heating assembly cables and the filaments behind the heating assembly.

Note: Be careful during this step to avoid using excessive force which may cause the cable to break.

- After cleaning, wipe it with a tissue paper for a second clean.

- At this point, the hotend heating assembly is clean.

¶ Clean the Silicone Sock for Hotend

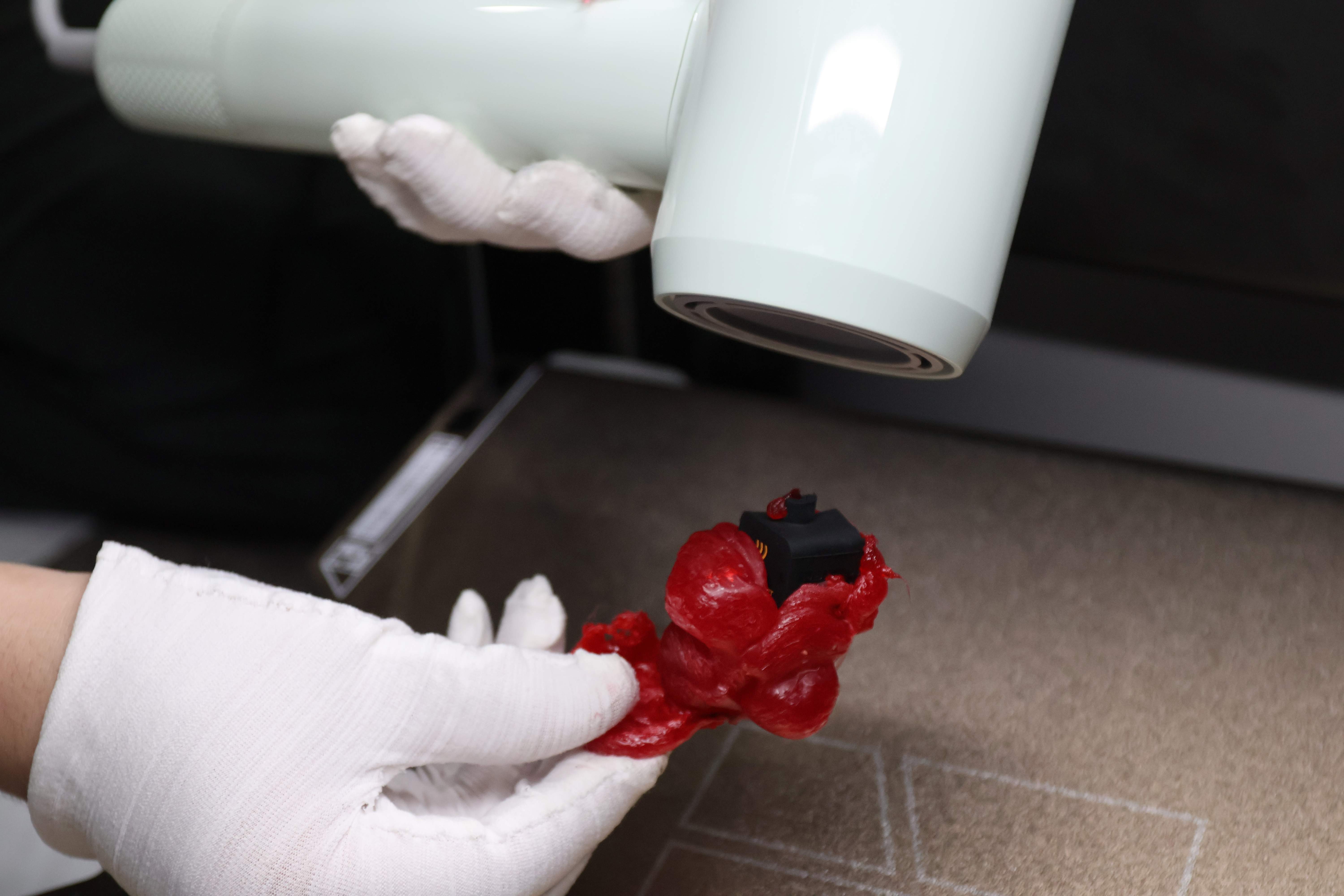

- Using a hair dryer with the high-temperature setting, blow dry the silicone sock for 1-2 minutes until the filament begins to soften.

Note: When using a hair dryer, be careful not to blow for too long or too close.

- After removing the large pieces of residue, use tweezers to continue cleaning the remaining filaments in the silicone sock.

Note: If there is damage to the silicone sock, it should be replaced so it does not cause a failure during printing.

Purchase link: Silicone Sock for Hotend - H2D

¶ Install the Hotend and Silicone Sock for Hotend

- Reinstall the cleaned hotend back into the toolhead;

- Use a tissue paper to wipe off any remaining filament on the hotend surface;

- After cleaning, fasten the heating assembly buckle;

Note: The middle section of the buckle needs to be buckled correctly.

- Reinstall the silicone sock for hotend.

¶ Verify the Functionality

¶ Extrusion Test

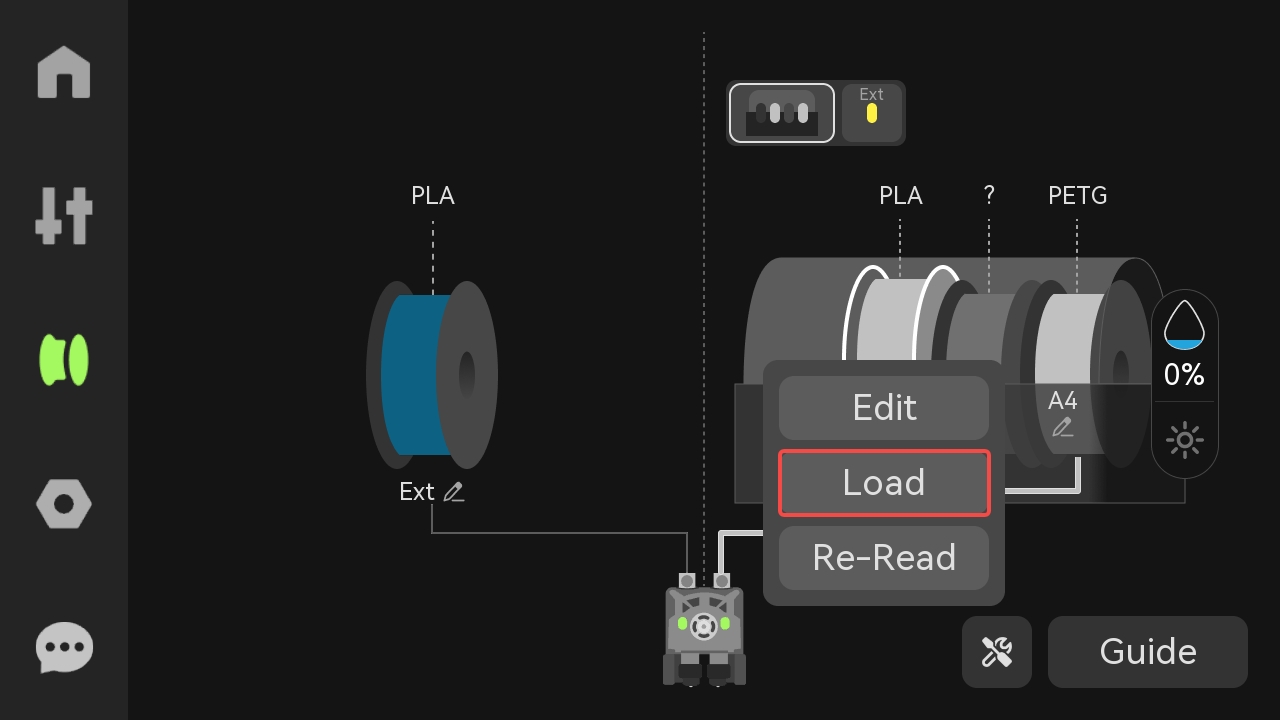

Click the "Load" option on the screen to observe whether the filament is extruded normally;

¶ Nozzle Offset Calibration

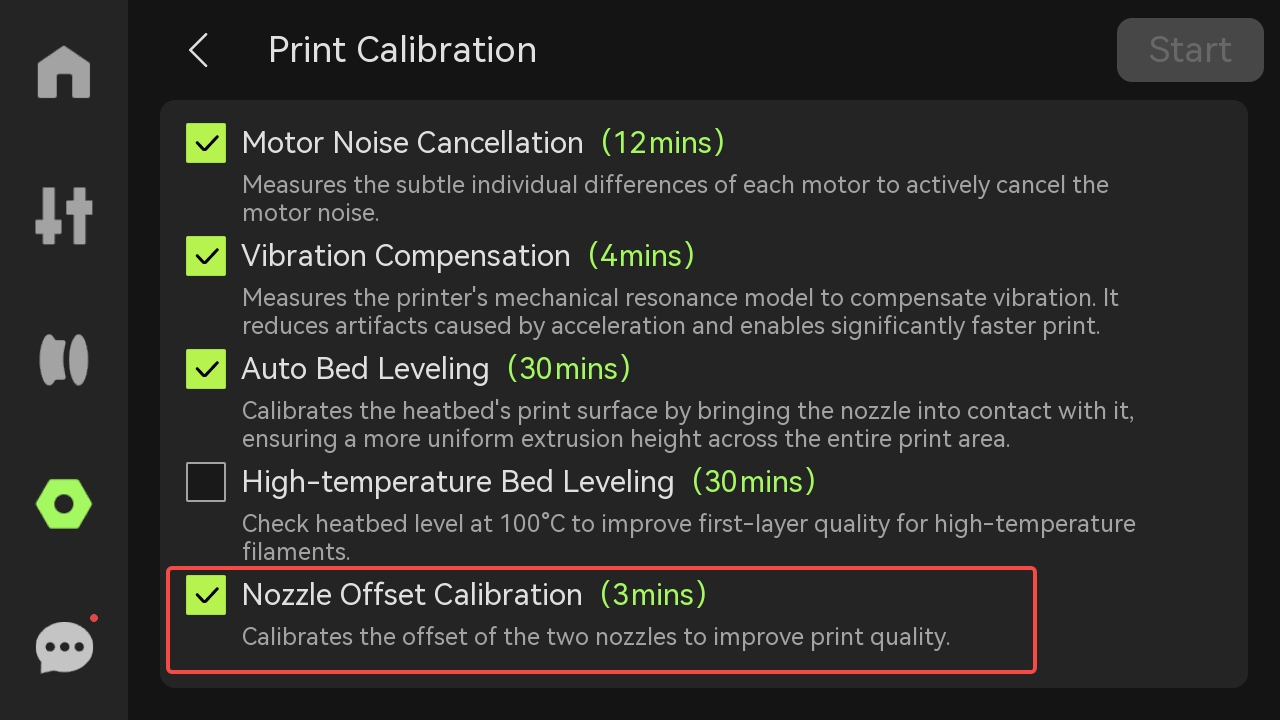

After reinstalling the nozzle, the nozzle offset may change. To obtain high-quality printing, please perform nozzle offset calibration.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!