¶ Issue Description

The Z motor drives the toolhead to move vertically up and down through the timing pulley, belt, and lead screw. When the system detects excessive Z motor load, it triggers an alarm and immediately stops the printing task.

Common fault phenomena include:

-

During homing or leveling, the motor cannot drive the heatbed to contact the nozzle on the toolhead.

-

During homing or leveling, the motor continuously drives the heatbed to press against the nozzle, causing excessive Z motor load.

-

During the printing process, the heatbed encounters resistance while moving along the Z-axis.

Possible causes include:

-

Foreign objects on the Z sliders.

-

The Z motor timing belt is obstructed by foreign objects at the bottom of the printer.

¶ Troubleshooting

¶ Tools, Equipment and Materials

Tweezers (flat-head)

¶ Fault Isolation Process

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Foreign object inspection and cleaning

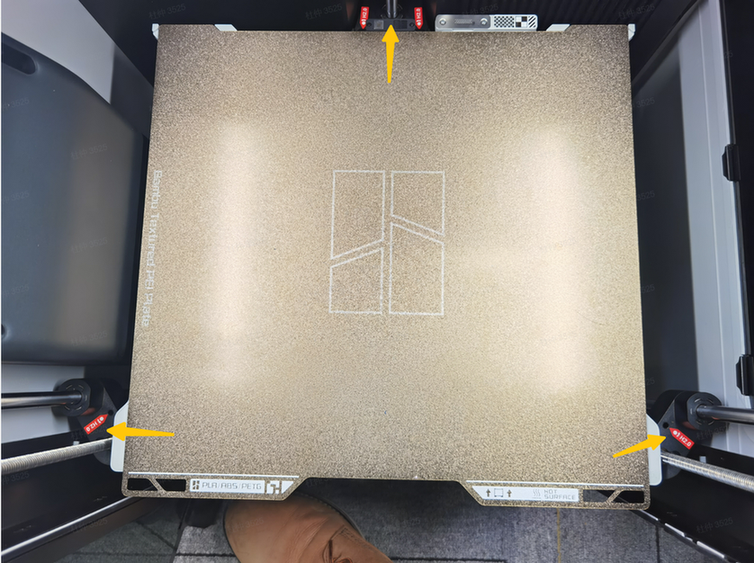

- Clean foreign objects on Z sliders

- Clean foreign objects under the heatbed

If foreign objects are found, clean them and perform a homing test.

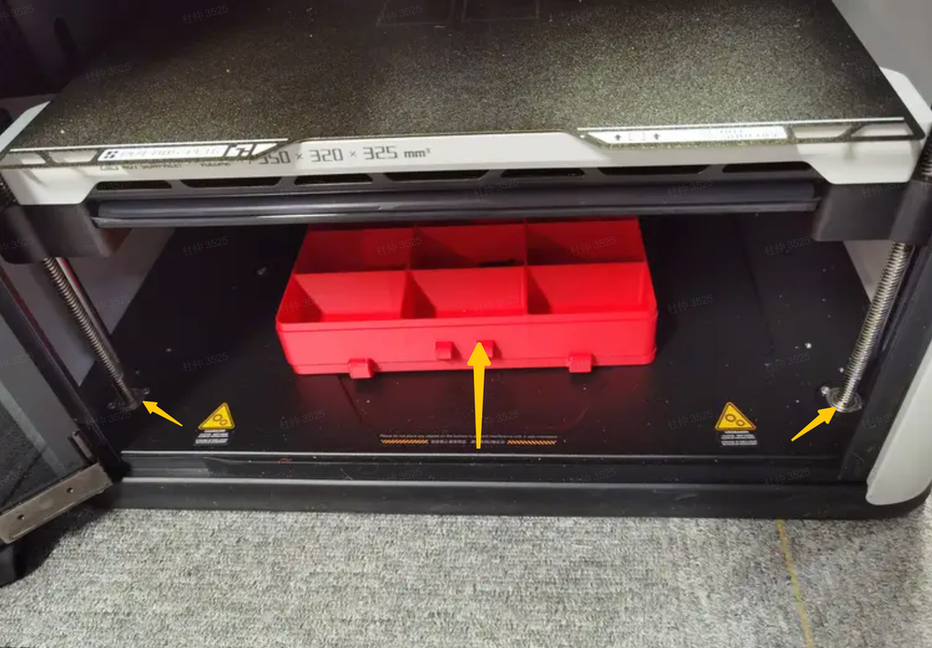

- Clean foreign objects on the Z timing pulley

Carefully tilt the printer to check if foreign objects are stuck in the Z timing pulley at the bottom. Manually pull the belt to observe if Z-axis movement is obstructed. Also, check for foreign objects on the work surface. If foreign objects or blockages are found, carefully remove them.

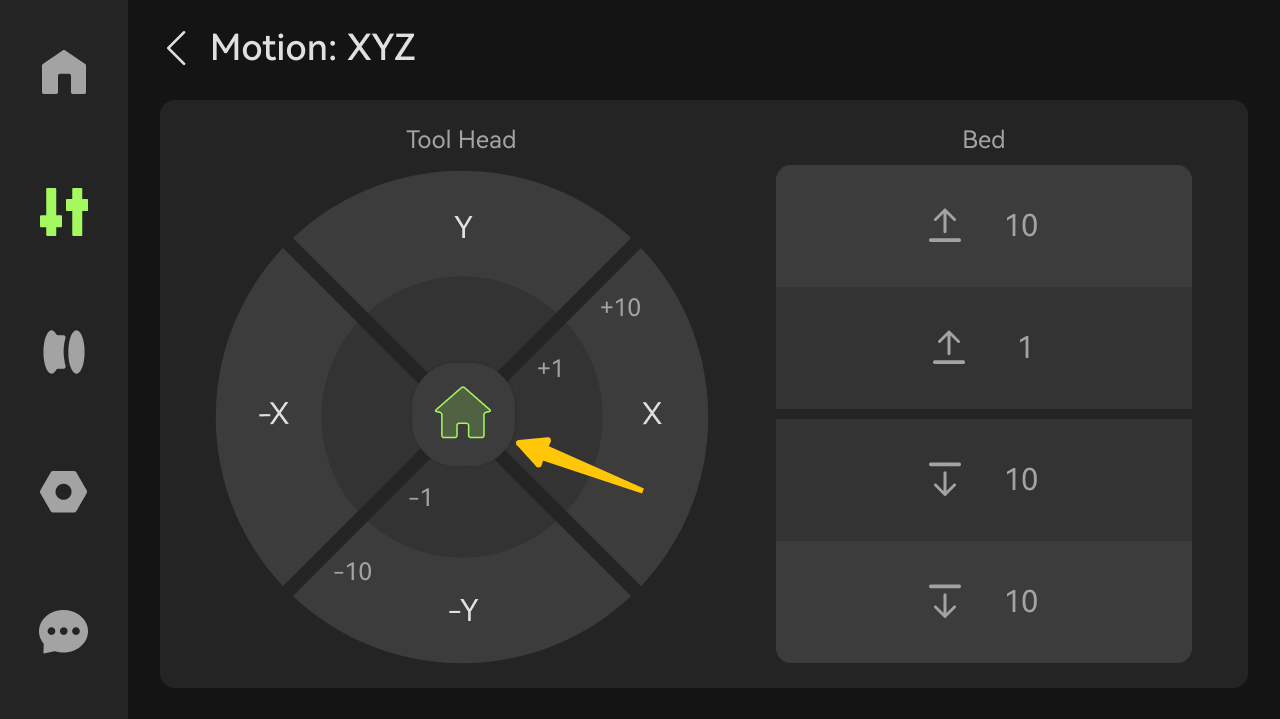

¶ Step 2. Homing test

If the test proceeds normally without alarms, the troubleshooting is successful.

¶ Equivalent Codes

The following HMS codes represent the same type of issue.

| HMS Code | Description |

|---|---|

| 0300-2500-0001-0005 | Z axis motor rotation is obstructed; please check if there are foreign objects stuck in the Z slider or Z timing pulley. |

| 0300-2600-0001-0005 | Z axis motor rotation is obstructed; please check if there are foreign objects stuck in the Z slider or Z timing pulley. |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!