¶ Applicable Scenario

-

The printer reports extruder motor overload, air printing, or no error but it can be observed that the hotend is unable to extrude filament.

-

Printing with TPU filament

¶ Possible Locations of Clogging

Due to the soft nature of TPU, the filament may become tangled around the extruder gear during loading.

¶ Troubleshooting Steps

¶ Step 1. Heat the hotend

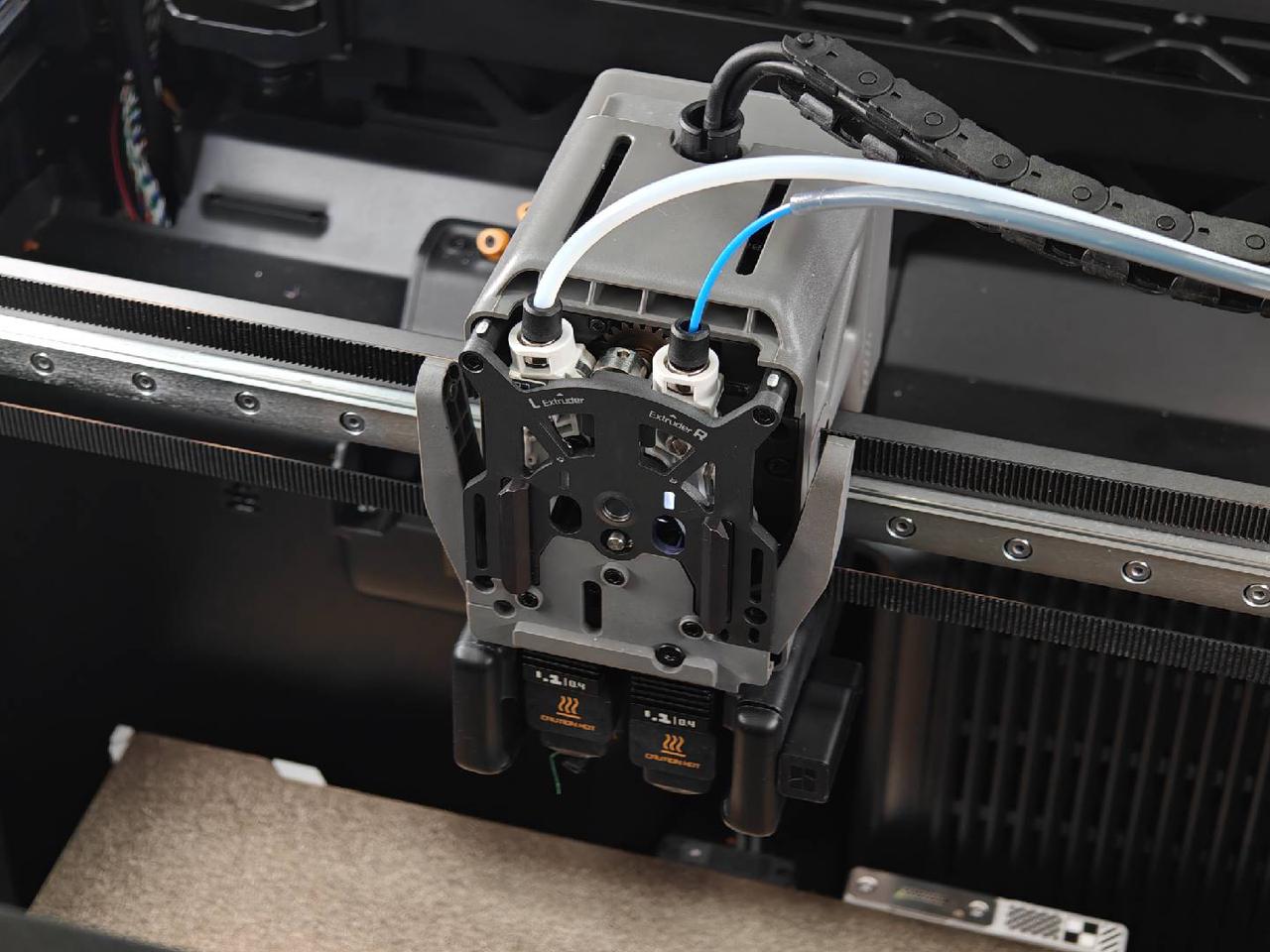

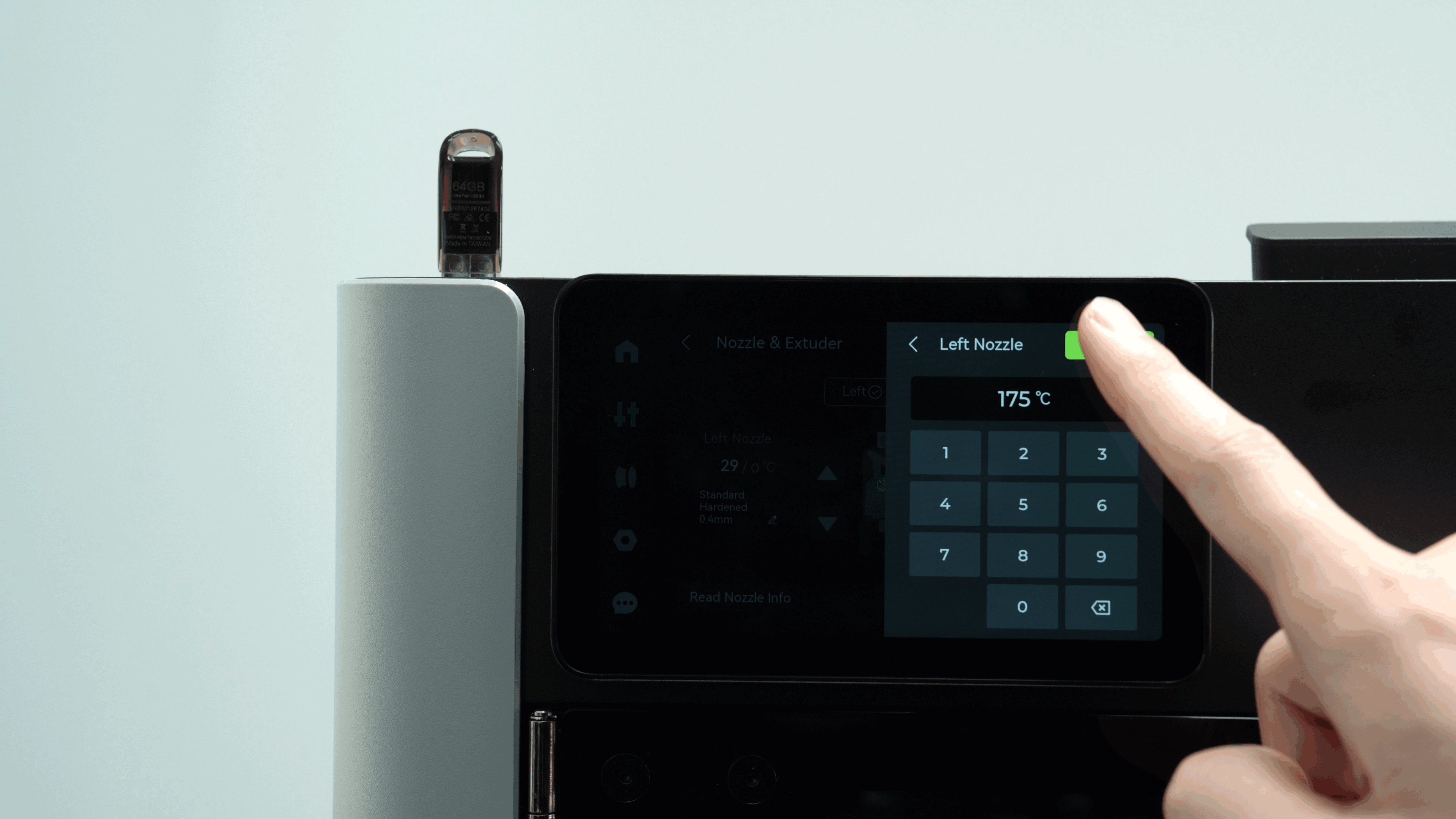

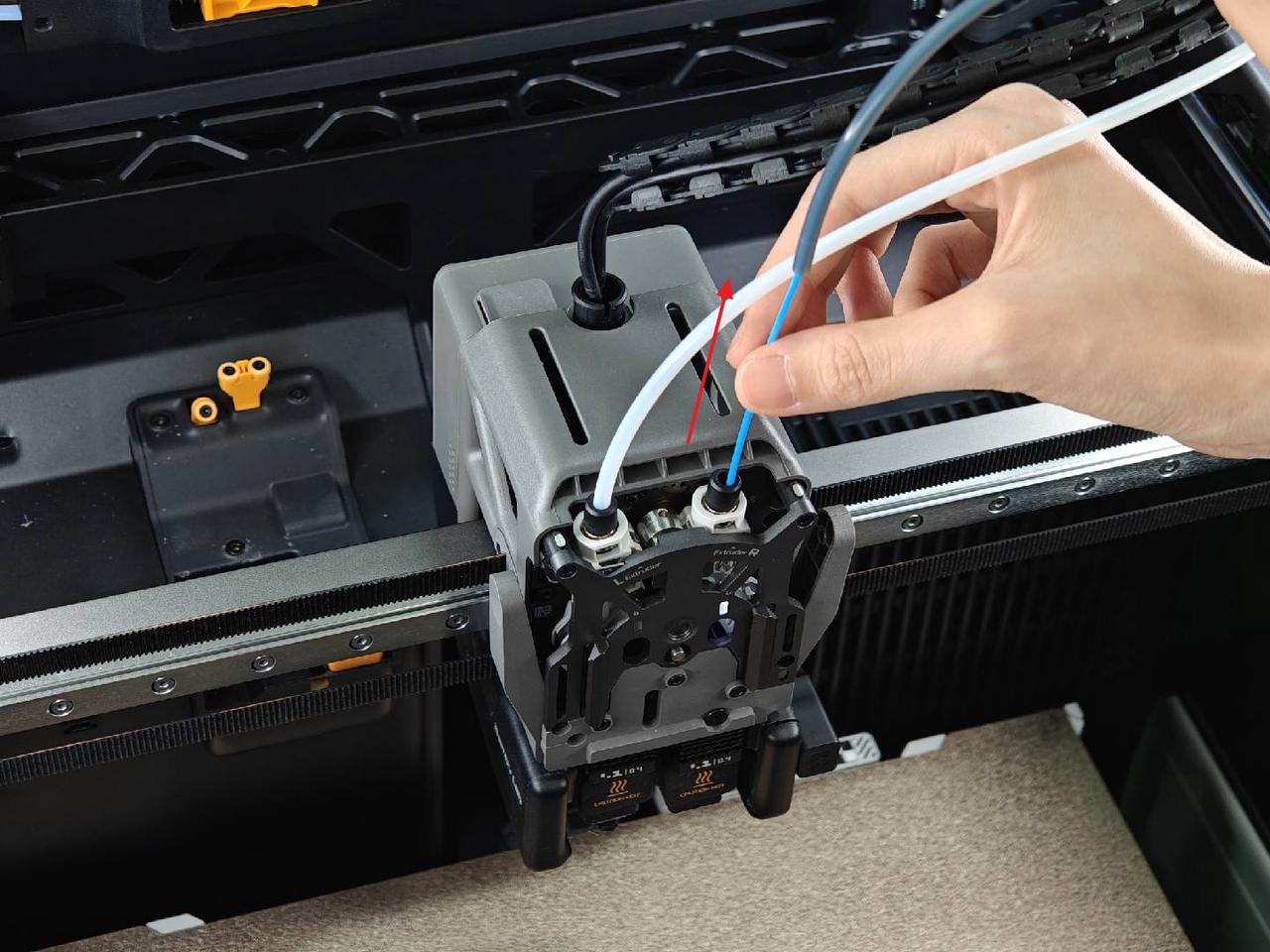

Open the front door of the printer, and remove the top cover. Then pinch both sides at the top of the toolhead front cover and remove the toolhead front cover; press the black outer ring to disconnect the PTFE tube. And heat the hotend to 175°C.

The prerequisite for controlling the rotation of the extruder gear is that the hotend temperature is above 170°C. Therefore, we recommend setting the hotend temperature to 175°C for easier control.

¶ Step 2. Manually unload the filament

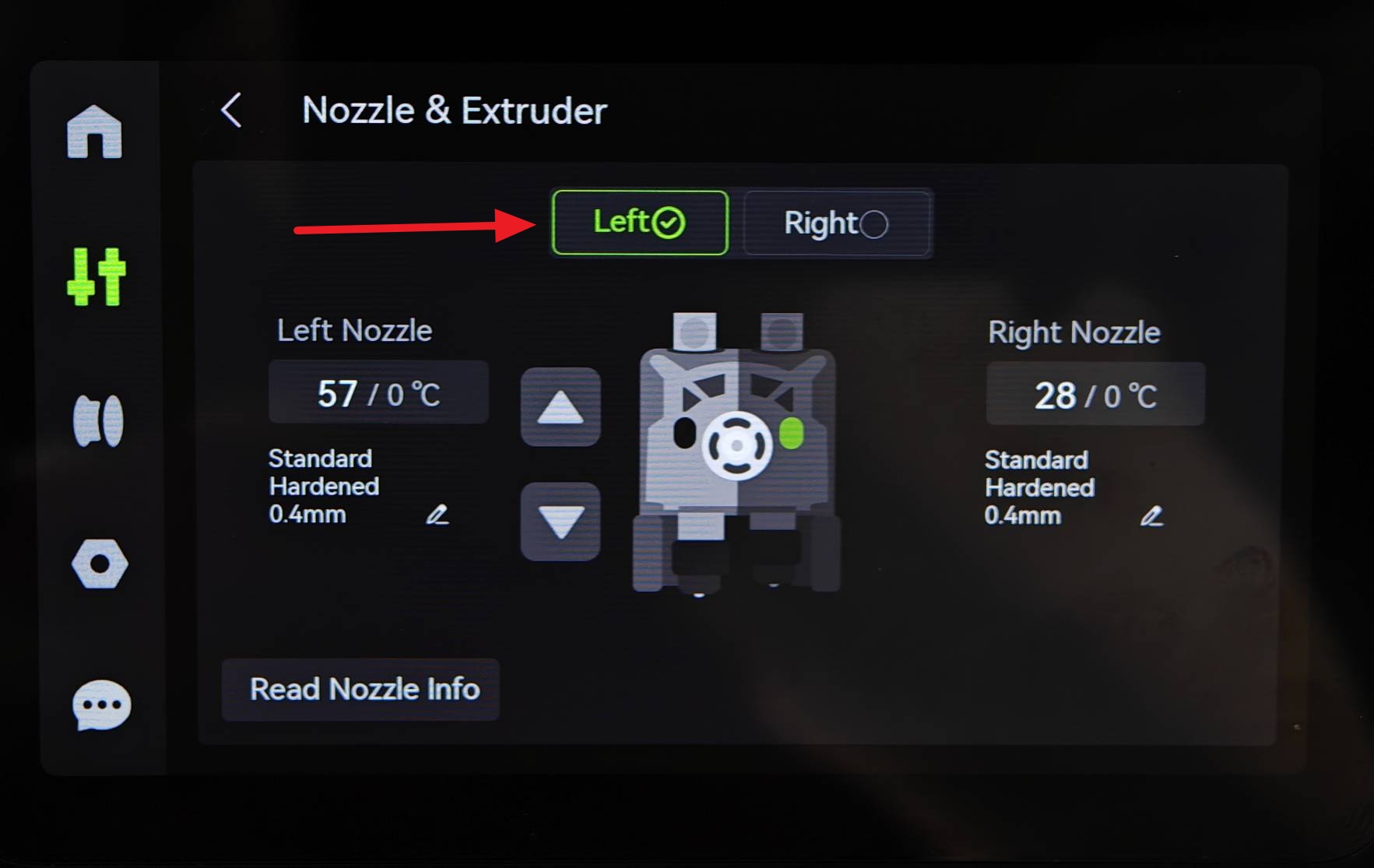

Wait for the hotend to reach 175°C, and slowly click the retract button twice on the screen (do not click too quickly to avoid more clogs or filament entanglement). Please note that clicking the retract button twice is sufficient. Excessive unloading may cause the TPU filament to curl to the other side of the extruder gear, making it more difficult to clean.

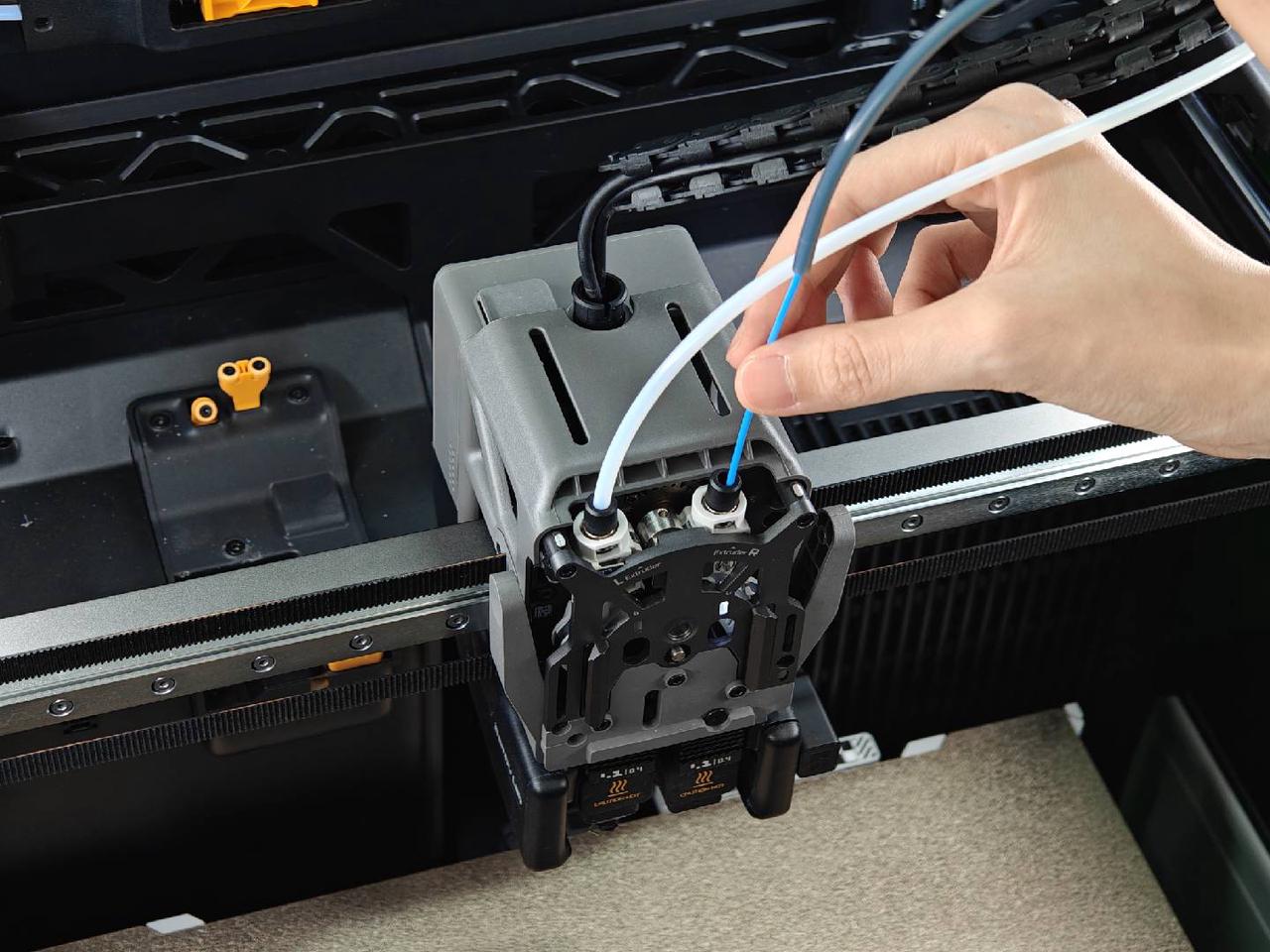

¶ Step 3. Remove the TPU

After completing step 2, please do not click the load or retract button again and keep the extruder gear stationary. Use your hand to pull up the TPU while switching the extruder on the screen, taking advantage of the gap created by the extruder switch to remove the TPU.

If severe filament entanglement occurs inside the extruder, please manually cut the filament, then refer to this wiki for detailed instructions on removing the front shell of the extruder for deep cleaning.