¶ Issue Description

The corresponding function is "Filament Runout Detection". Printer can detect that the external spool is not installed or the filaments are used up, and then automatically pauses printing and prompts the user to load new filaments.

The phenomenon when the fault occurs:

-

The printing is paused, the toolhead is moved to the purge chute, and a pop-up box on the screen prompts that the filaments of the external spool are used up;

-

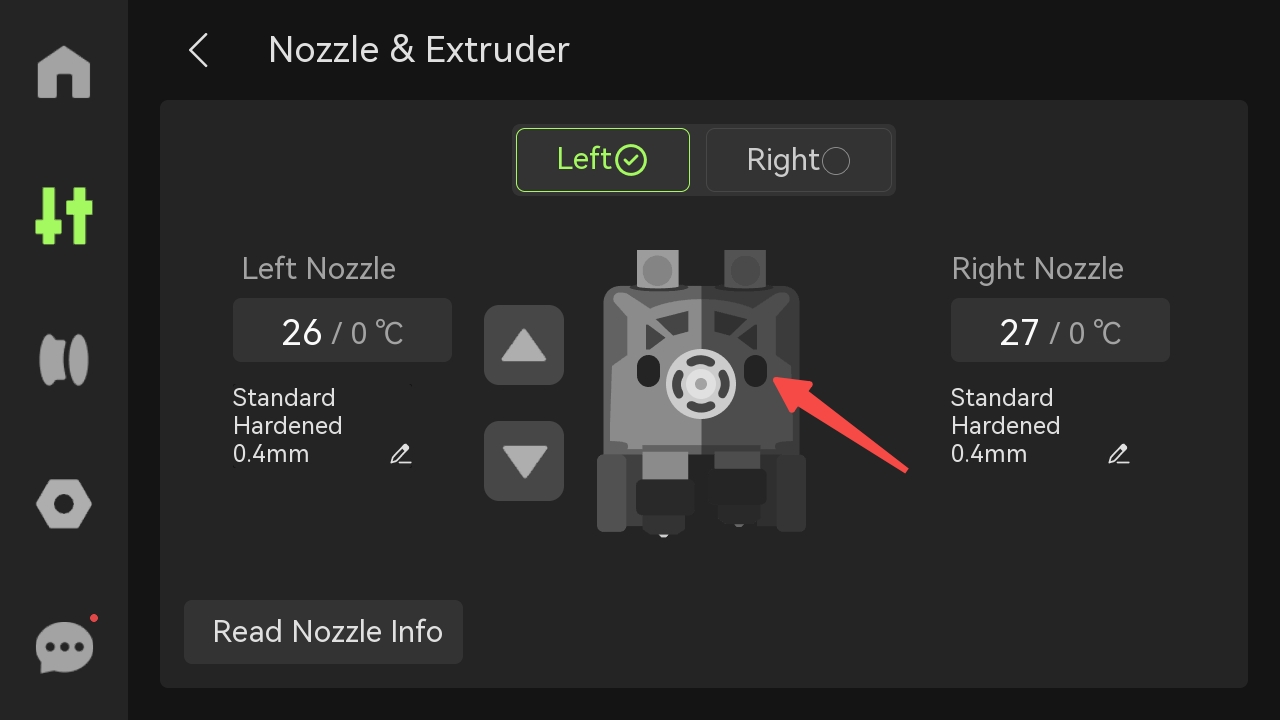

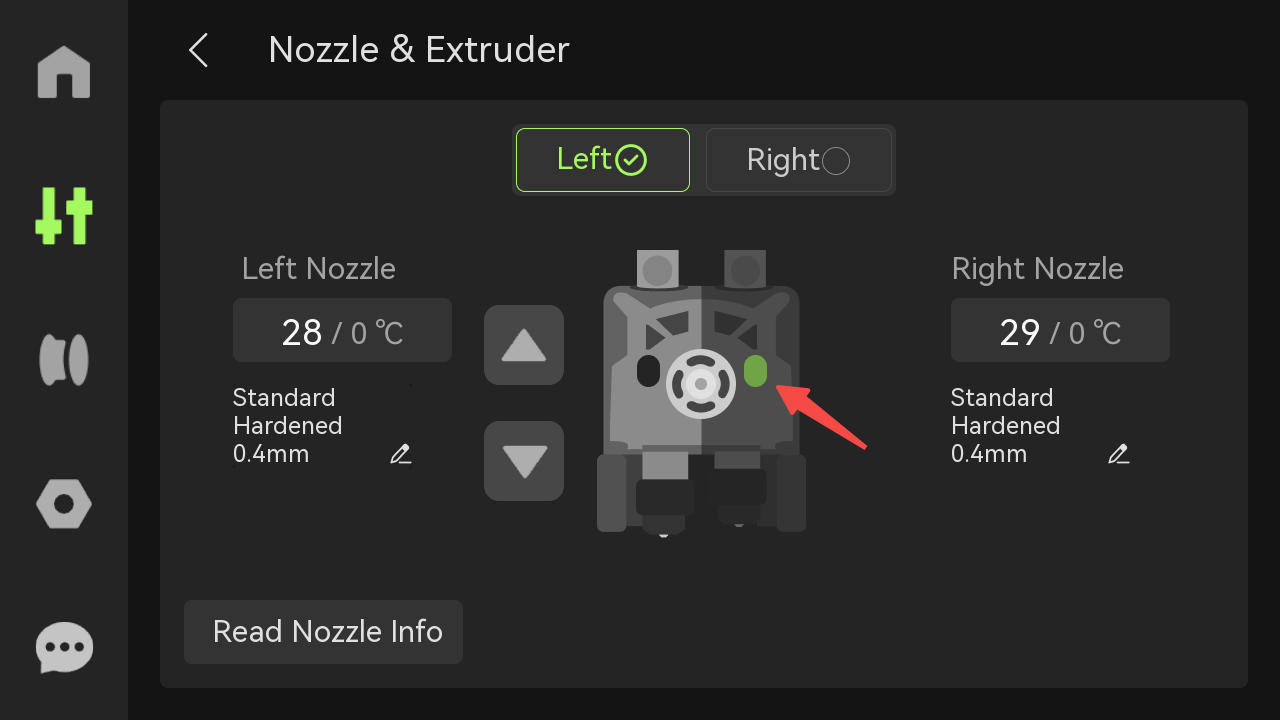

The extruder indicator icon on the filament page on the screen turns gray, it is normally green.

¶ Troubleshooting

¶ Tools, Equipment and Materials

-

Tweezers (flat head)

-

Silicone

¶ Solutions

¶ Step 1: Check if the filaments in the external spool at the rear of the printer are really used up

If you find that the filament is indeed used up, follow the on-screen prompts to load new filament into the extruder, and then click Continue to resume printing.

¶ Step 2: If the filaments are not used up and there are still filaments in the toolhead

If the filaments are not used up and there are still filaments in the toolhead, continue to check whether the extruder indicator icon on the filament page turns gray;

- Gray icon: Hall switch is off

- Green icon: Hall switch is on

If you have actually checked that there is filament at the toolhead (at the extruder Hall sensor), but the filament indicator icon on the screen is still gray, it may be that the sensor is abnormal, resulting in a false alarm of no filament. You need to further check whether the loading Hall sensor and the corresponding magnet are abnormal.

If there is a problem with the Hall switch, such as the magnet falling off, you will need to replace the follower rod assembly or contact customer support for further assistance.

Replace H2D Dual Extruder Idlers and Filament Sensor

¶ Equivalent Codes

The following HMS codes represent the same type of issue.

| HMS Code | Description |

|---|---|

| 07FE-2000-0002-0001 | External filament of left extruder has run out; please load a new filament. |

| 07FF-2000-0002-0001 | External filament of right extruder has run out; please load a new filament. |

| 18FE-2000-0002-0001 | External filament of left extruder has run out; please load a new filament. |

| 18FF-2000-0002-0001 | External filament of right extruder has run out; please load a new filament. |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!