¶ AMS Silicone Desiccant

New Silicone Desiccant Packaging

You can purchase it at our store here: Silicone Desiccant for AMS(6 pack)

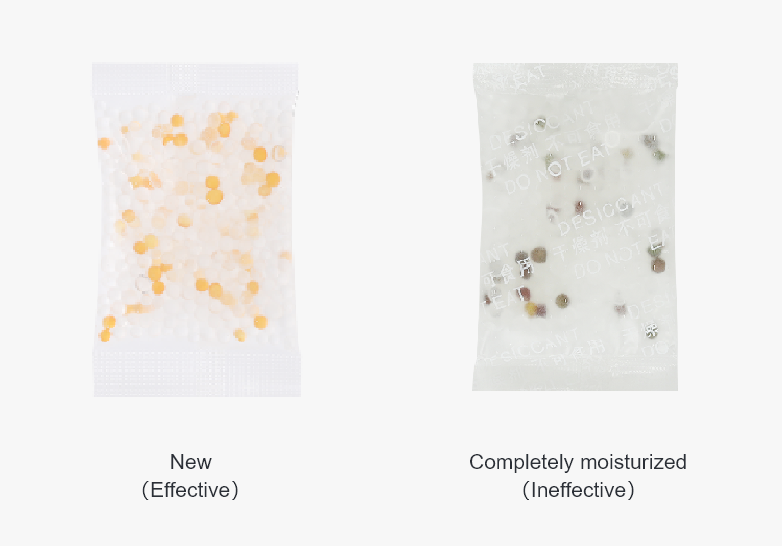

¶ Desiccant status

When the desiccant has absorbed sufficient moisture, the internal yellow beads will gradually turn purple (as shown on the right side of the image below). If the beads appear predominantly purple, the desiccant should be replaced or reactivated by drying before reuse.

Note: Please remove the desiccant from the sealed transparent plastic bag before placing it into the AMS.

You can refer to the Desiccant Replacement Guide for routine maintenance.

¶ How to Dry the Silicone Desiccant

Safety Warning:

Do not exceed a drying temperature of 100°C (212°F) to avoid damaging the silicone structure. Ensure proper ventilation during the drying process and wear heat-resistant gloves. Use heatproof containers such as ceramic, glass, or aluminum foil—do not use plastic. If using a household oven, clean it thoroughly after drying. Keep children and pets away from the high-temperature area during operation.

¶ 1. Drying with a Household Oven

Steps:

1. Preparation:

Remove the moisture-absorbed desiccant from the AMS and take it out of the plastic packaging.

2. Spread Evenly:

Spread the beads evenly (maximum thickness: 2 cm) in a heat-resistant container such as a ceramic dish, aluminum foil tray, or glass beaker.

3. Temperature Setting:

Set the oven to 80–90°C (176–194°F).

Do not exceed 100°C (212°F) to avoid degrading the desiccant.

4. Drying Duration:

- Slightly Moist (light purple): 1–2 hours

- Fully Saturated (dark purple): 2–3 hours

5. Cool & Inspect:

Allow the desiccant to cool down after drying. Once the beads return to their original orange color, they can be reused.

Note: Avoid using trays or containers that are shared with food. A dedicated tray is strongly recommended.

¶ 2. Drying with a 3D Printer

Compatible Models: Bambu Lab X1, X1C, and P1S.

Steps:

1. Preheat the Heated Bed:

Use the printer touchscreen or the Bambu Handy app to set the heated bed temperature to 80°C (176°F). Preheat for 10 minutes.

2. Place the Desiccant:

Pour the silicone beads into a heat-resistant container with the lid open, then place the container on the print bed.

3. Drying Time:

Let it dry for 3–4 hours. (Note: Drying takes longer than with an oven due to lower heating power.)

Optionally, stir or shake the beads every 30 minutes for even drying.

4. Check Condition:

Inspect the color of the desiccant—once it turns orange, it's ready for reuse.

Advantages:

- No additional equipment required—ideal for users without access to an oven.

- Allows simultaneous drying of both filament and desiccant.

¶ 3. Post-Drying Handling

1. Usage Recommendations:

After drying, place the desiccant beads into a breathable pouch, such as a gauze or mesh bag of appropriate size, before reinserting them into the AMS unit.

2. Storage Recommendations:

If the desiccant will not be used immediately after drying, seal it in an airtight bag or container right away to prevent moisture reabsorption from the air.

3. Service Life Assessment:

Silicone desiccant can typically be reactivated by drying 5 to 15 times.

Replace the desiccant if color change becomes noticeably slower or if the beads begin to break apart.

¶ AMS Calcium Chloride Desiccant

Note:

Due to the risk of dissolution and leakage after moisture absorption—which may lead to circuit corrosion—the use of calcium chloride desiccant has been discontinued in newly manufactured AMS, AMS 2 Pro, and AMS HT units. These units now come equipped with the silicone desiccant described above.

Legacy Calcium Chloride Desiccant (with Outer Packaging)

You can purchase it at our store here: Calcium Chloride Desiccant for AMS (6 pack)

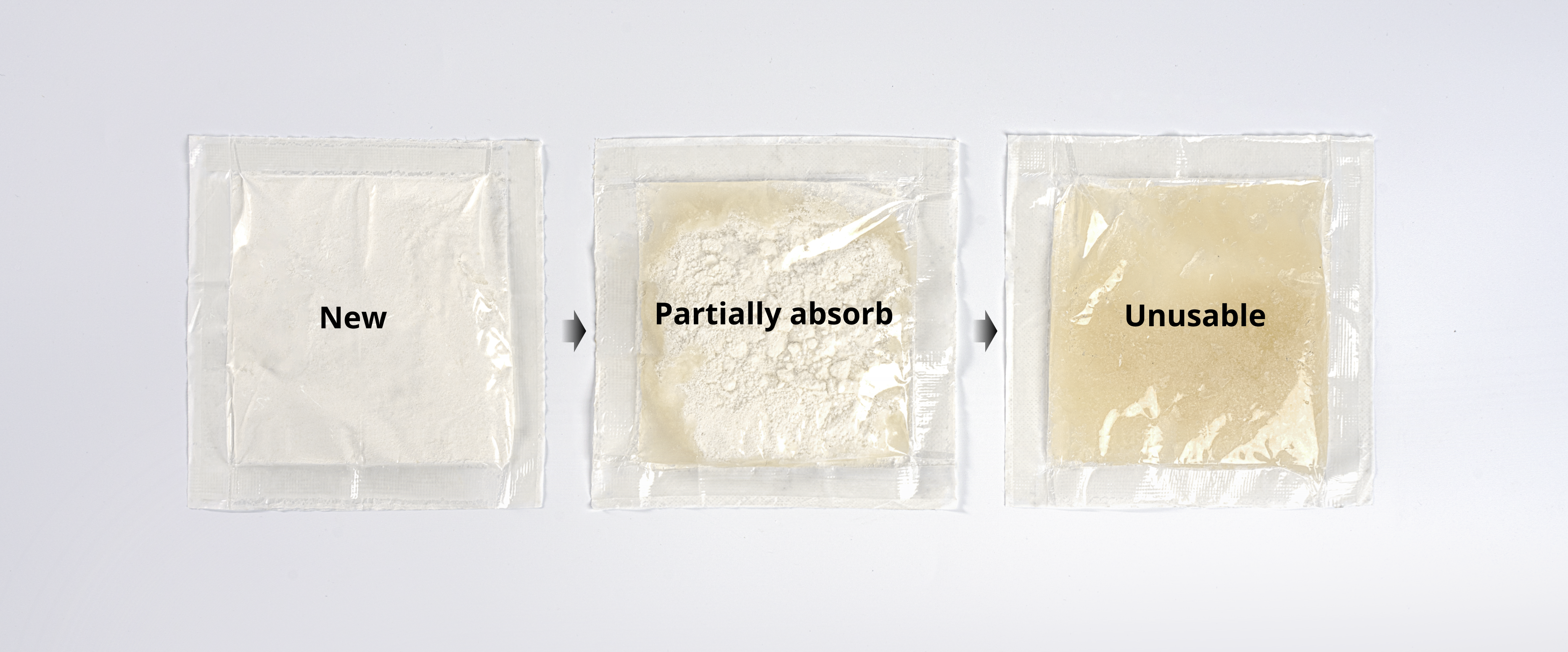

¶ Desiccant status

Please note that this IS NOT GREASE, instead, it is a fully moisturized desiccant. DO NOT try to apply it on any bearing or rail as it will damage them.

When it reaches the final stage (ineffective) please dispose of the package.

The image below (Figure 1) shows the three states of the desiccant from left to right:

- Brand New (Effective) Condition

- Partially Moist (Partially Ineffective) Condition

- Fully Moist (Completely Ineffective) Condition

Important Notes:

- Before use, please remove the outer packaging bag with the printed instructions. After removing the packaging, the desiccant will be in the brand new, moisture-free state as shown in the left image of Figure 1. Also, here is the Wiki to replace the desiccant.

- It is recommended to check the condition of the desiccant every two weeks and replace it immediately if it becomes ineffective.

- If not replaced for an extended period, the desiccant will lose its moisture absorption capability and will no longer effectively protect the filament.

- If the desiccant is not replaced for more than 3 months, moisture leakage may occur, which can severely cause short circuits or damage to the internal circuits and electronic components of the AMS.