¶ Fault Description

When the extruder is performing homing, leveling, or Z-offset calibration, an error will be triggered if the extrusion force sensor detects a signal frequency that is too low. At this situation, the heatbed will lower a short distance, then automatically cancel the task and display an error prompt.

The eddy current coil is installed on the extruder, above the hotend. Once correctly installed, the gap between the coil and the hotend heatsink should be ≥ 0.15 mm and ≤ 0.5 mm.

Possible causes include:

-

Hotend Not Installed:The hotend is not properly installed, preventing the sensor from detecting a valid signal.

-

Hotend Not Fully Installed*:The hotend is not installed enough. It will result in an excessive distance between the heatsink and the sensor, and affect signal detection.

-

Eddy Current Sensor Not Fully Installed:

The eddy current sensor is mounted too high, causing an excessive distance between the heatsink and the sensor. -

Loose connection between the extrusion force sensor and the TH board.

-

Severely deformed hotend heatsink:Warping of the heatsink may cause abnormal sensor readings.

¶ Troubleshooting

¶ Tools, Equipment, and Materials

None

¶ Troubleshooting Measures

Users may adjust the order of these measures depending on the situation.

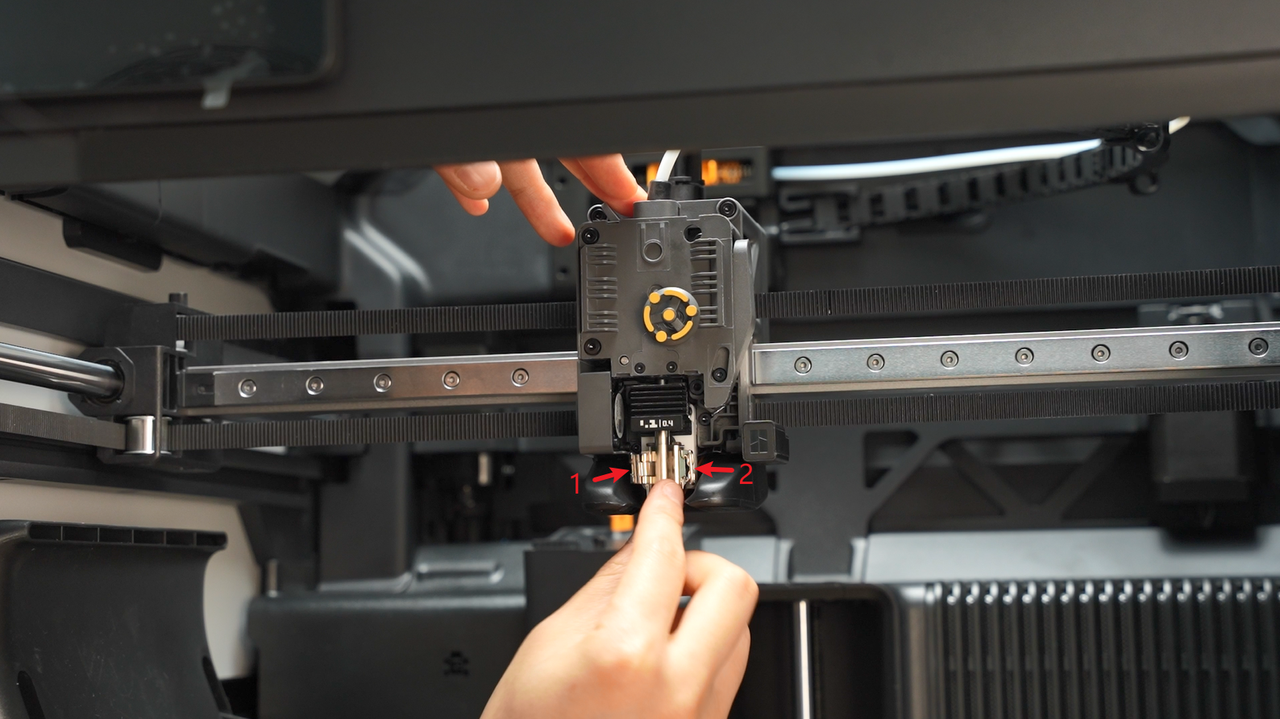

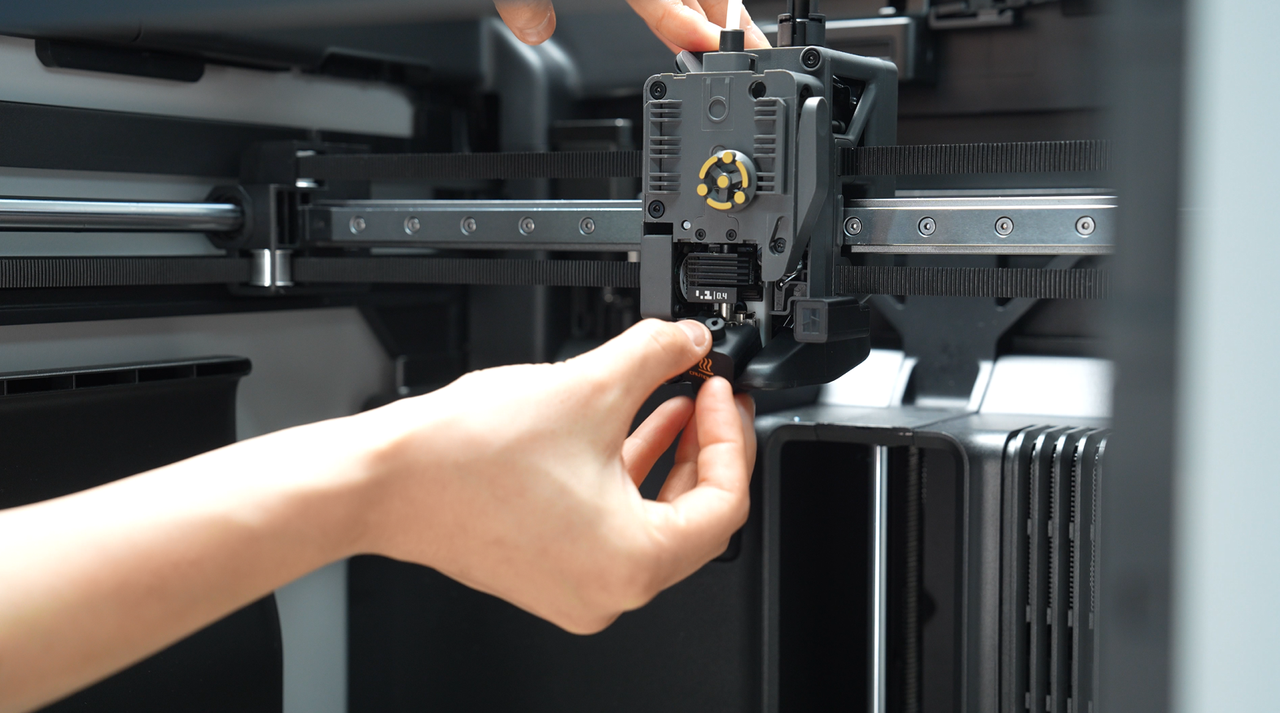

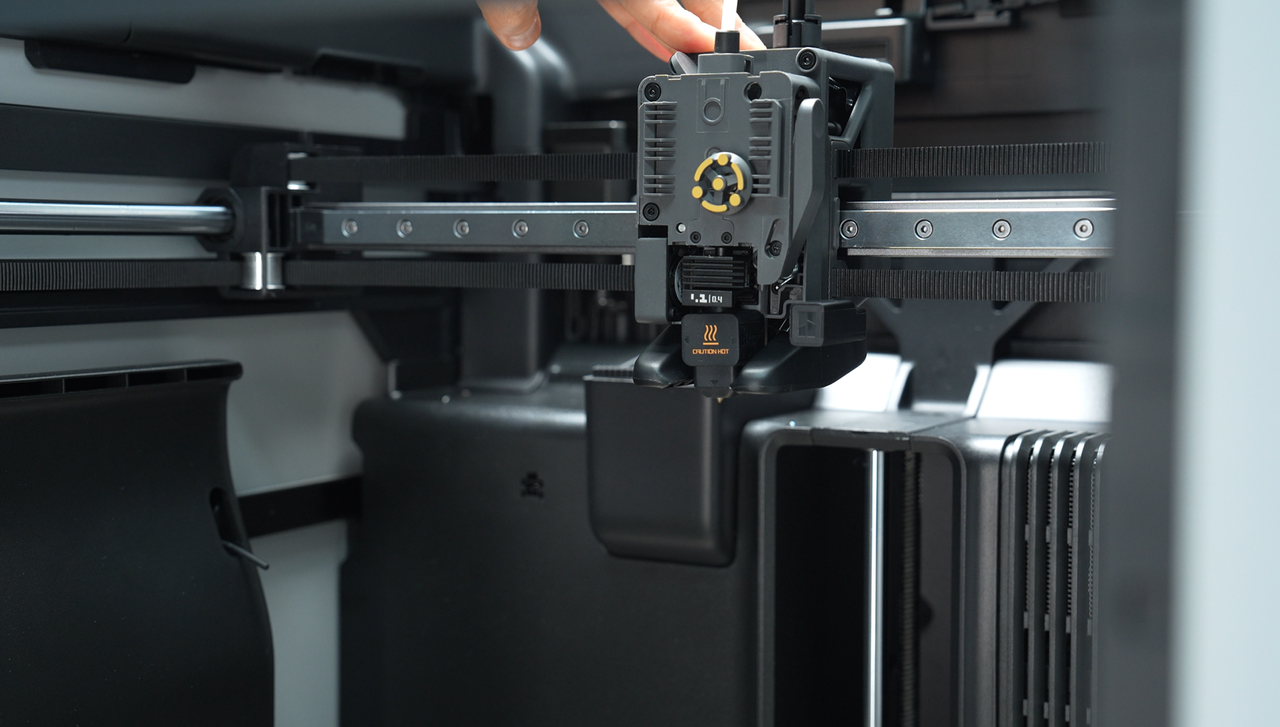

¶ Step 1. Check hotend installation

-

If the hotend is not installed, please re-install it.

-

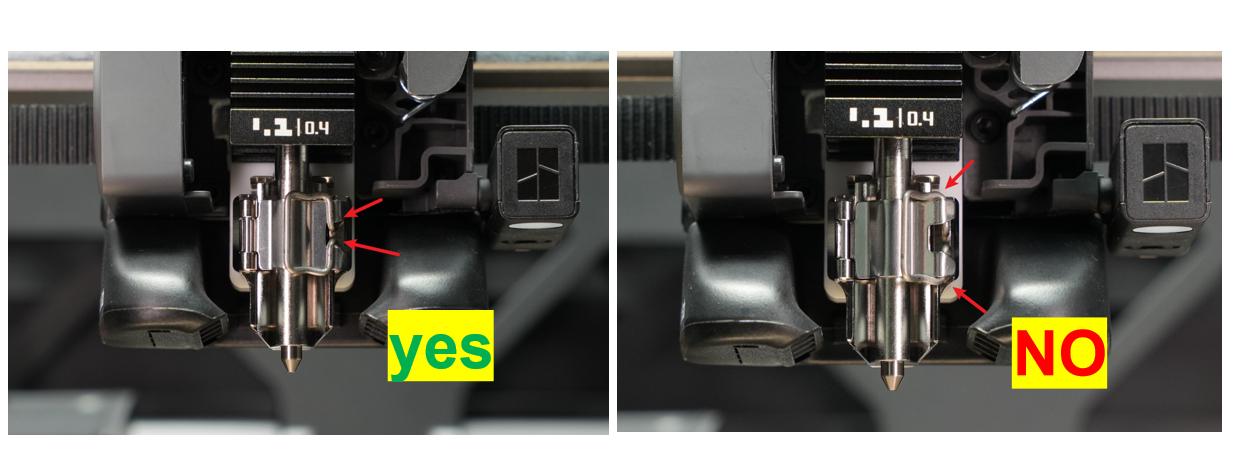

If the hotend is installed, please check and ensure that: ① The nozzle is flush against the hotend heater base. ② The locking latch is secured. ③ The hotend is stable and not loose.

|

|

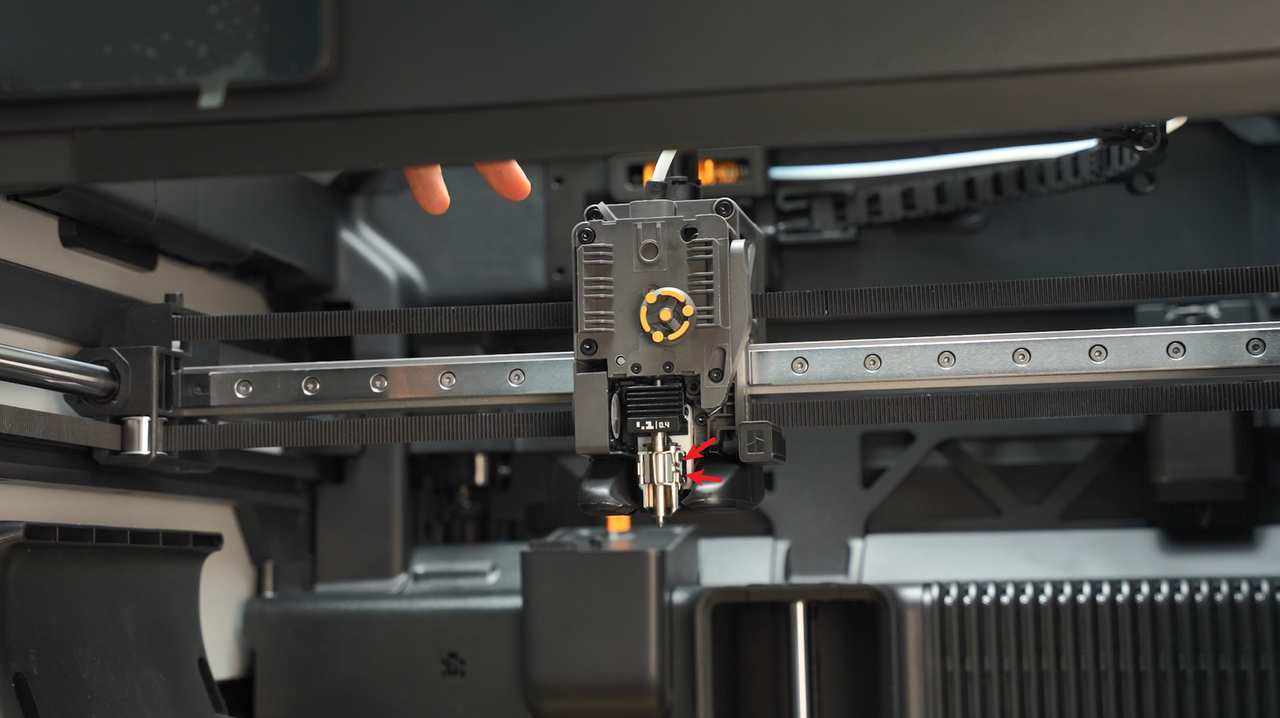

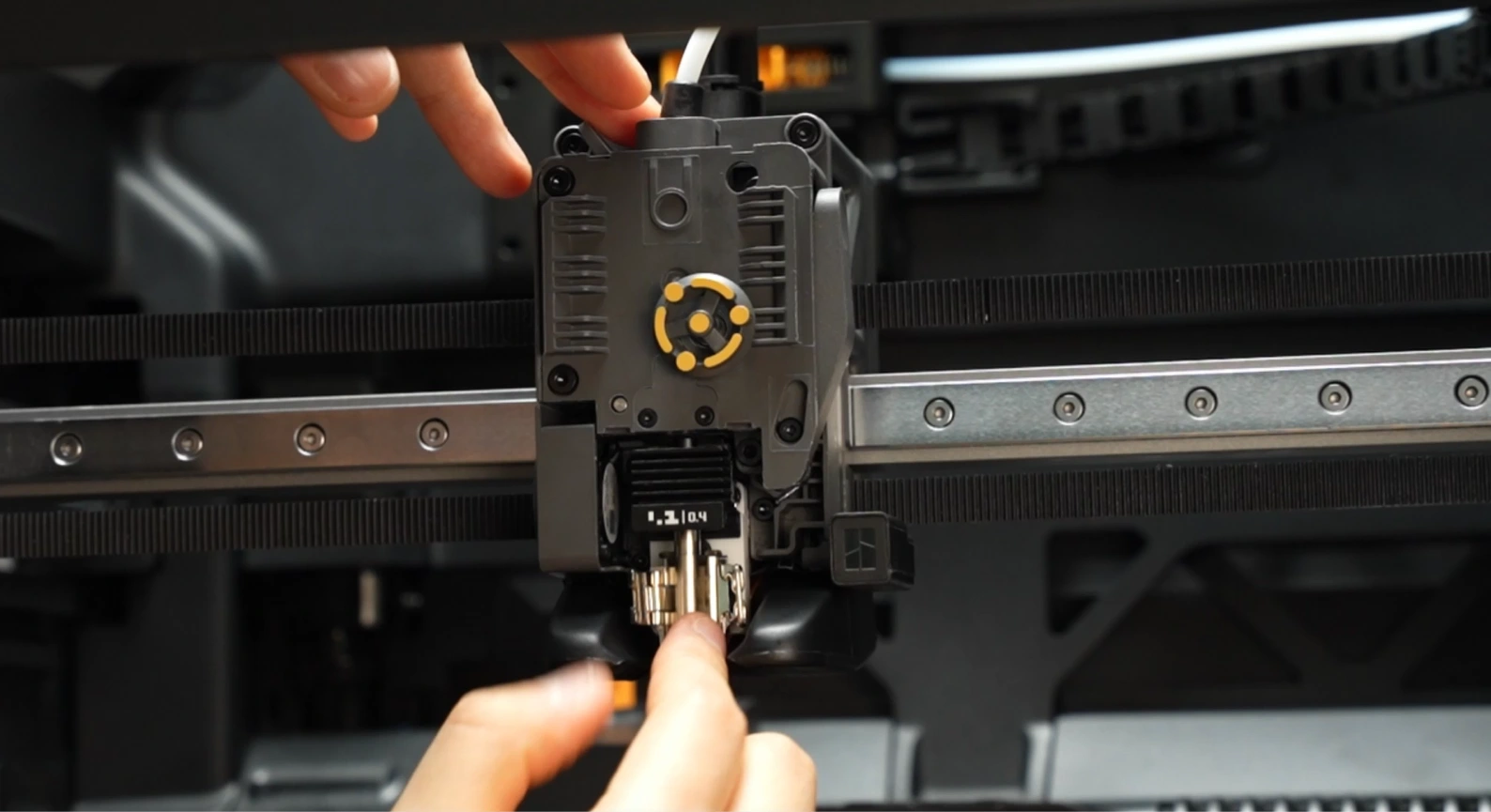

Tips: How to properly install the hotend?

- Install the hotend's silicone sock.

|

|

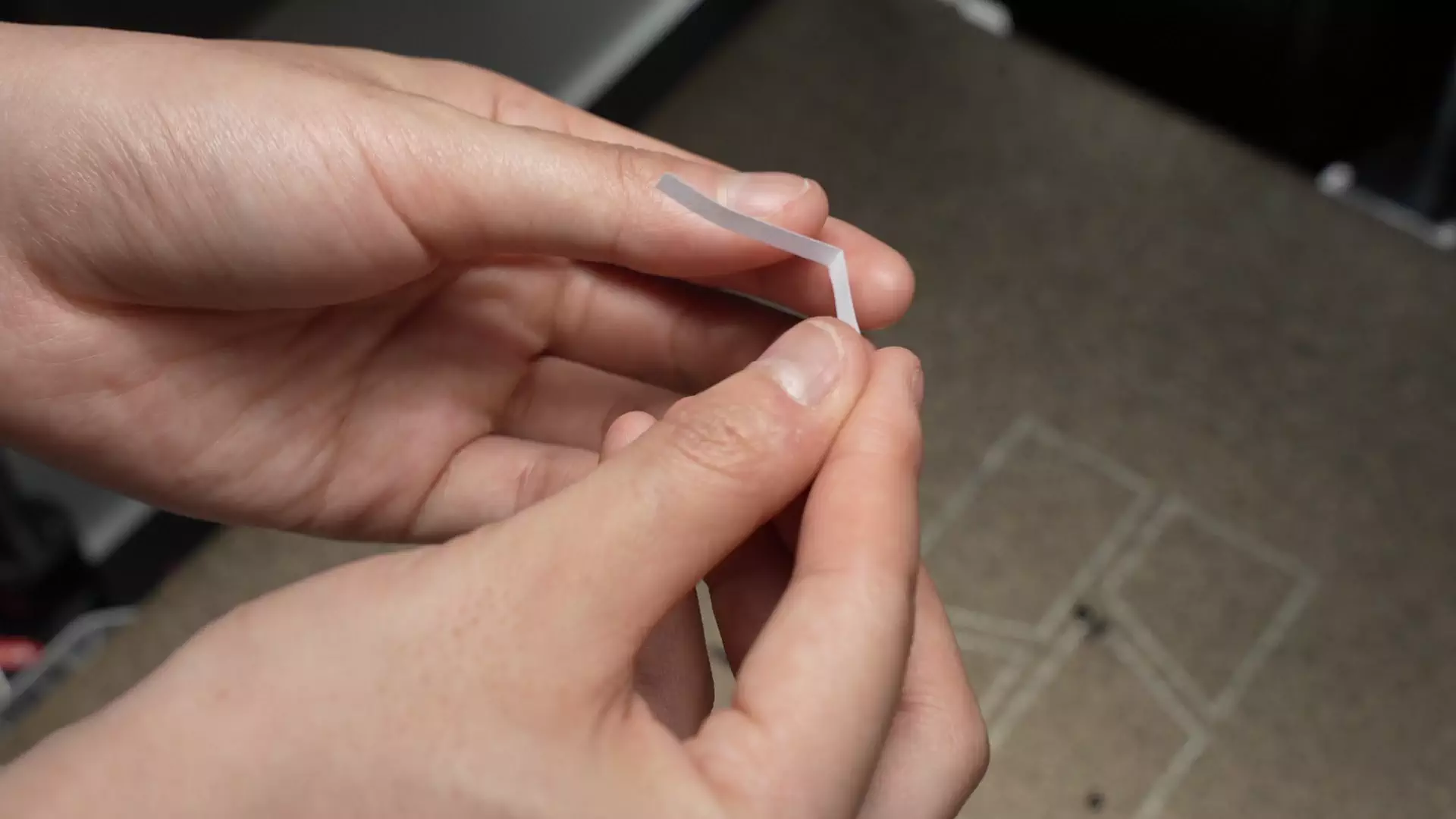

¶ Step 2. Check the installation gap between eddy current coil and hotend

Refer to the H2S eddy current coil replacement guide on the Wiki.

Use a folded A4 sheet of paper to check whether the gap is within the specified range

If the gap is too large, adjust the coil following the replacement procedure.

Calibrating the eddy current coil position (important): Fold a piece of A4 paper in half and insert it between the hotend and the coil. When sliding the paper back and forth, you should feel some friction, but the paper should still move freely. This corresponds to a gap of approximately 0.2–0.3 mm.。

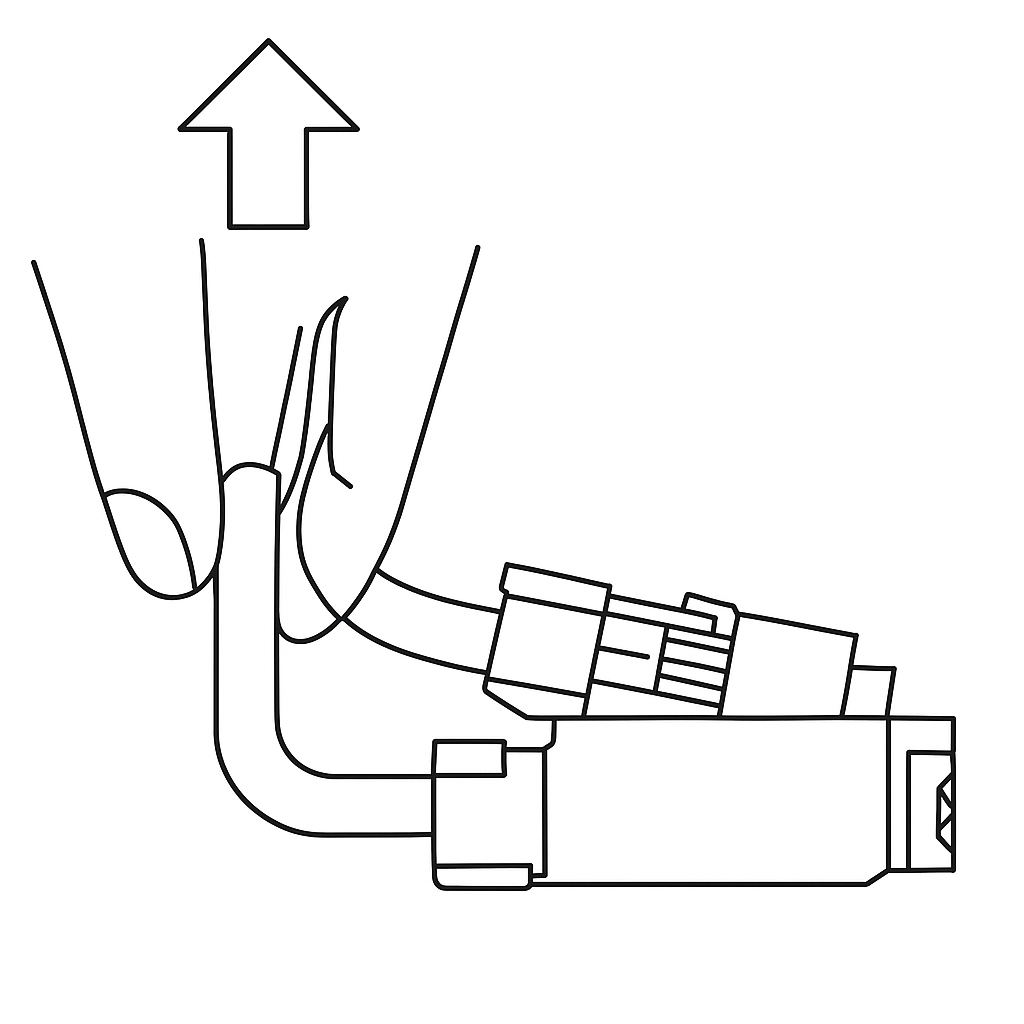

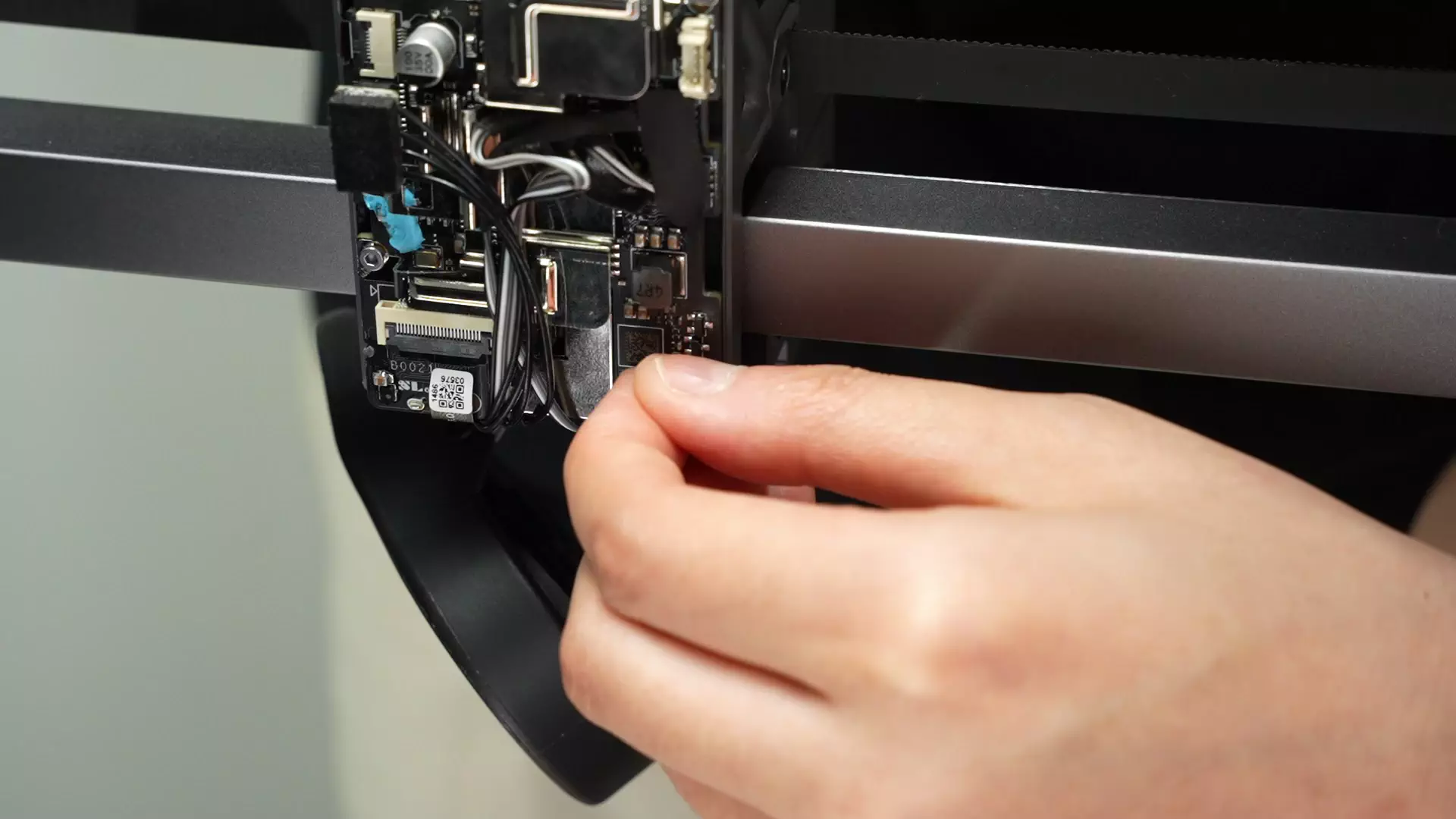

¶ Step 3. Check extrusion force sensor to TH board connection

It is recommended to re-plug the connector once.

¶ Unplugging method:

- Pinch the connector base.

- Pull in the vertical direction away from the PCB board to disconnect the eddy current coil connector.

¶ Plugging method:

- Connect the fan cable.

- Align the connection socket of extrusion force sensor with TH board receptacle (the connector’s metal solder side should face the back of the chassis). And then, please push the connector down into place.

- Press any extra wire length under the TH board and secure it with Kapton tape.

¶ Step 4. Check whether the hotend heatsink is deformed

After pressing the cutter to cut the filament, remove the hotend and inspect the heatsink.

-

If it has warped downward (instead of remaining level or slightly upward as is normal), it may cause detection issues.

-

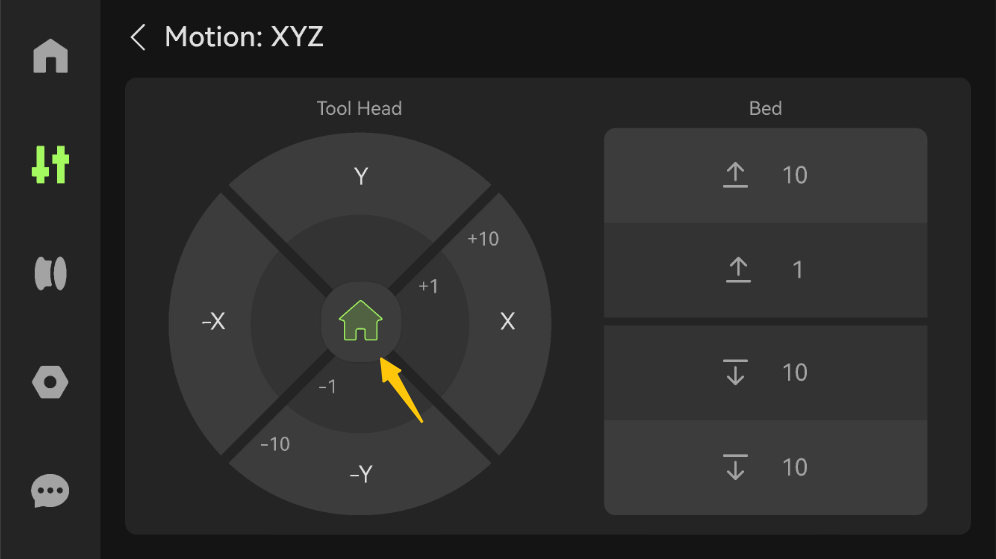

If there is not obvious deformation, please re-install the nozzle as following instruction. Then tap "Home" on the screen to check if homing works correctly or not.

-

Note: Using a third-party hotend may also cause this issue.

Example of deformed hotend heatsink:

¶ Step 5. Perform homing test

Tap the printer screen to re-initiate homing.

If the error does not reoccur, troubleshooting has been successful.

If the above troubleshooting measures do not resolve your issue, please submit a support ticket and upload the printer's operation log.

¶ Conclusion

We hope this guide will provide you with useful information to help you solve problems.

If this guide does not solve your problem, please contact online technical support (service hours 9:00-21:00), we are ready to answer your questions and offer assistance.

If you have any suggestions or feedback on this Wiki, please leave a comment in the comment section. Thank you for your support and attention!