¶ Troubleshooting

¶ Fault Isolation Process

(If there are multiple root causes corresponding to the HMS, a process to locate the specific root cause is provided here; if there is only one root cause corresponding to the HMS, this process is not required)

Cause: During the print then cut operation, the toolhead camera is required to identify the four markers on the paper to determine the cutting position.

If any marker is not detected, the device cannot correctly determine the cutting position and will stop the operation process.

Cause 1: The camera recognition range of the current version is not very large. Therefore, if the user does not stick the paper near the correct position, the marker cannot be found, resulting in an error.

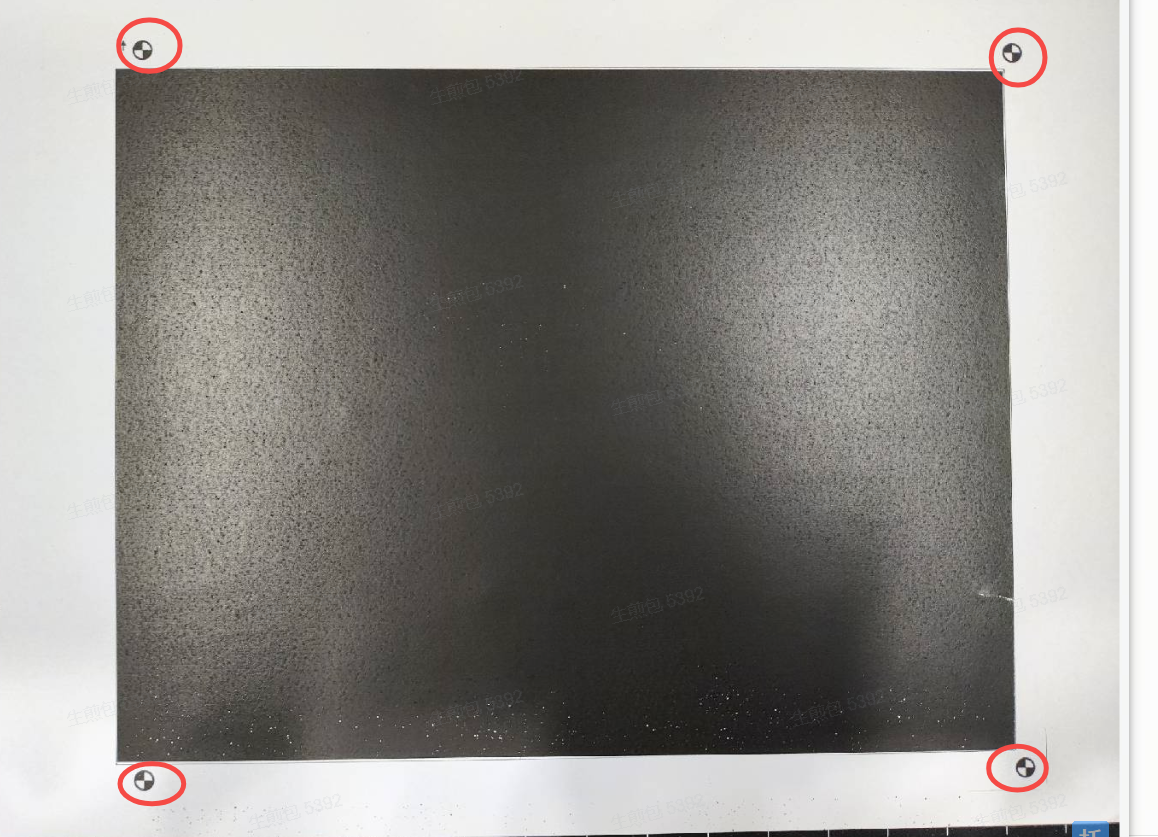

The correct position is actually marked:

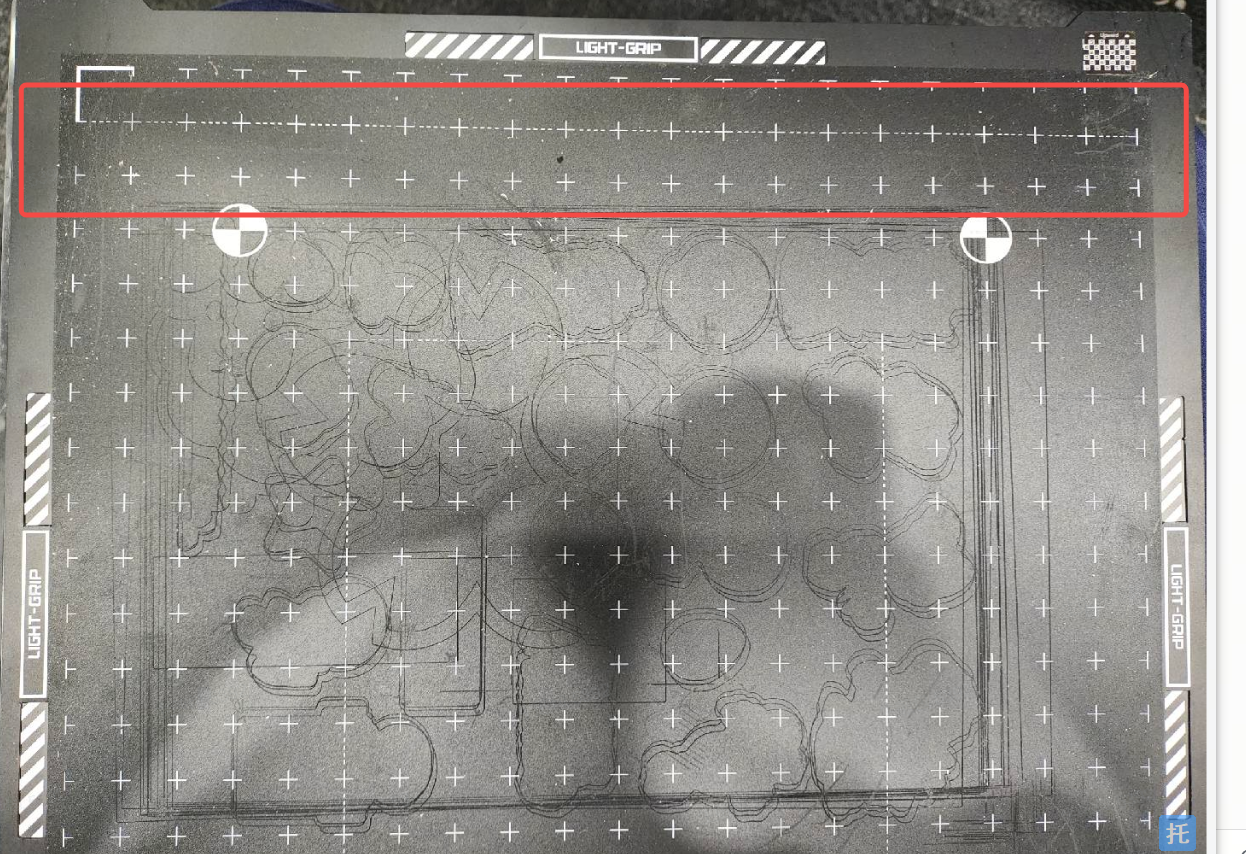

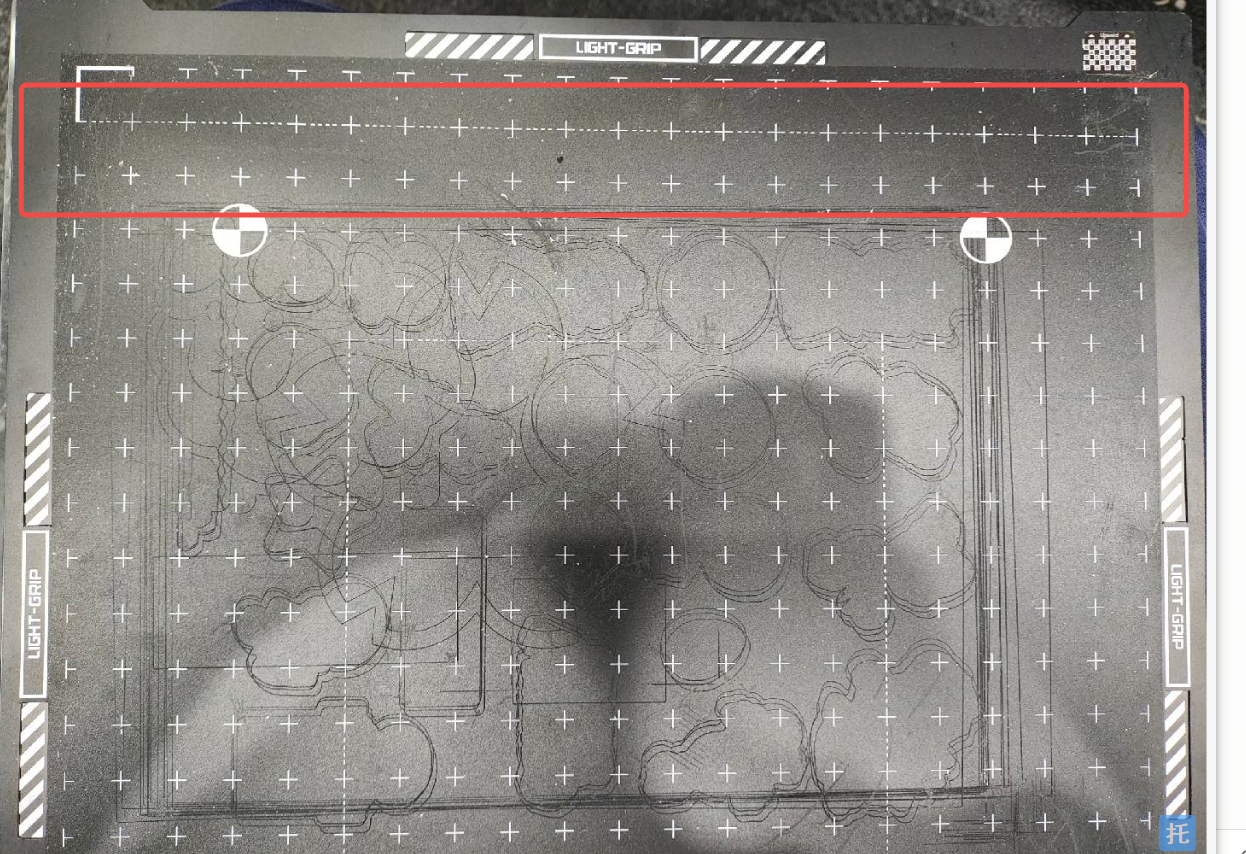

The cutting platform also has corresponding marks:

Cause 2: The error may also occur if the user sticks the paper upside down.

Cause 3: The markers on the printed paper are damaged or contaminated.

¶ Troubleshooting Measures

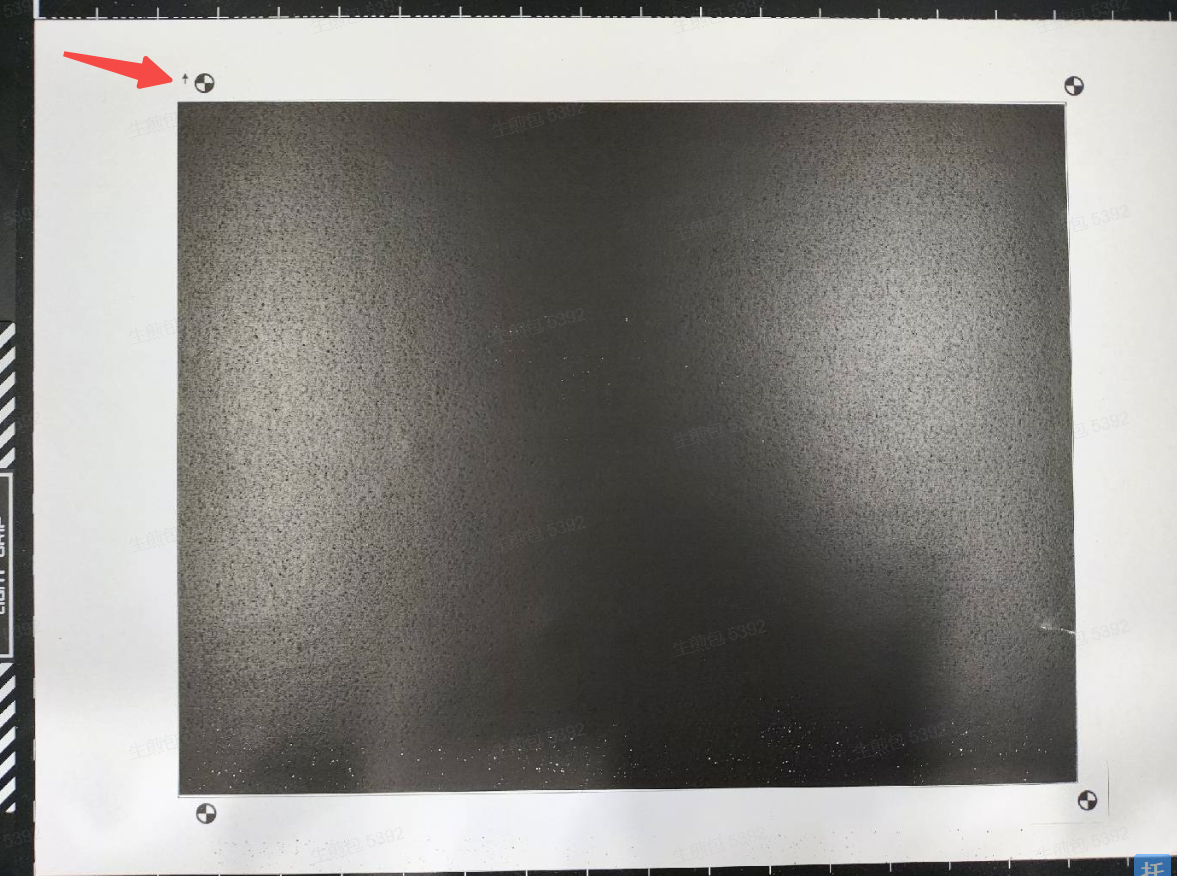

For Cause 1: The paper needs to be stuck to the correct position. There will be a diagram on Bambu Suite indicating where to stick it.

The cutting platform also has corresponding marks:

For Cause 2: Note that there is an arrow here; ensure the arrow points upward when sticking the paper.

For Cause 3: Restart the operation and ensure the printed markers are clear. This may also be a problem with the 2D printer.

¶ Equivalent Codes

The following HMS codes all represent the same type of fault.

| HMS Code | Fault Description |

|---|---|

| 0C00-0400-0002-0017 | Markers not detected during print then cut; please reattach the material to be cut |

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!