¶ Functional Overview

Bambu Suite provides 3D status perception throughout the entire processing cycle, which can provide users with a more intelligent processing and production experience.

-

Processing preparation stage: display the platform type, material information, and chamber door status in real-time, and send safety inspection reminders;

-

Intelligent parameter matching: automatically adapts to the best processing parameters in conjunction with the CodeSync QR code of the official material.

-

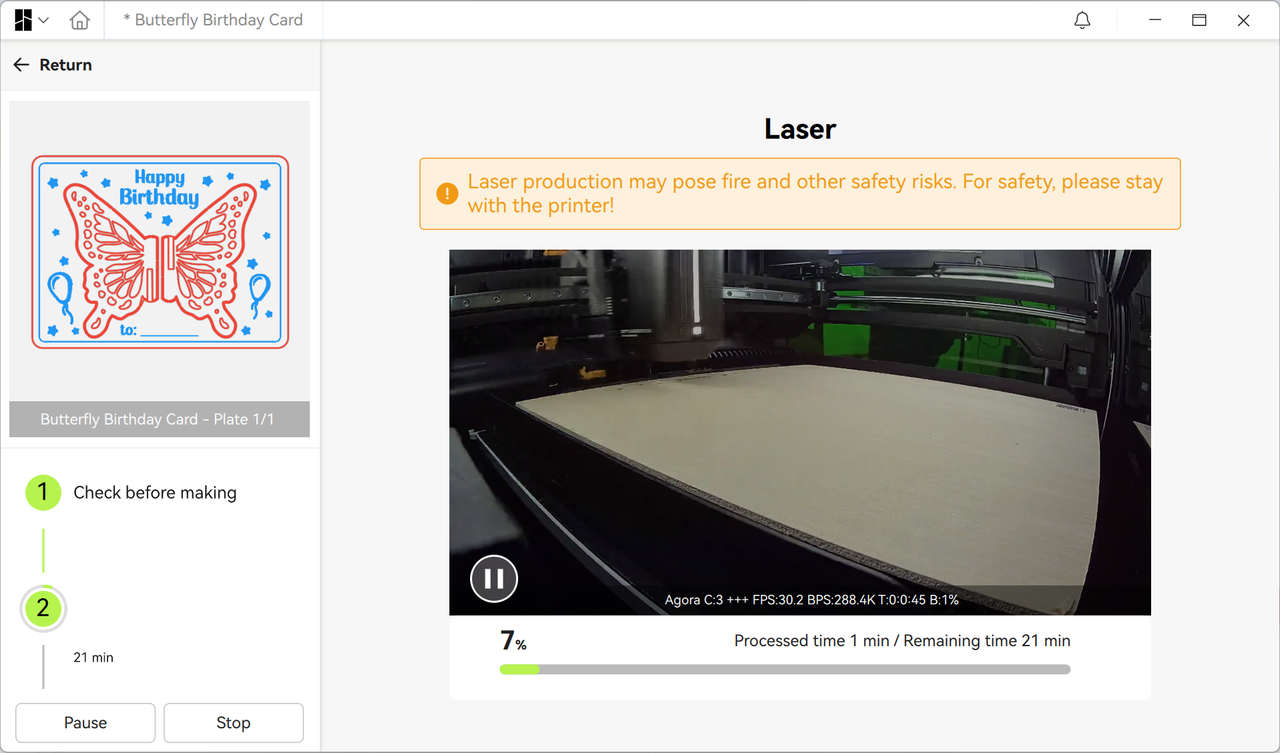

Production execution stage: monitor the processing progress and equipment status in real-time through Liveview;

¶ Display of the Status Inside the Chamber

¶ Platform type detection and safety protection

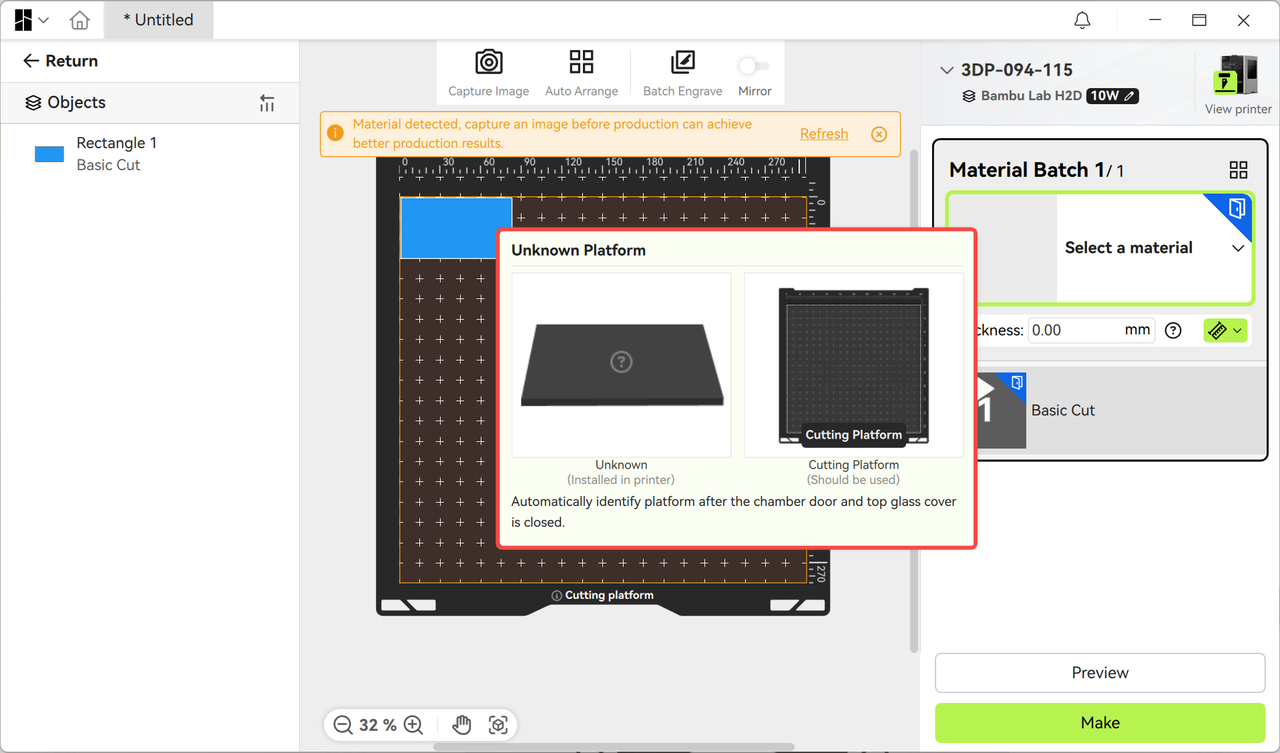

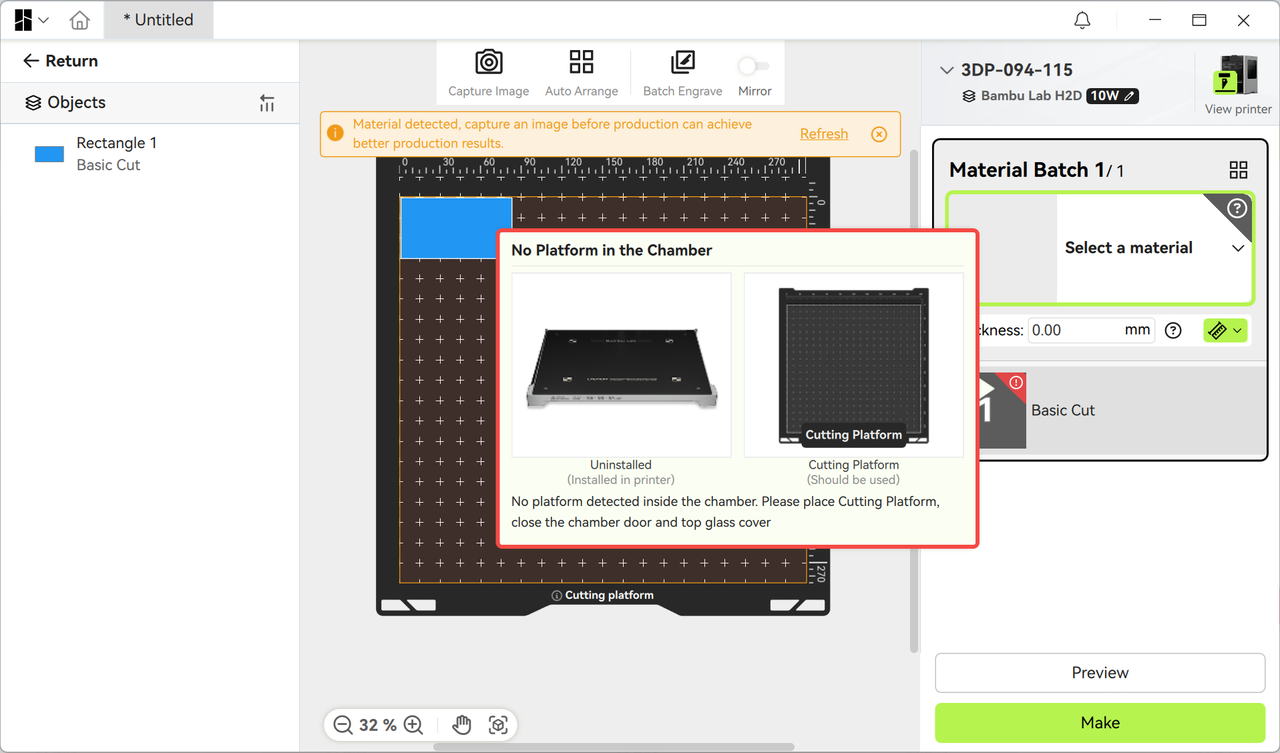

The correct use of the platform is the basis for successful processing and directly affects the safety of the equipment and the quality of the finished product. If the wrong platform is used, such as using the laser to ablate the cutting platform, it will damage the printer and produce toxic and harmful gases. Therefore, it is particularly important for users to fully perceive the status inside the chamber.

When the platform type required by the user's project is inconsistent with the platform type in the chamber, Bambu Suite will prompt in multiple places so that the user can replace the correct platform in time and successfully produce the project.

¶ 1. Identification and prompts for each platform

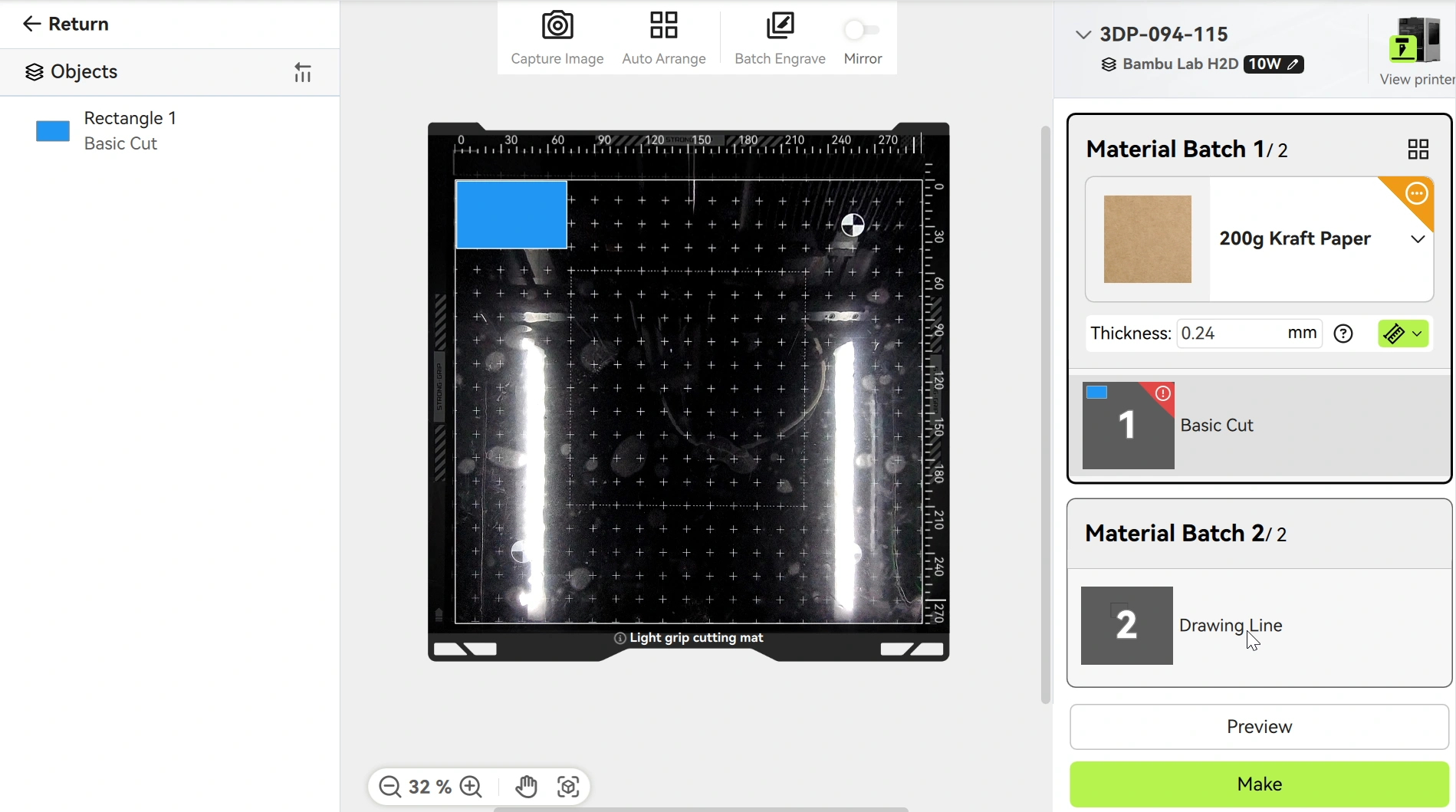

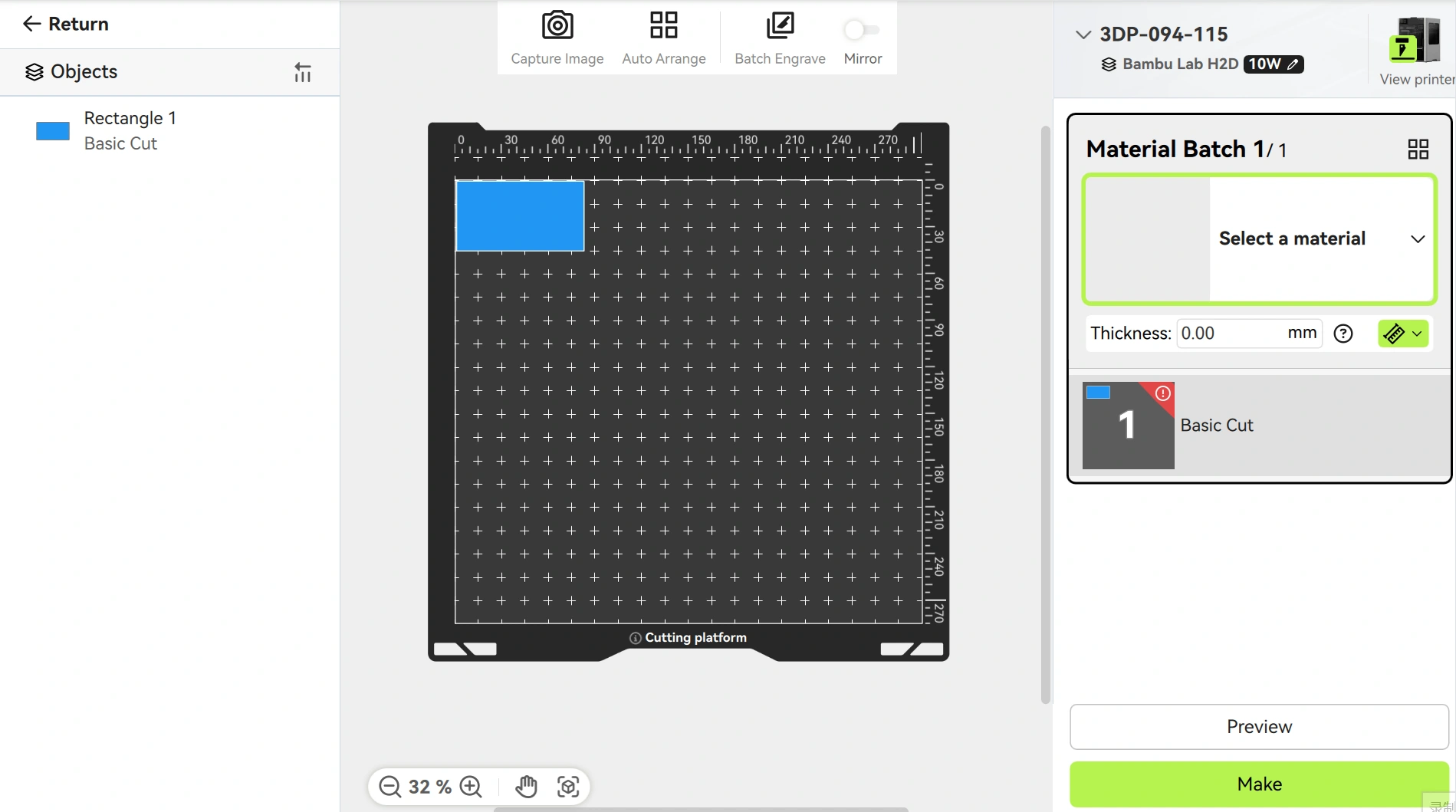

The platform status icon is displayed on the right side of the preparation page, and there are usually the following types of prompts:

- The platform placed in the chamber is wrong, and the platform type is detected to be inconsistent with the project.

- The platform type in the chamber is not detected. This may be because the chamber door and top cover are not closed, or the platform identification code is blocked.

- It is detected that no platform was placed in the chamber.

¶ 2. Pop-up warning after taking a photo

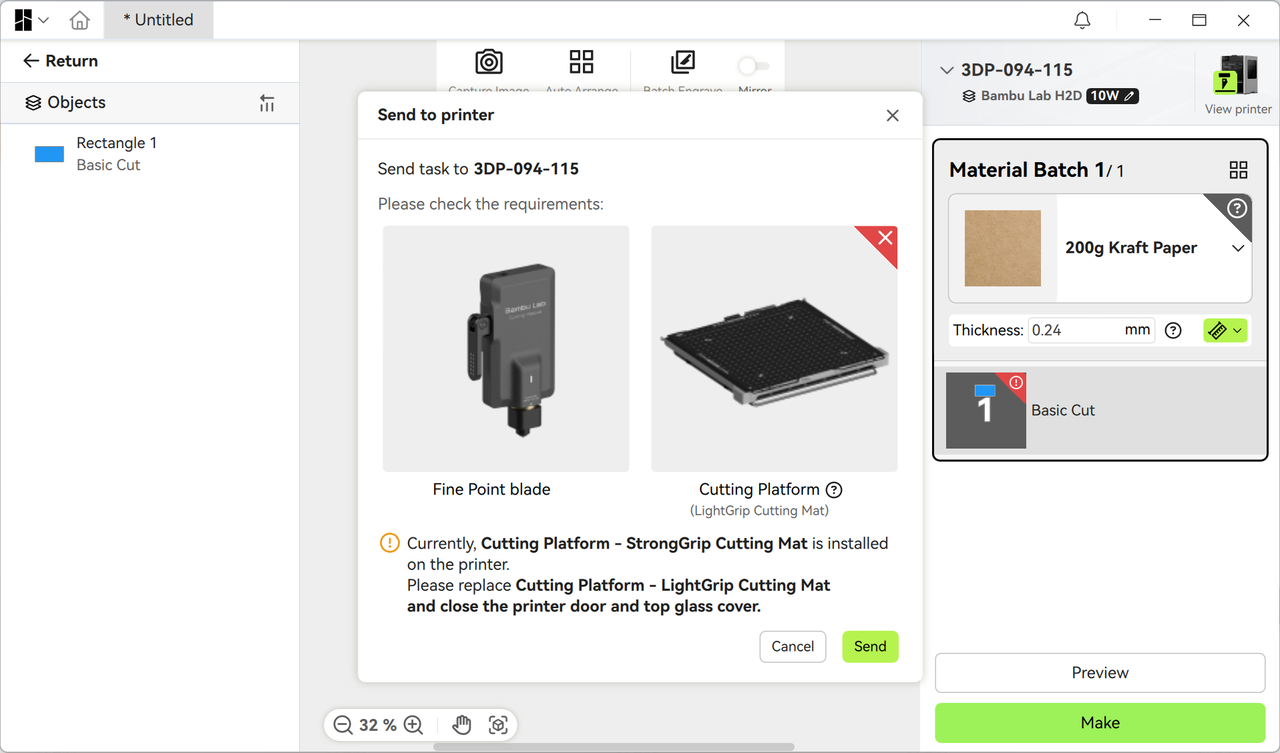

When the user triggers the photo function in Bambu Suite, if the platform type does not match → a pop-up window will pop up immediately to remind the user to change it.

¶ 3. Mandatory confirmation before sending the task

If the user does not pay attention to the previous information, the software will remind the user to change the correct platform again when clicking "Make".

¶ Material identification and matching management

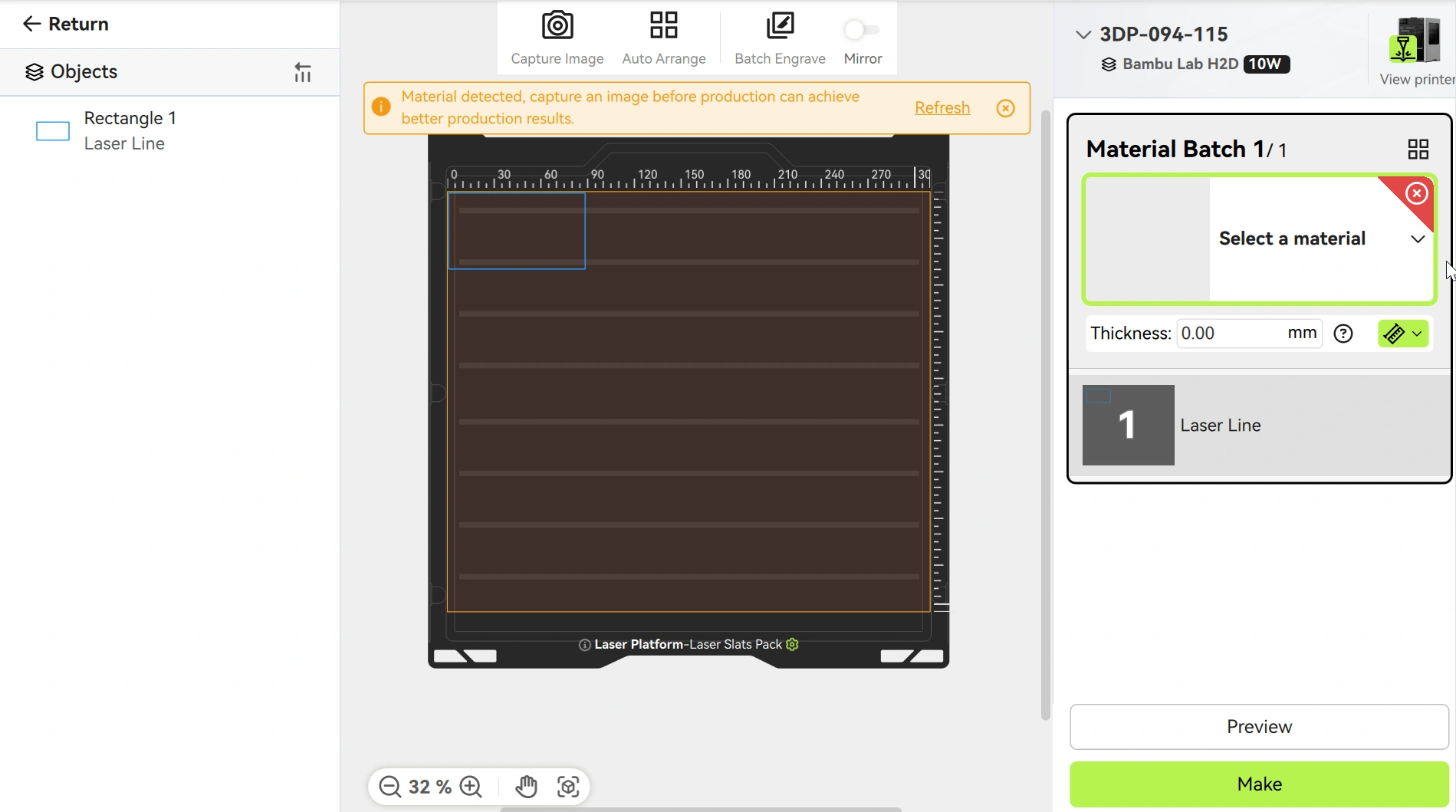

¶ 1. The preparation page prompts you to take a photo

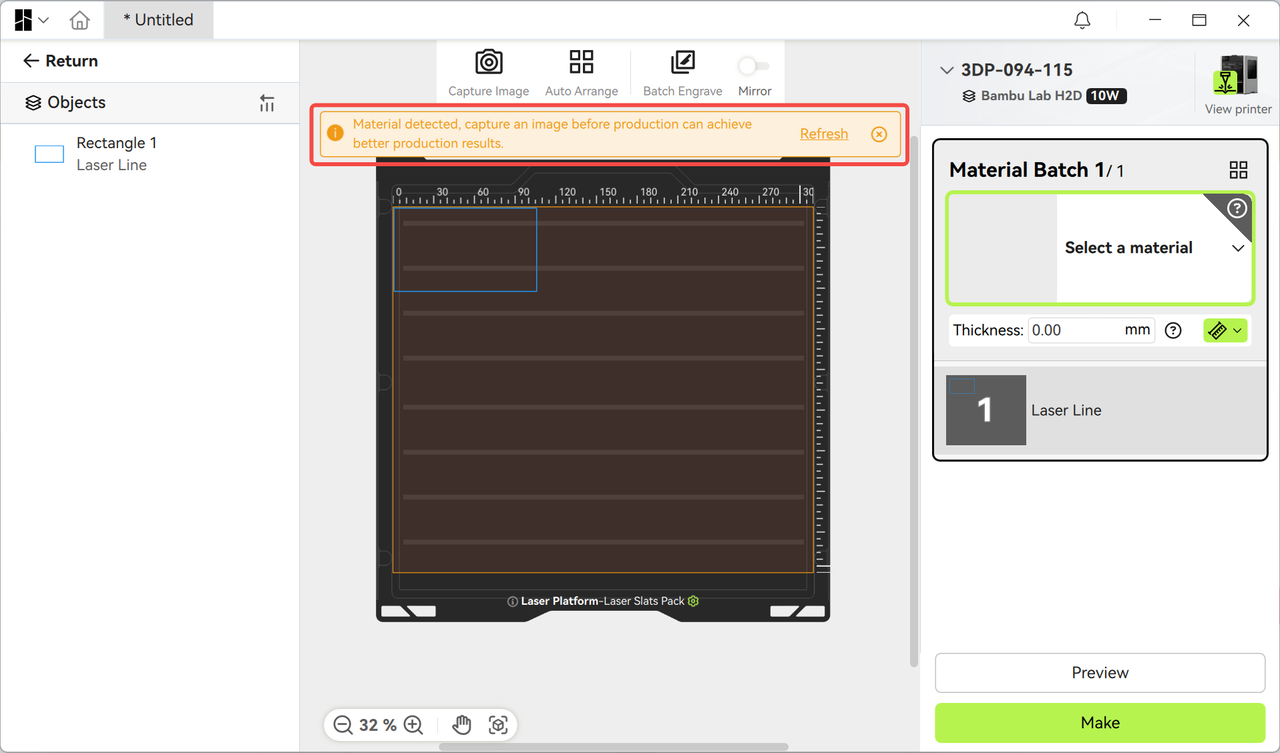

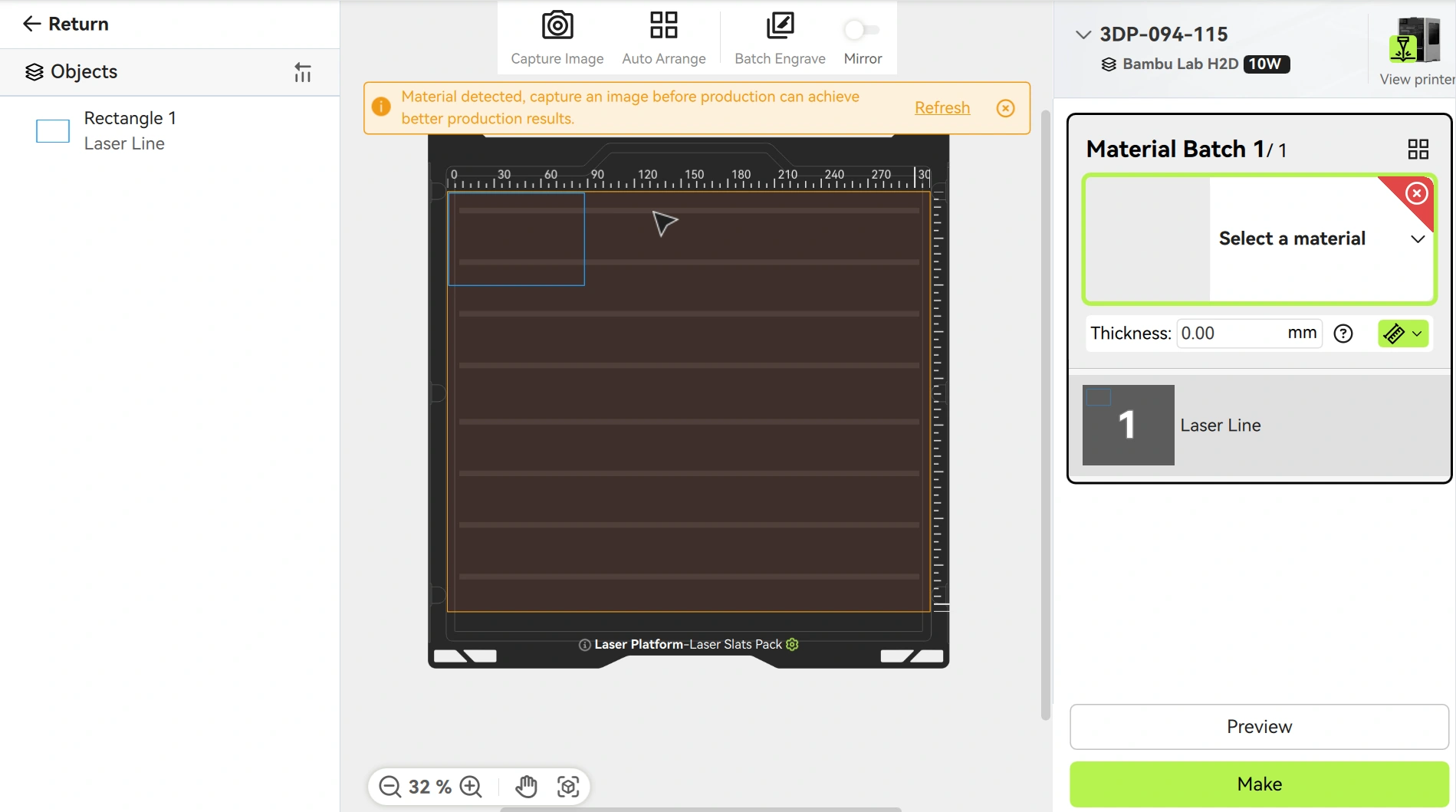

When Bambu Suite is connected to the printer, if it detects that there is material in the chamber, it will actively remind the user to take a photo so that the processing pattern can be correctly placed on the material.

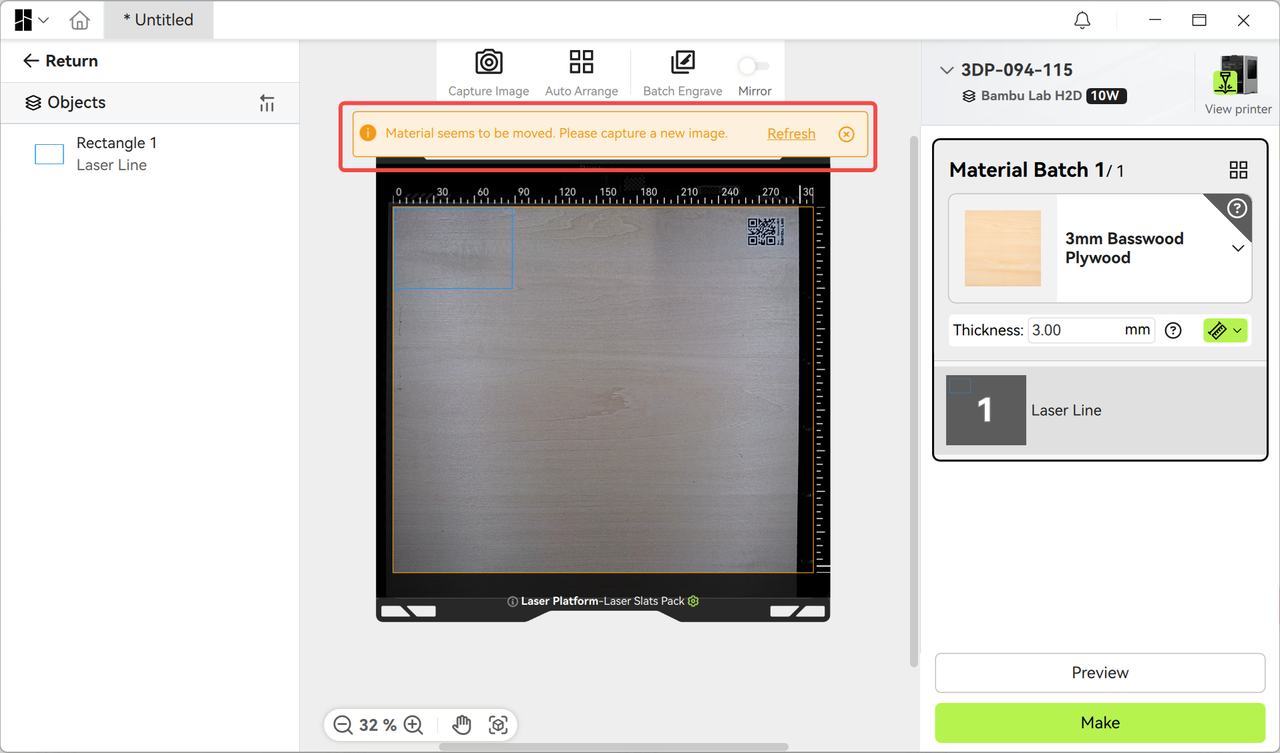

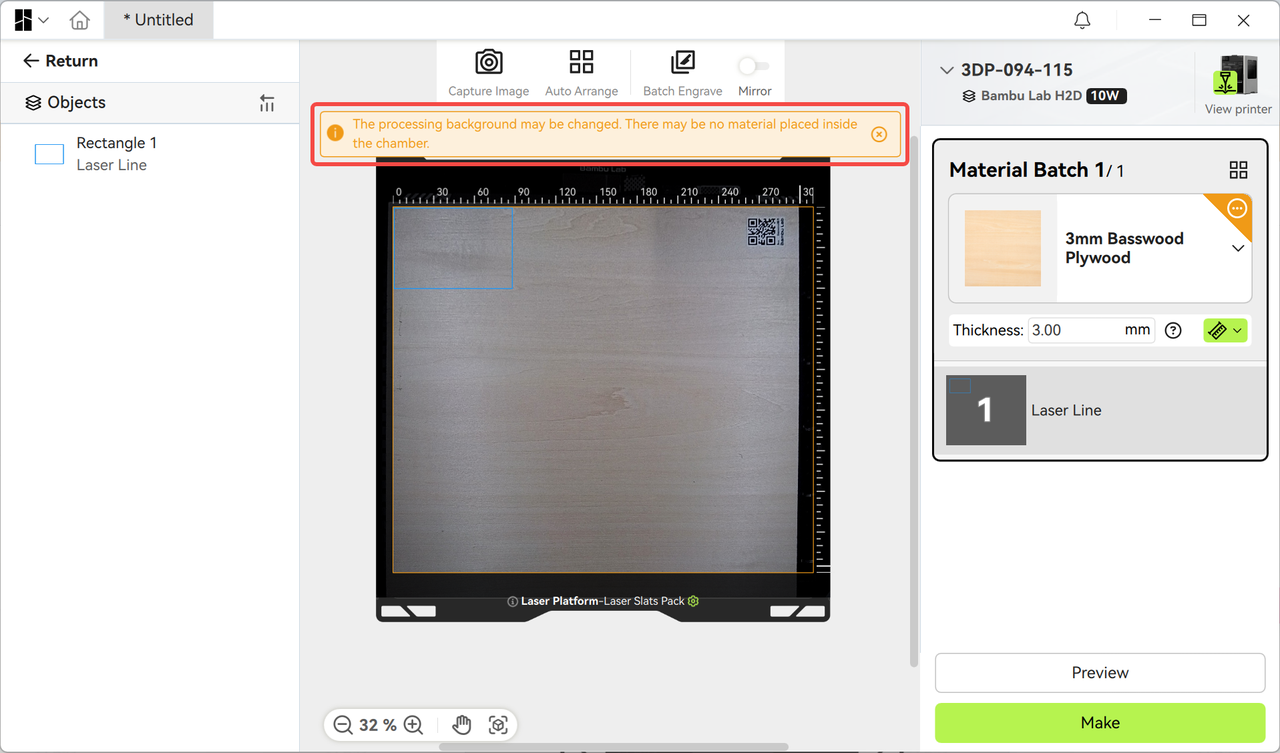

¶ 2. Material position change reminder

- If the user changes the material in the chamber or adjusts the material position, Bambu Suite will also remind the user that the previously taken photos have expired and need to be retaken.

- When the user takes out the material from the chamber, Bambu Suite will remind the user that there is no material placed inside the chamber and processing cannot be performed directly at this time.

¶ 3. Material information tips

¶ Statement of the material group in the upper right corner

When the user is on the preparation page, the upper right corner of the material group will prompt the material information or status in the chamber and the current chamber door status. The upper right corner of the material group displays the following information in real time:

-

Type of material placed in the chamber (such as white cardboard)

-

Chamber door status (open/closed)

-

Matching status identification (unmatched/unknown material/no material placed)

¶ Material identification and matching process

Scenario 1: Using materials with CodeSync QR codes

- Automatic identification

- The user places the material with CodeSync QR code → The printer automatically identifies the type and synchronizes it to Bambu Suite.

- Intelligent parameter matching

-

If the material in the chamber is inconsistent with the project selection → The mismatch mark is displayed in the upper right corner;

-

Click the mark → Select to switch to the material in the chamber → The system automatically calls matching parameters in the local material library for production.

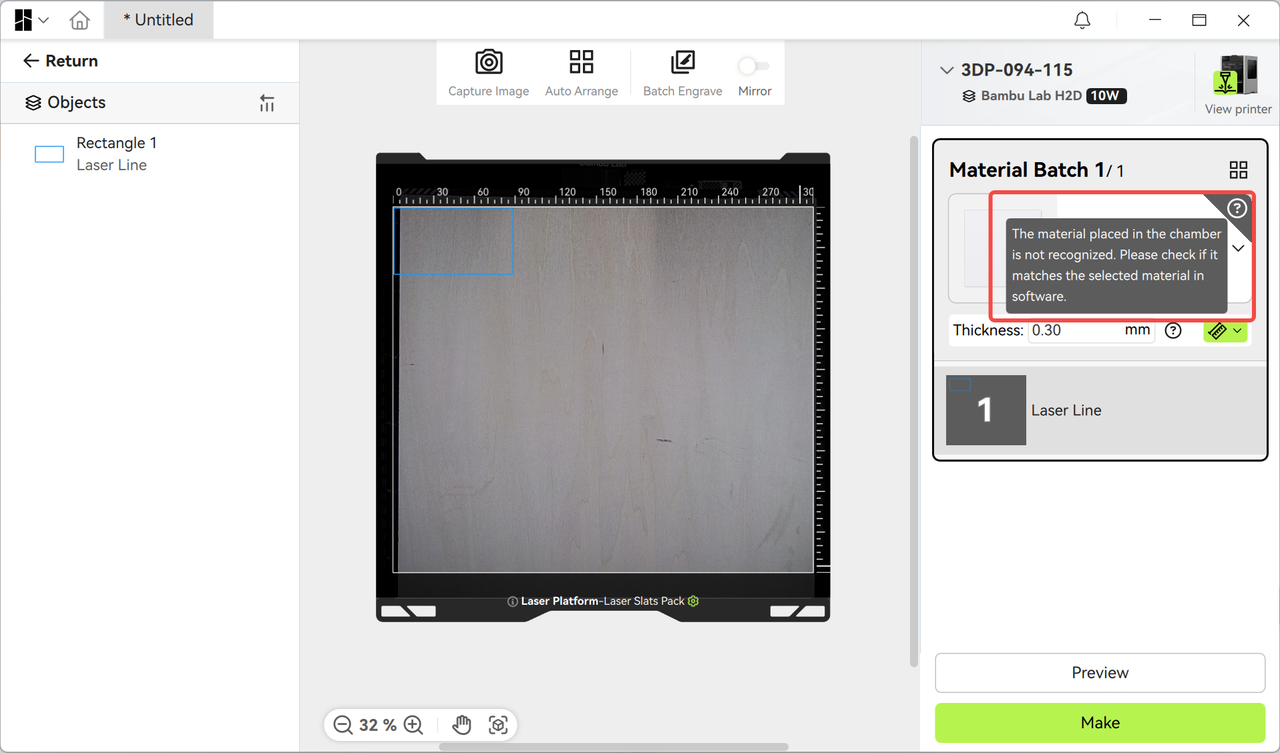

Scenario 2: Unknown material

-

Place a material without a QR code → Display the corresponding gray mark

-

Operation requirement: The user needs to manually confirm whether the placed material matches the material selected in the project.

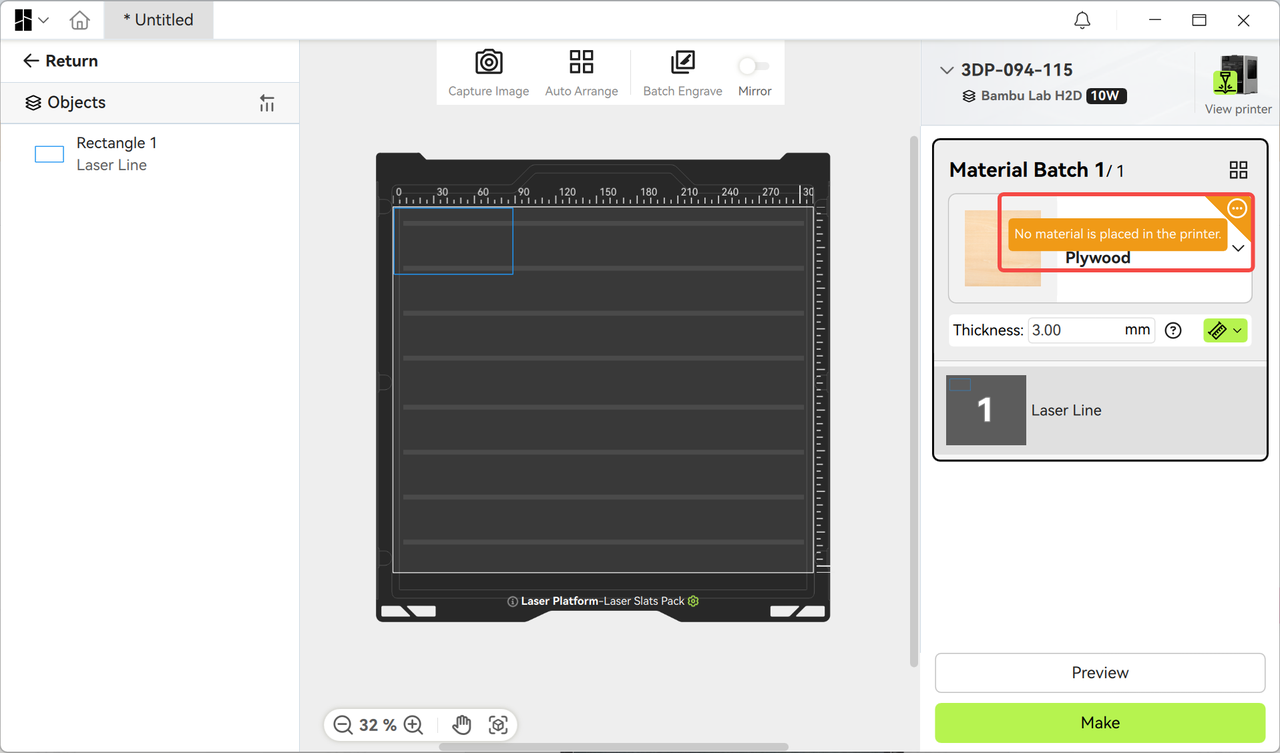

Scenario 3: Empty chamber detection

- When no material is detected in the chamber, Bambu Suite will also display a corresponding icon prompt.

¶ Material verification after taking photos

After the user completes the photo positioning:

-

If the material in the chamber does not match the project settings → a pop-up window will prompt the actual material type detected;

-

The user can choose "Do not use" or "Use now", and after use, the material group will automatically switch to the corresponding material for subsequent production.

¶ Liveview during the production phase

During the production stage, the current printing task status can be viewed through real-time monitoring (liveview), and users can see the processing status and progress at a glance.