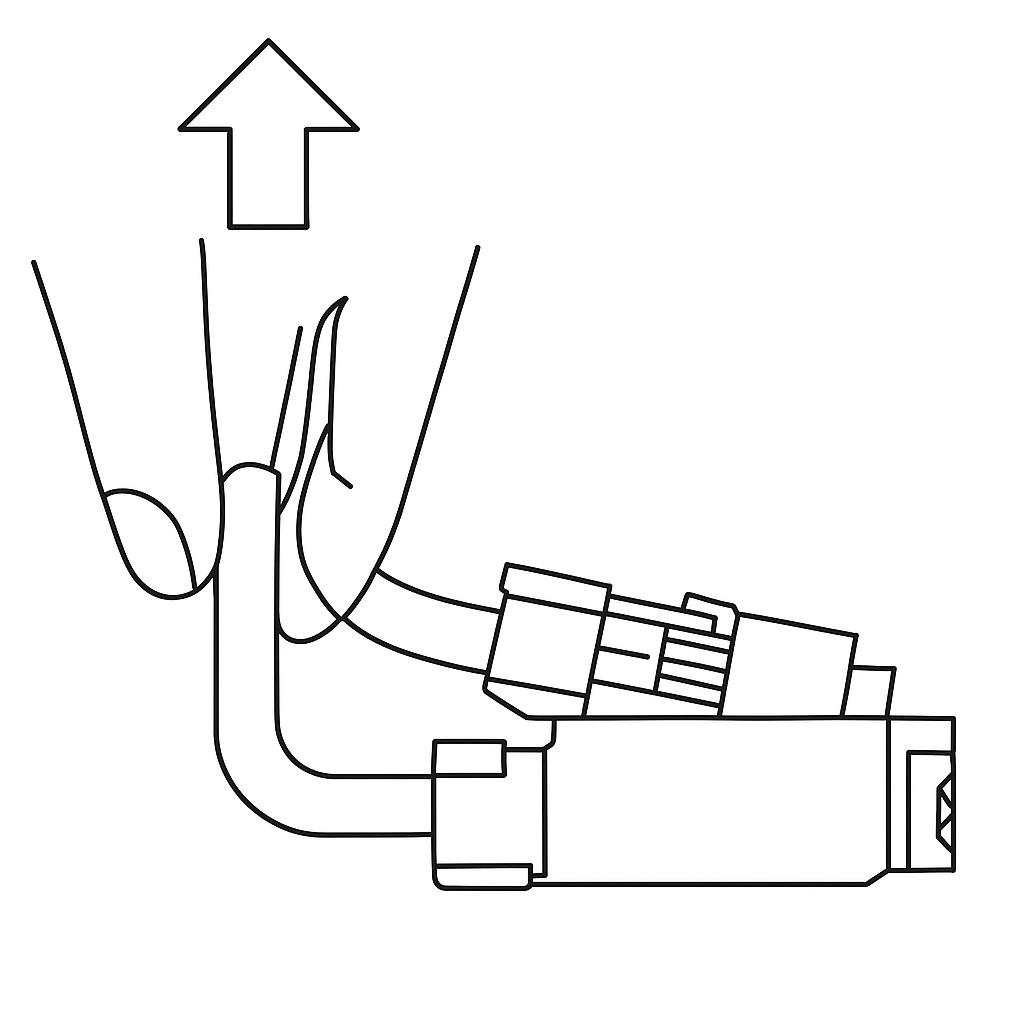

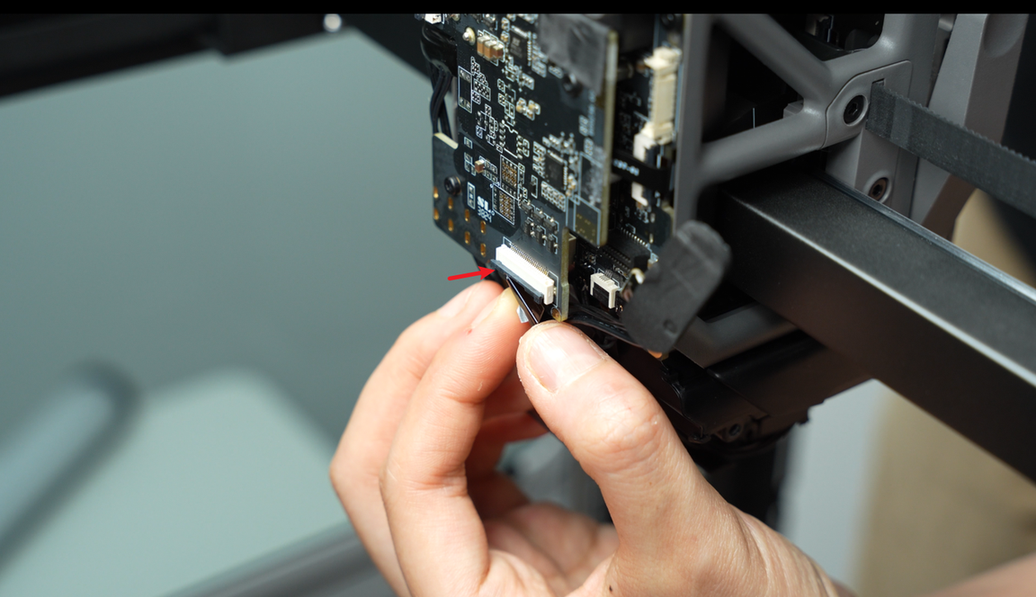

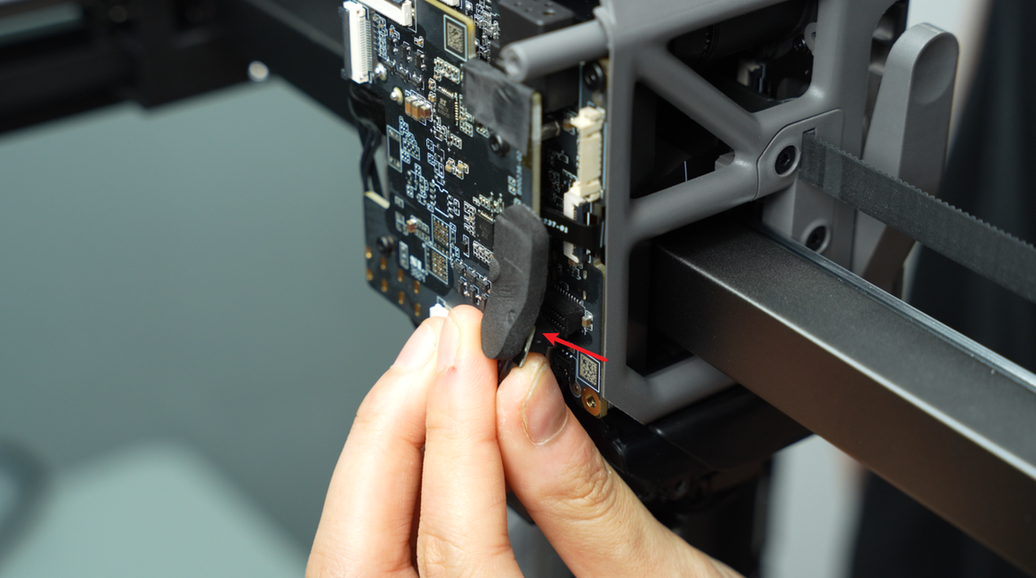

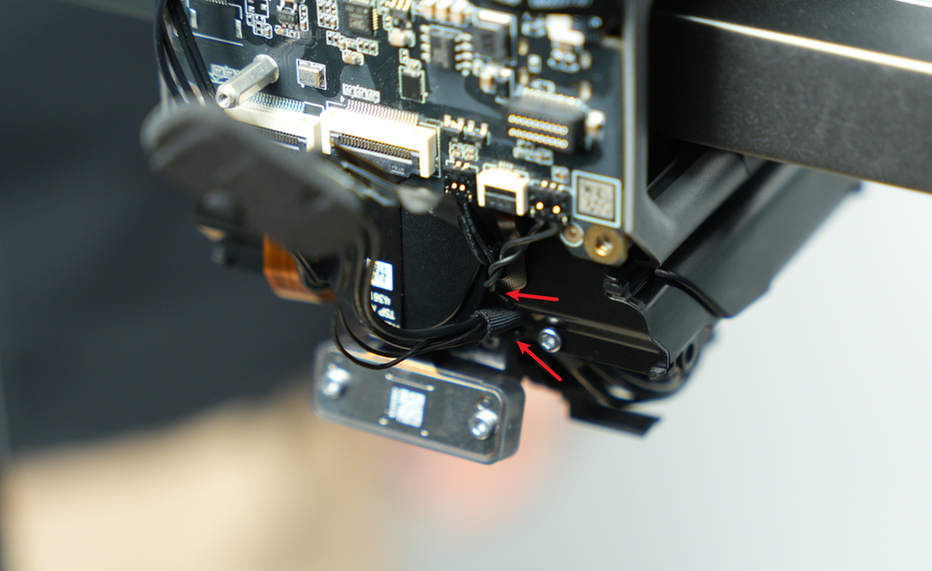

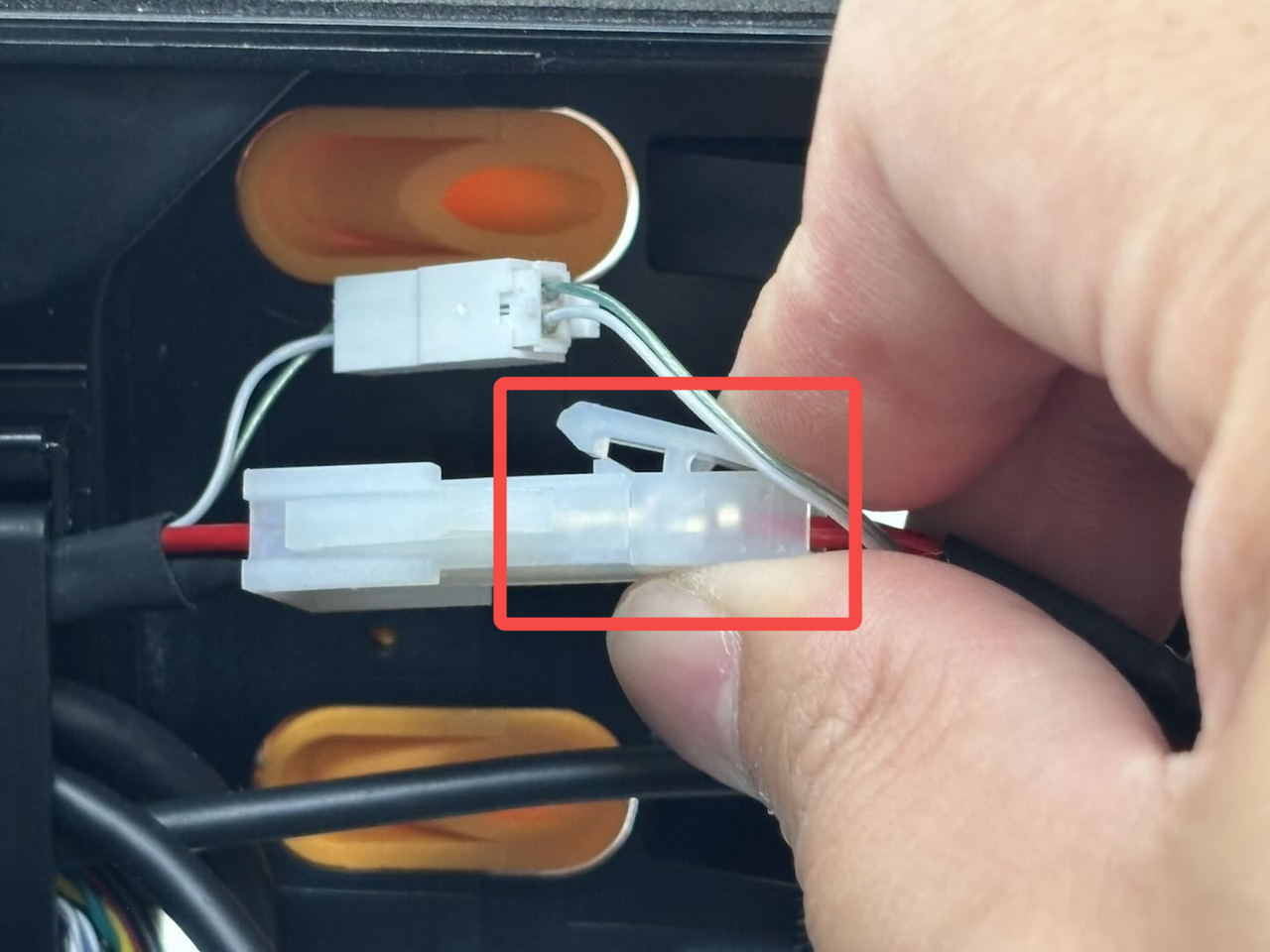

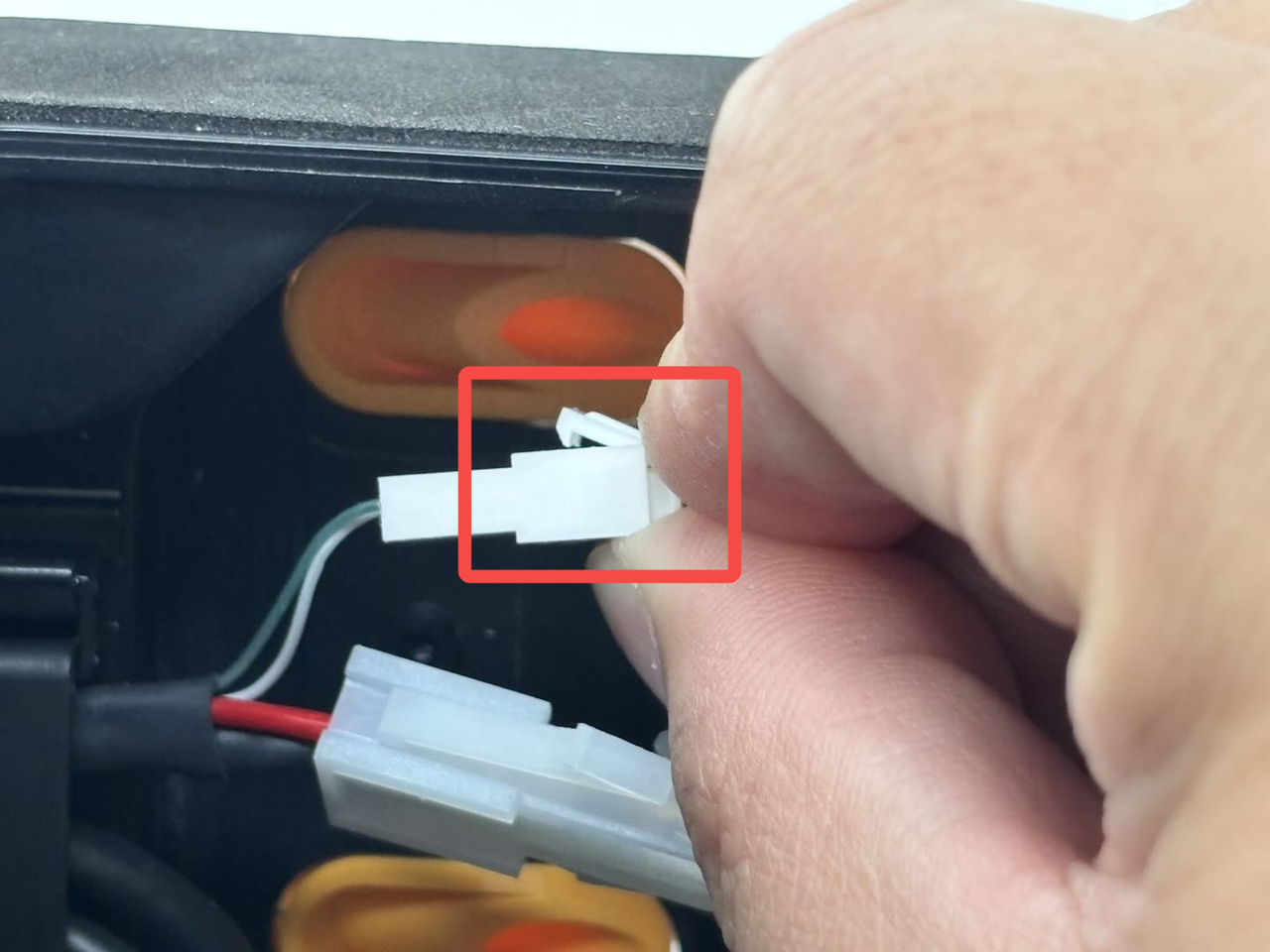

¶ Important Reminder

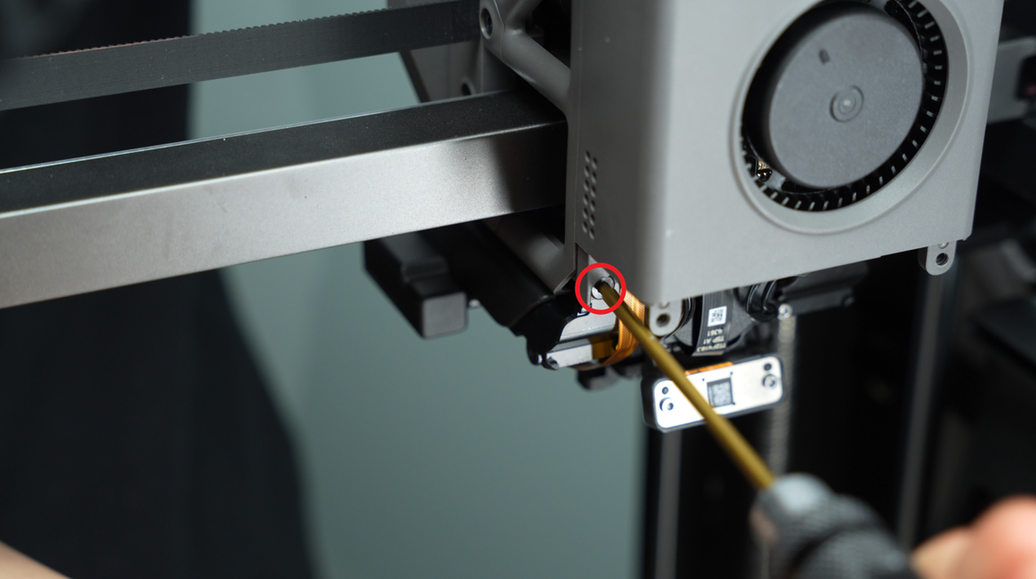

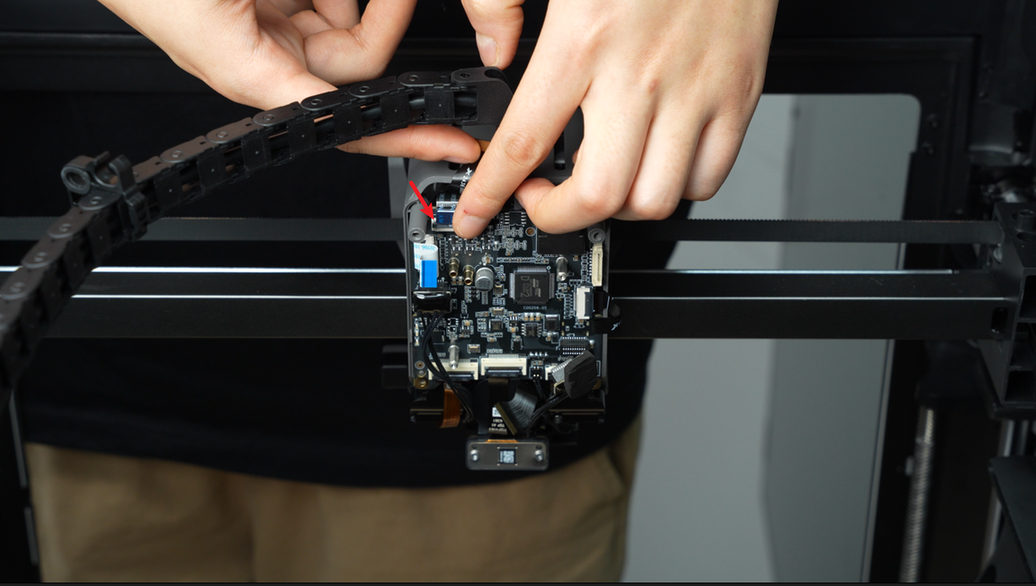

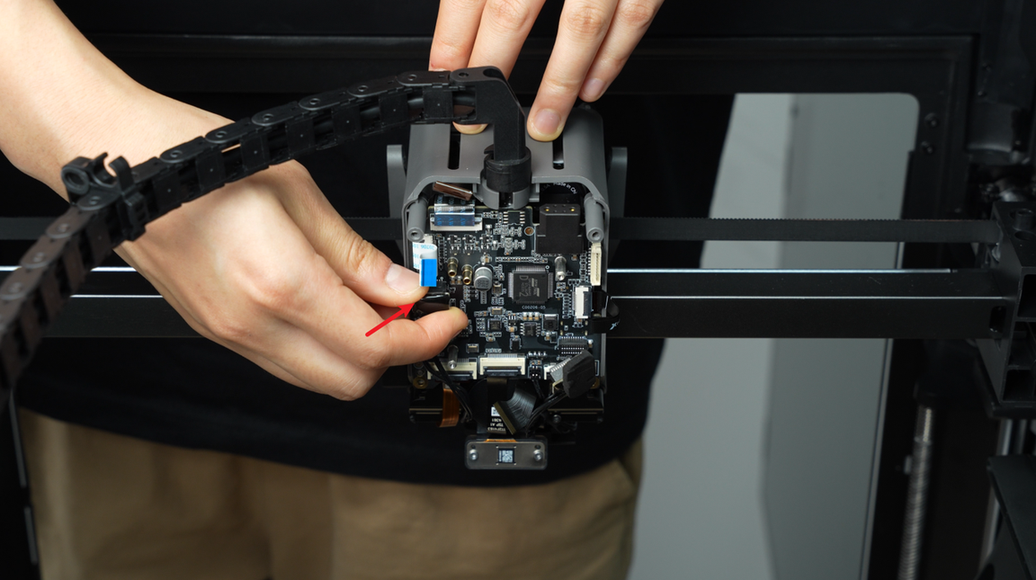

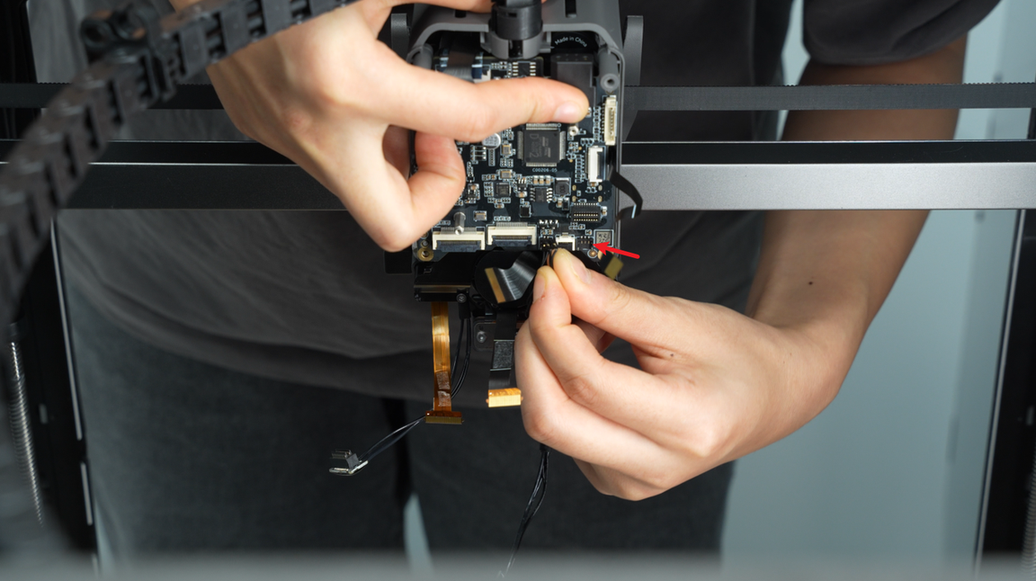

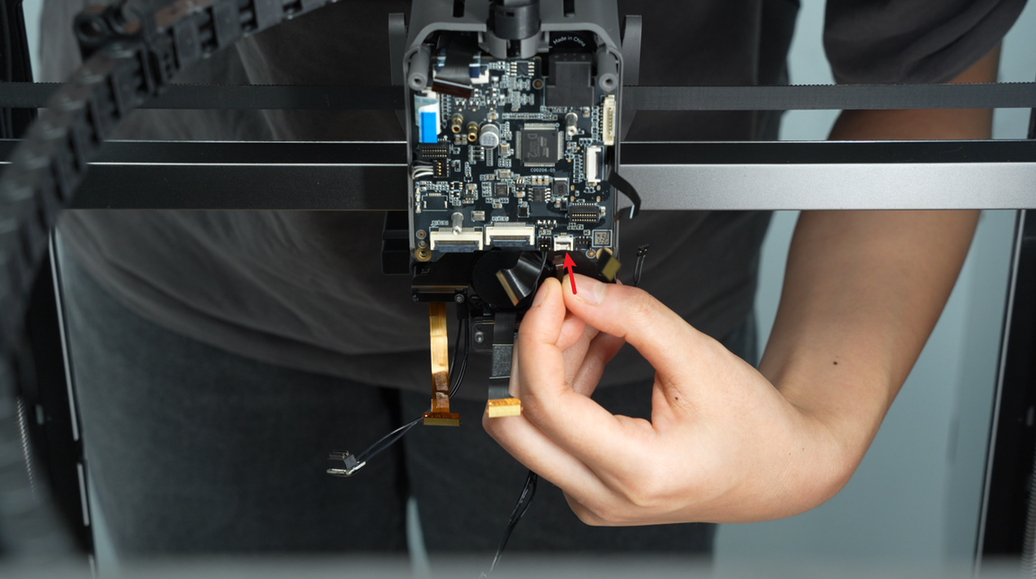

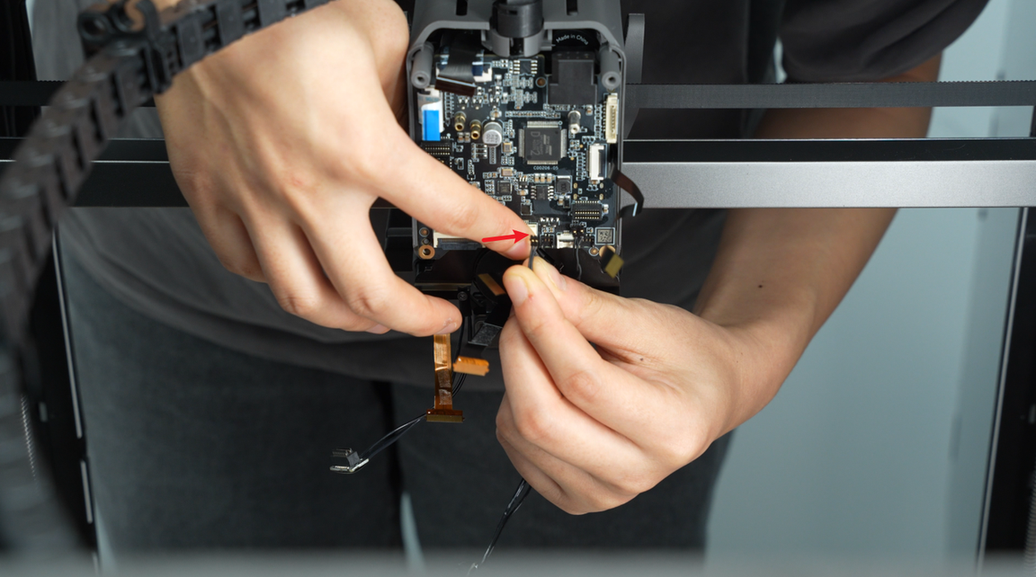

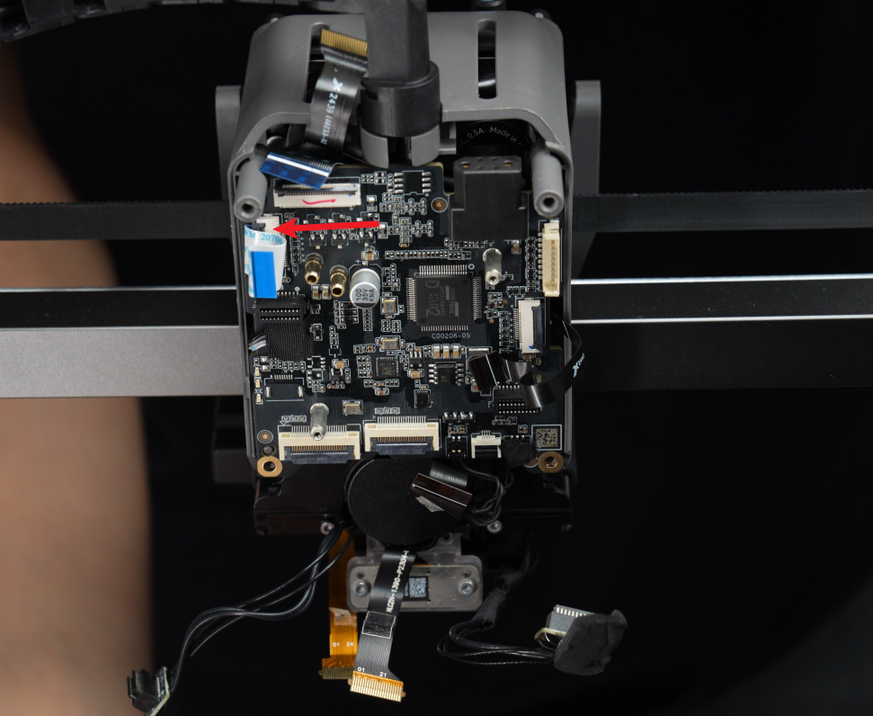

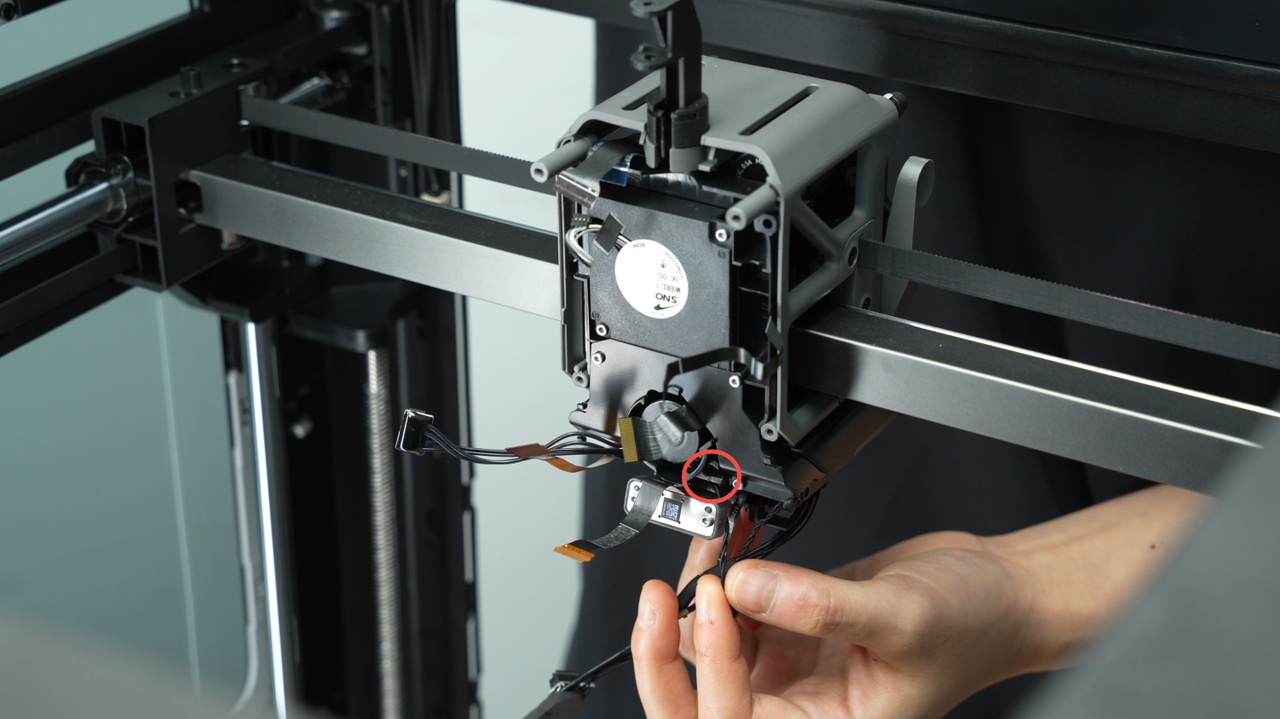

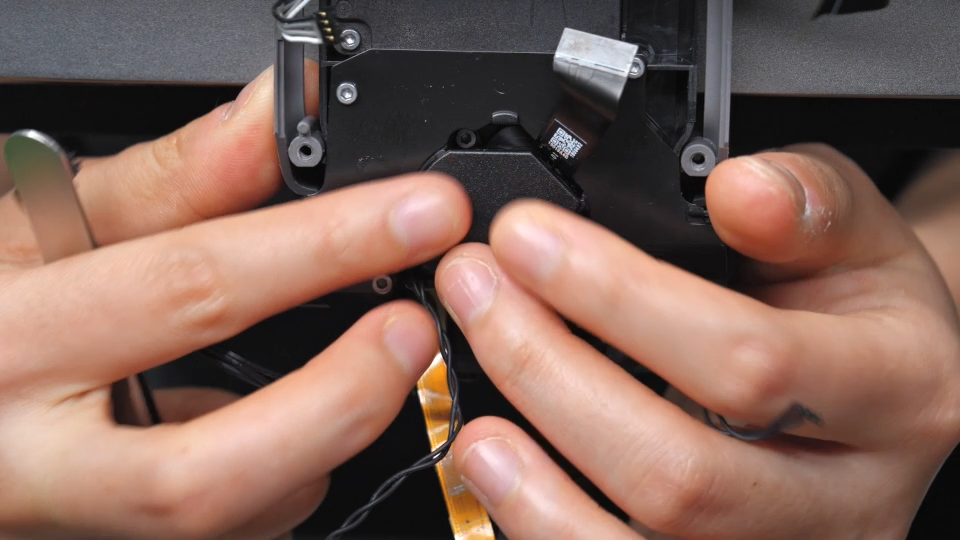

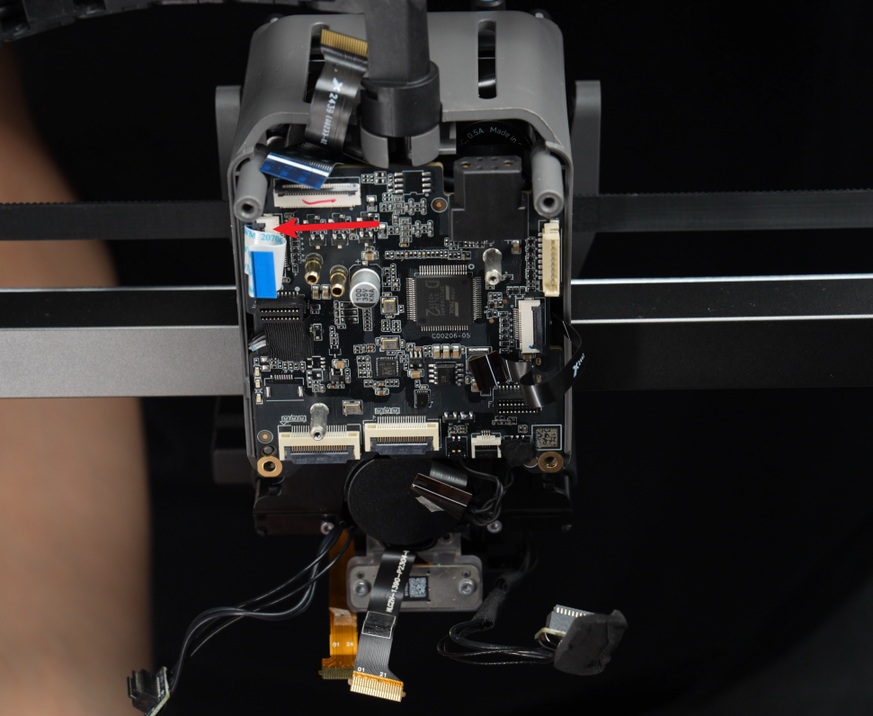

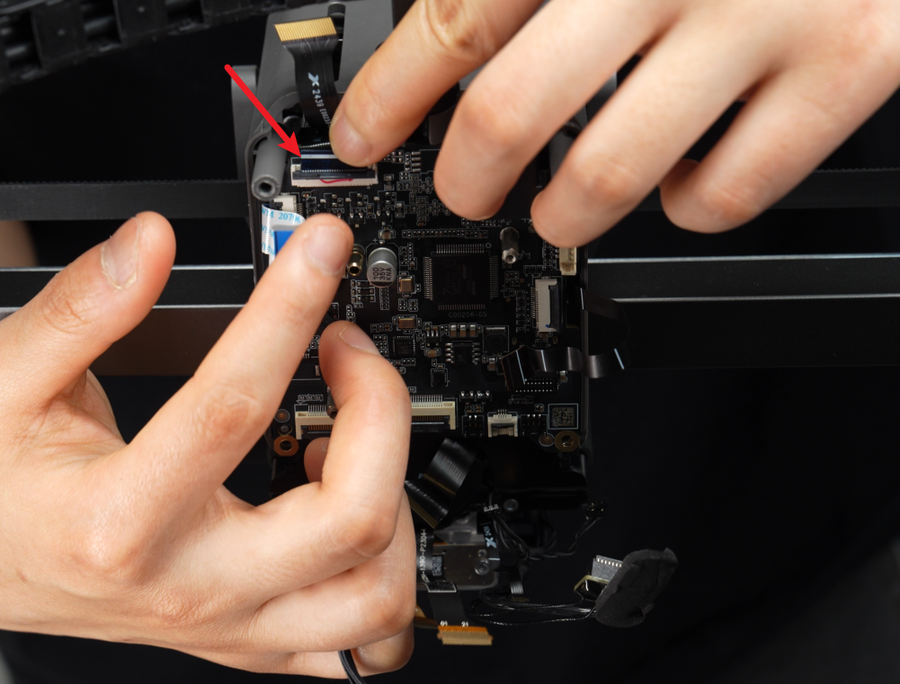

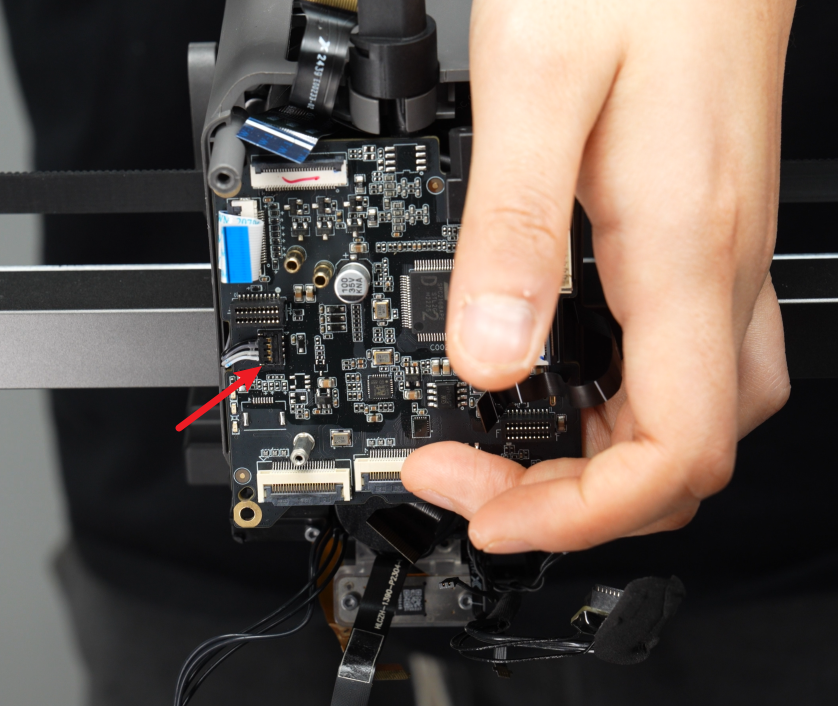

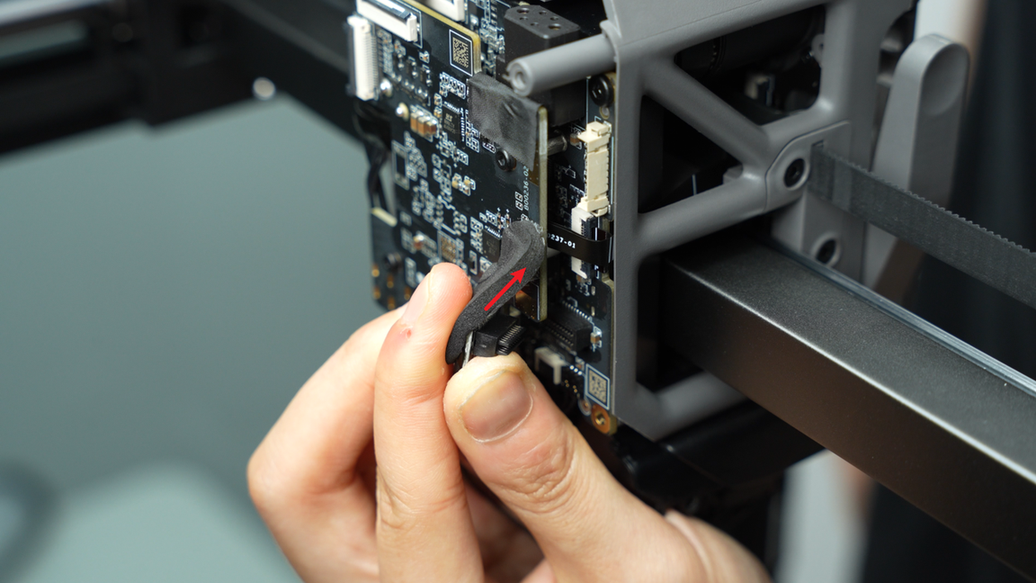

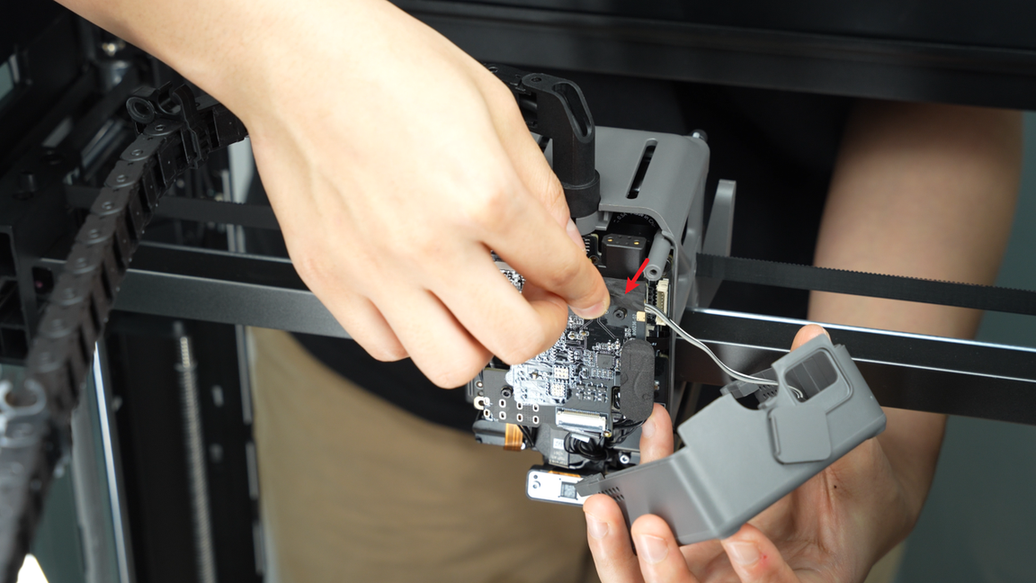

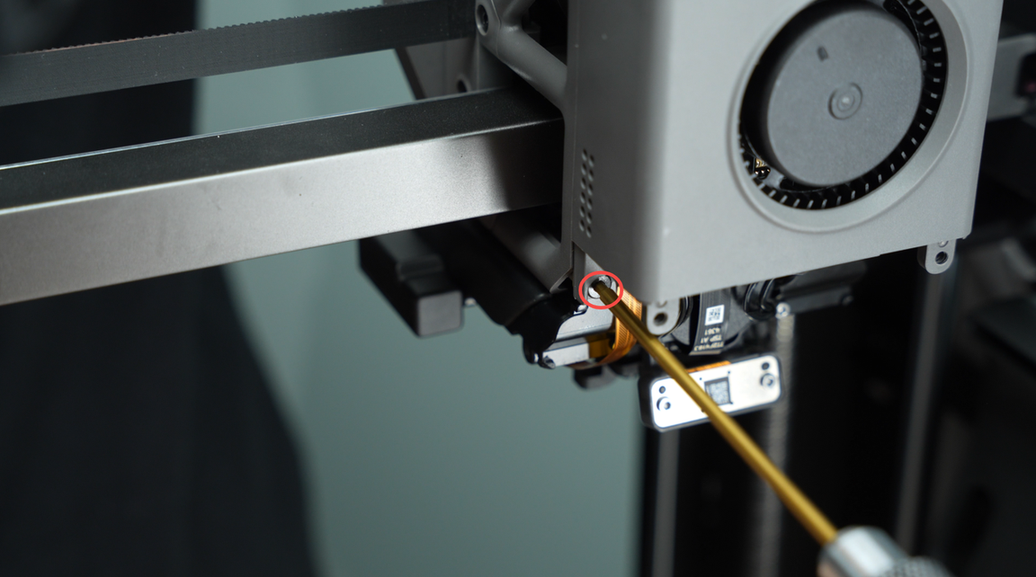

The eddy sensor coil connectors on the H2D feature this compact connector design. When removing the connector, please hold the base of the connector with your hand and lift straight up, perpendicular to the PCB surface, to unlock it. Never apply force in the horizontal direction to avoid damaging the connector.

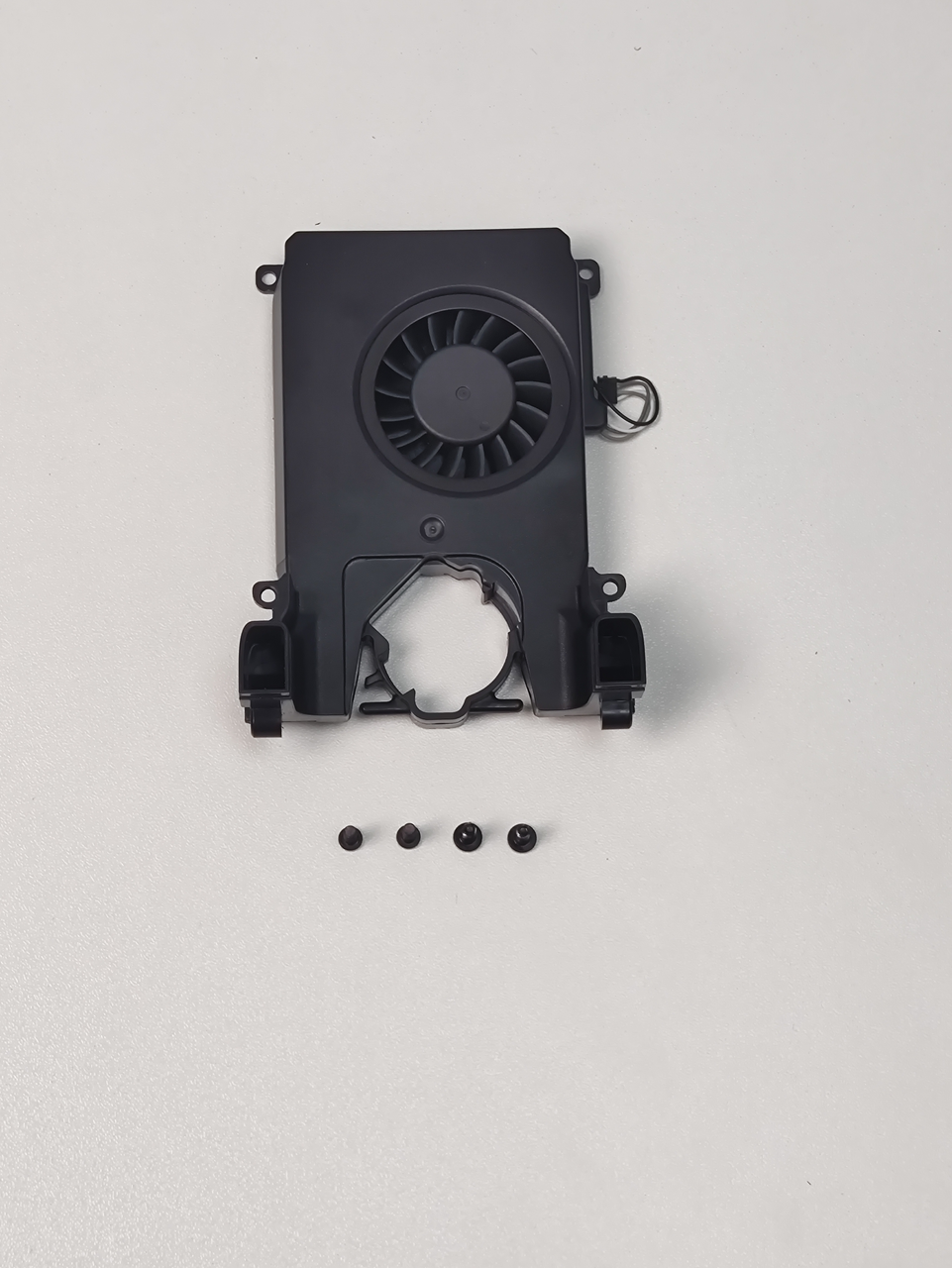

¶ Cooling Fan for Hotend

The cooling fan for hotend is installed between the TH board and the extruder to dissipate heat from the hotend, preventing the filament from softening prematurely in the hotend, which could lead to clogging. Below is a list of components included with the cooling fan for hotend:

-

Cooling fan for hotend * 1

-

M2.5x8 screws - for fixing the cooling fan for hotend * 2

-

BT2.6x8 screws - for fixing the cooling fan for hotend * 2

Cooling fan for hotend

¶ Tools and materials needed

-

New cooling fan for hotend

-

H2.0 Allen key

-

H1.5 Allen key

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, we recommend submitting a technical ticket regarding your issue and we will do our best to respond promptly and provide the assistance you need.

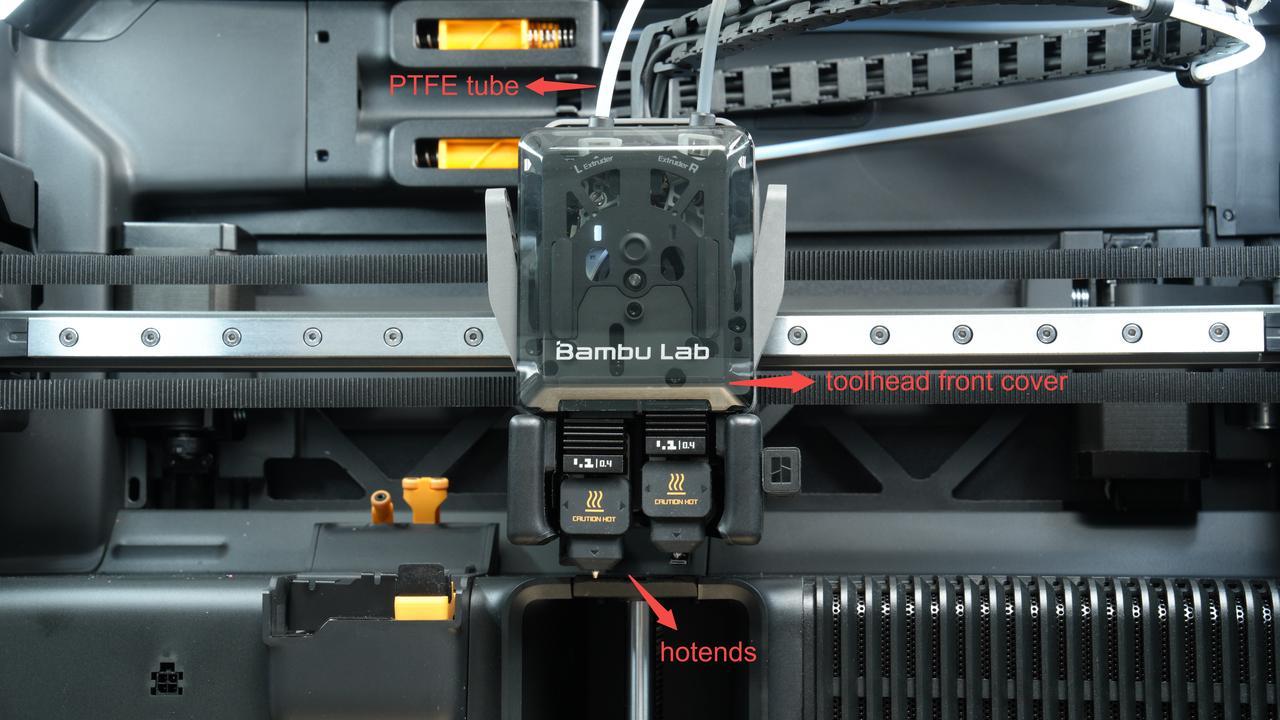

¶ Remove the cooling fan for hotend

This guide extracts the disassembly and assembly steps from the complete toolhead disassembly guide. In practice, when replacing the cooling fan for hotend, it is not necessary to remove the PTFE tube, toolhead front cover, or left and right nozzles. Please disassemble as needed.

¶ Step 1: Remove the part cooling fan duct

- Use a H2.0 hex key to remove the four fixed screws (BT3x8).

- Hold the rear end of the part cooling fan duct and pull it downwards to remove the duct carefully.

¶ Step 2: Remove the part cooling fan

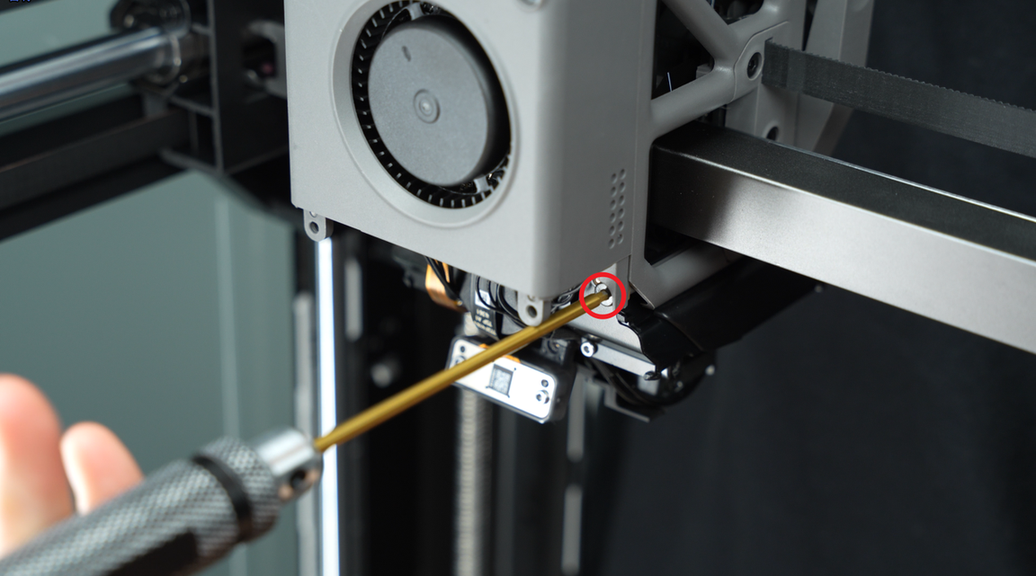

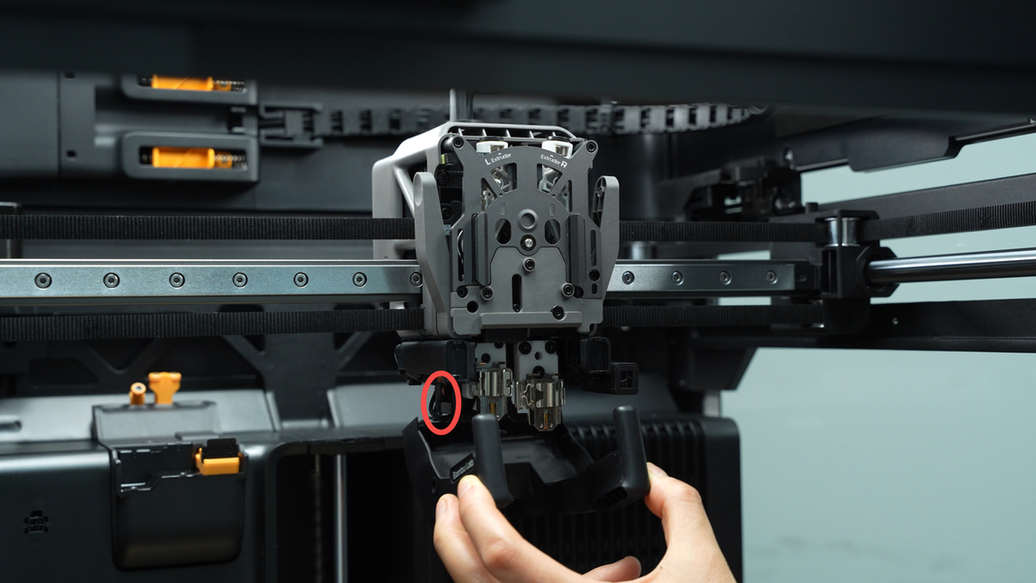

- Use a H2.0 hex key to remove the four fixed screws.(BT3x20 marked with a square symbol, BT2.6x8 marked with a circle symbol)

- Tear off the acetate tape of the plug, then unplug the plug. You can leave the removed tape on the circuit board for easier installation later on.

Please note that this type of plug should be carefully pushed upward along the plane where the plug is located, rather than pulled out along the direction of the cable. Please follow the operation in the video to avoid damaging the plug.

¶ Step 3: Remove the Extruder connection board

Disconnect the following connectors on the interface board in sequence: 2004 switching motor FPC connector, TH board FPC connector, left hotend heating assembly connector and its foam (the connector is on the TH board, and the foam is on the extruder connection board), and 2004 lifting motor FPC connector.

| No. | Connected to | No. | Connected to |

|---|---|---|---|

| 1 | 2004 switching motor | 2 | TH board |

| 3 | Left hotend heating assembly | 4 | 2004 lifting motor |

Note: The 2004 switching motor cable (No. 1), FPC cable (No. 2) and 2004 lifting motor cable (No. 4) are secured by latches. Unlock the latches before pulling out the FPC cables.

No. 1

No. 2

No. 4

When peeling off the foam on the left hotend heating assembly connector (No. 3), it is recommended to loosen the connector first, then peel from bottom to top to maintain the foam’s integrity.

Use an H1.5 Allen key to remove the 2 fixing screws (M1.6x4).

Gently wiggle the extruder connection board near the 2004 switching motor connector and carefully remove it.

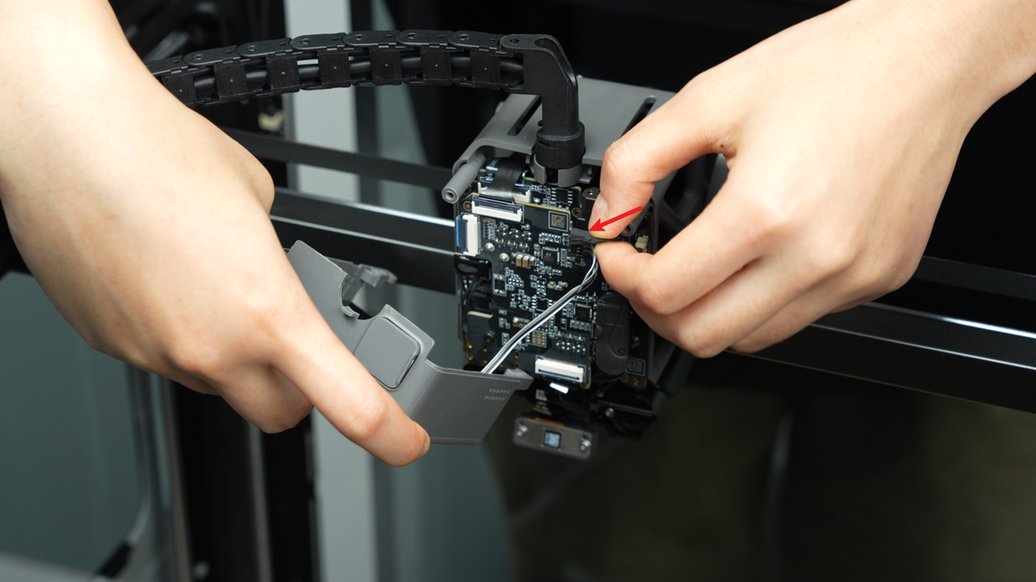

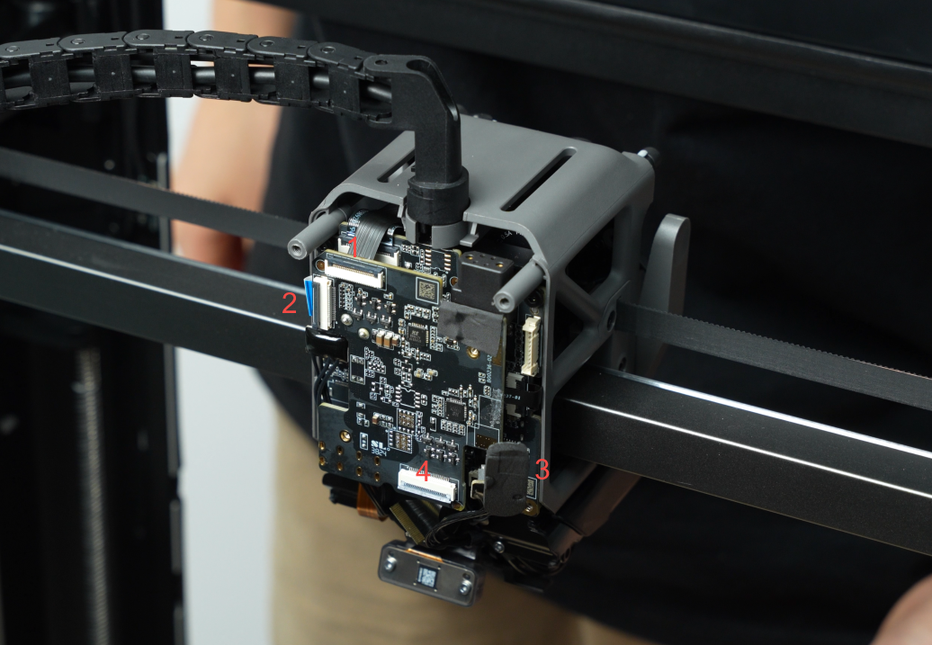

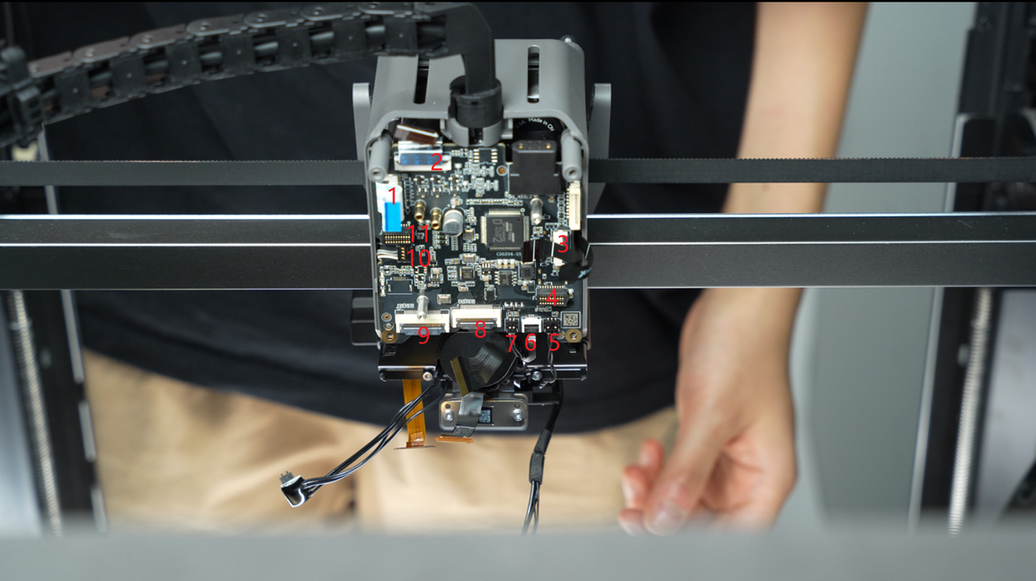

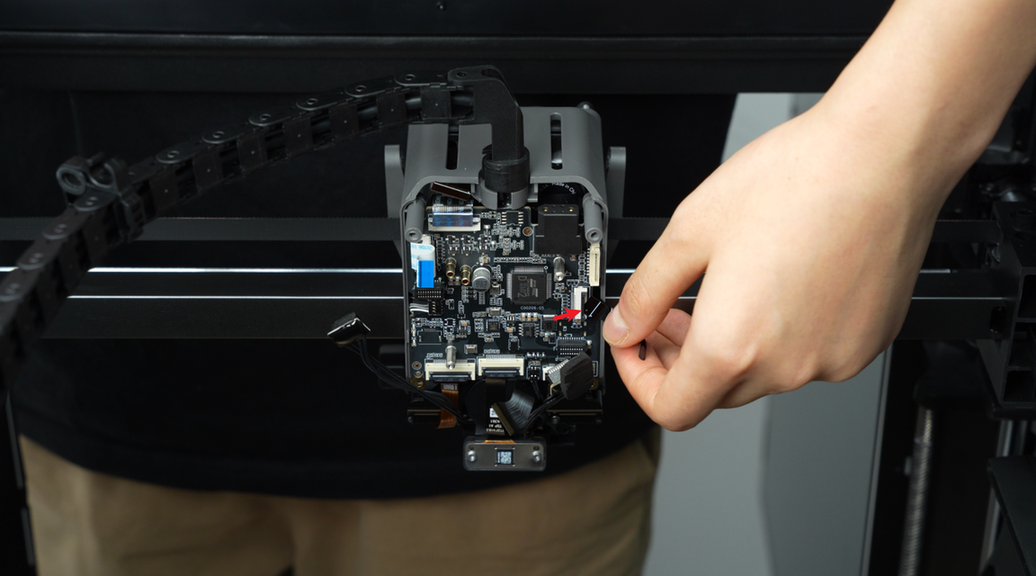

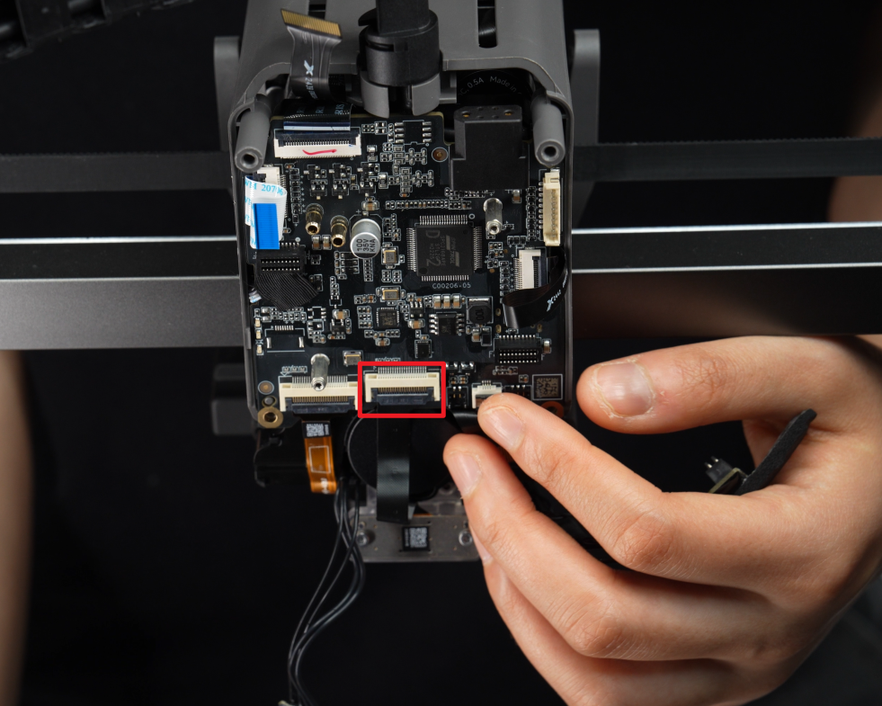

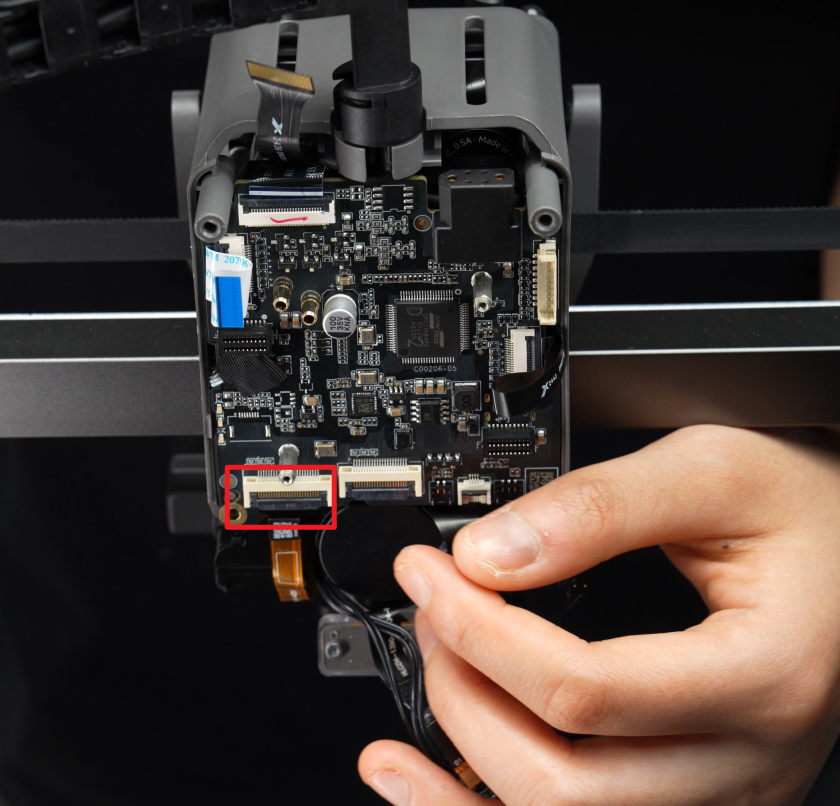

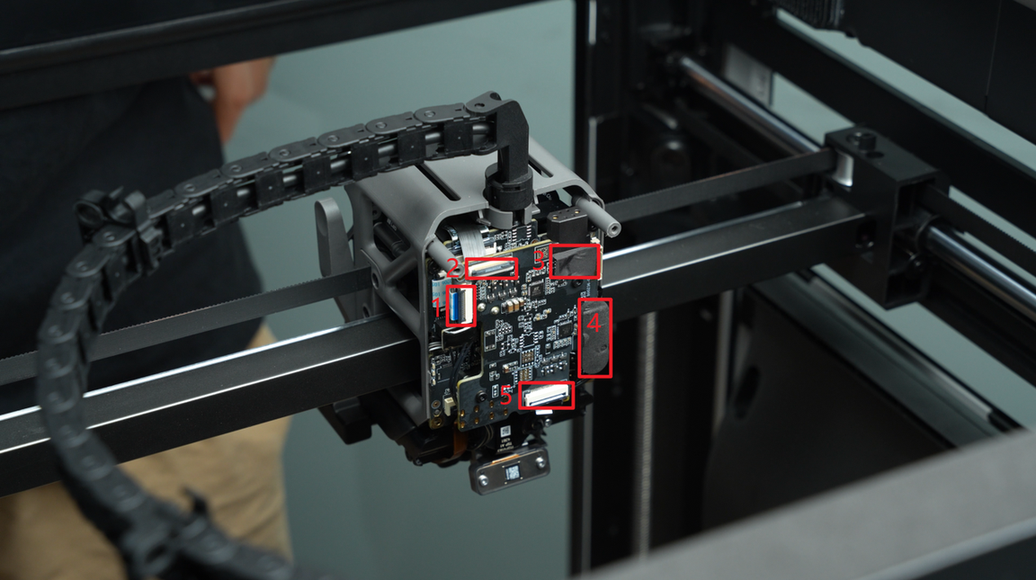

¶ Step 4: Disconnect cables on the TH Board

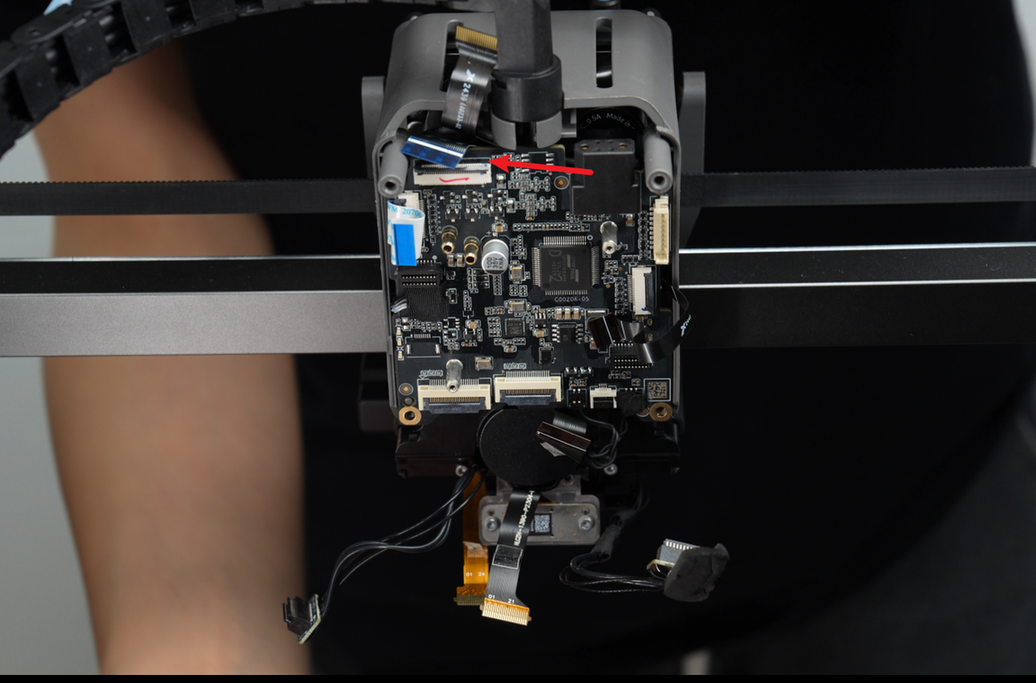

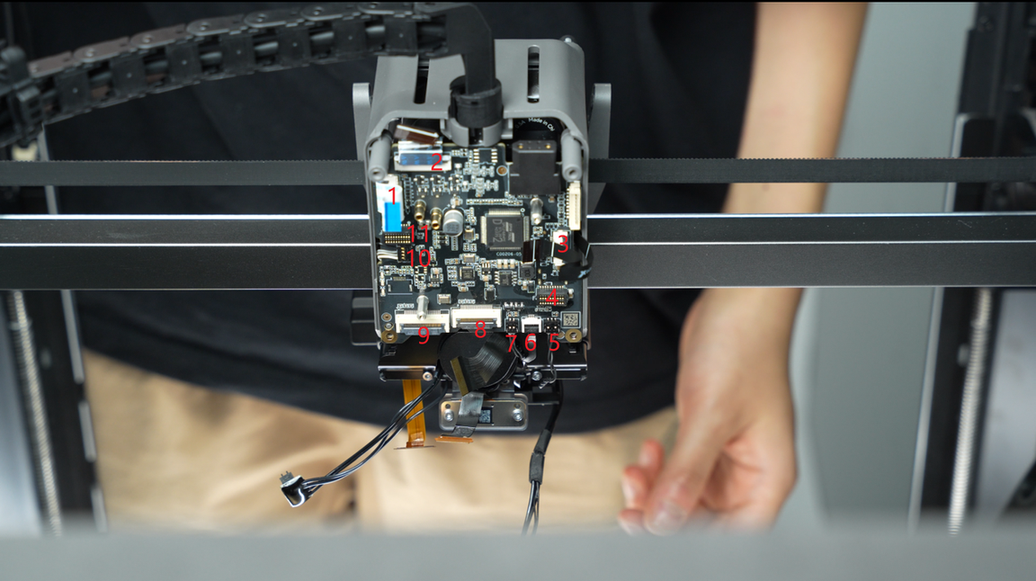

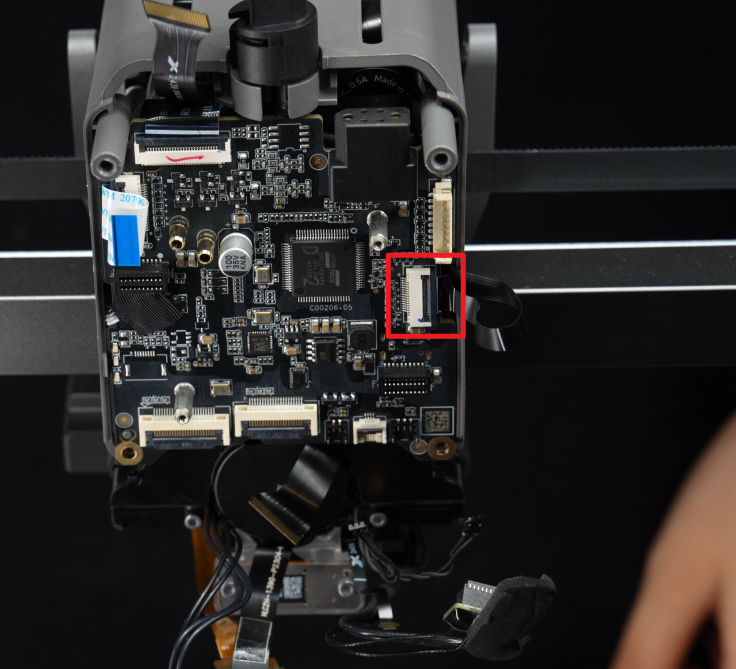

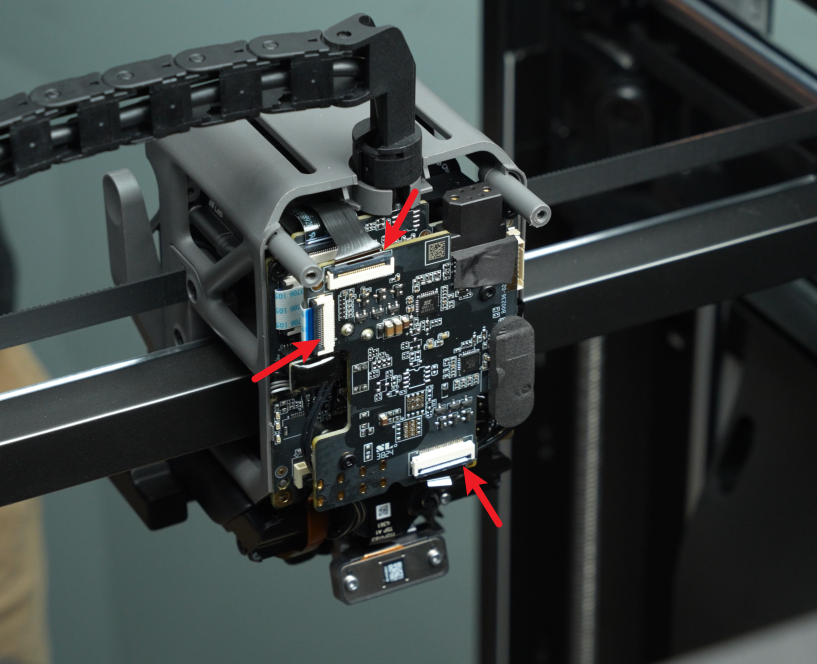

Disconnect all connectors on the TH board in sequence. Refer to the images and tables for the specific cable connectors and their connections.

| No. | Connected to | No. | Connected to |

|---|---|---|---|

| 1 | Extruder connection board - TH board FPC cable | 7 | Right eddy current coil |

| 2 | 3513 extruder servo motor | 8 | Nozzle camera |

| 3 | Toolhead sensor FPC cable | 9 | Toolhead camera |

| 4 | Left hotend heating assembly | 10 | Cooling fan for hotend |

| 5 | Left eddy current coil | 11 | Right hotend heating assembly |

| 6 | Lifting hall effect sensor |

There are three types of plugs on the TH board, and you can use different methods to disconnect depending on the type of plug.

-

Connectors 1, 2, 3, 6, 8, and 9 are secured by latches. Unlock the latch and remove the cable.

-

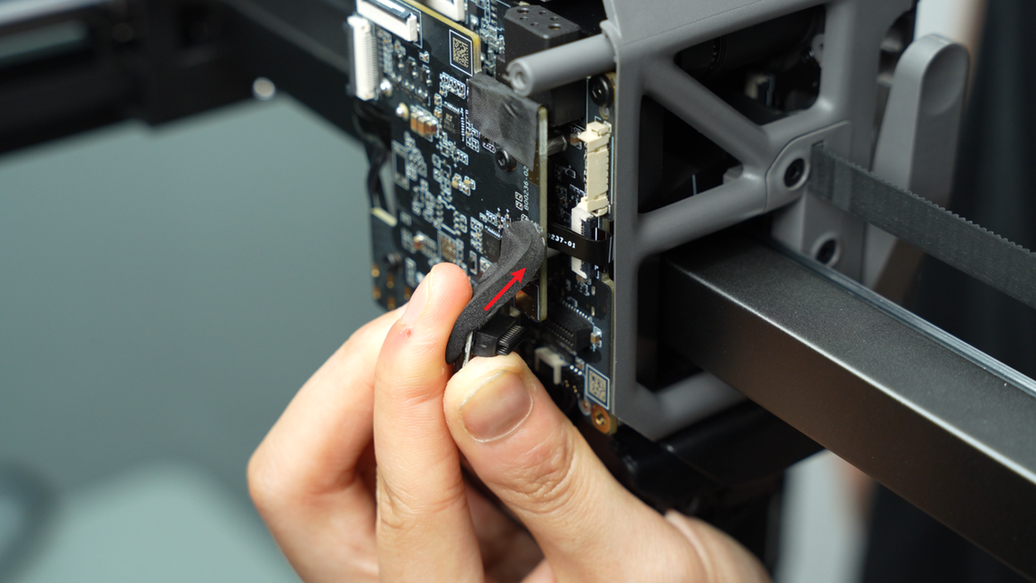

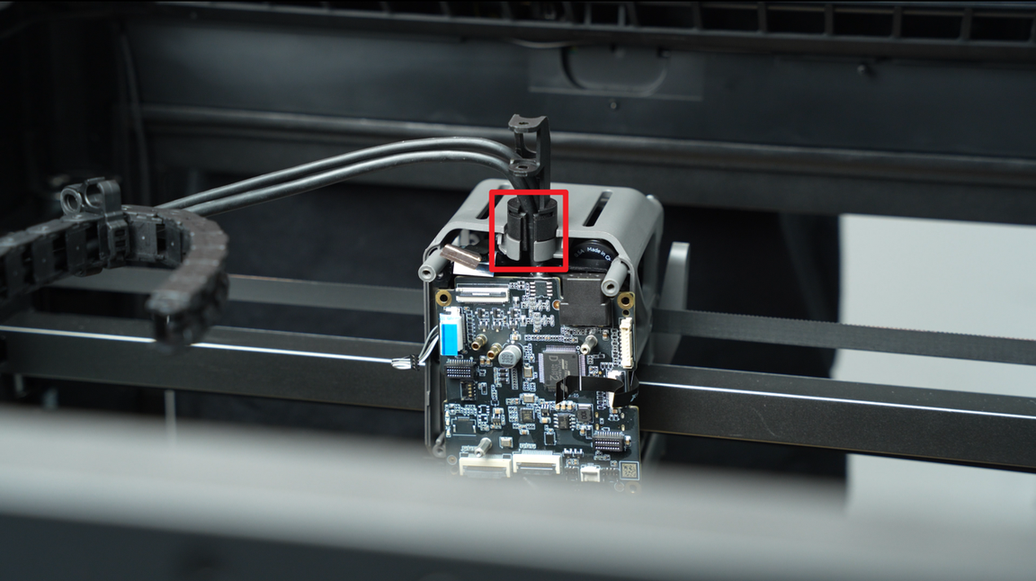

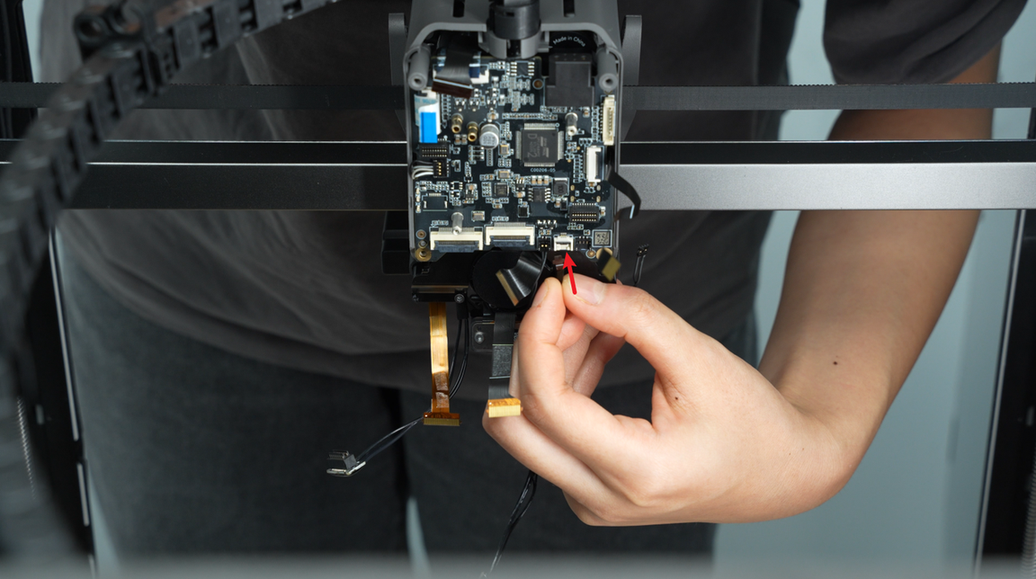

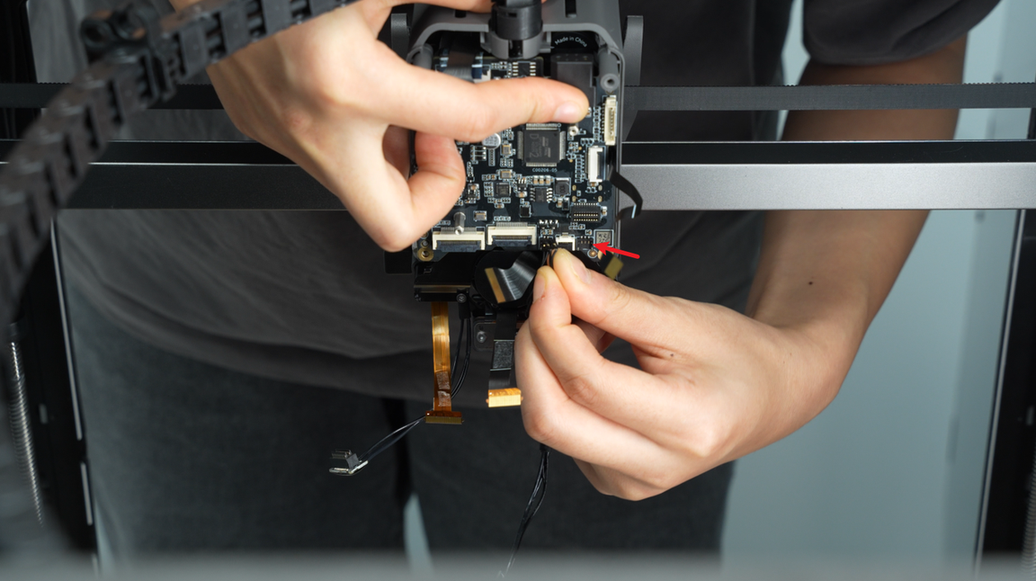

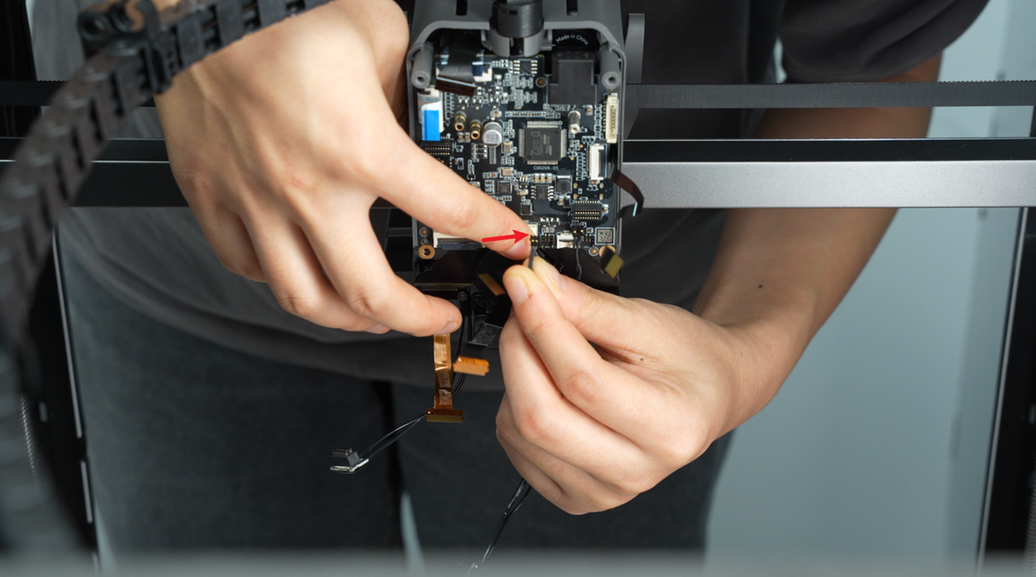

Connectors 5, 7, and 10 are secured from the front. Push the connector out along the plane.

-

Connectors 4 and 11 are secured by headers. Pull directly to disconnect.

Note: 4 - The left hotend heating assembly has been removed in "Step 2".

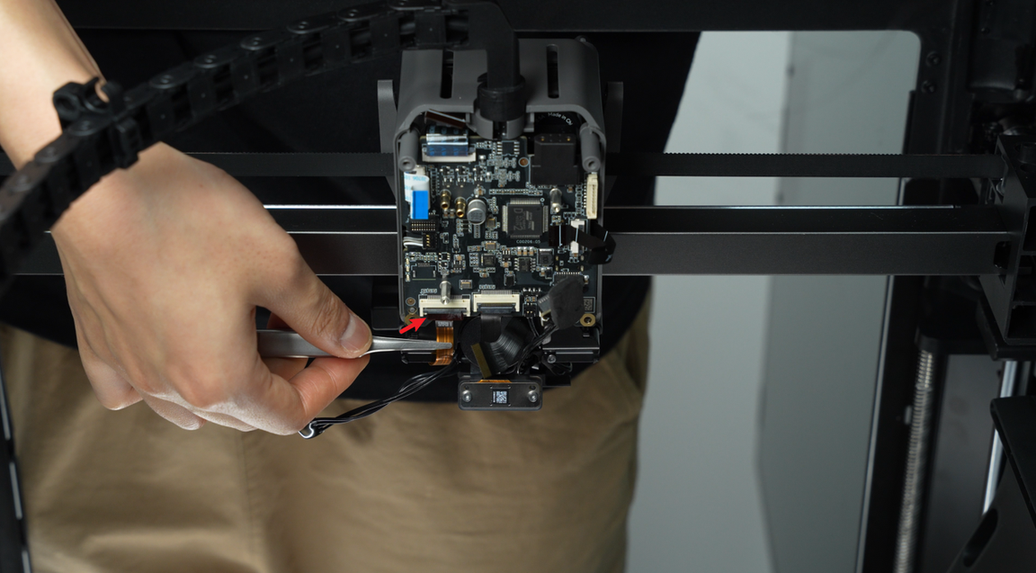

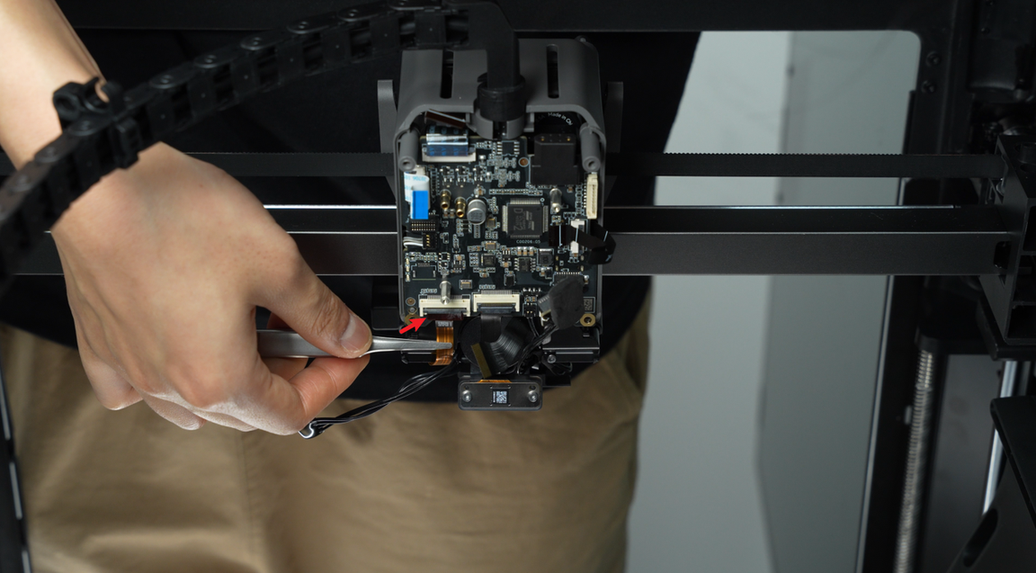

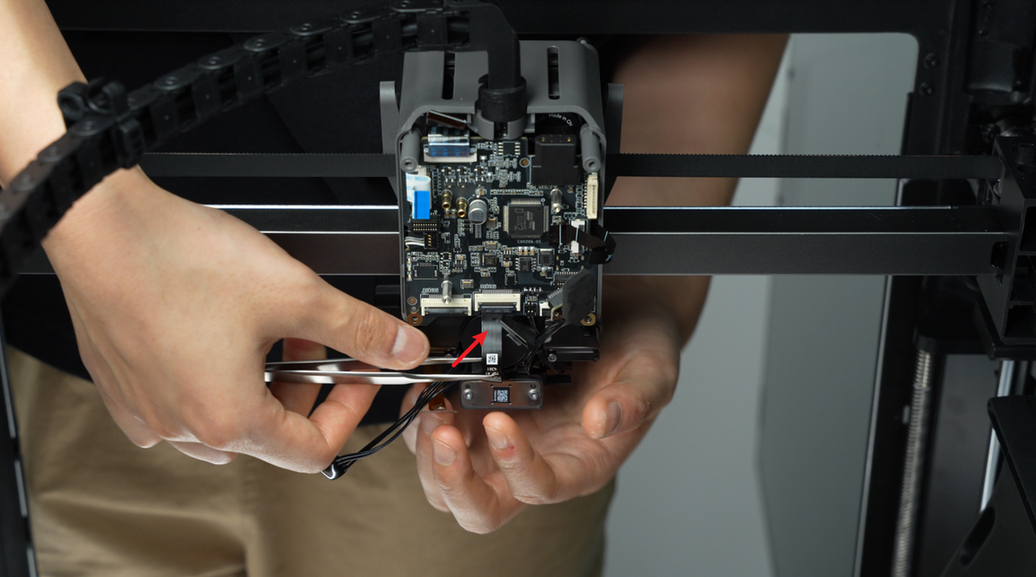

The detailed steps to disconnect the connection wires on the TH board are as follows:

Detailed steps:

- Disconnect the right hotend heating assembly cable. Unlock the latch on the toolhead sensor FPC cable and remove the cable.

- Use tweezers to peel off the backing tape of the toolhead camera and nozzle camera FPC cables. Unlock the latch and remove the FPC cables.

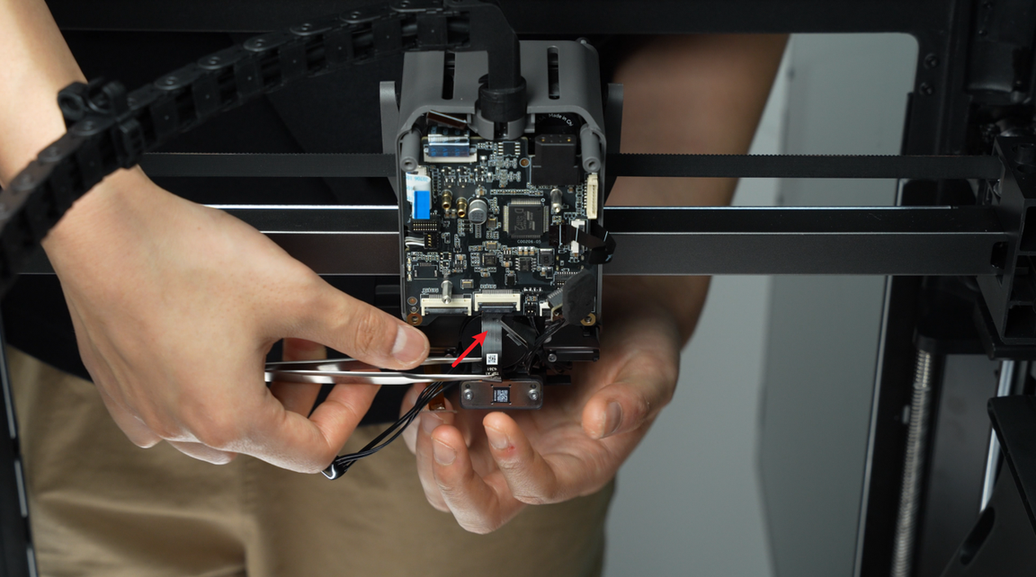

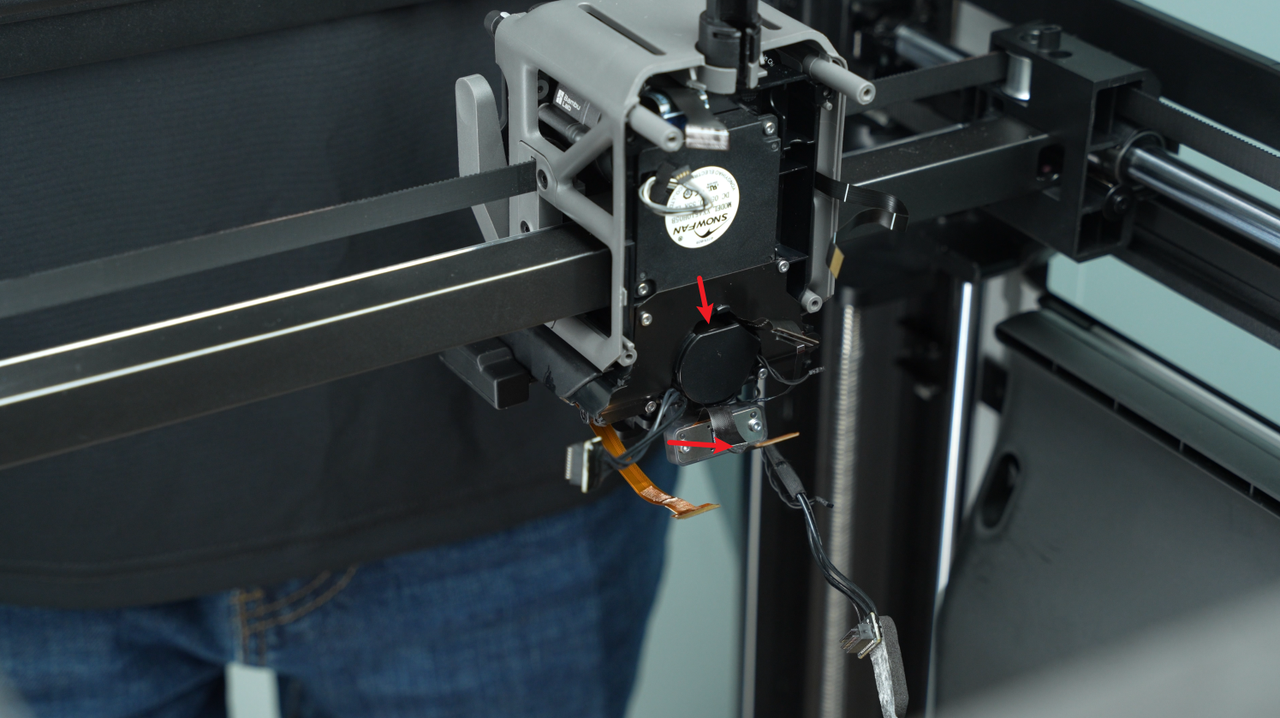

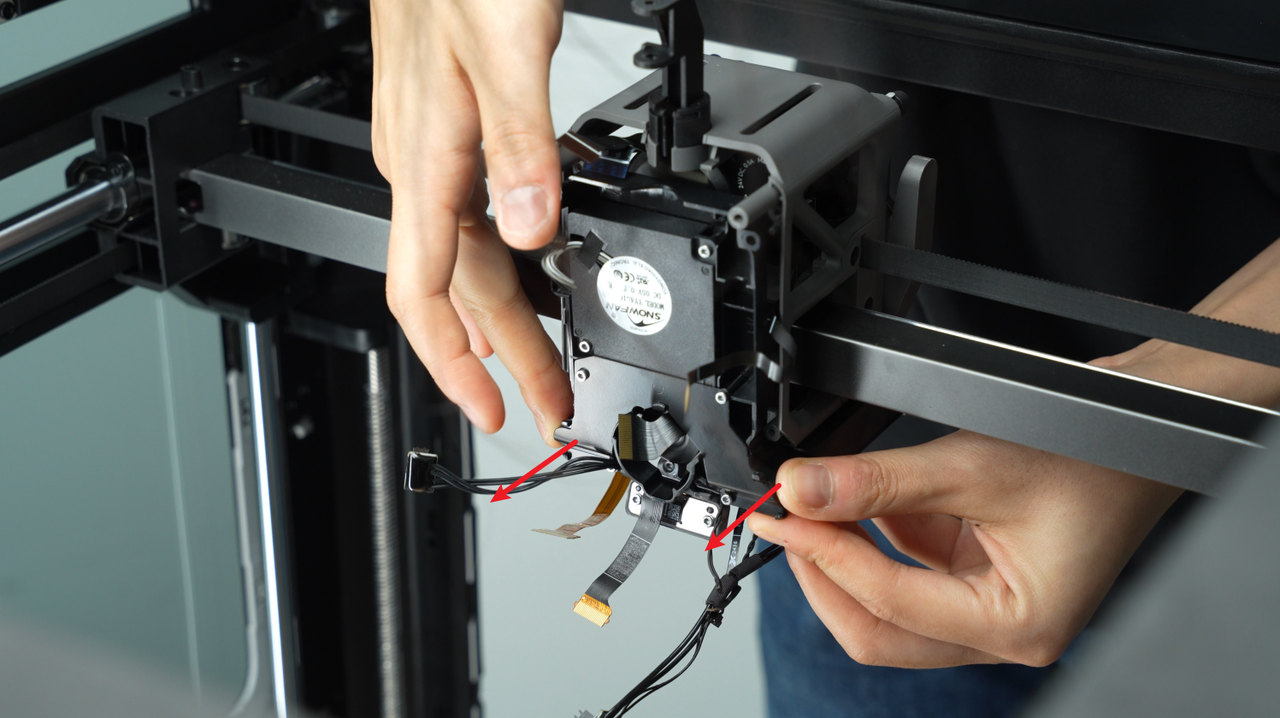

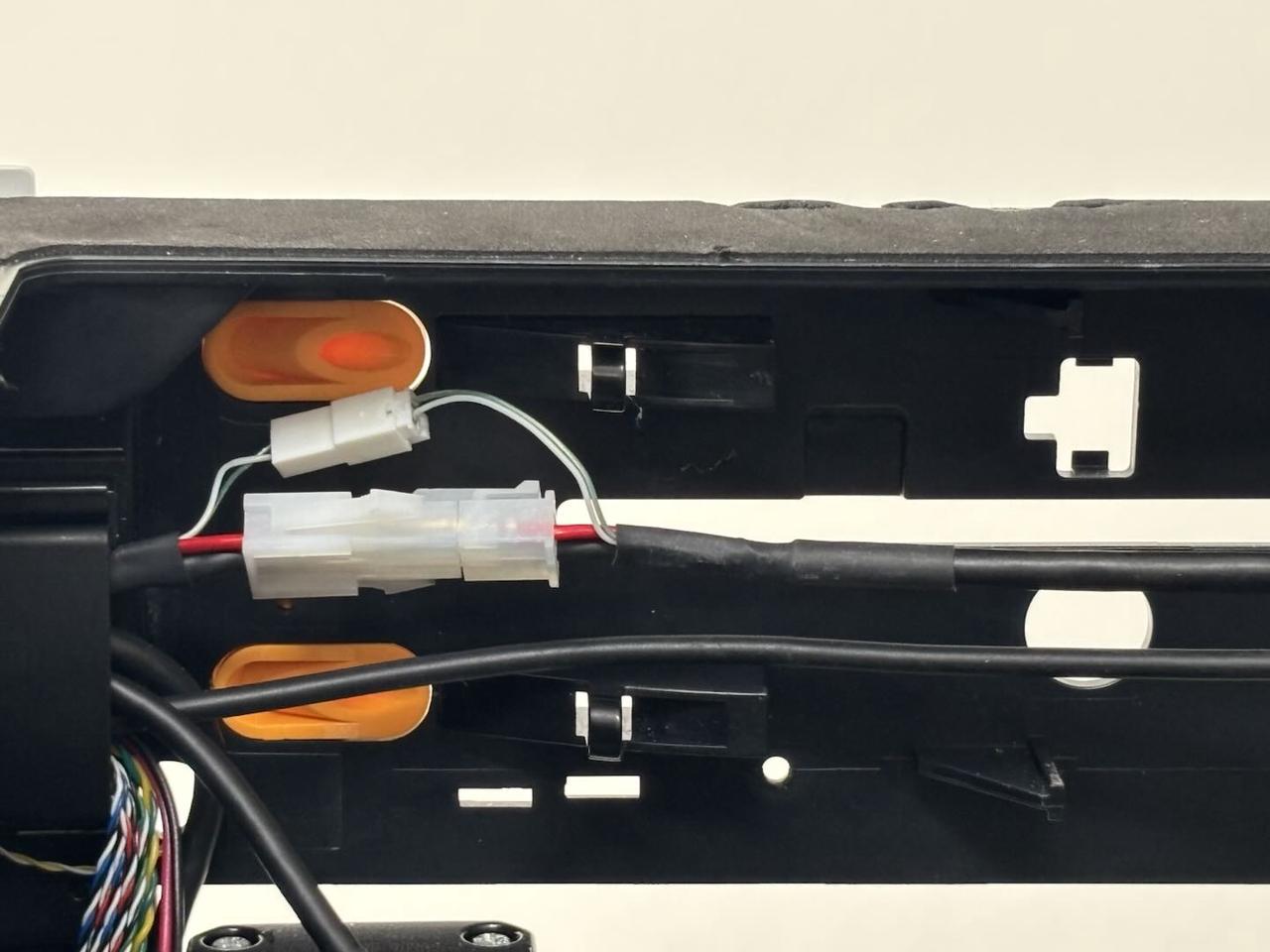

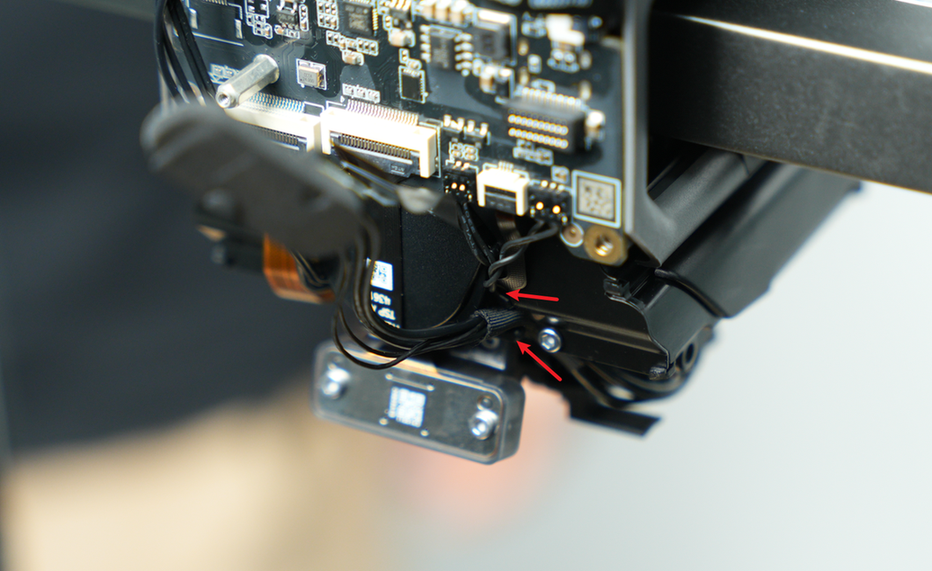

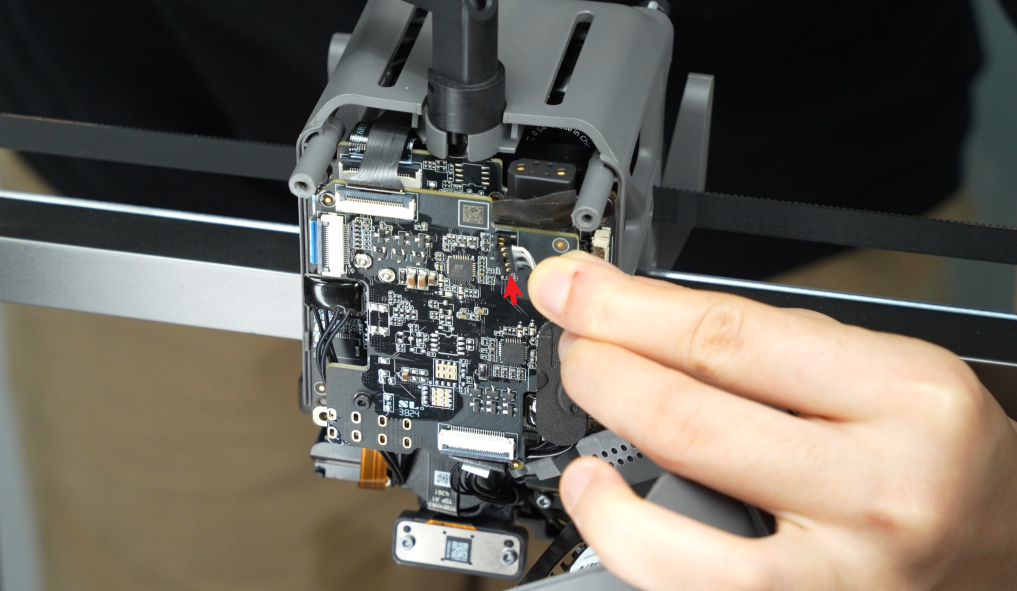

- As shown in the figure, there are two cable channels at the arrows. The large cable channel at the lower arrow is used to store the cables of the left hotend heating component, and the small cable channel at the upper arrow is used to organize the cables of the left eddy current coil plug, the right eddy current coil plug and the lifting hall plug. Before unplugging these three small plugs, you need to pull out the cables in the two cable channels in turn to increase the cable length and facilitate unplugging.

Remove the cables from the two cable channels in the following order:

- Unlock the FPC interface and 3513 extruder servo motor interface latches. Remove the FPC cable and place it on the table (keep it safe for later installation). Take out the 3513 extruder servo motor cable from the latch.

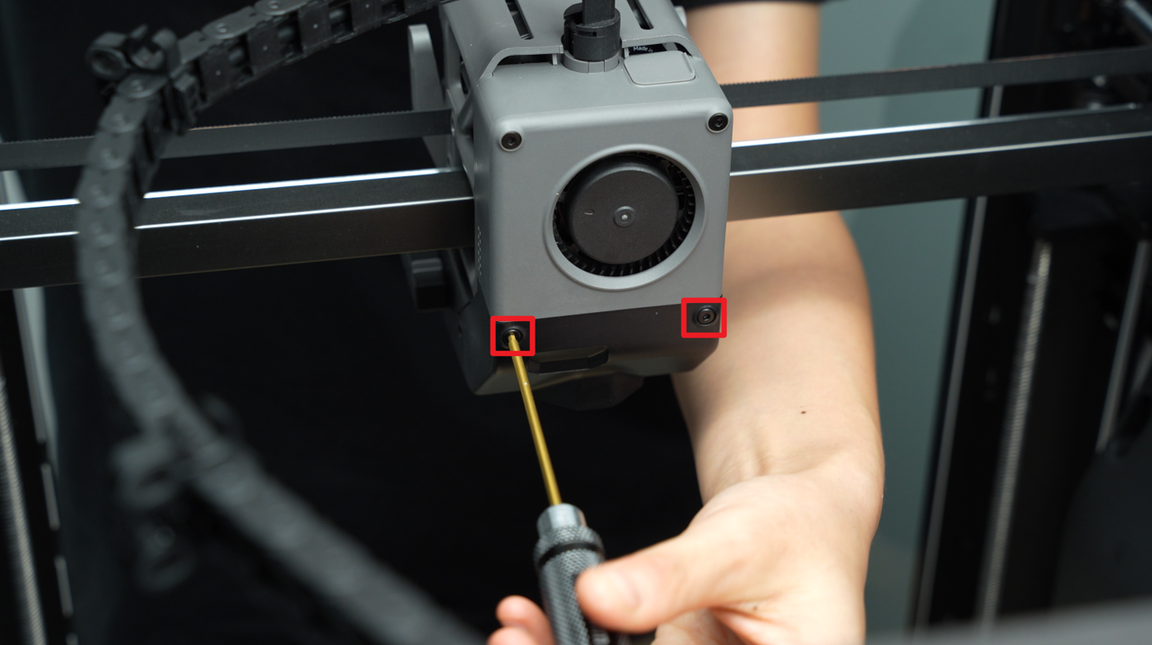

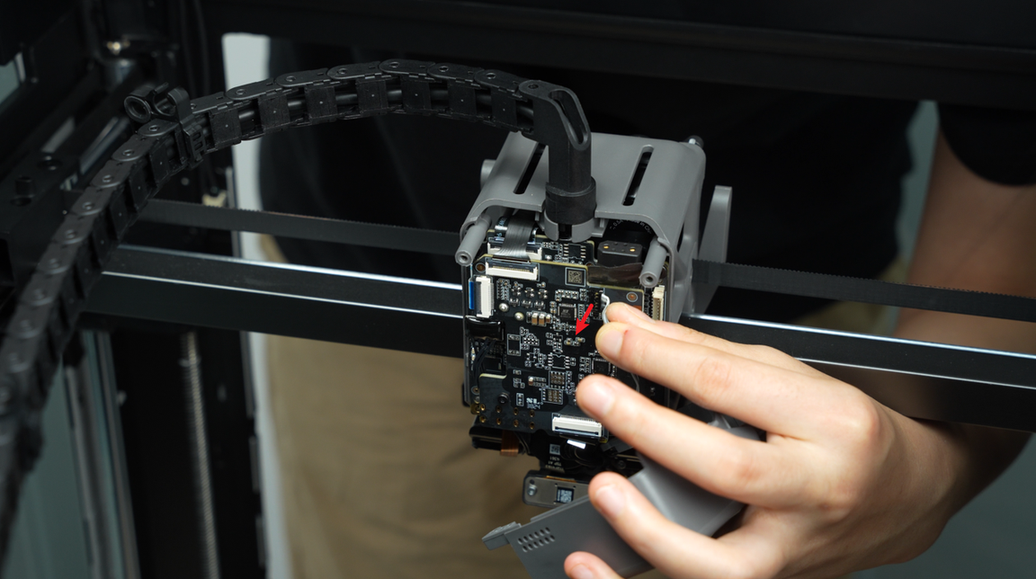

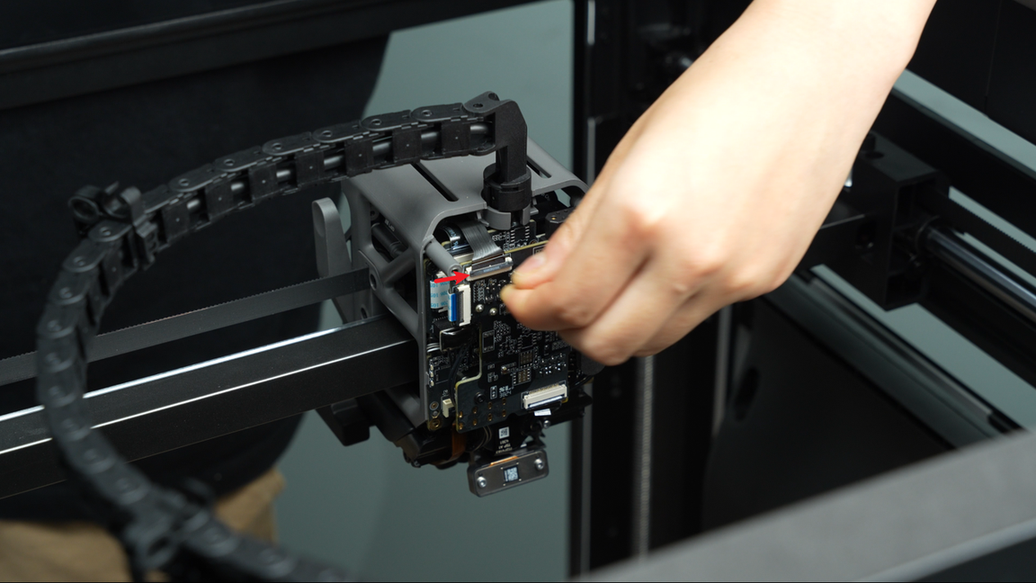

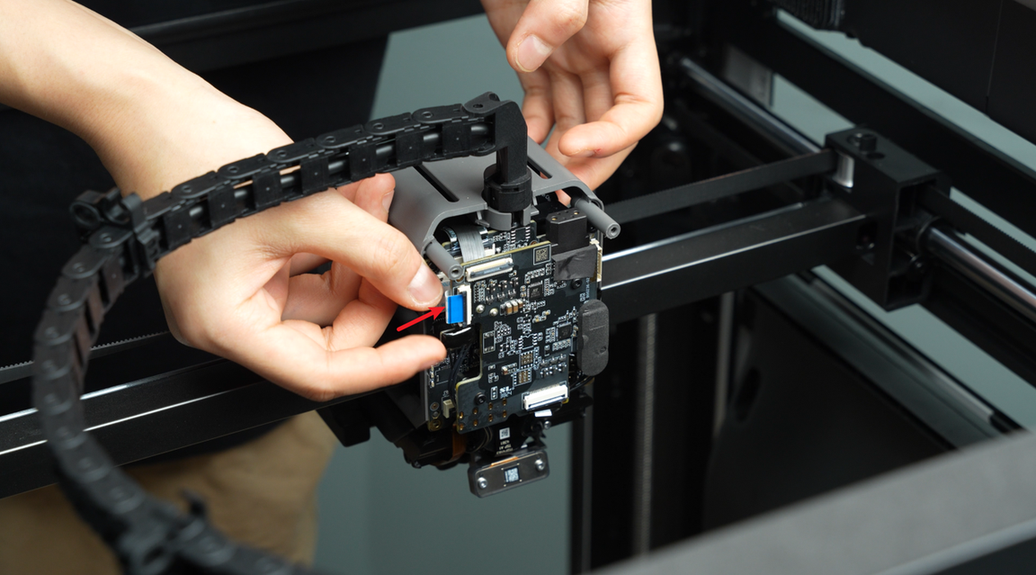

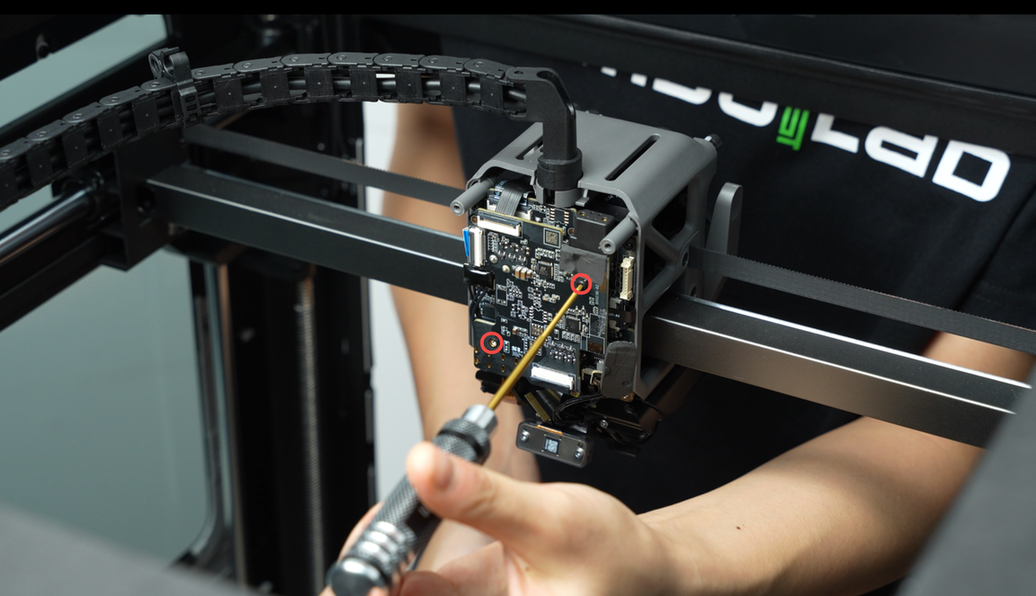

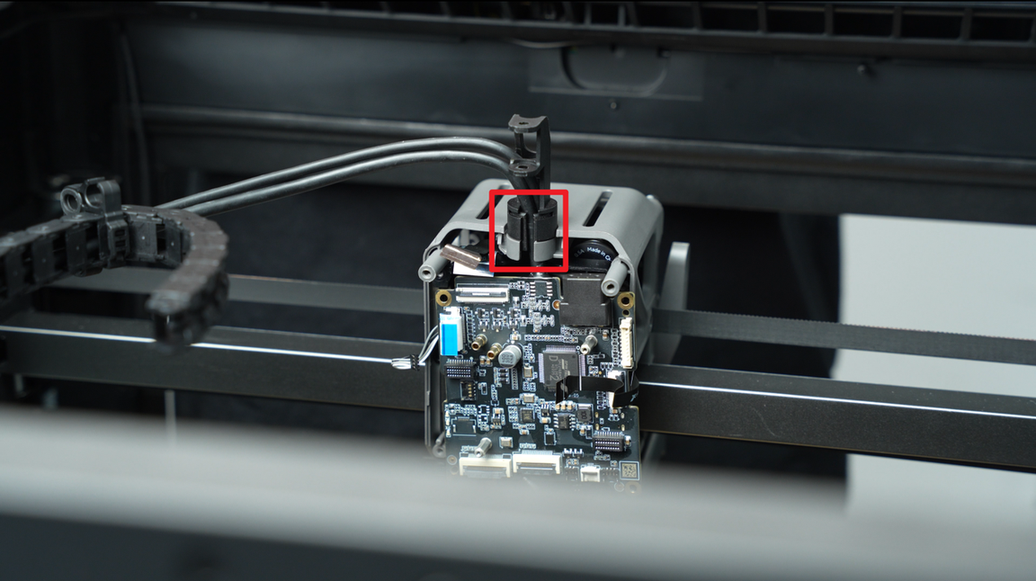

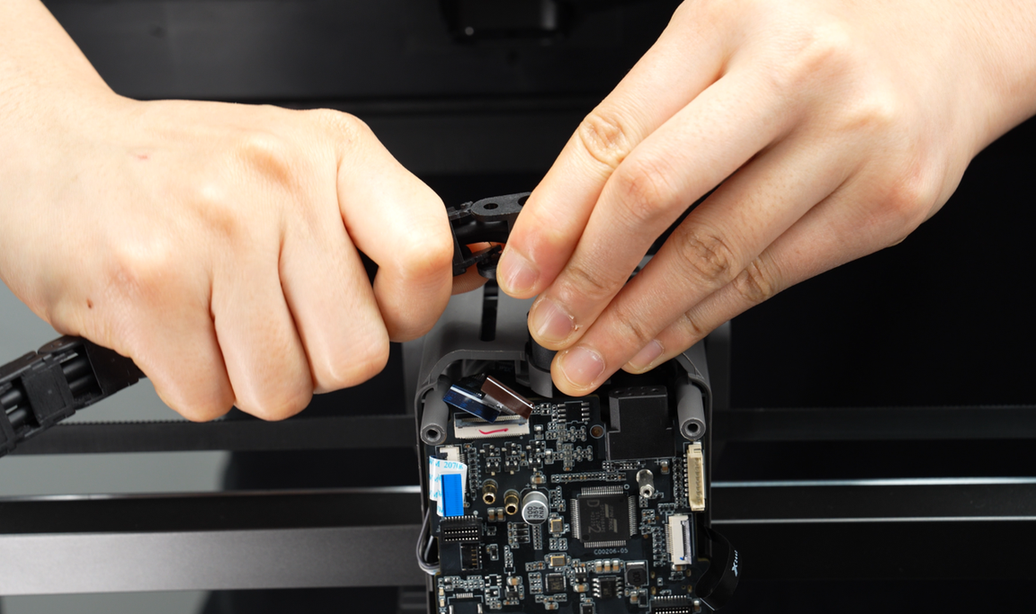

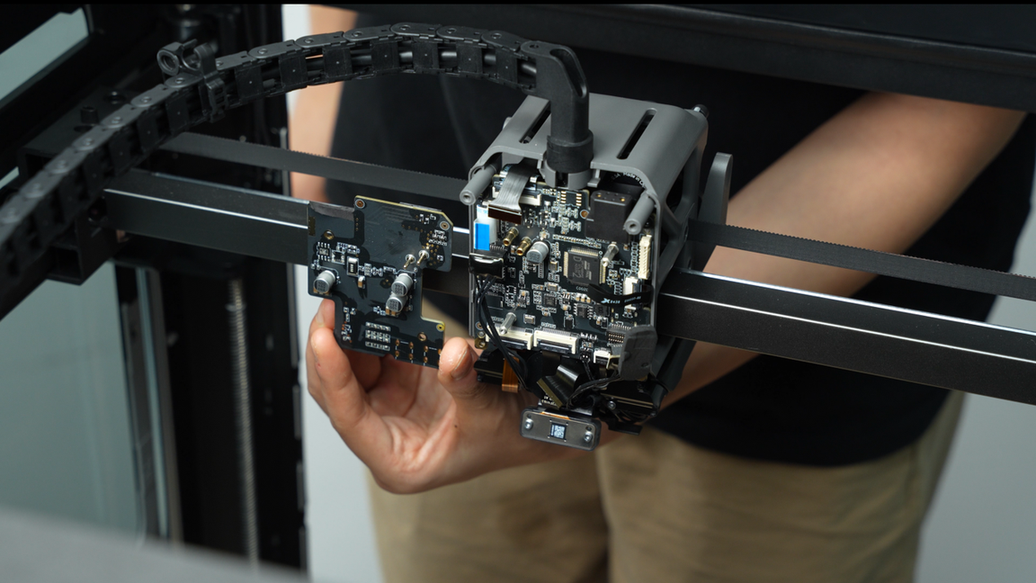

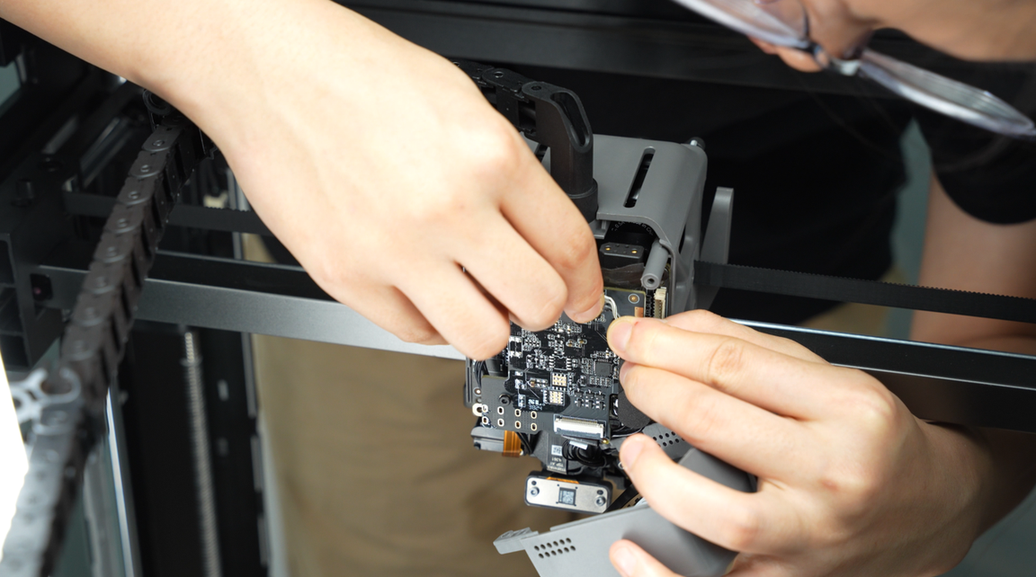

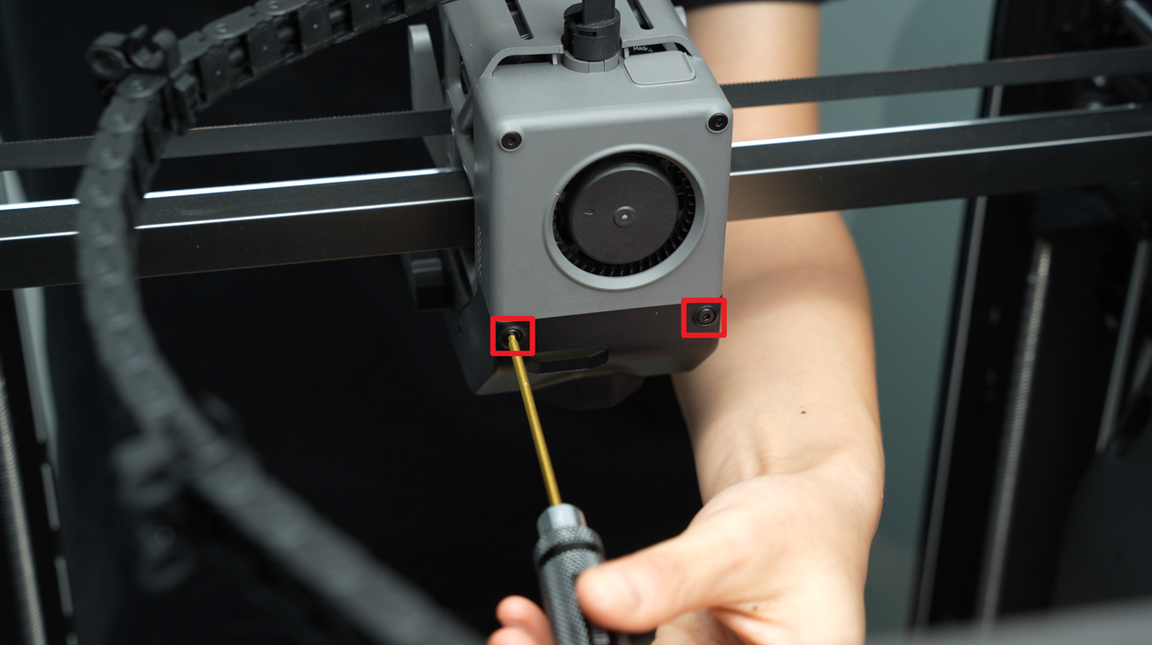

¶ Step 5: Remove the TH Board

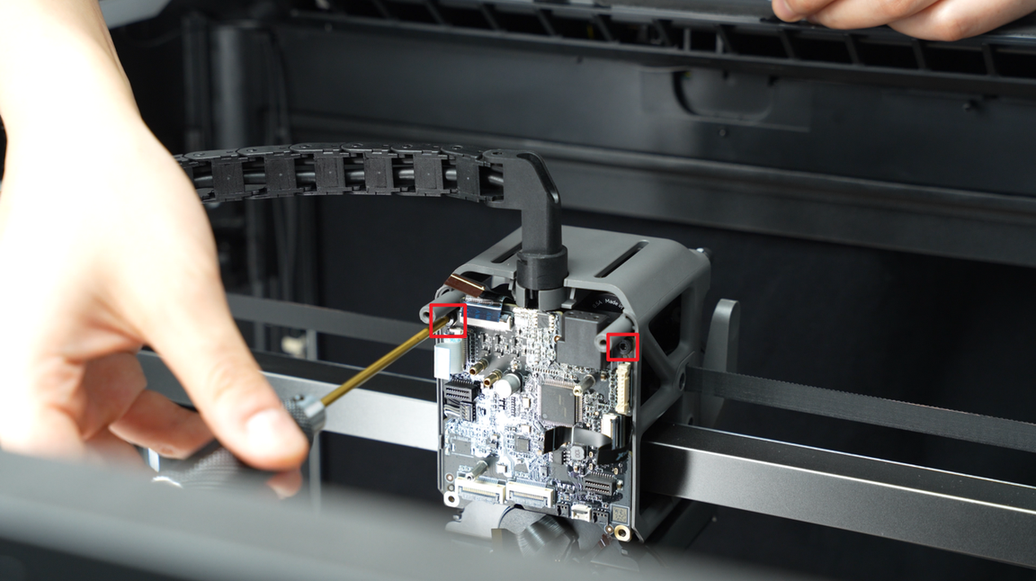

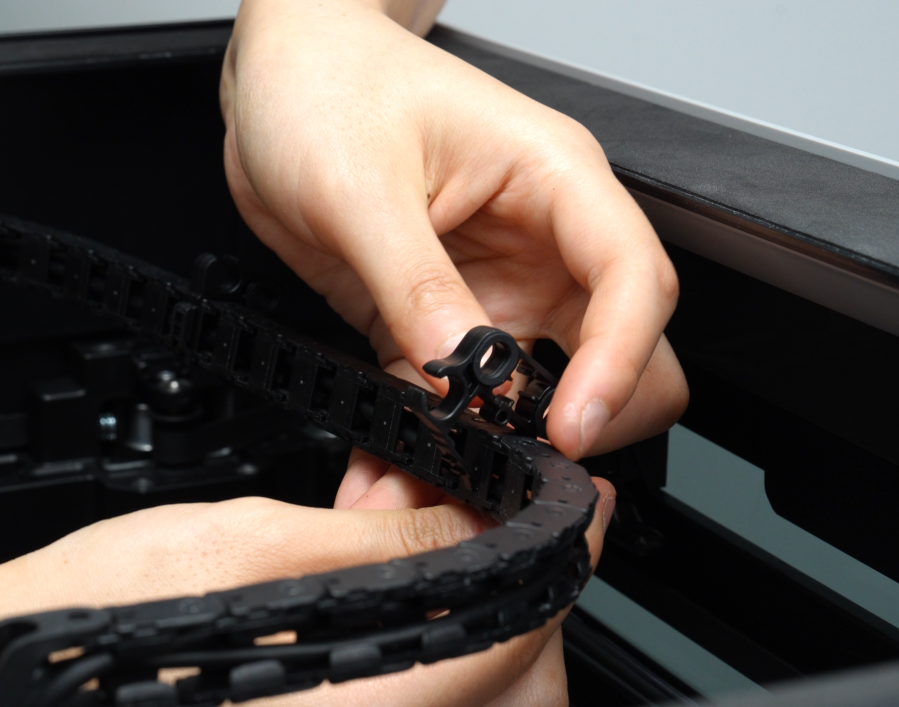

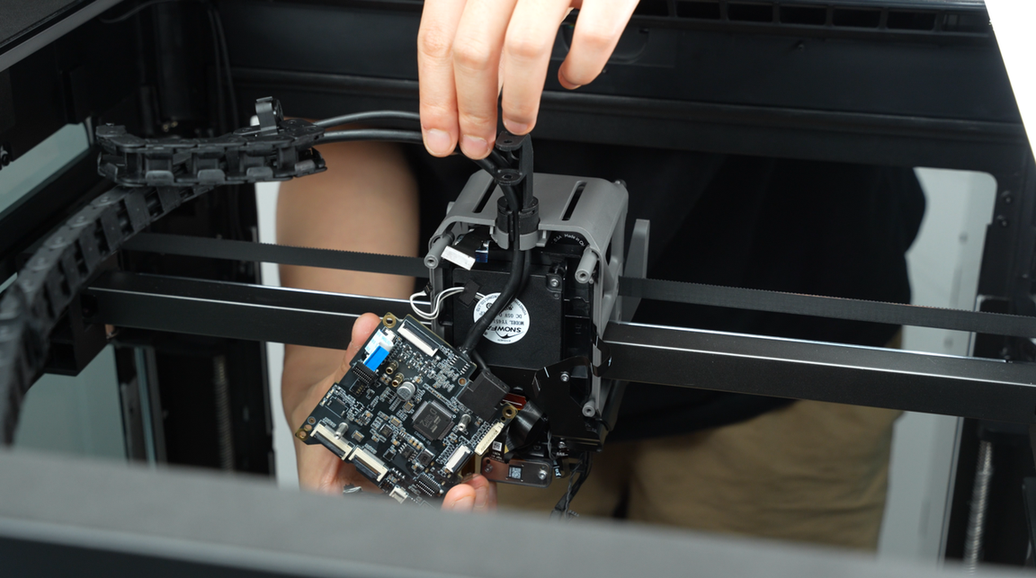

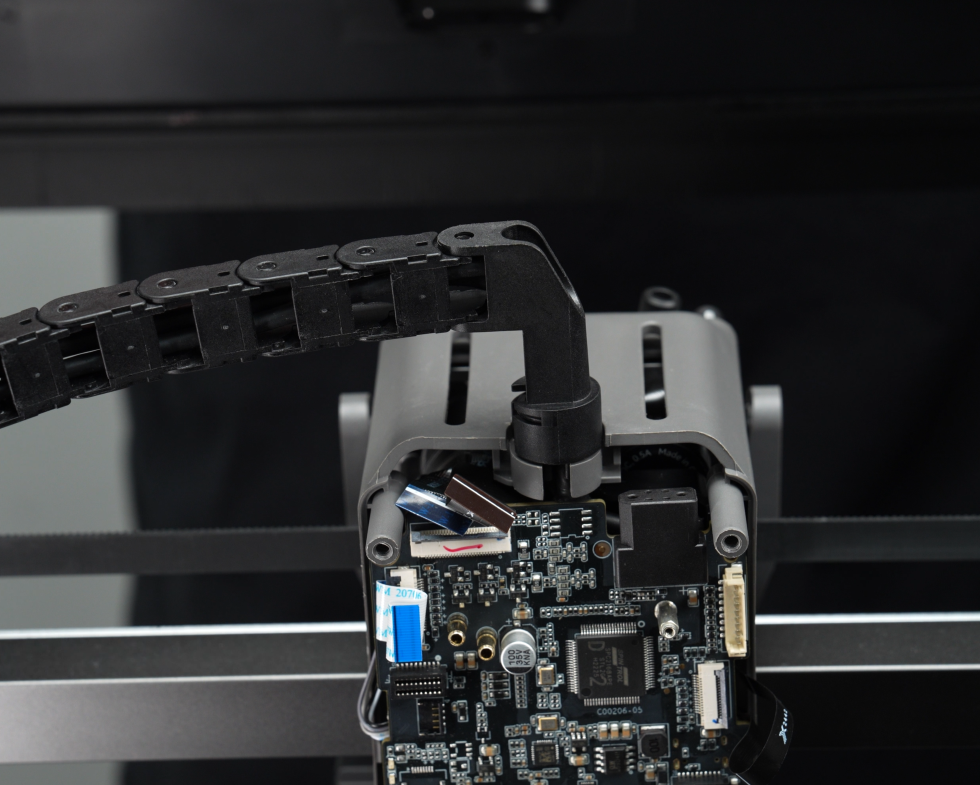

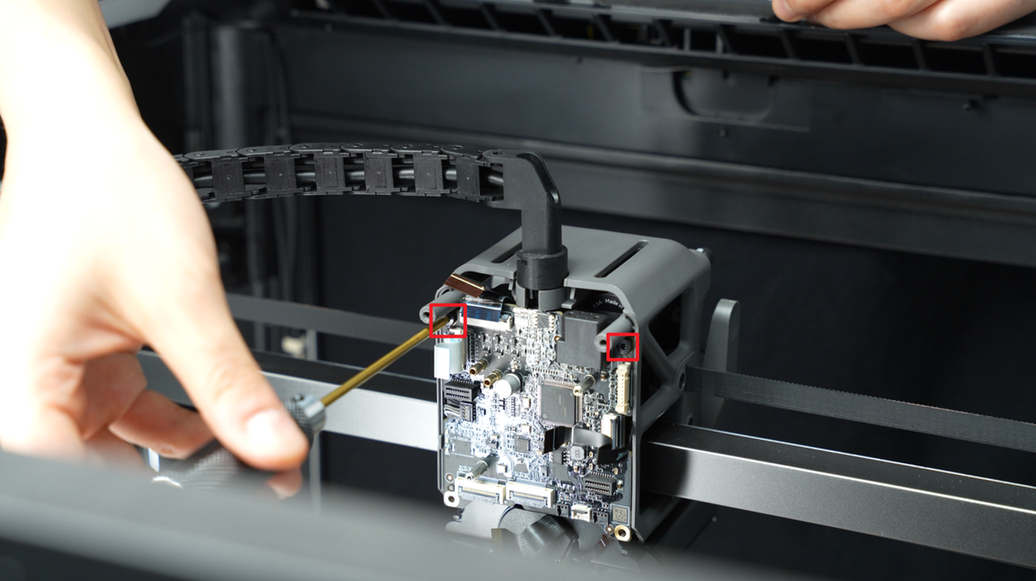

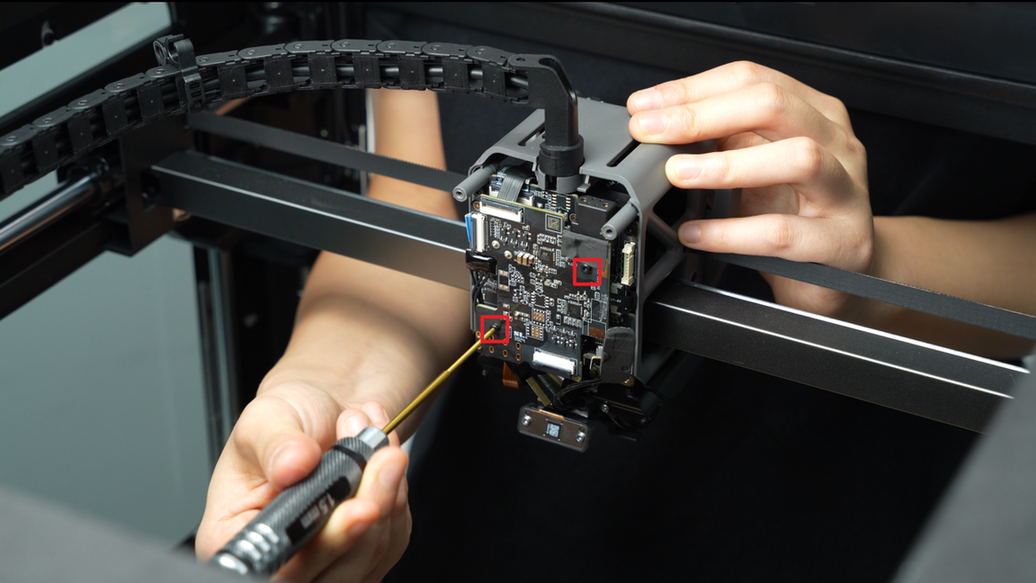

- Use an H2.0 Allen Key to remove the two fixing screws (BT2.6x8). Disconnect the cable chain from the cable chain base and pull out the MC-TH cable and USB-C cable from the cable chain.

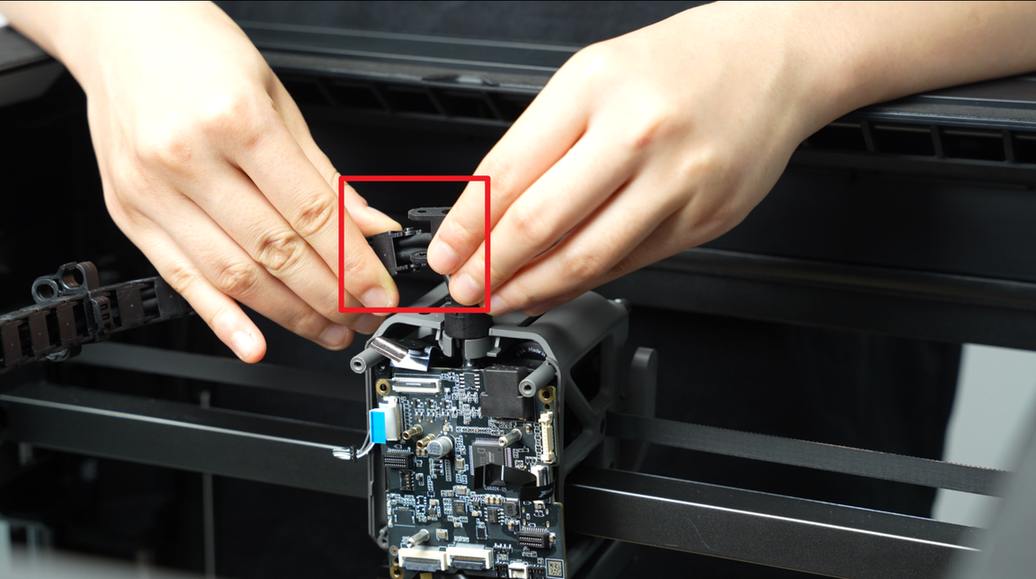

- Rotate the cable chain base to align the notch with the notch on the toolhead middle housing. Pull the TH board slightly downward and remove the MC-TH cable and USB-C cable from the notch. Disconnect the USB-C cable from the TH board.

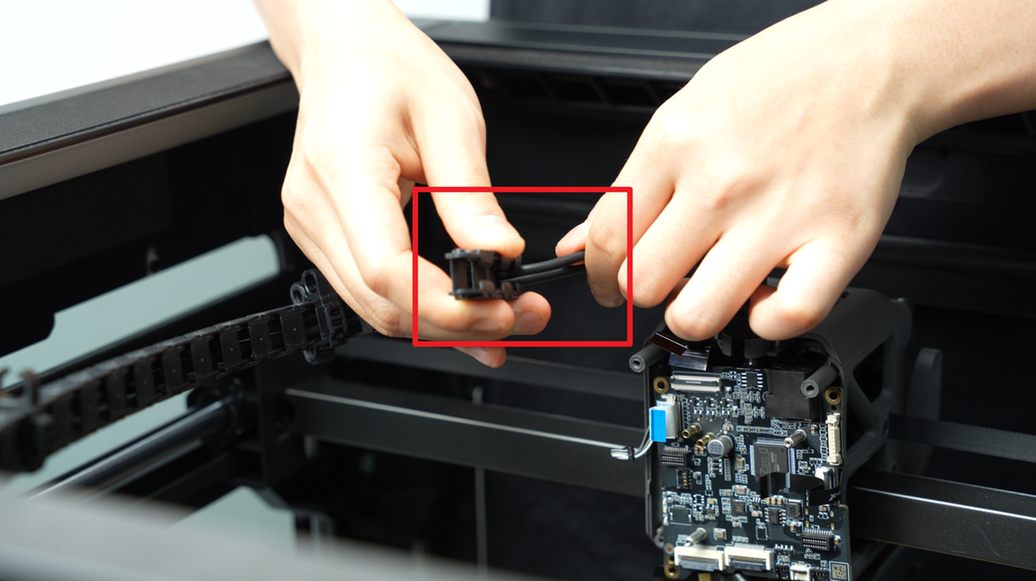

- Unlock the two latches on the cable chain (located on the 8th and 18th links, counting from the toolhead side).

- Disconnect the cable chain from the printer top cover and remove the MC-TH cable. Press the latch on the MC-TH cable to disconnect it from the toolhead to MC board cable and remove the TH board.

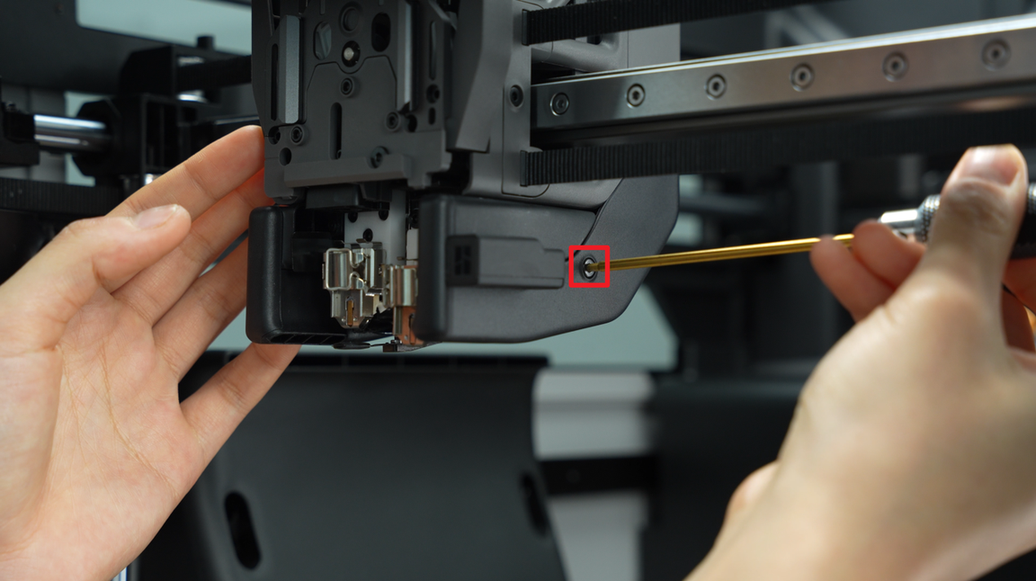

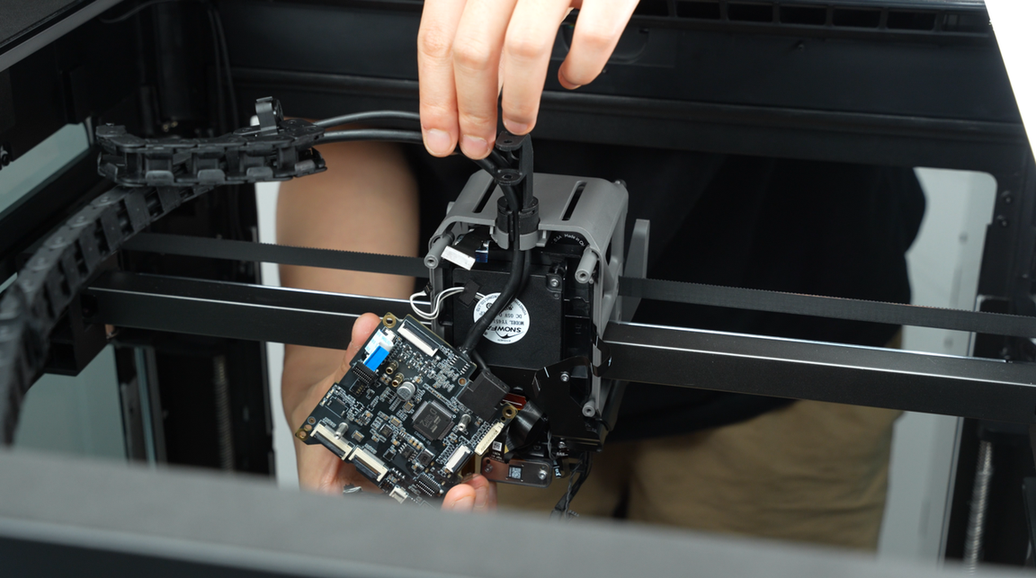

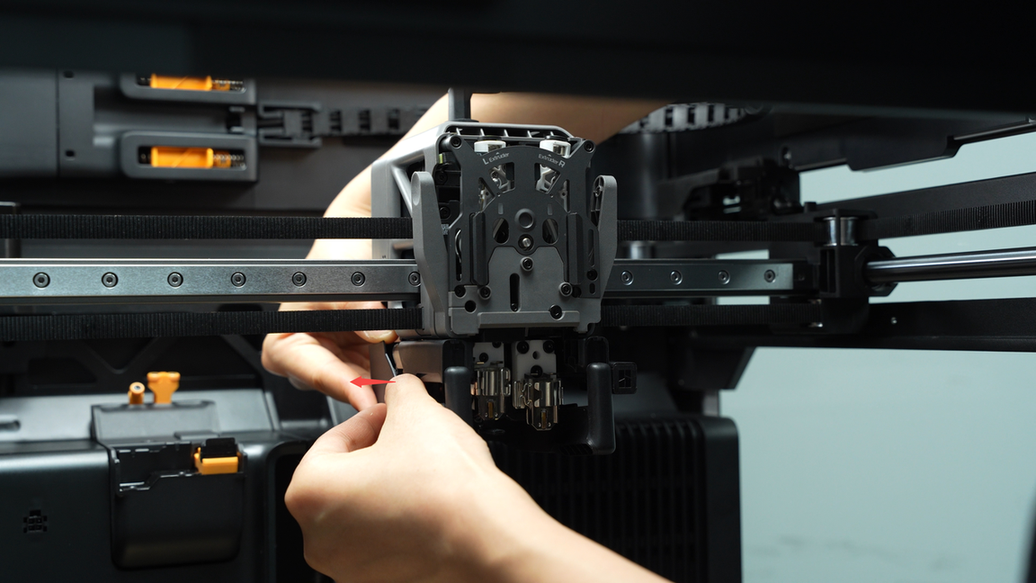

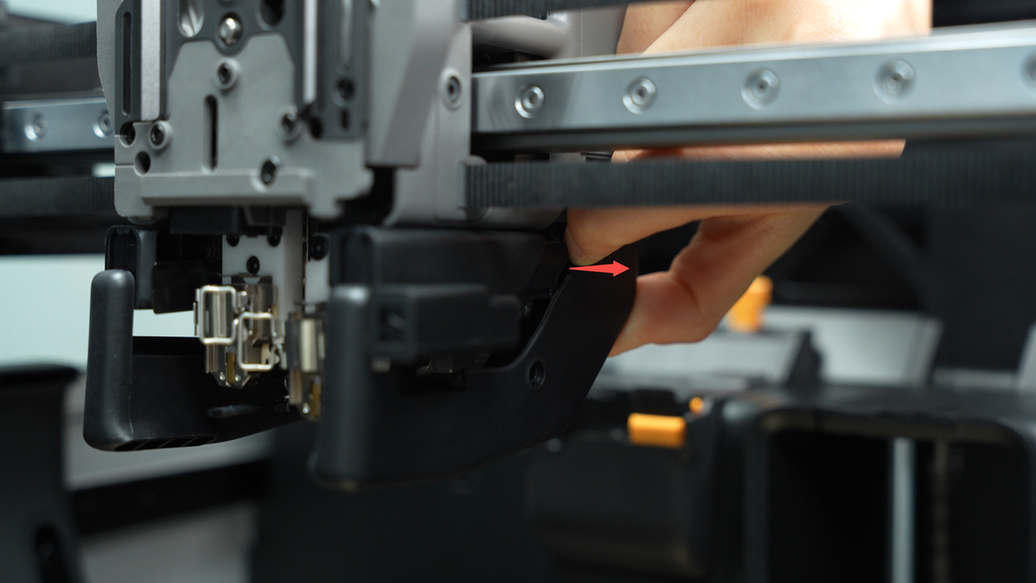

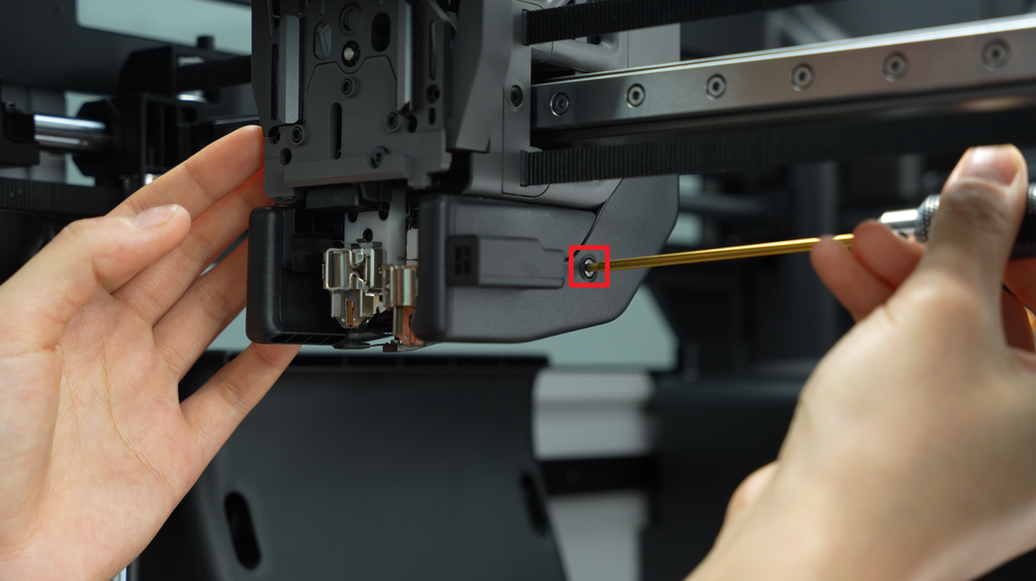

¶ Step 6: Remove the Cooling Fan for Hotend

- After confirming that the nozzle camera FPC is not stuck to the lifting motor rear cover, use tweezers to pry open the lifting motor rear cover.

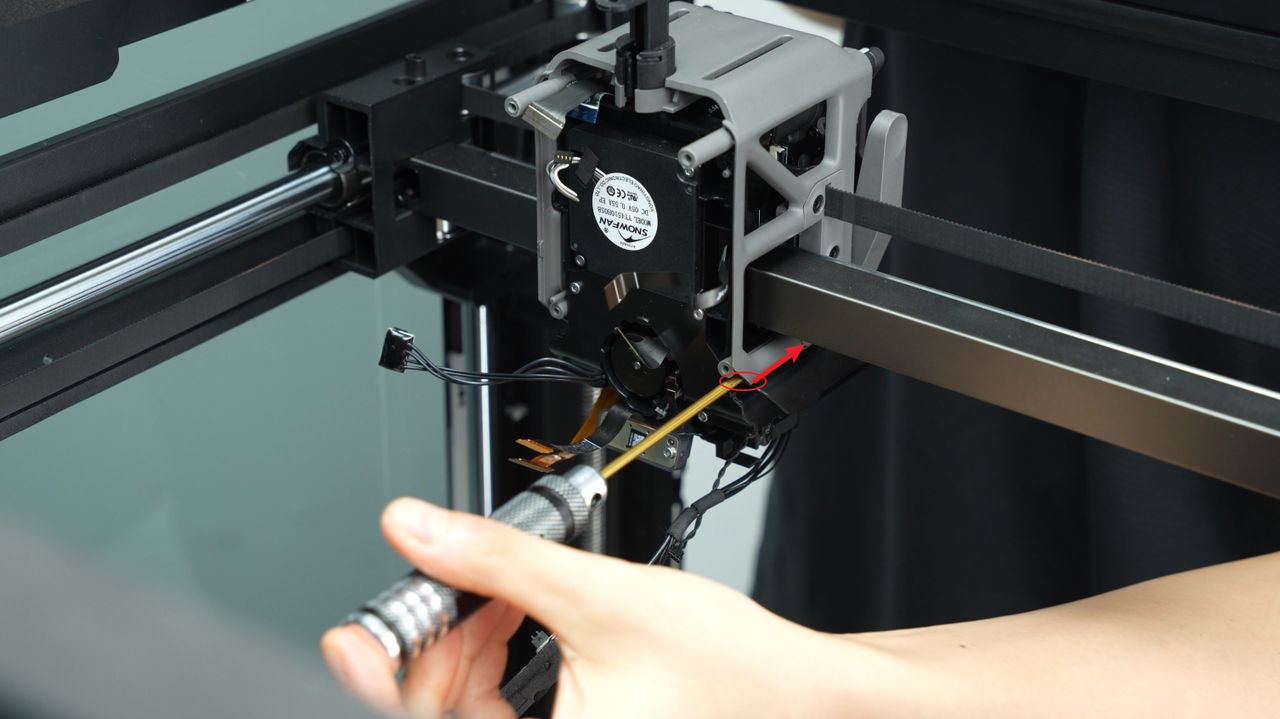

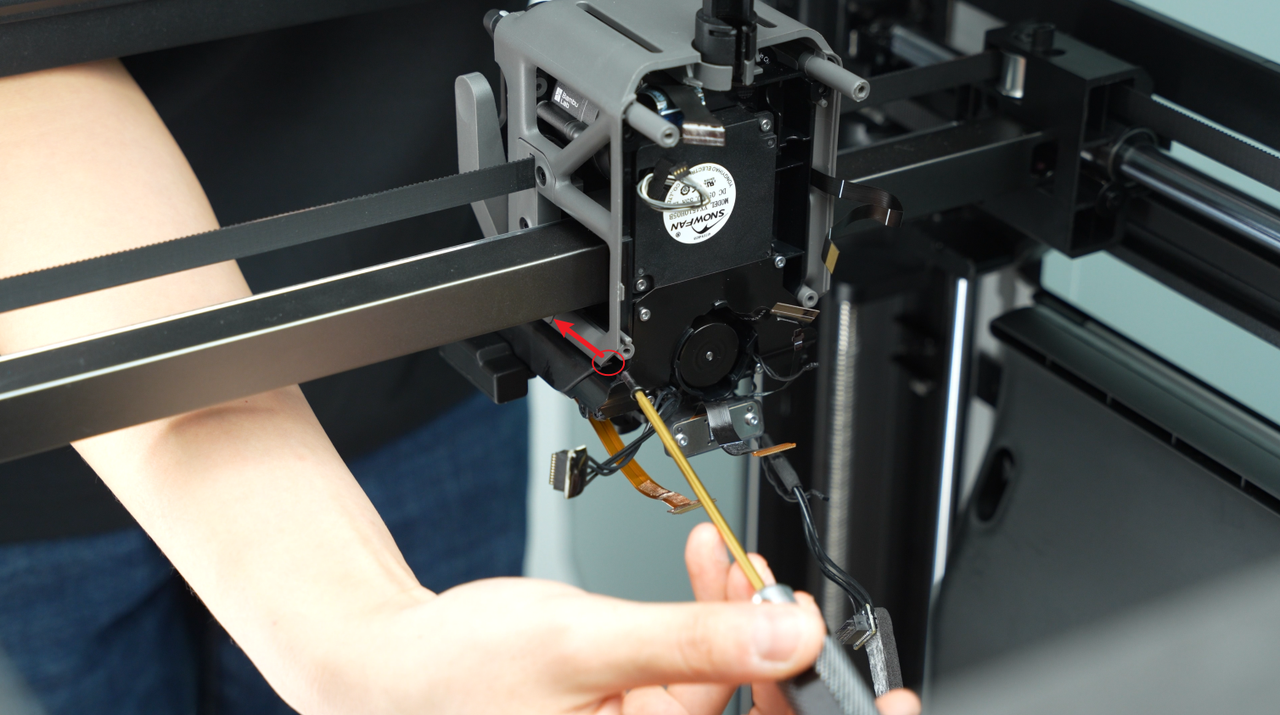

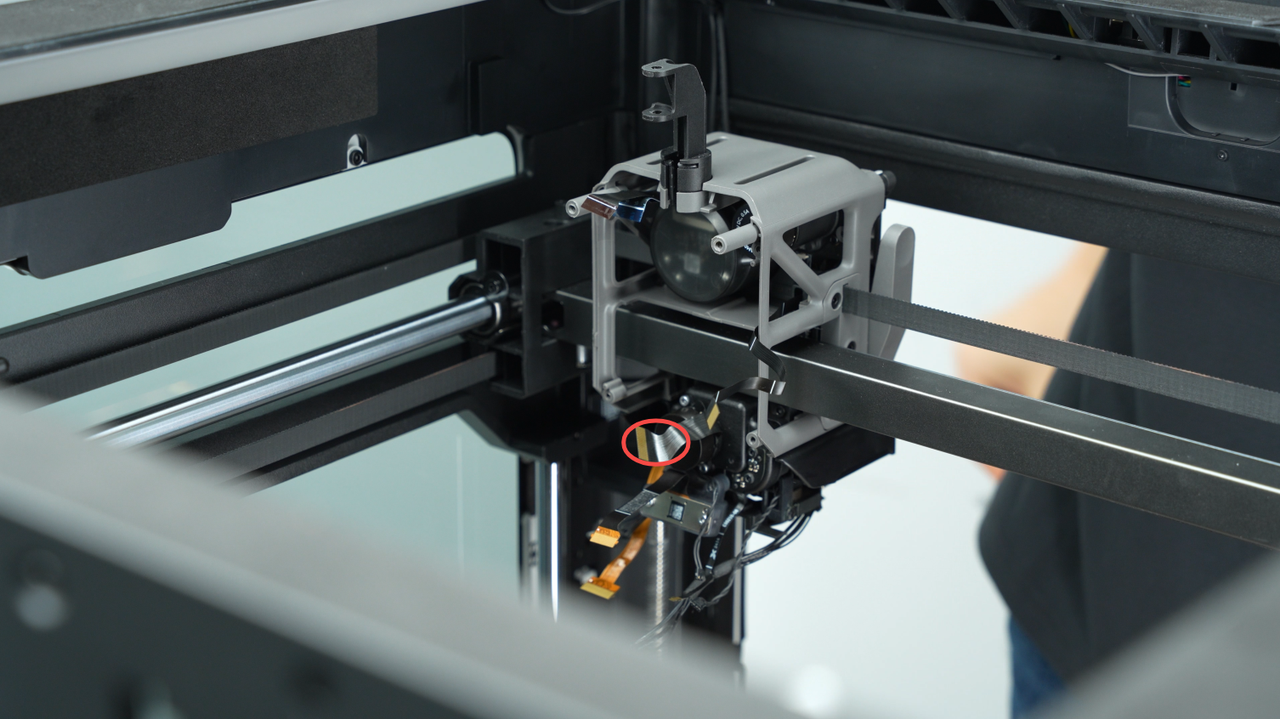

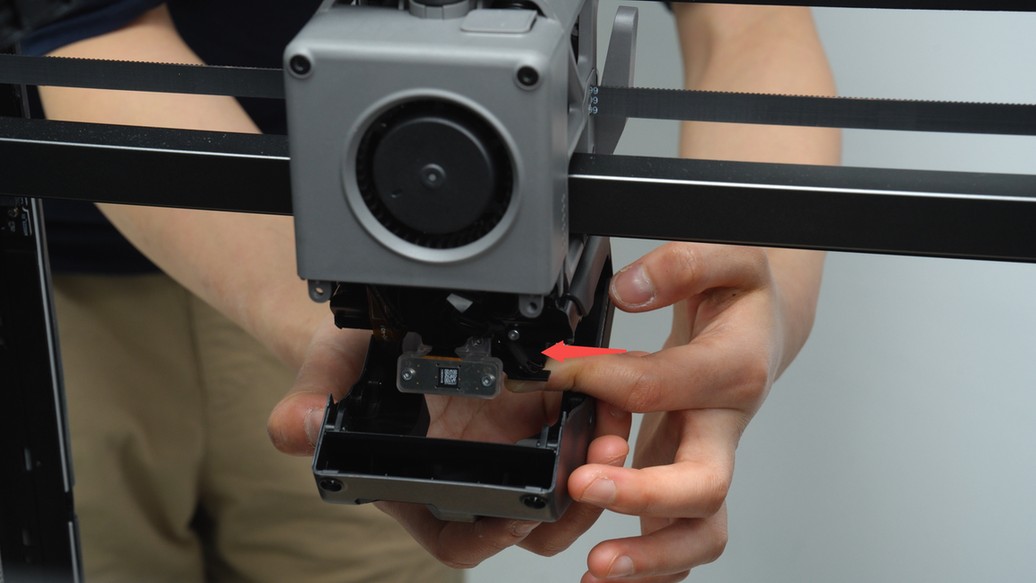

- Use an H2.0 Allen key to remove the two fixing screws (M2.5x8). These screws are located inside the plastic middle frame slot. Insert the screwdriver in the direction shown in the image to unscrew them. It is highly recommended to use a screwdriver with a magnetic tip.

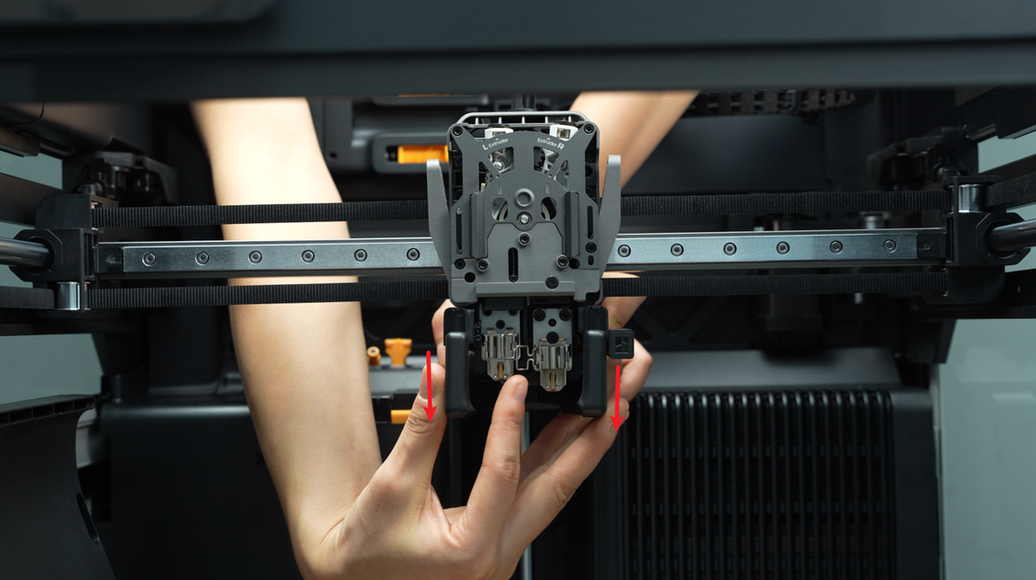

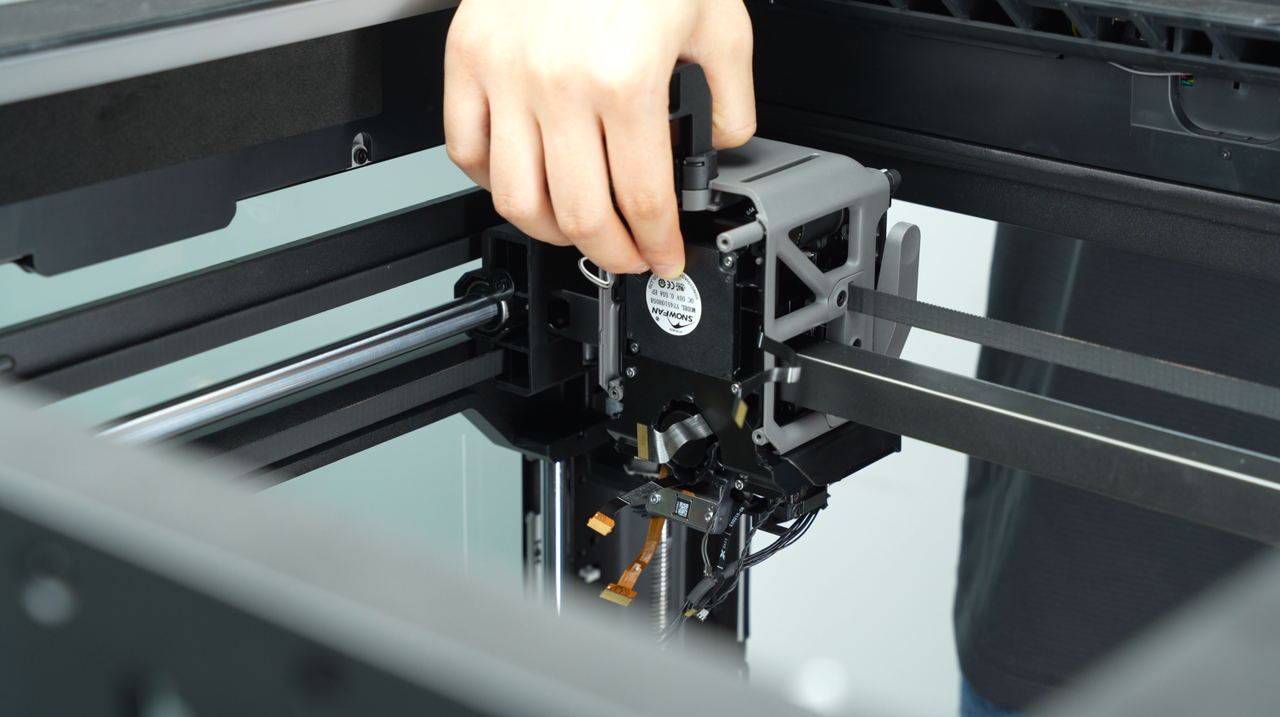

- Check the cable routing slot to ensure no cables are stuck (important). Then, pinch the lower part of the cooling fan for hotend and push it out backward.

¶ Install the Cooling Fan for Hotend

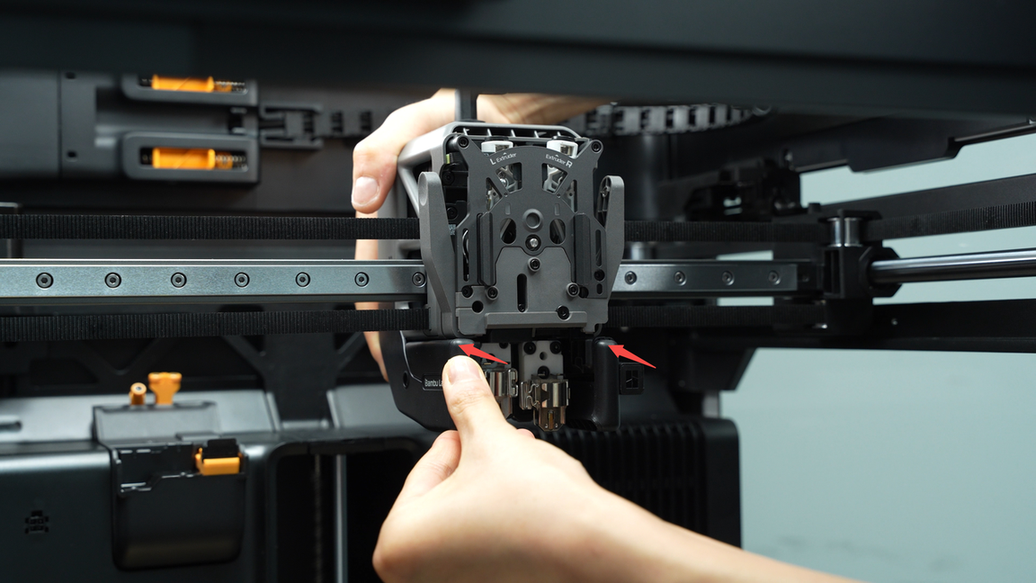

¶ Step 1: Install the Cooling Fan for Hotend

-

Organize the cables. Thread the lifting motor FPC through the hole in the fan bracket, and ensure all other cables are pulled away and not pinched. It is strongly recommended to confirm that no cables are pinched after installing the cooling fan for hotend before tightening the screws.

-

From top to bottom and left to right, the cables to be checked include: switching motor, extruder motor, extruder hall sensor board FPC, toolhead camera, nozzle camera, left and right eddy current coils, lifting hall, and lifting motor FPC (the last one should be threaded through the hole behind the motor rotor).

- Use an H2.0 Allen key to tighten the two fixing screws (M2.5x8) and snap the lifting motor cover back into place.

¶ Step 2: Install the TH board

- Connect the new TH board to the toolhead to MC board cable and secure the cable into the cable chain. Reconnect the cable chain to the top cover.

- Connect the USB-C cable to the TH board.

Note: Ensure the "T" shape faces outward!

- Rotate the cable chain base to align the notch with the toolhead middle housing notch. Snap the MC-TH cable and USB-C cable into the cable chain base and toolhead middle housing. You can snap the thinner cable (USB-C cable) in first, then the thicker cable (MC-TH cable).

- Reconnect the cable chain to the cable chain base and reattach the latches (on the 8th and 18th links, counting from the toolhead side).

- Align the TH board with the screw holes on the toolhead. Use an H2.0 Allen Key to tighten the 2 fixing screws (BT2.6x8).

Before tightening the screws, ensure no cables are trapped under the TH board!

Check the following cables:

From top to bottom and from left to right, the cables that need to be checked in turn include: 2004 switching motor, 3513 extruder servo motor, cooling fan for hotend, extruder connection board plug, toolhead sensor FPC cable, toolhead camera, nozzle camera, left and right eddy current coils, lifting hall and 2004 lifting motor cable, left and right hotend heating assemblies.

¶ Step 3: Reconnect all cables to the TH board

Reconnect all cables to the TH board in sequence. Refer to the images and tables for the specific cable connectors and their connection methods.

| No. | Connected to | No. | Connected to |

|---|---|---|---|

| 1 | Extruder connection board - TH board FPC cable | 7 | Right eddy current coil |

| 2 | 3513 extruder servo motor | 8 | Nozzle camera |

| 3 | Toolhead sensor FPC cable | 9 | Toolhead camera |

| 4 | Left hotend heating assembly | 10 | Cooling fan for hotend |

| 5 | Left eddy current coil | 11 | Right hotend heating assembly |

| 6 | Lifting hall effect sensor |

- 1, 2, 3, 6, 8, 9 plugs are fixed by buckles. You need to insert the cable into the interface of the TH board and tighten the buckle after the cable is fully inserted;

1 - FPC cable

2 - 3513 extruder servo motor

3 - Toolhead sensor FPC cable

6 - Lifting hall effect sensor

8 - Nozzle camera

9 - Toolhead camera

Reattach the toolhead camera and nozzle camera FPC cables. Use tweezers to secure the cables back onto the toolhead.

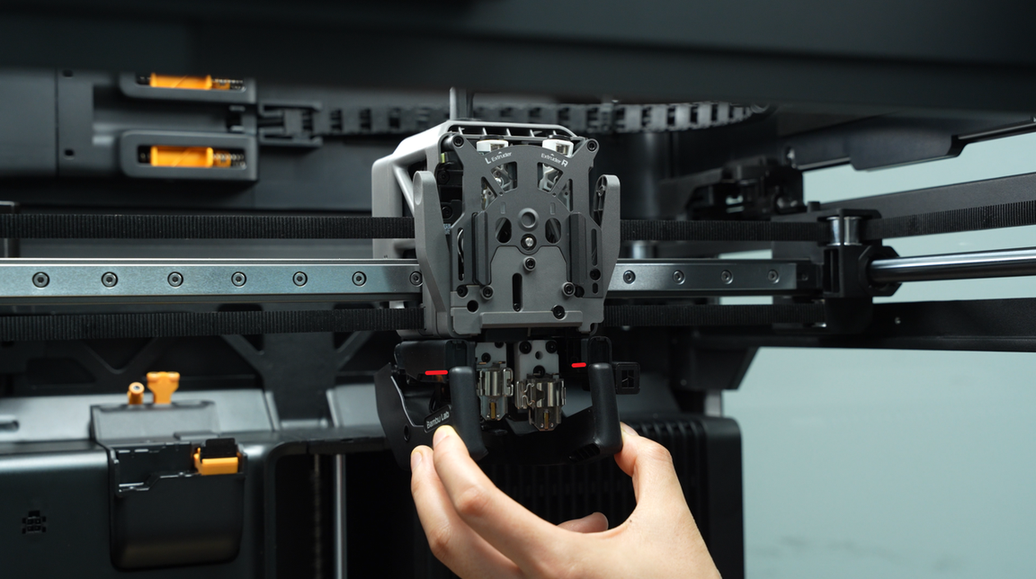

- Connectors 5, 7, and 10 are secured from the front. Ensure the metal side of the connector faces upward, align the connector with the interface, and press downward to disconnect.

10 - Cooling fan for hotend

5 - Left eddy current coil

7 - Right eddy current coil

- Connectors 4 and 11 are secured by headers. Align the header with the connector and insert it directly, ensuring it is fully seated.

Insert the cables into the cable clip:

As shown in the figure, there are 2 cable channels at the arrows. The large cable channel at the lower arrow is used to store the left hotend heating assembly cable, and the small cable channel at the upper arrow is used to organize the left eddy current coil plug, right eddy current coil plug and lifting hall plug cables. You can reconnect these 3 plugs to the TH board and then re-insert the cables into the small cable channel.

The order of inserting the cables is:

¶ Step 4: Install the extruder connection board

- Align the extruder connection board latches with the slots on the TH board.

- Install the extruder connection board and tighten the 2 fixing screws (M1.6x4) using an H1.5 Allen Key.

- Reconnect the following cables to the extruder connection board:

The name of the cable that corresponds to the number in the picture:

- FPC cable

- 2004 switching motor cable

- Part cooling fan cable (to be connected in Step 5)

- Left hotend heating assembly cable

- 2004 lifting motor cable

Detailed Steps:

- Connect the left hotend heating assembly to the TH board. Insert the header into the TH board’s socket and secure the foam onto the extruder connection board.

- For No. 1, 2, and 5, these plugs are fixed by buckles. You need to insert the cable into the interface of the extruder connection board, and then tighten the buckle after the cable is fully inserted;

NOTE: No. 3 - The part cooling fan connector will be connected in "Step 5".

¶ Step 5: Install the part cooling fan

- With the metal side facing up, align the interface, then press down the part cooling fan plug and stick back the acetate tape.

- Align the screw holes, cover back the part cooling fan, and tighten the 4 fixing screws.(BT3x20 marked with a square symbol, BT2.6x8 marked with a circle symbol)

¶ Step 6: Install the part cooling fan duct

- The left hotend heating assembly cable needs to be installed in the cable management slot. Before installing the duct, make sure to press the hotend heating assembly cable into the cable management slot to prevent the duct from pressing on the cable.

- First, install the front 1/4 of the duct to make it easier to tilt the rear half of the duct, avoiding interference with the nozzle camera. Then, grasp the rear half of the duct and push it upwards.

- After pushing it in, gently bend the sides of the duct outward, slotting them onto the tool head on each side, and then firmly press the duct upwards to secure it in place.

- Next, push the top of the front section of the duct forward to ensure a snug, gap-free fit.

- Use an H2.0 hex key to tighten the four fixing screws (BT3x8).

¶ Verify the Functionality

Connect the power, turn on the printer, and initiate a print job to check if it prints

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!