¶ Fault Description

When users install the engraving laser module onto the toolhead, the clamping state of the laser may vary, causing potential deviations in the focal point position of the laser beam compared to previous calibrations. To ensure accurate engraving/cutting positioning during imaging, the Engraving Laser Focal XY Calibration must be performed.

The issue manifests as an HMS error, specifically "Engraving Laser Focal XY Calibration Failed." Possible causes include:

-

Laser module damage – The laser fails to emit properly or is significantly misaligned.

-

Thermal label contamination or damage – The heat-sensitive calibration sticker is dirty or torn.

-

Dirty laser homing platform – The laser calibration platform has debris or residue.

-

Improperly installed or reversed homing platform – The platform is not seated correctly or is mounted upside-down.

-

Chamber temperature out of range – The calibration sticker requires an ambient temperature of 16–32°C (60–90°F).

¶ Troubleshooting

¶ Tools & Materials

Cleaning wipes

¶ Fault Isolation Procedure

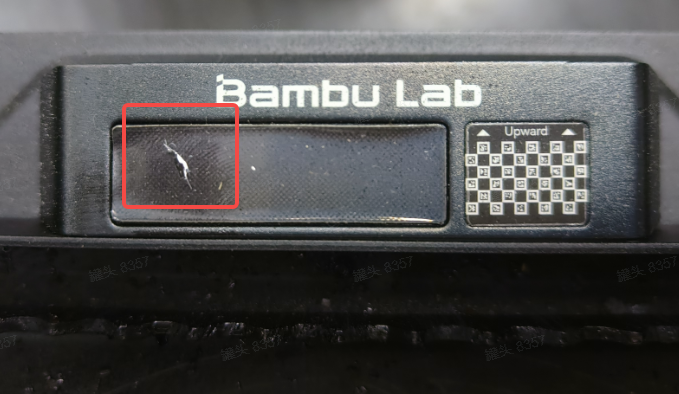

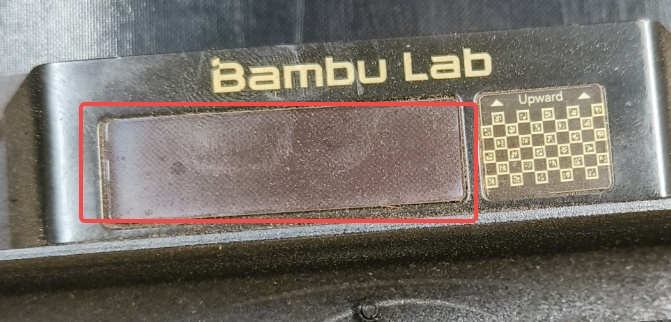

- Inspect the thermal label – Ensure it is clean and undamaged.

Examples of contamination/damage:

-

Clean the homing platform – Wipe it thoroughly with a damp cloth and let it dry.

-

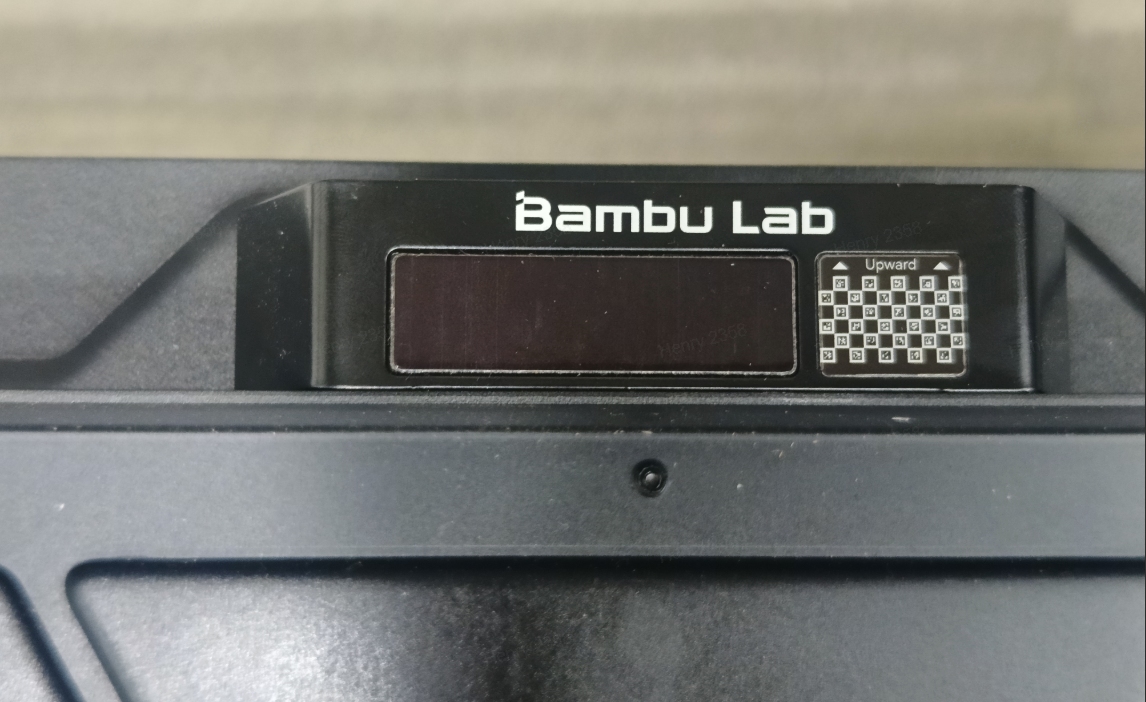

Verify homing platform installation – If installed upside-down, loosen the two bottom screws and reorient it correctly.

Example of incorrect (reversed) installation:

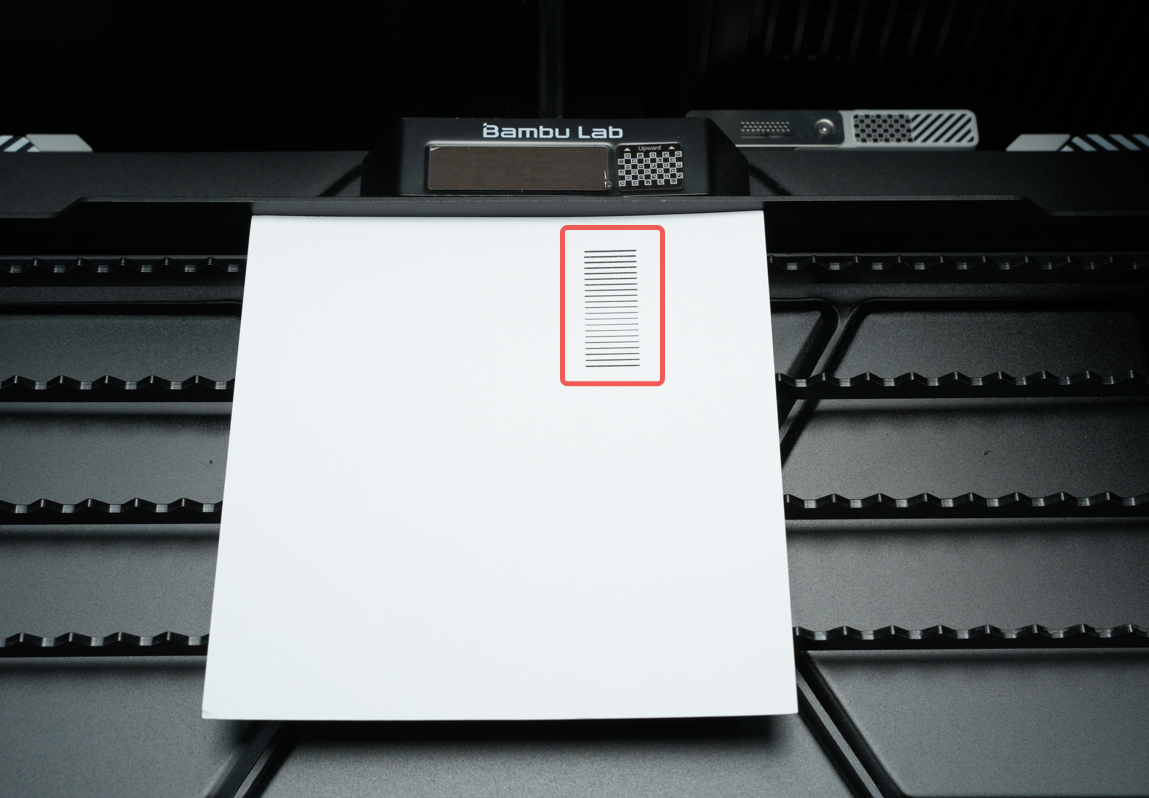

- Perform the initial installation of the laser module (do not execute the mounting calibration), then observe whether burn marks appear on the calibration card and check for any abnormalities.

-

If the burn marks on the calibration paper are clearly visible (without reporting "Focal Z Calibration Failed") or no burn marks appear but the Focal XY calibration still fails, please submit a support ticket.

-

If the burn marks on the calibration paper appear intermittent or abnormal, replace the laser head and retry. If other laser heads work normally, the current laser head may be damaged.

-

If other operations have just been completed, the high temperature of the platform or chamber may affect the calibration paper's performance. Wait for the machine to cool down to near room temperature (the calibration paper's operating temperature range is 16-32°C) before initiating the laser mounting calibration.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!