¶ Issue Description

During the homing, leveling, and hotend Z offset calibration process of the 3D printer, the nozzle lightly touches the heatbed to determine its precise position. However, if there are foreign objects between the nozzle and the heatbed, the printer will detect abnormal touch data. This causes the nozzle to attempt touching at the same position multiple times, eventually leading the heatbed to automatically lower by a certain distance and trigger an error message.

Possible causes:

-

Nozzle residue: Residual filament on the nozzle that has not been cleaned properly, affecting touch detection.

-

Foreign objects on the heatbed or nozzle: Presence of foreign objects on the heatbed surface or under the nozzle, resulting in abnormal touch data.

-

Loose hotend installation: Improperly secured hotend, which may cause position deviation or inaccurate touch detection.

¶ Troubleshooting

¶ Tools, Equipment and Materials

None

¶ Solutions

Users may adjust the order of these solutions as needed.

¶ Step 1. Clean the nozzle

Inspect and clean residual filament from the nozzle to ensure the nozzle surface is clean and free of foreign objects.

¶ Step 2. Clean the heatbed

Inspect the heatbed surface and clean any foreign objects to ensure the contact area between the heatbed and nozzle is flat and clean.

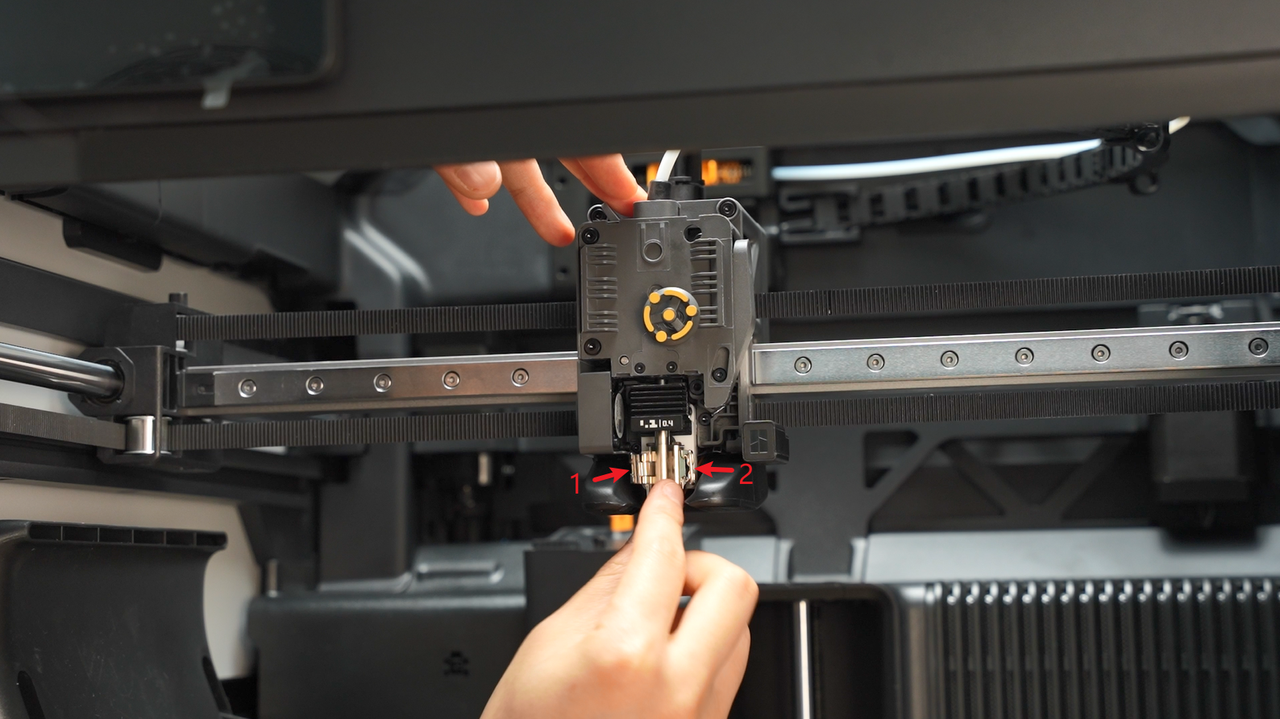

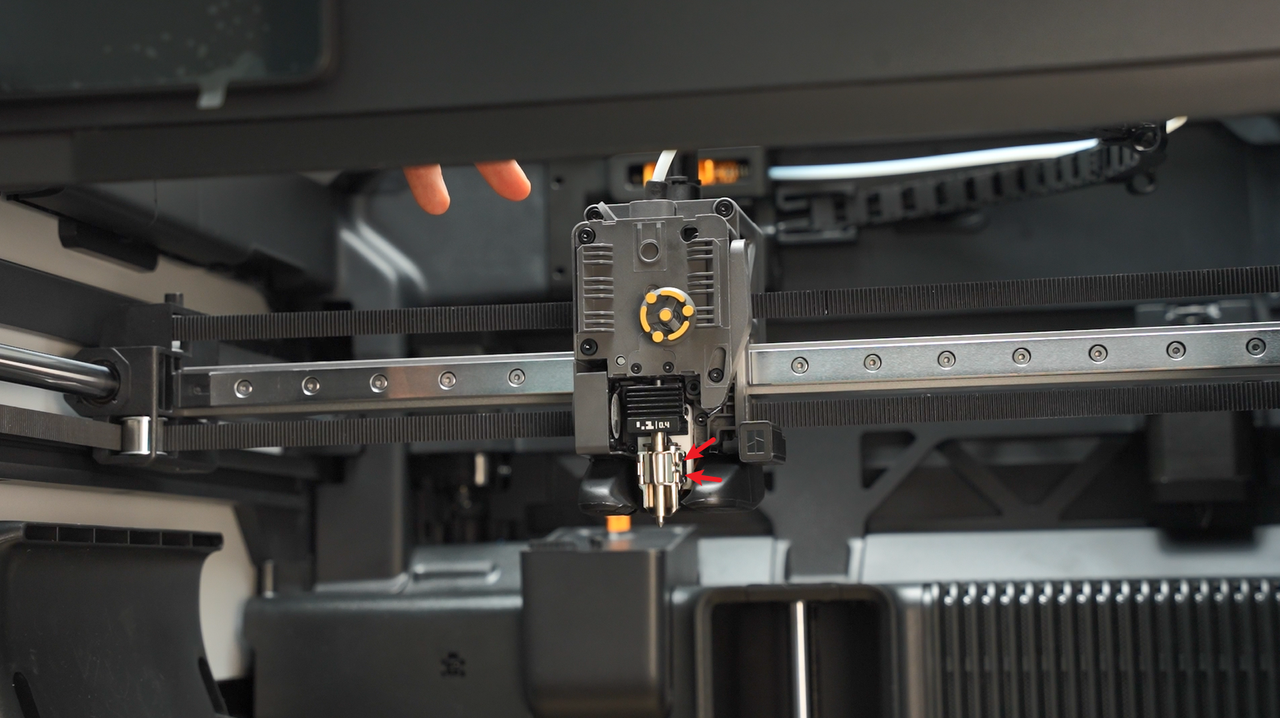

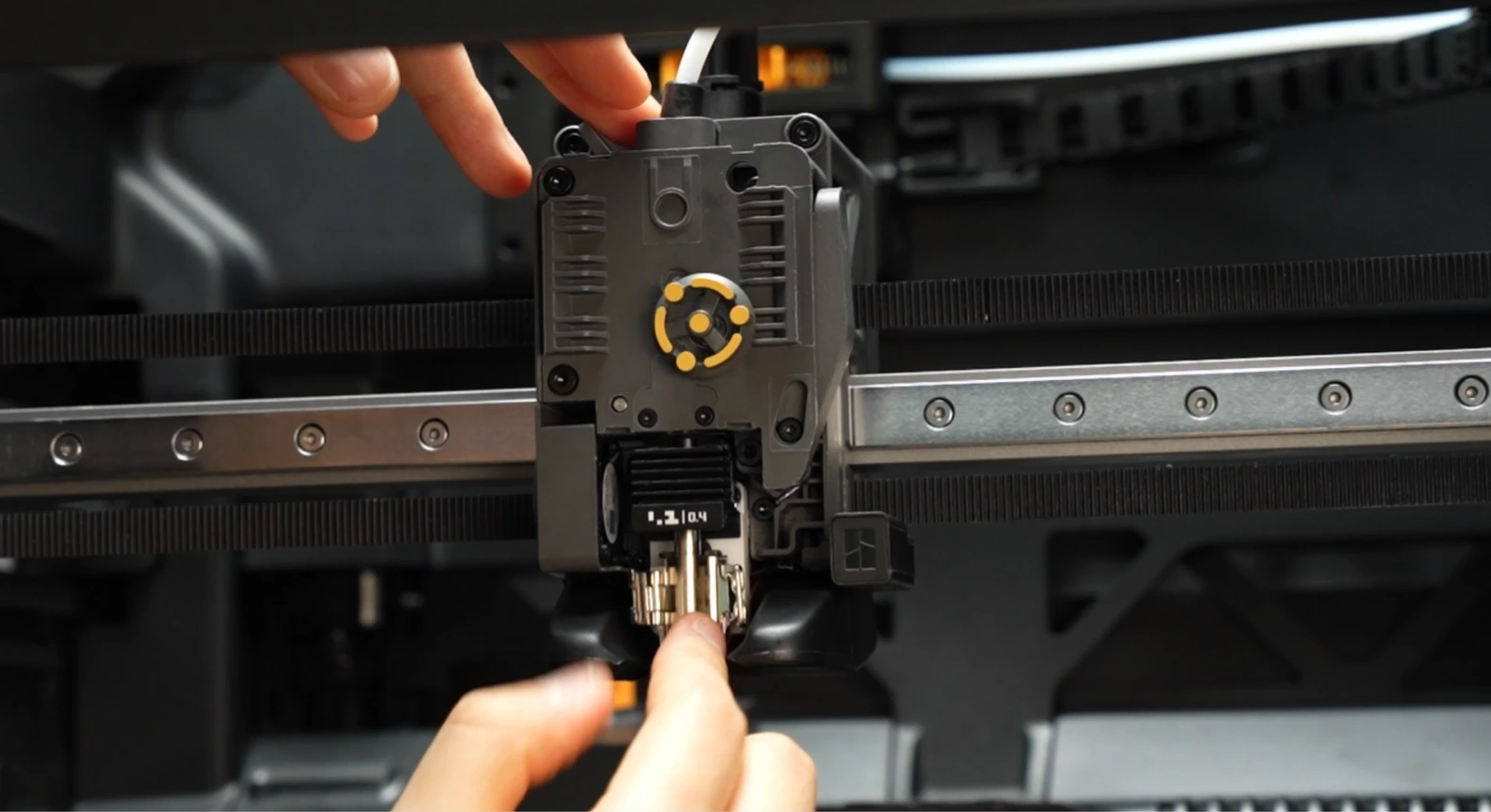

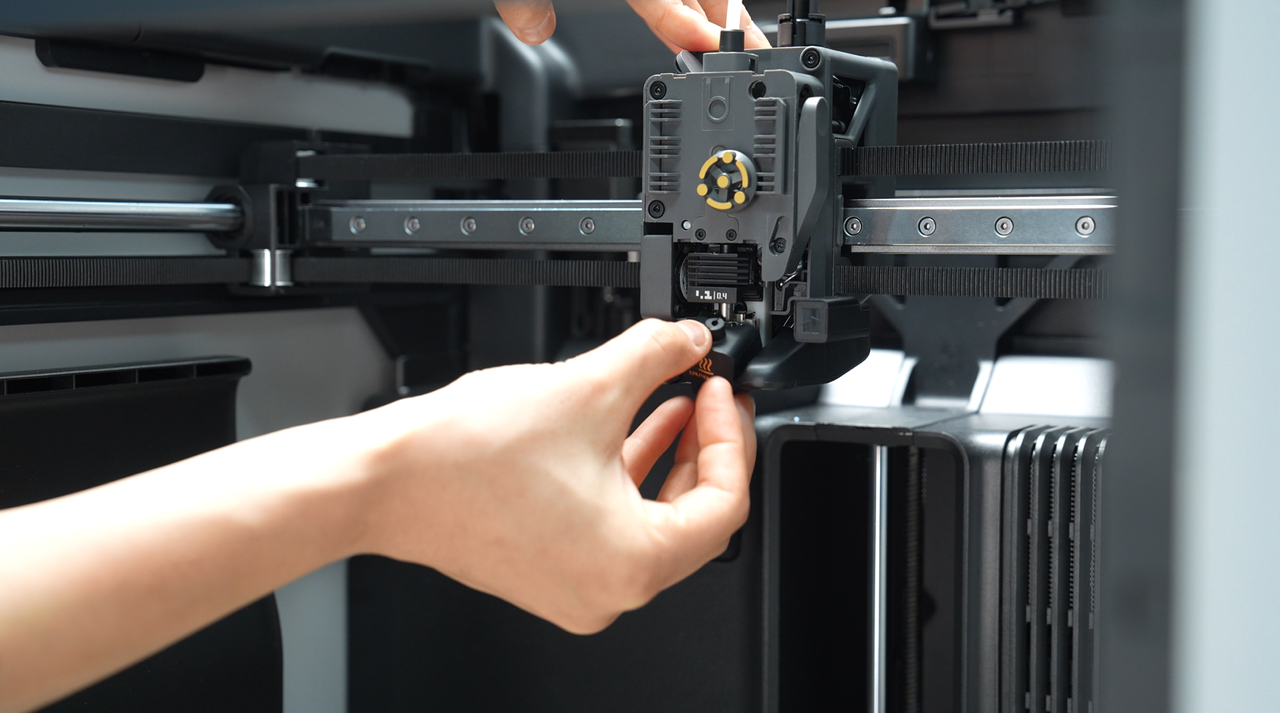

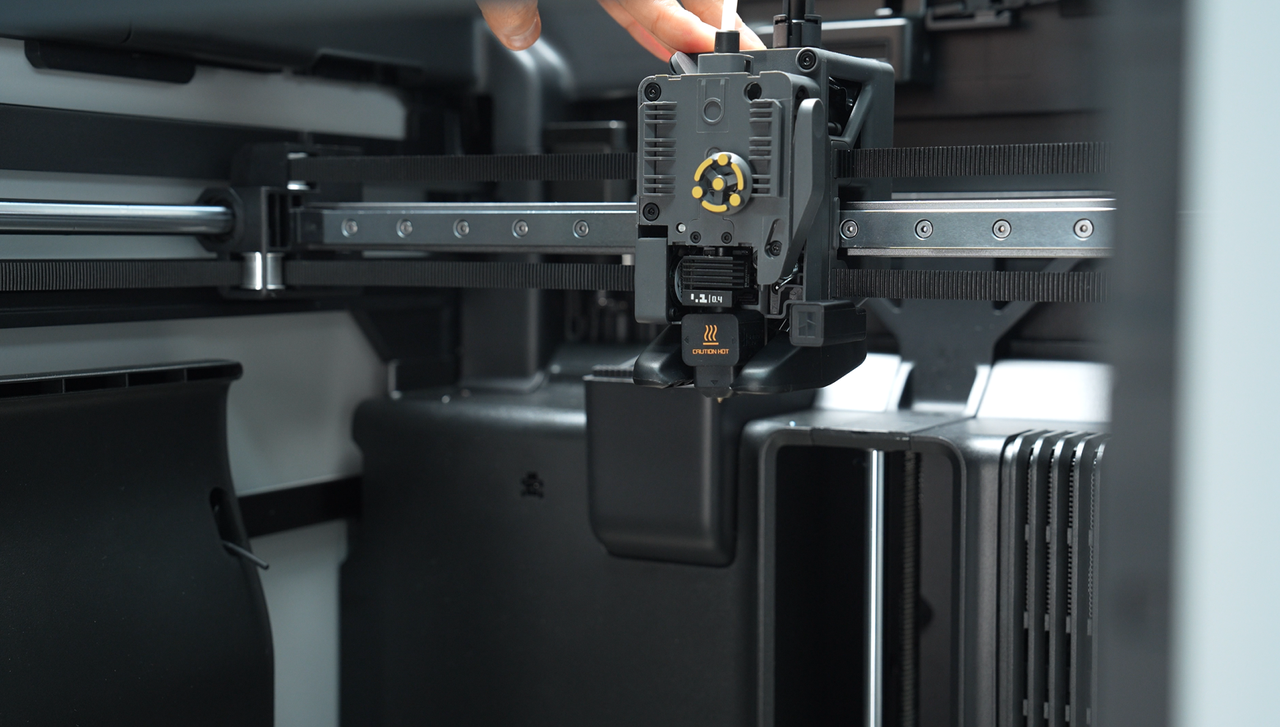

¶ Step 3. Check hotend installation

Inspect the hotend installation to ensure it is securely fixed and tightened, avoiding position deviation caused by looseness.

Tips:How to properly install the hotend?

|

|

- Install the silicone sock for hotend.

|

|

If the above steps do not resolve your issue, please submit a ticket and upload your printer logs

¶ Conclusion

We hope this guide will provide you with useful information and help you solve problems.

To ensure that you operate safely and effectively, if you have any doubts or questions about any steps in the guide, please contact our Customer Support team before starting the operation.

We are always happy to answer your questions and provide support.

Click here to contact online technical support (service hours 9:00-21:00)