¶ Issue Description

During the printing process, if a print task involves the use of two nozzles, it is essential to ensure that the positioning of both nozzles is completely aligned to achieve optimal print quality. If the positioning of the two nozzles deviates, it may result in misaligned models or layer shifts during printing. Nozzle offset calibration includes both Z-axis and XY-axis offset calibration.

If foreign objects are present between the nozzle and the heatbed, it may lead to inaccurate calculations of the offset distance in the Z-axis, potentially damaging the nozzle offset calibration sensor during subsequent calibration procedures. Therefore, when the system detects foreign objects, it will immediately halt the print task to ensure device safety and prevent further damage.

Potential causes of this issue include:

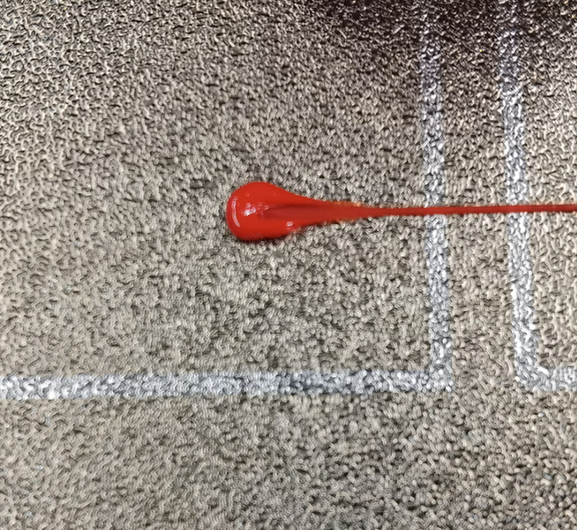

-

Filament residue on the nozzle

-

Foreign objects on the heatbed that were not cleaned properly

¶ Troubleshooting

¶ Tools, Equipment and Materials

Tweezers

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Check for filament residue on the nozzle or heatbed

If filament residue is found, clean it and re-level the heatbed. Caution: Beware of high temperatures when cleaning the hotend to avoid burns.

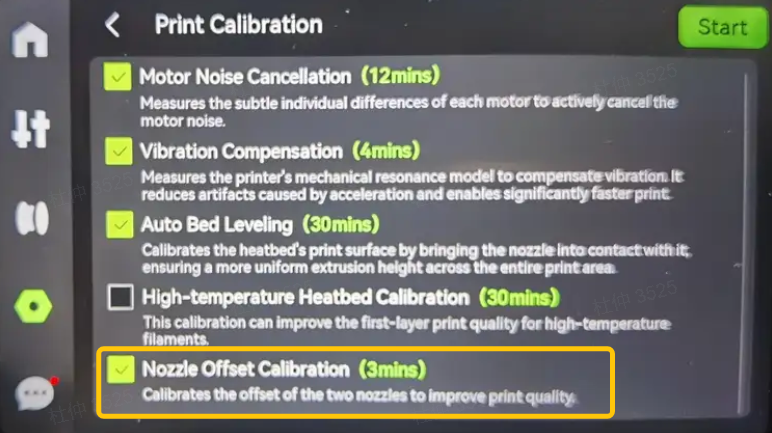

¶ Step 2. Retry nozzle offset calibration

Option 1:

Click: Print Calibration > Nozzle Offset Calibration.

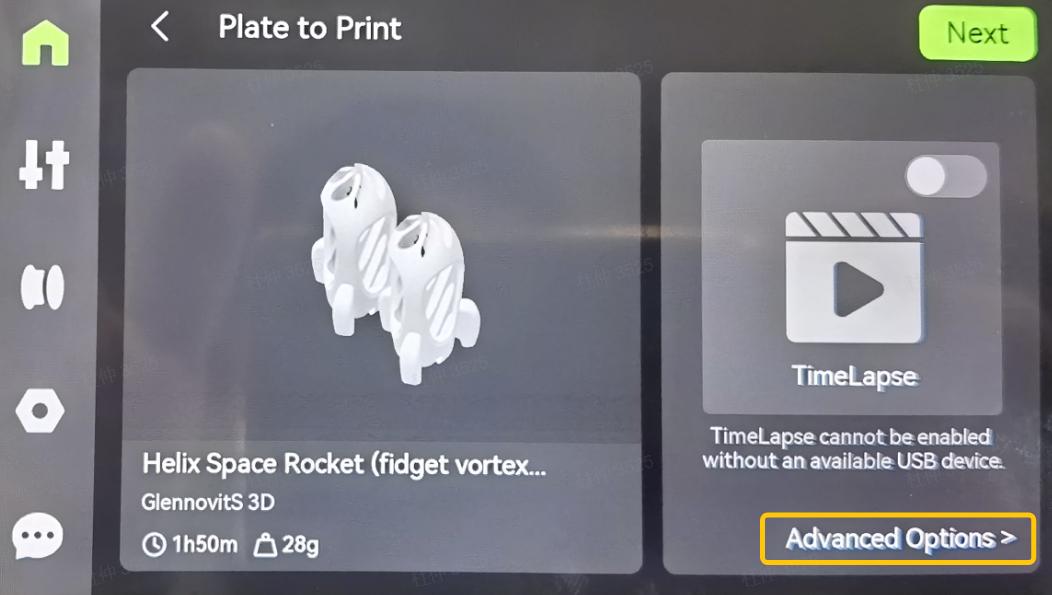

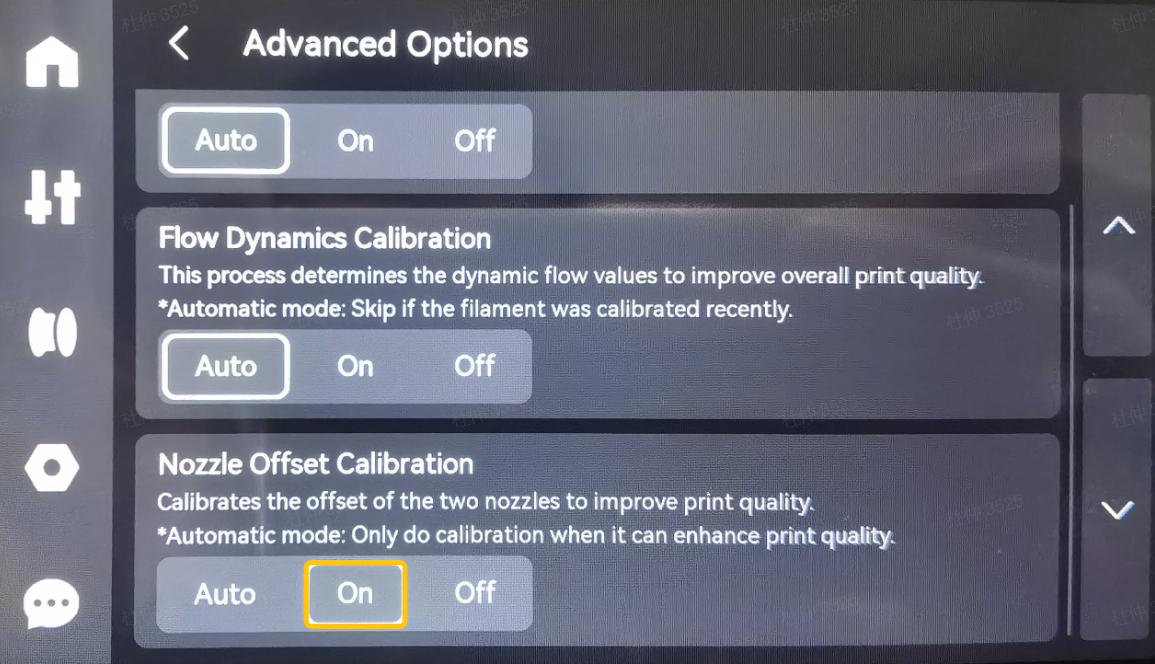

Option 2:

Restart the print and enable "Nozzle Offset Calibration" in the "Advanced Options."

If the above solutions do not resolve the issue, submit a ticket and upload the printer’s log files.

¶ Equivalent Codes

The following HMS codes represent the same type of issue.

| HMS Code | Description |

|---|---|

| 0300-2500-0001-000A | Nozzle offset calibration failed. Filament sticks to the nozzle, which may affect print quality. Please clean the nozzle and try again. |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!