¶ Precautions:

Please be sure to follow the disassembly sequence outlined in this article strictly. Especially before removing the cover of the extruder, make sure to first remove the extruder filament sensor (handle with care to avoid pulling too hard), as failure to do so may result in the wiring of the sensor broken.

¶ Safety Warning

IMPORTANT!

Before performing any maintenance on the printer or its electronic components (including toolhead cables), turn off the printer and disconnect the power supply to avoid short circuits, which may cause damage to electronic devices and safety hazards.

When maintaining or troubleshooting the printer, first check the temperature of the hotend and heatbed. Avoid operating at high temperatures. If high-temperature operation is necessary, wear heat-insulating gloves to ensure safe and effective maintenance.

If you have any questions about this guide, please click to submit a service ticket, and we will respond promptly to provide the help you need.

¶ Tools and Materials Needed

-

New extruder unit front cover

-

Allen keys H2.0

¶ Disassembly Instructions

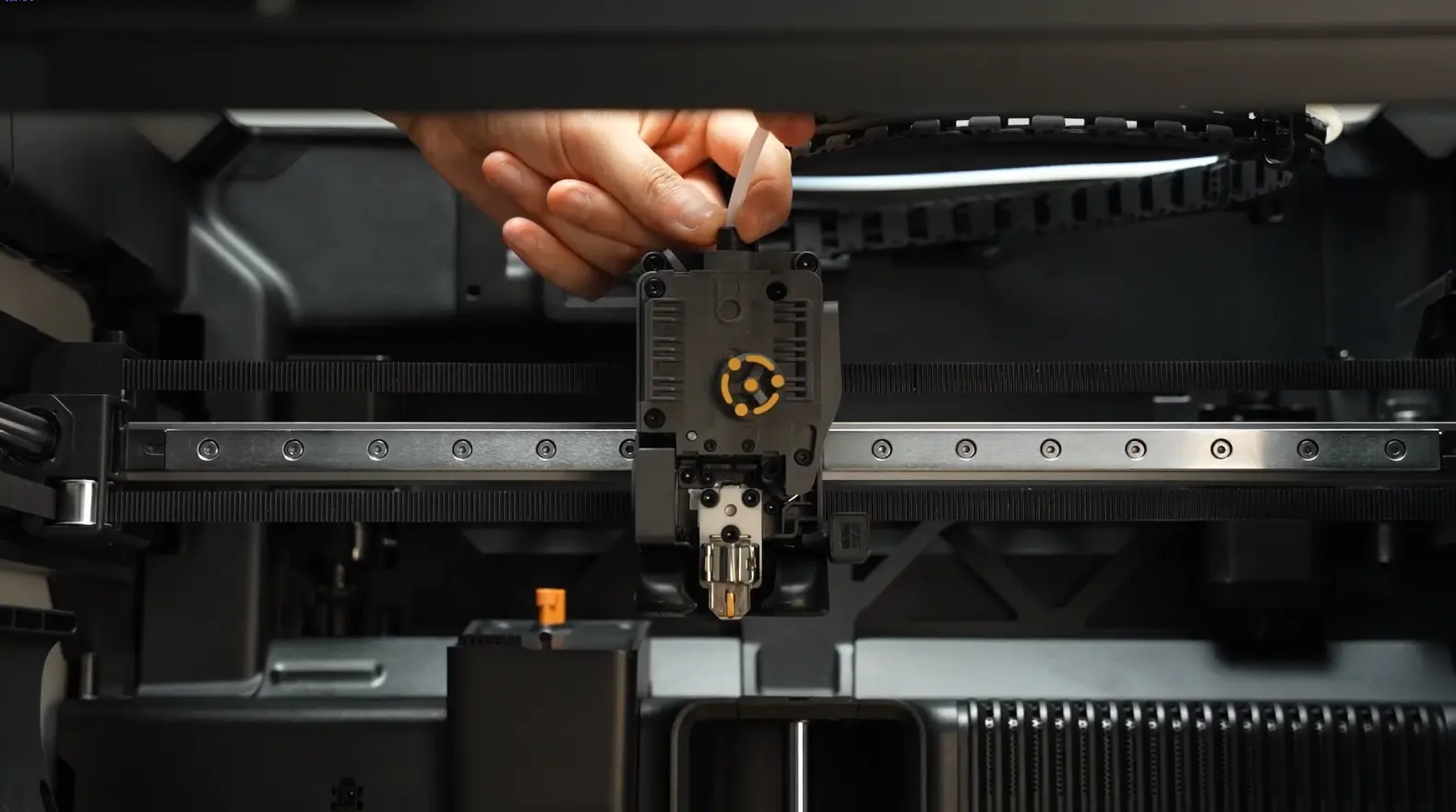

¶ Step 1: Remove the Hotend

Refer to this tutorial to remove the hotend.

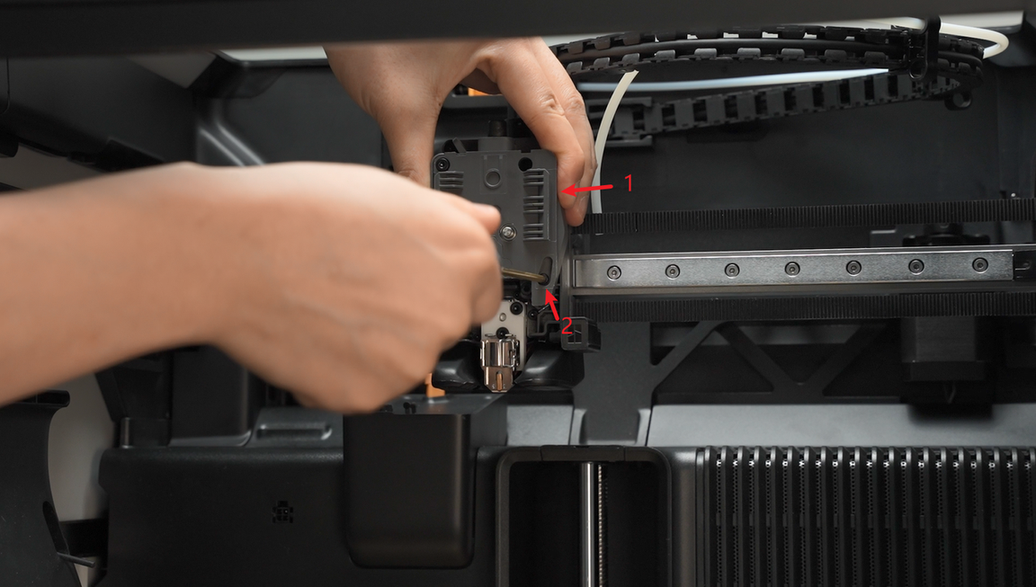

¶ Step 2: Disconnect the PTFE Tube

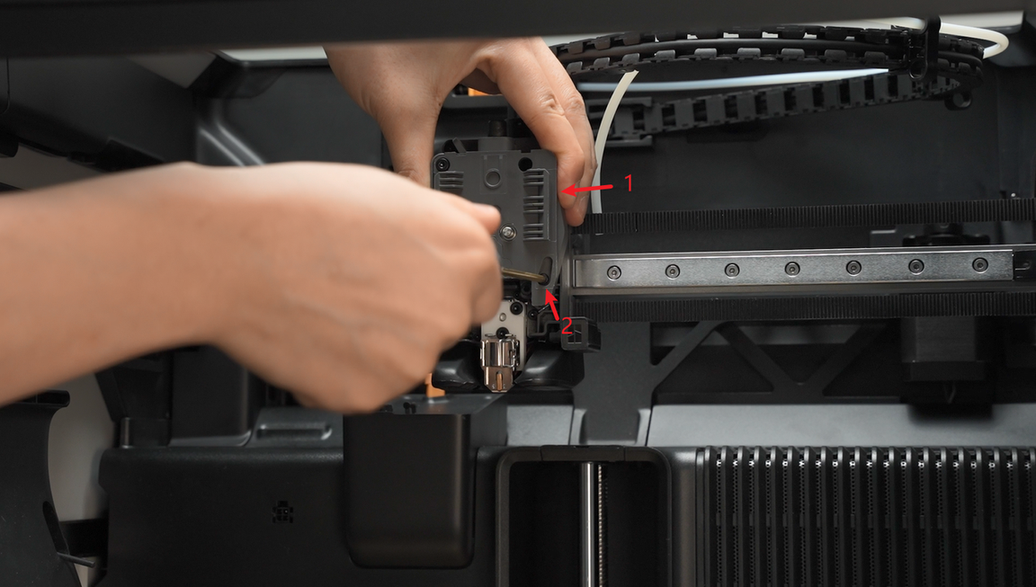

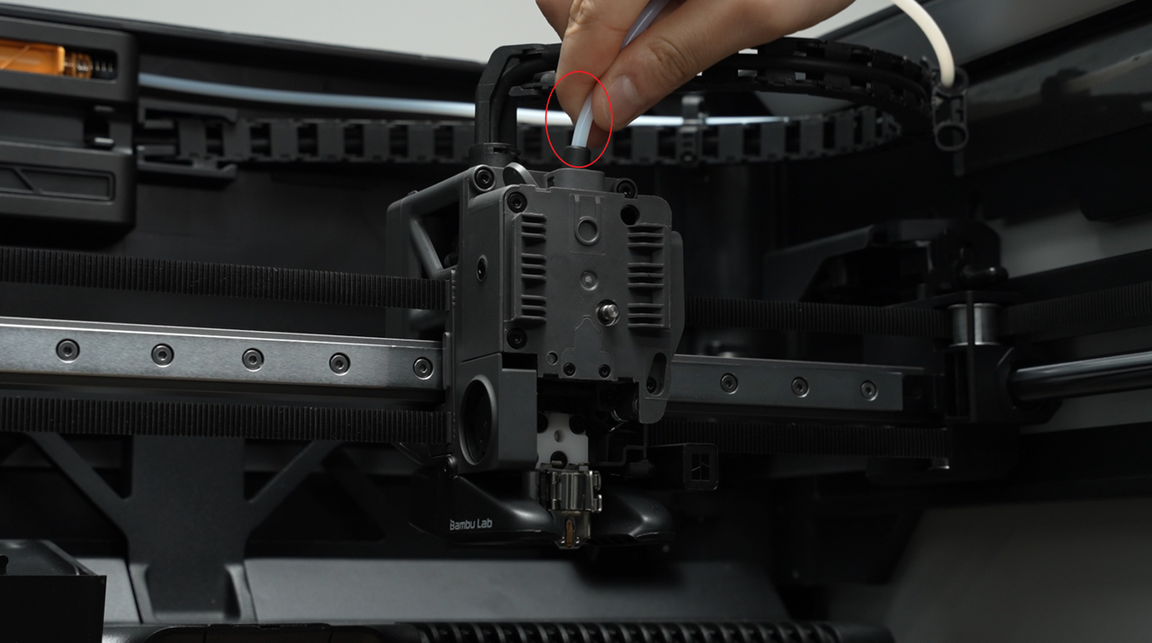

Press the pneumatic connector to disconnect the PTFE tube;

¶ Step 3: Remove the Rotating Wheel

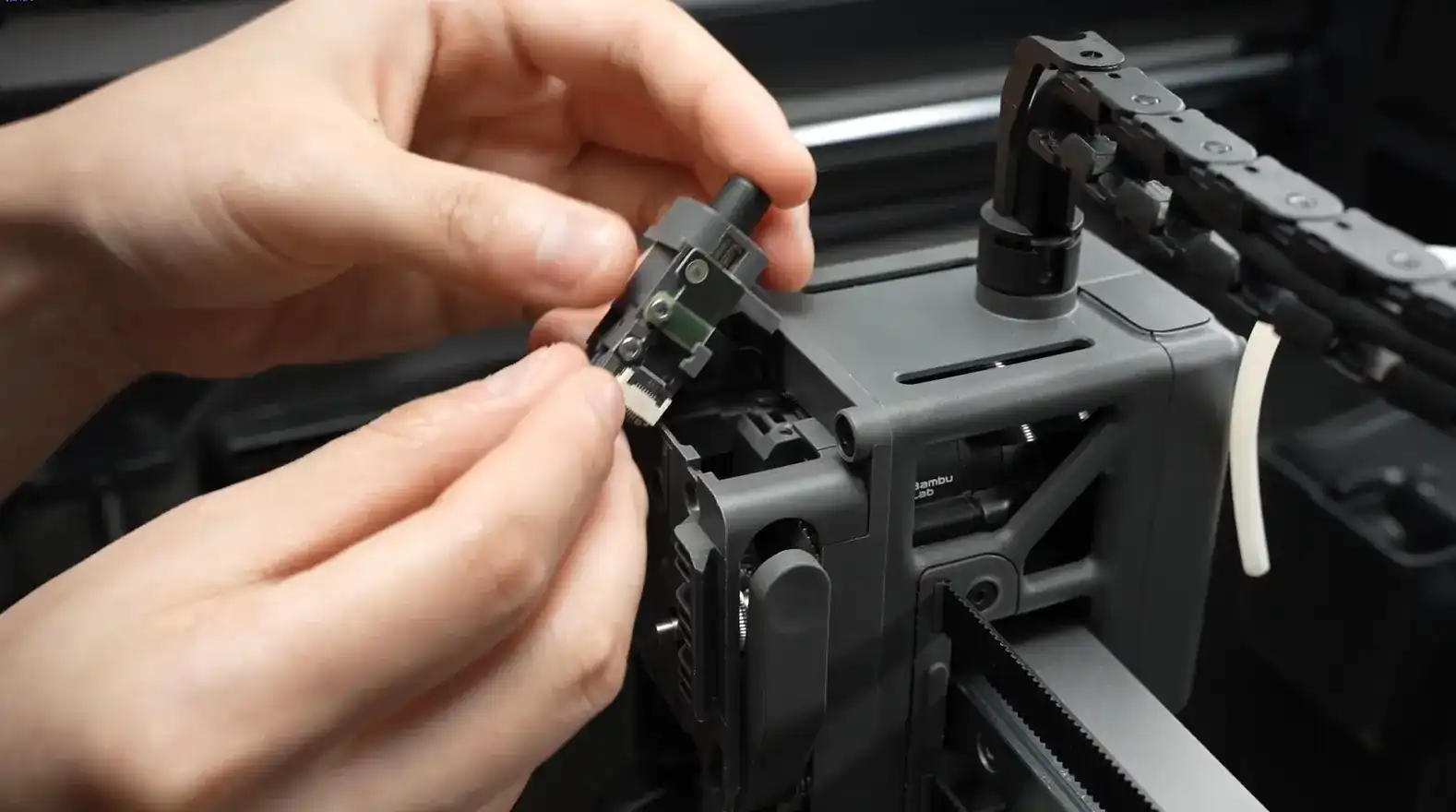

Rotate the rotating wheel and take it off.

¶ Step 4: Loosen the Cutter Handle

Hold the cutter handle and use a screwdriver to remove 1 screw. After the screw is fully removed, gently release the cutter handle and let it hang naturally.

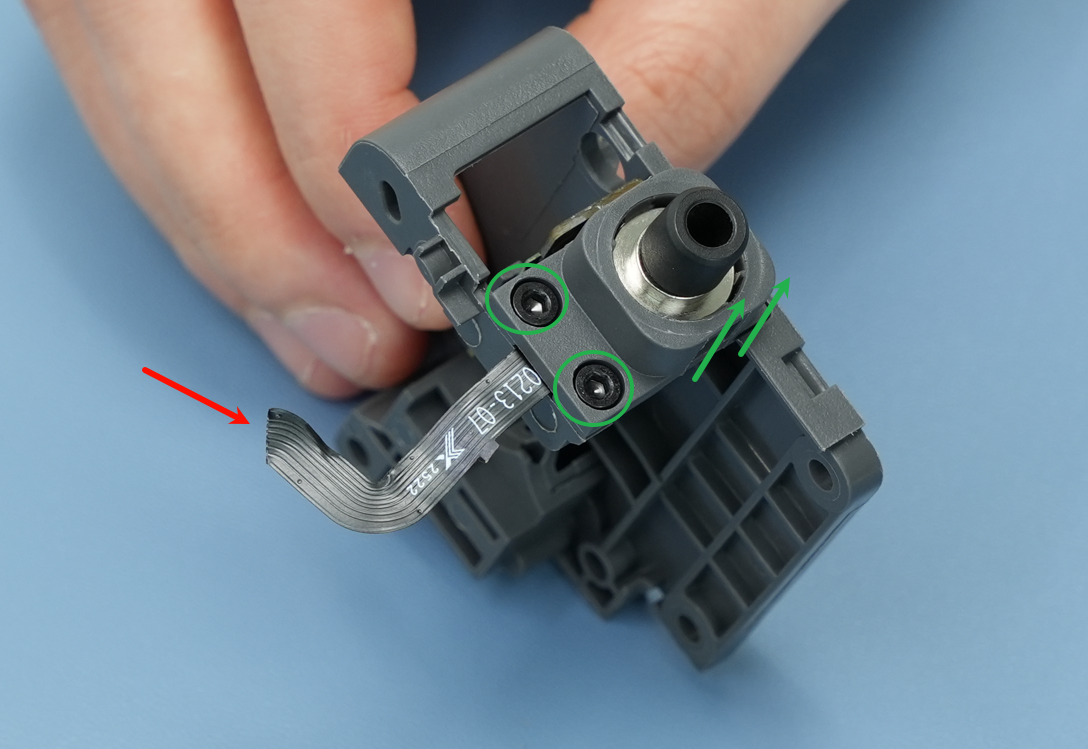

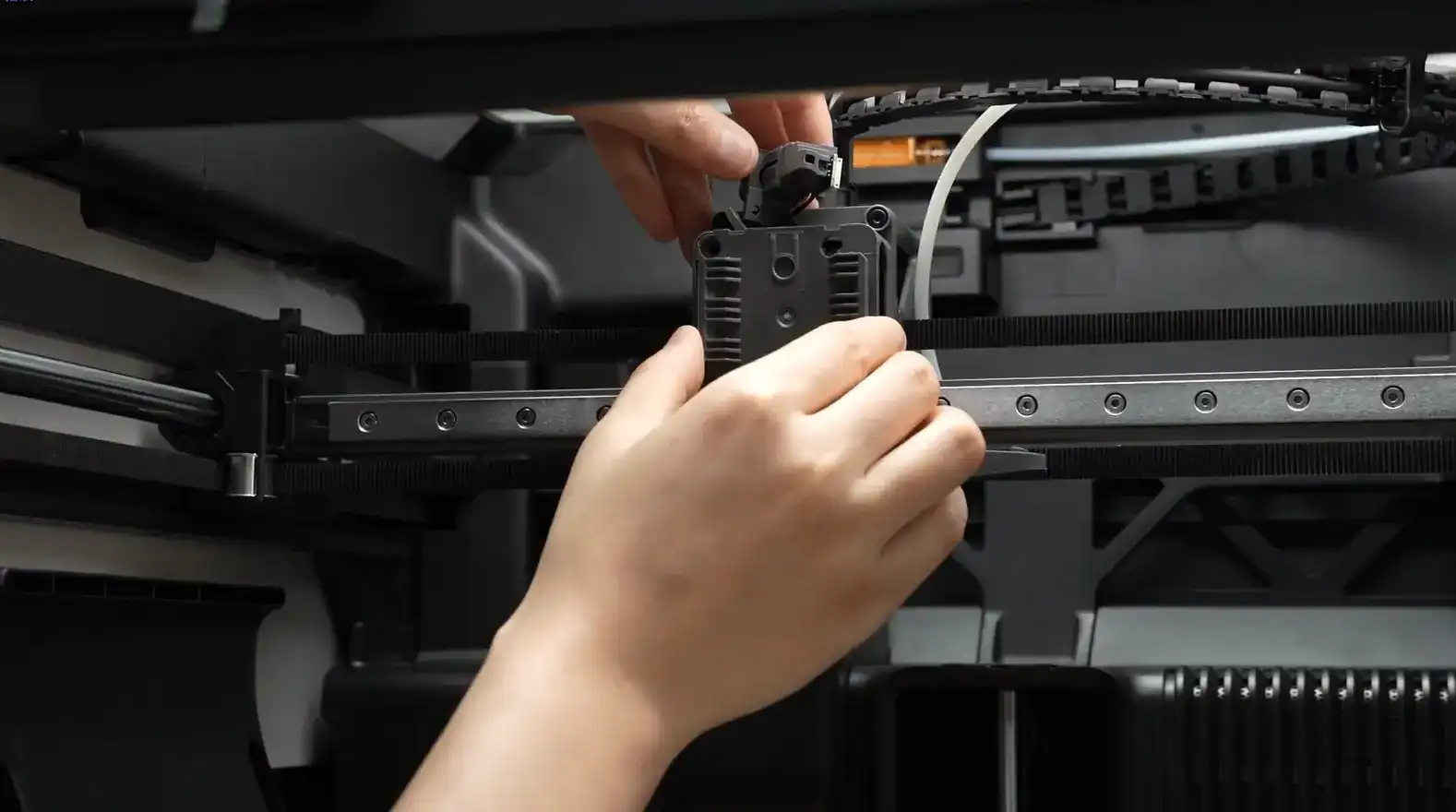

¶ Step 5: Remove the Filament Sensor

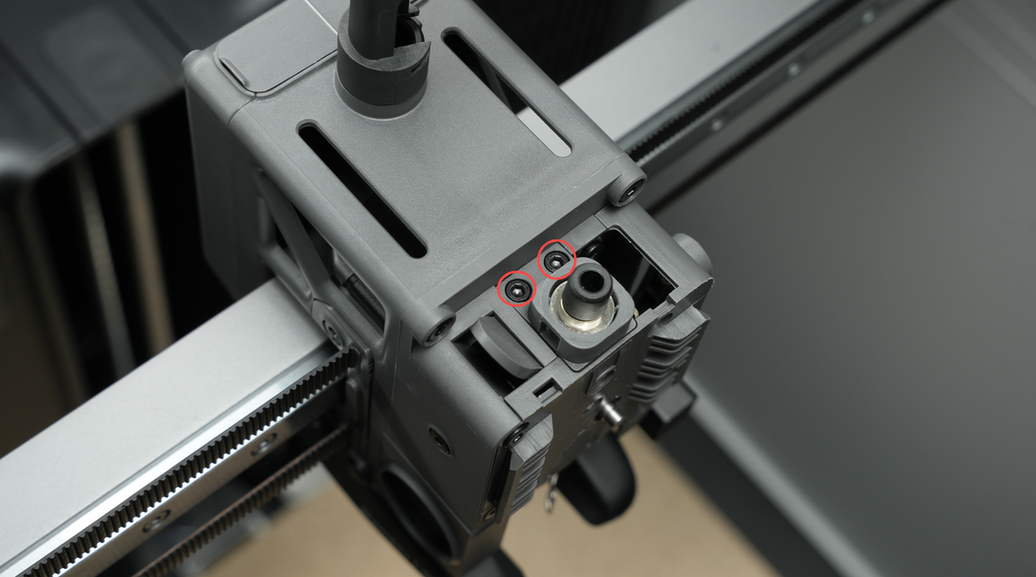

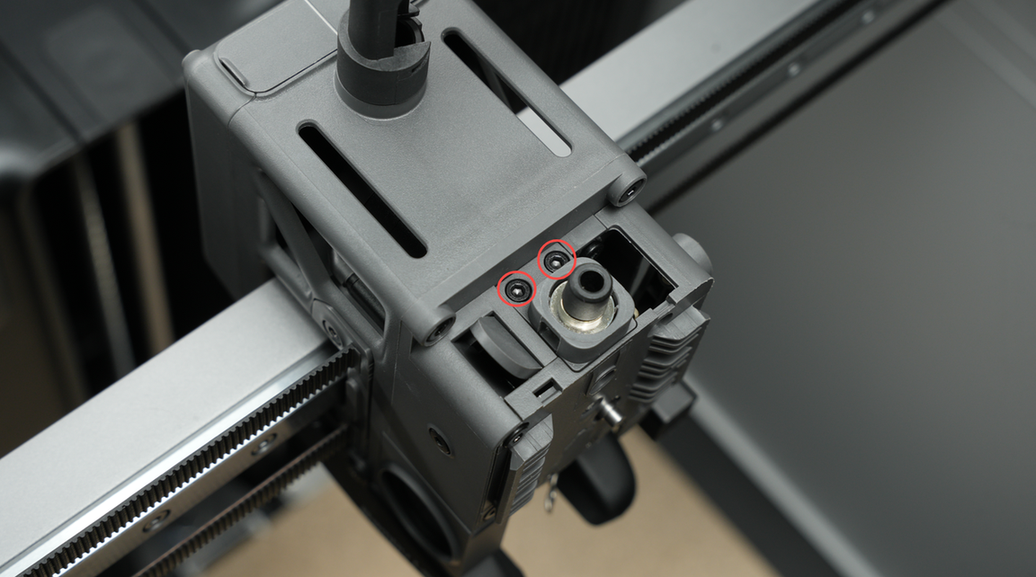

Use an H2.0 Allen key to remove 2 screws. If possible, attach double-sided tape to the top of the toolhead to place the filament sensor, preventing it from falling during subsequent disassembly and assembly. Note: Do not pull hard when removing the filament sensor, and handle it carefully to avoid damaging the black FPC cable.

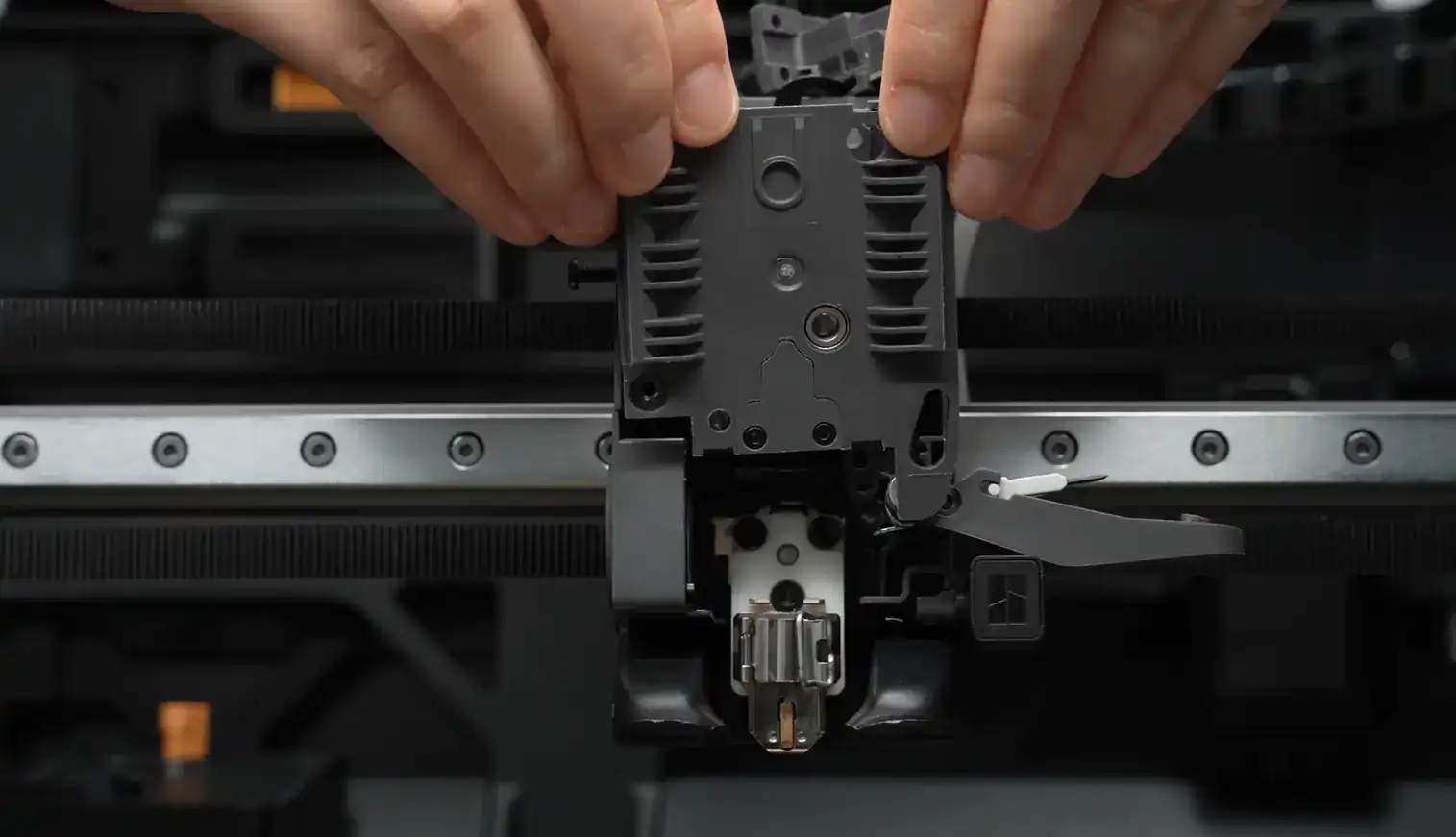

¶ Step 6: Remove the Extruder Unit Front Cover

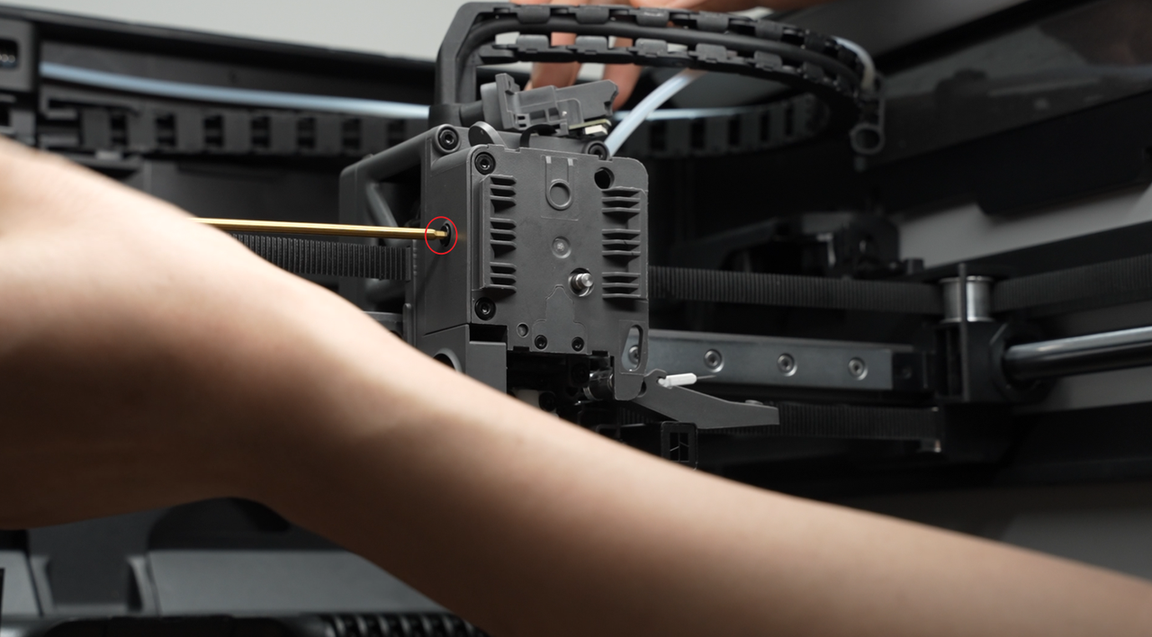

Use an H2.0 Allen key to loosen the tension driven lever locking screw on the side by one full turn;

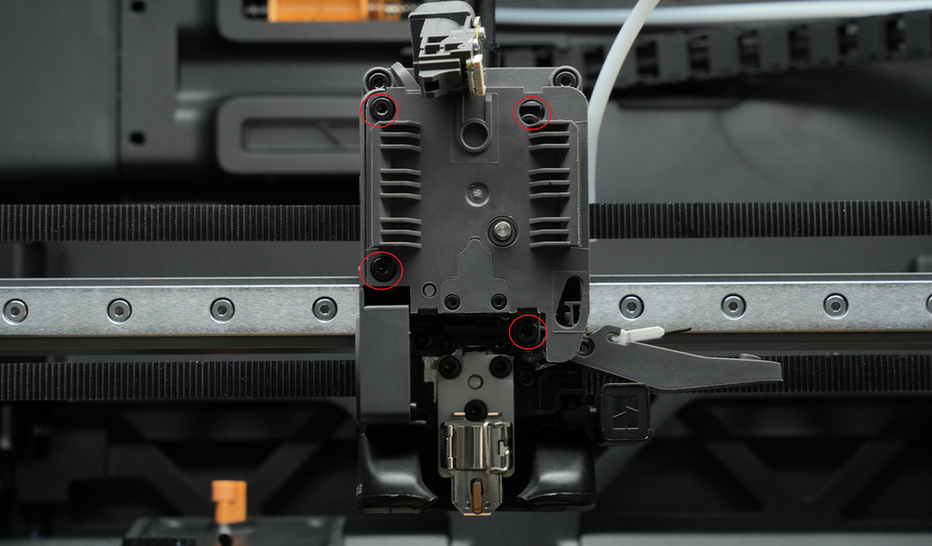

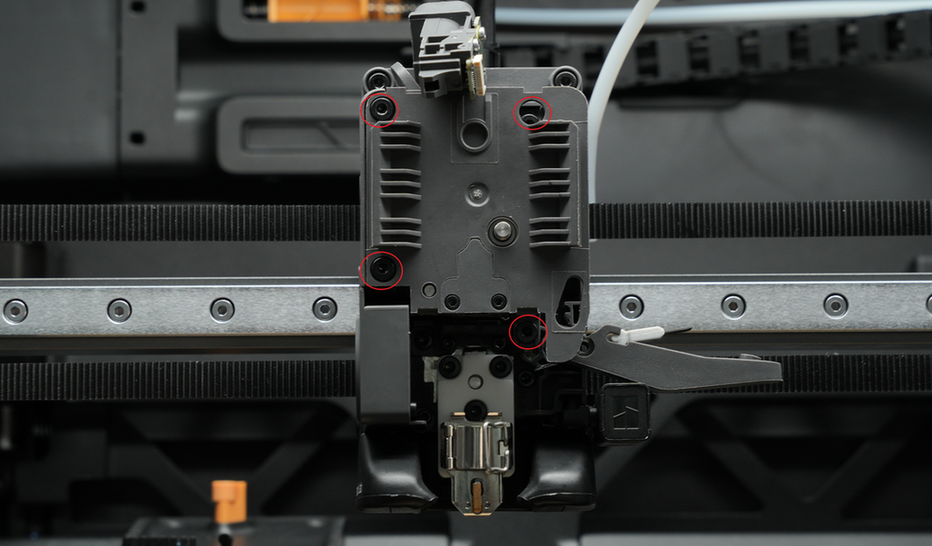

Use an H2.0 Allen key to remove the 4 screws on the front cover.

Remove the extruder unit front cover.

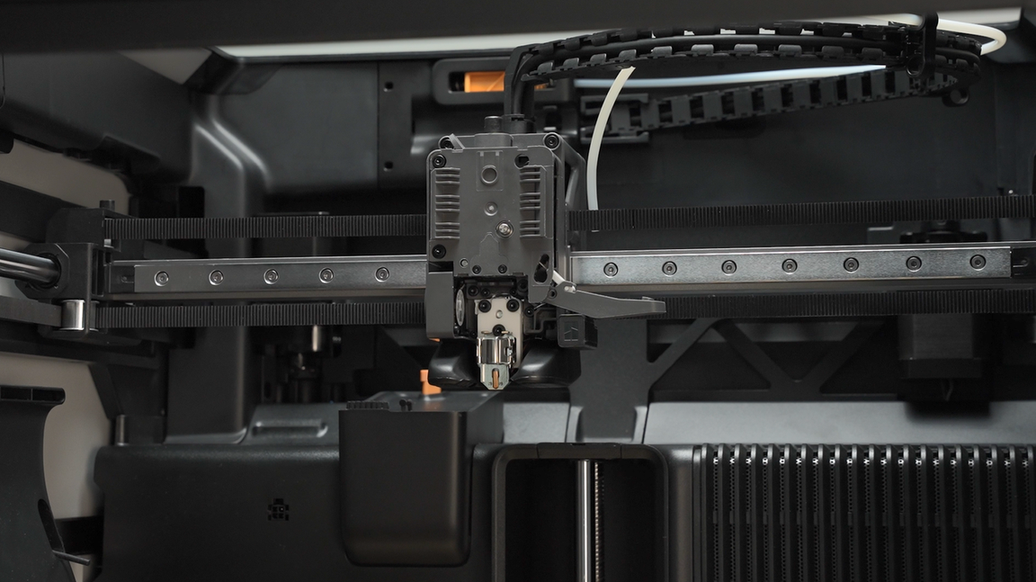

¶ Assembly Instructions

¶ Step 1: Install the extruder unit front cover

Reattach the extruder unit front cover and screw in the 4 front cover screws.

Tighten the extruder side screw;

¶ Step 2: Install the filament sensor

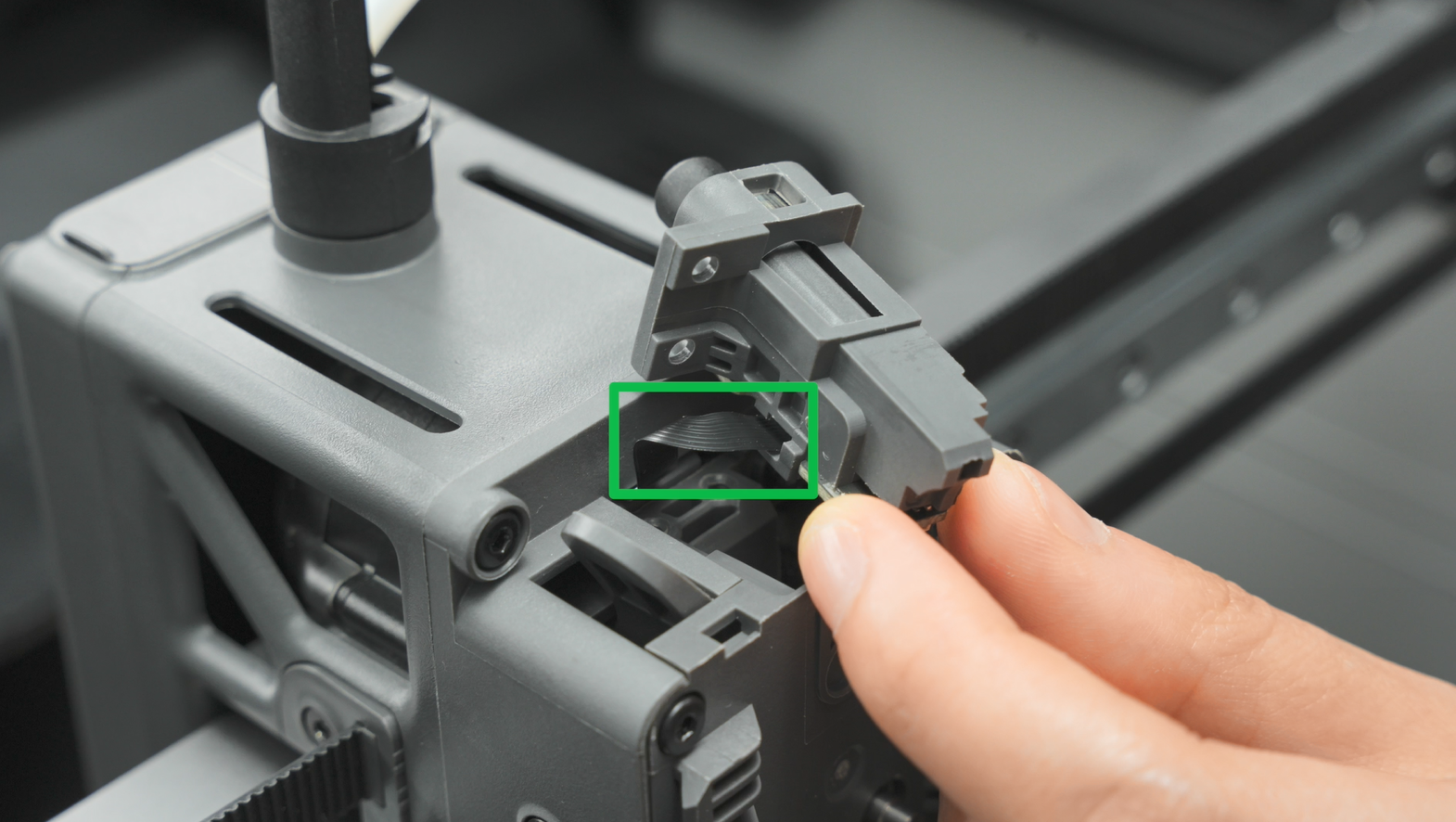

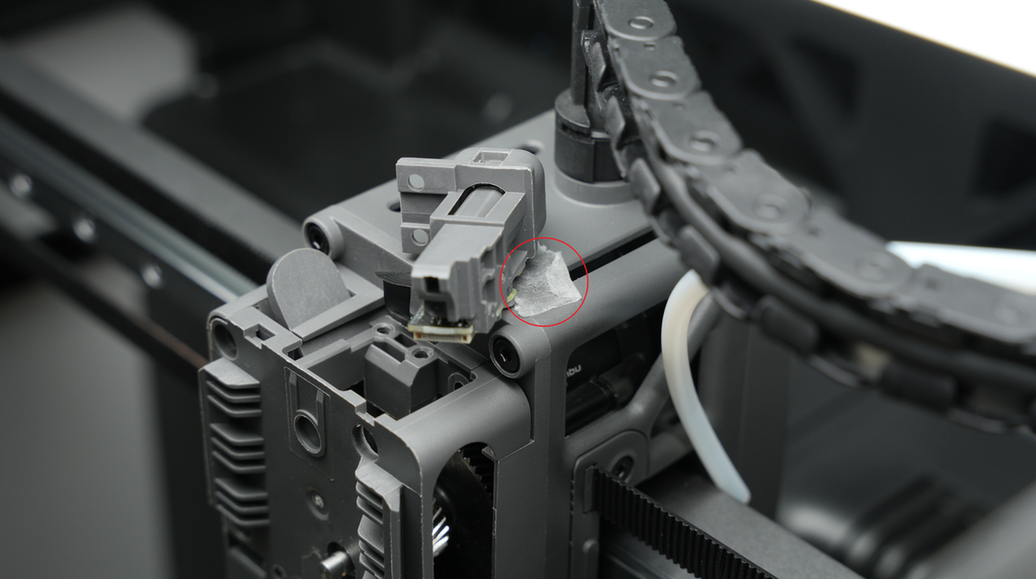

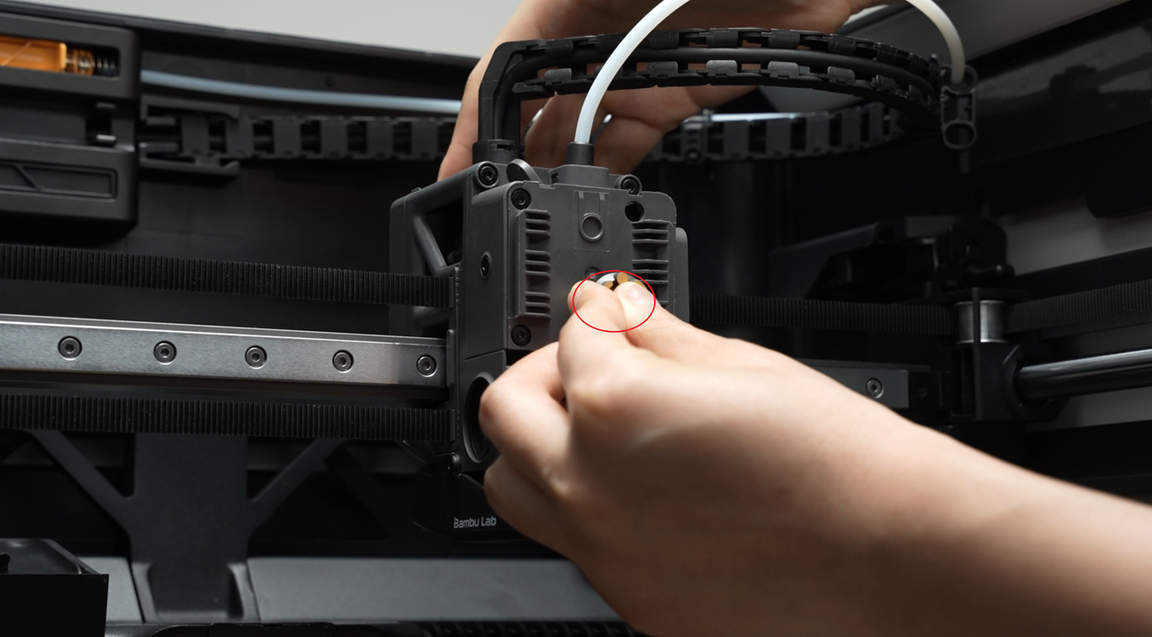

When installing the extruder filament sensor, make sure the black FPC cable is not bent and is placed smoothly into the gap. Then fasten the extruder filament sensor with 2 screws.

When assembling, be careful not to pinch the sensor cable. Use your finger or a plastic tool to move the cable away from the screw holes. Before tightening the screws, check the holes from the top to ensure the cable is not blocking them.

¶ Step 3: Reattach the Cutter Handle

Before re-tightening the screw, hold the cutter handle firmly in position. When tightening the screw, avoid excessive force to prevent thread stripping.

¶ Step 4: Connect the PTFE Tube

Insert the PTFE tube.

¶ Step 5: Reinstall the Rotating Wheel

Reattach the rotating wheel.

¶ Step 6: Install the Hotend

Refer to this tutorial to install the hotend.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!