¶ Screw Types & Applications

M(Metric machine screws) M-series screws are the most common metric machine screws. M-series screws are standard metric machine screws used withmatching nuts or pre-tapped holes. The thread is full-length, providing strong joints and good repeatability for assembly/disassembly. Typical use: secure connections that may be removed and reinstalled. |

BT(Self-tapping Screws for Plastics) They have shallower threads with a wider pitch and a blunt or semi-pointed tip. They can form their own threads in plastic parts while reducing the risk of cracking caused by overly deep threads, making them a better match for plastic materials. |

ST(Self-tapping Screws for Sheet-Metal) They feature sharp thread profiles with a relatively fine pitch and a pointed tip, giving strong cutting ability. They can tap directly into thin sheet metal (typically 1–3 mm) without pre-drilling/tapping, improving assembly efficiency. |

MG(Partially Threaded Screws) Partially threaded screws have threads on only part of the shank, with an unthreaded portion usually near the head. This design combines the clamping strength of full threads with the locating function of a smooth shank, so it is often used where both firm fastening and precise positioning are required. |

Do not interchange BT, ST, and M-series screws!

They have different thread profiles and pitches; intermixing can cause stripped threads, cracking of plastics, or permanent damage to the tapped holes.

¶ Size & Marking Rules

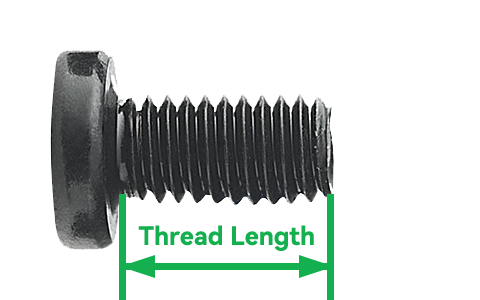

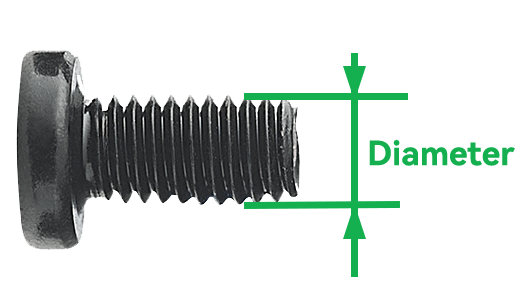

General notation: “Type + Diameter × Thread Length (mm)”。or example, M3×10 means the screw is M series with a diameter of 3 mm and a length of 10 mm.

Diameter: the major (outside) diameter of the external thread. Thread length: the distance from thebearing surfaceunder the head to the end of the shank; the head height is not included.

¶ Hex Socket Screw

Bambu Lab printers extensively use hexagon socket screws for machine assembly and securing core components. For the most part, these screws can be removed and installed using only H1.5 and H2.0 hexwrench.

Note: MakerWorld assembly tasks may require H1.3 and H2.5 hexwrench; please select the appropriate size as needed. For 40 W Laser Module, the PU air assist tube coupler must be removed with an H2.5 hexwrench.

In the screwdriver's size labels, "H" stands for Hexagon Socket, while the following number (e.g., 1.5, 2.0) precisely indicates the millimetre (mm) measurement of the tool's across-flats size. This design not only ensures a secure connection but also provides users with a convenient maintenance experience.

¶ Threadlocker

Threadlocker is a material, which is pre-applied to the threads of fasteners (on part or all of the thread) at the factory. It provides resistance to loosening and vibration during assembly without the need for additional adhesive. Screws used in Bambu Lab printers fall into two categories: red-threadlocker screws and blue-threadlocker screws.

| Type | Red-threadlocker screws (High strength) | Blue-threadlocker screws (Medium strength) |

|---|---|---|

| Definition | Coated with a high-strength threadlocker, offering the strongest anti-loosening performance. | Coated with a medium-strength threadlocker, balancing retention and serviceability. |

| Main use | Important parts that should never come loose and are rarely opened. | For joints that require both anti-loosening performance and periodic maintenance or inspection. |

| Typical applications | Lead-screw nut fastening, motion frame, and other critical structural components. | Motor mounting. |

| Anti-loosening performance | Very hard to remove; needs high torque. | Good stability while maintaining moderate removability |

| Notes | Bambu Lab red-threadlocker screws use a chemical adhesive. They are best treated as one-time assemblies. After installation, the coating requires about 24 hours to fully cure. If later removal is necessary, the cured adhesive’s strong adhesion means significant force is needed to back the screw out; after removal, the anti-loosening structure is damaged, so anti-loosening performance will be noticeably reduced upon reassembly. | Bambu Lab blue-threadlocker screws use a blue nylon patch. They support multiple assembly/disassembly cycles and can maintain stable clamping force through repeated tightening and loosening, meeting repeated assembly needs. |

| Illustrations |

|

|

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!