¶ What is Air Printing Detection

During 3D printing, "air printing" occurs when the nozzle fails to extrude filament properly due to clogs, damp/irregular filament, or incorrect temperature settings, causing the nozzle to print in mid-air. The H2 series printer uses multi-module collaboration to detect air printing, pausing immediately and prompting users to resolve the issue. It should be noted that the H2S does not support nozzle-camera vision detection for air printing.

¶ Three Detection Solutions

¶ **1. Camera-Based Visual Detection (Monitors Nozzle Extrusion) **

Since it does not have a nozzle camera, the H2S does not support vision-based air printing detection.

¶ How It Works

The nozzle camera continuously checks two critical conditions:

-

No filament is extruded when expected.

-

The distance between the nozzle and the printed object increases over time.

|

|

¶ Requirements

- The printer must be equipped with a nozzle camera.

¶ Conditions for Use

-

The nozzle camera and auxiliary fill light must function properly, with a clean lens.

-

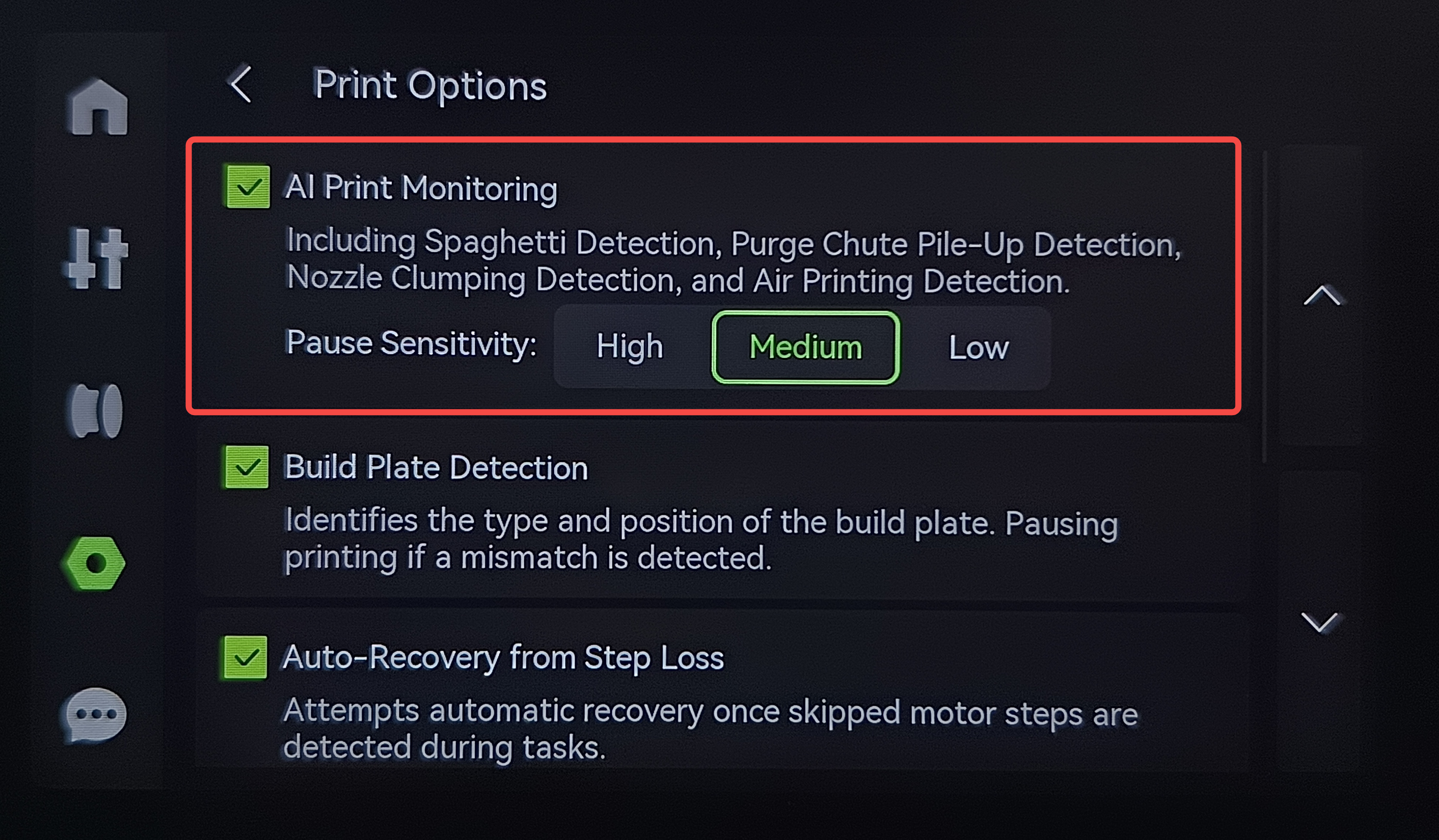

Enable the "AI Print Monitoring" option in print settings.

¶ Notes

False Alerts: Models with long traveling (e.g., scattered small parts) may trigger false alarm.

Accuracy: Due to limited training data in the current firmware version, detection accuracy is being continuously improved through algorithm updates.

¶ 2. AMS-Based Detection (Measures Filament Feed Length)

¶ How It Works

The AMS continuously monitors the filament feed length during printing:

- If feeding length remains unchanged → Extrusion failure is detected → Filament is automatically cut and retracted.

¶ Requirements

- Enabled by default when using AMS for printing.

¶ Notes

Error Handling:

When an air printing error occurs, the printer automatically cuts the filament and pulls it back to the AMS. To resolve:

-

Pull the filament from the corresponding AMS slot.

-

Trim damaged sections (e.g., worn filament).

-

Reinsert the filament and resume printing.

-

If extrusion errors persist, check for nozzle clogs or extruder jams.

Post-Recovery Check:

- Under-extrusion may appear on the model surface due to air printing that occurred before detection. Inspect the print quality before deciding to continue or restart the task.

¶ 3. Closed-Loop Servo Motor Detection (Senses Extrusion Resistance)

¶ How It Works

Monitors the servo motor’s torque output:

- High extrusion speed + low torque → Indicates gear slippage (e.g., filament not grabbed or worn down).

The H2D uses a closed-loop servo motor to track torque in real time. If rapid extrusion speed is paired with abnormally low torque, the system detects extrusion failure.

¶ Common causes include:

-

Manually loaded external filament triggering the hall sensor but not being grabbed by gears.

-

Filament wear reduces its diameter, preventing proper grip.

¶ Requirements

- Enabled by default when using external spools.

¶ Conditions for Use

-

External spool printing only

-

0.4mm nozzle required (other sizes unsupported)

-

The print speed must be moderate: Detection requires a print flow rate >9.6 mm³/s (low-speed scenarios like first-layer printing may bypass detection)

-

Supported materials: PLA, PLA-CF, PETG, PETG-CF

¶ Troubleshooting Steps:

-

Trim damaged sections of filament.

-

Reinsert filament → Preheat nozzle → Manually test extrusion.

-

If extrusion fails, check and clear the nozzle/clogged extruder.

¶ Notes:

- Less effective for models with frequent retractions (e.g., tall thin pillars).

- Post-recovery prints may show minor material gaps due to delayed alerts (affected by material type/speed). Inspect print quality carefully before deciding to resume the print.

¶ Application Scenarios

In summary, the system automatically activates dual detection based on the material feeding method:

When Using AMS:

-

Camera Detection: Monitors nozzle extrusion status. (Not including H2S)

-

AMS Feed Tracking: Precisely measures filament feeding length.

When Using External Spools:

-

Camera Detection: Monitors nozzle extrusion status. (Not including H2S)

-

Motor Torque Detection: Tracks extrusion resistance changes.

By combining two detection methods, the H2 series ensures higher sensitivity to air printing in both scenarios, significantly improving print reliability and success rates.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!