We recommend doing this change only if you have a specific need where the entire 256x256x256mm³ printing volume is mandatory. Otherwise, we recommend keeping the machine stock.

¶ Why is the build volume smaller than the advertised 256x256x256mm³?

Bambu series printers, of which the X1 series, P1 series, and A1 all have a build volume of 256x256x256mm ³. While the build volume of the A1 mini is 180x180x180mm ³. This is as far as the printer's tool head can go on the XYZ three axes. In Bambu Studio, we limited the movement of the tool head for the X1 series and P1 series printers by preventing it from moving to certain areas to achieve certain functions such as cutter cutting and Z hop.

Lifting the Z-axis during retraction is important for printing to avoid nozzle drag and collision with the print model. Z-axis lift (heat bed drop) is allowed when the retraction is enabled, so that a small print volume buffer is reserved, which can prevent the heat bed from colliding with residual filament debris that may exist at the bottom of the chamber. You can refer to: Retraction | Bambu Lab Wiki

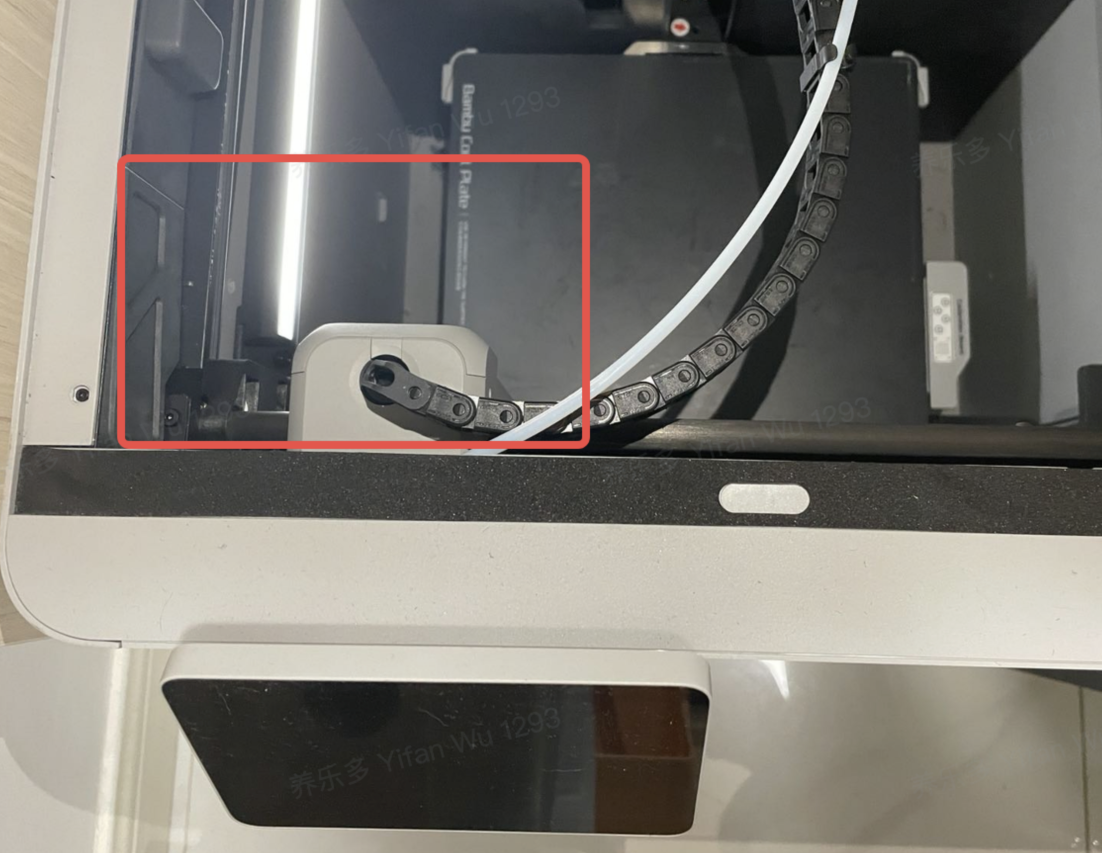

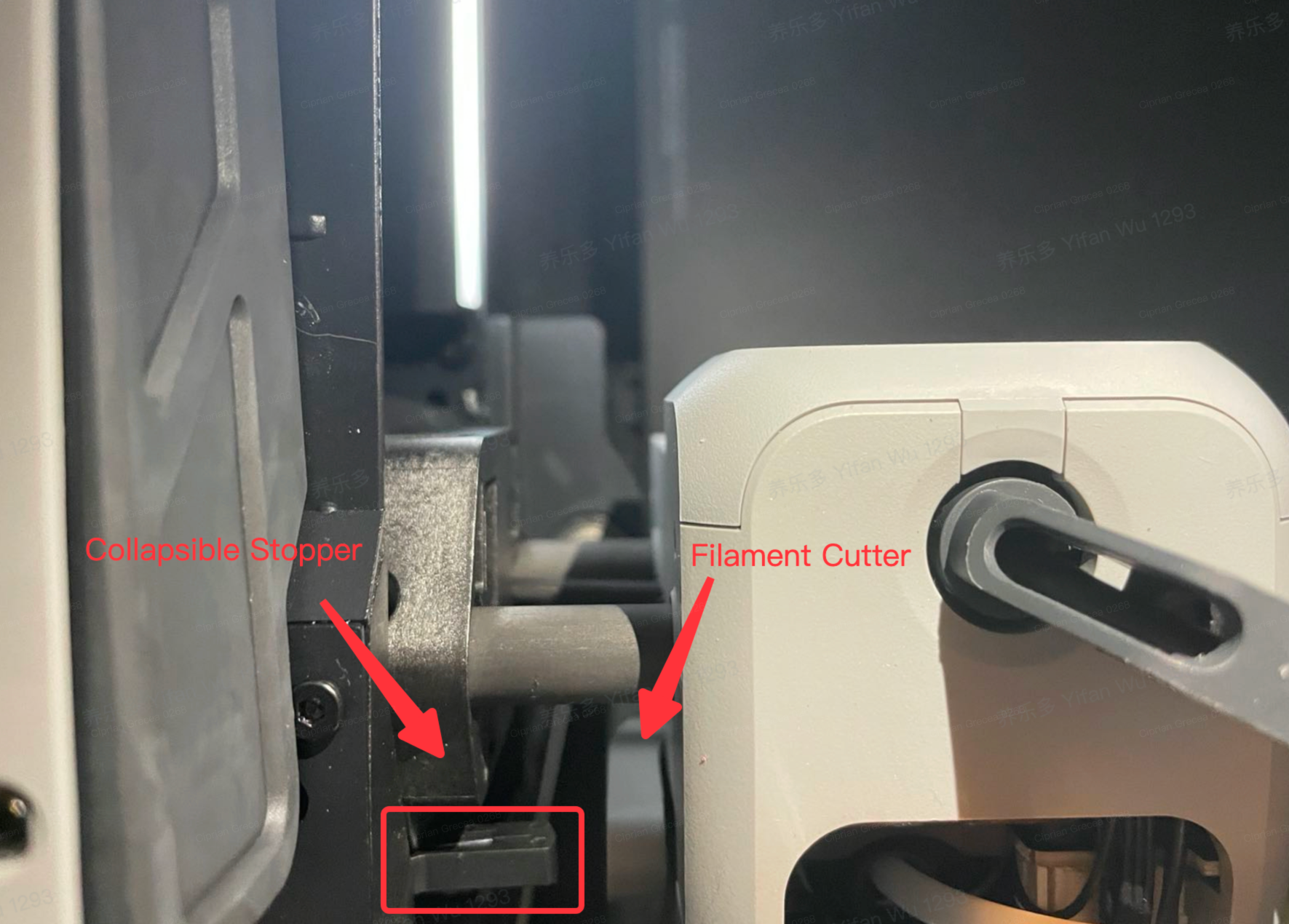

In addition, the Bambu Lab series printers are equipped with a cutter that is used when you need to unload the filament using AMS. To ensure the normal operation of the cutter, there is a foldable stopper on the left front of the X1 and P1 series printers where the cutter lever mechanically presses on it to perform the filament-cutting operation.

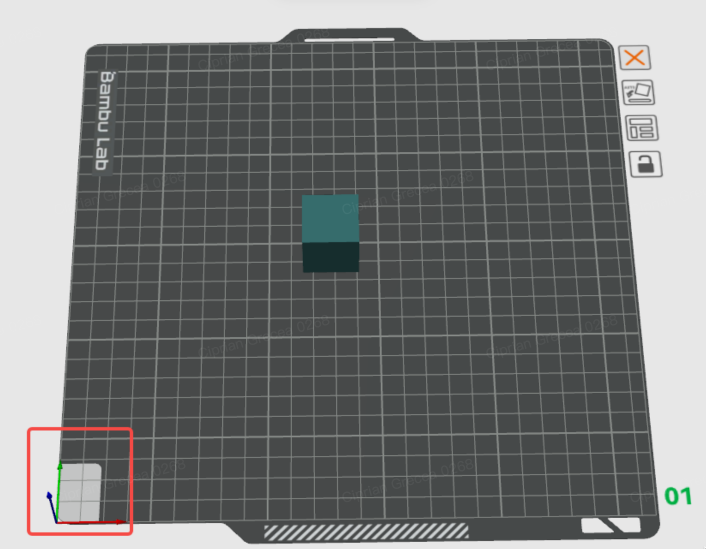

When the tool head moves into the front-left corner with a right-to-left motion, the lever of the cutter is pressed against the stopper, so we also added a visual representation of the area in Bambu Studio to know about this limitation and avoid issues during printing. The lost print volume is 18x28mm² for the front left corner.

¶ How to print using the full build volume?

We have a solution to the issue described above, but the following points need to be understood before doing this modification:

- The full print volume is only accessible when the AMS system is NOT used. The filament cutter cannot be used when unloading filament, while this method is used.

- The bottom of the heated chamber needs to be clean and free from any debris.

- Ensure that the height of the Z hop when retracting during the printing process does not exceed the maximum printable Z height limit, which is 256mm.

We recommend doing this change only if you have a specific need where the entire 256x256x256mm³ printing volume is mandatory. Otherwise, we recommend keeping the machine stock.

¶ Hardware change for the mechanical stopper and clean the bottom of the printer chamber

The solution is to collapse the lever stopper and fix it in place using a small printed model that will keep it tucked away during printing, to allow the print head to travel to the previously inaccessible position.

We recommend printing this model with a higher-temperature material, like PETG/ABS to ensure it does not fail during printing. This will also allow you to print higher temperature materials with a higher temperature inside the chamber.

Then clean up foreign objects such as filament debris at the bottom of the printer chamber to avoid hitting foreign objects when the heat bed falls to the lowest place.

¶ Bambu Studio changes for using the full print volume

Besides the hardware modification, we also need to update the following settings in Bambu Studio:

1. Update Bambu Studio to the latest version available.

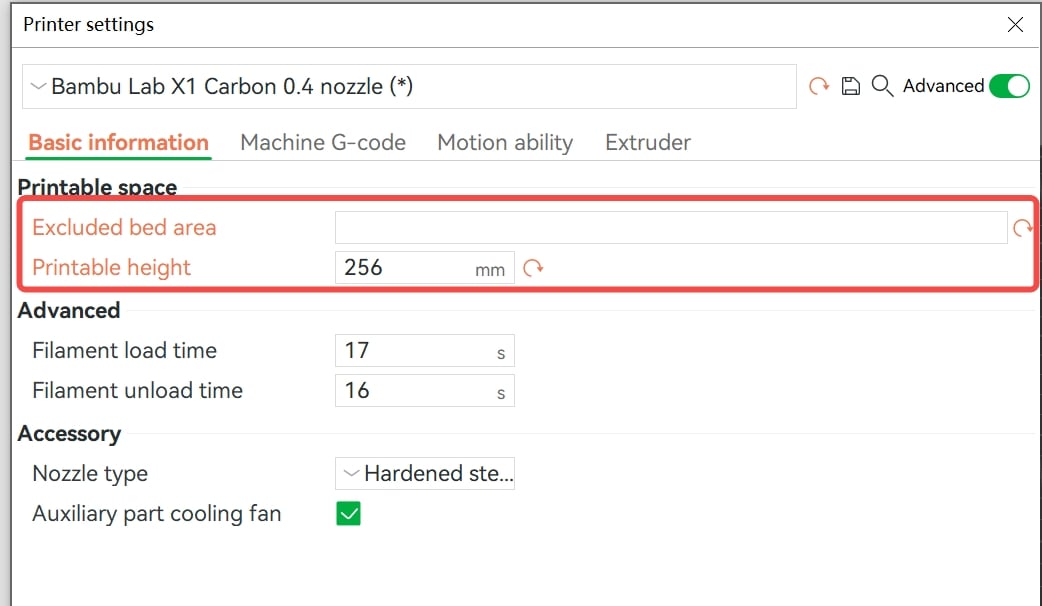

2. Clear the "Excluded bed area" in Printer settings, and change the printable height from the default 250mm to 256mm. This step is to disable filament cutter protection.

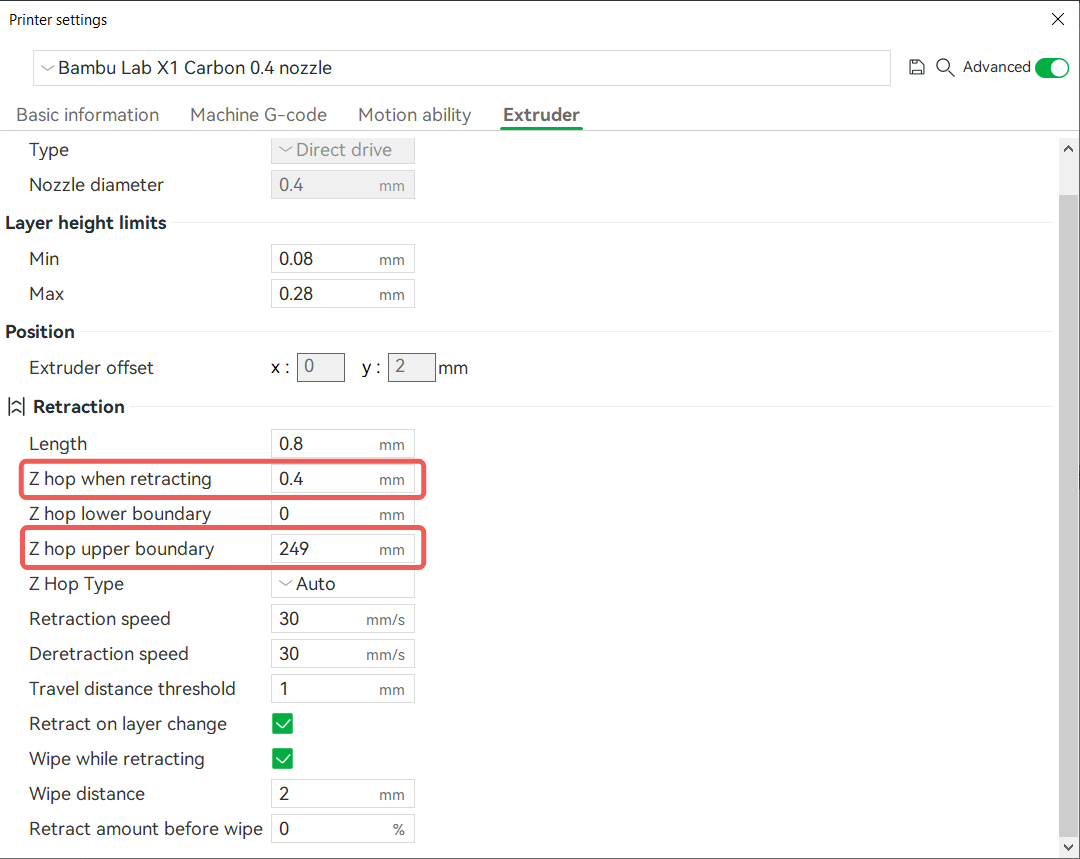

3. In the Printer settings ->Extruder ->Retraction, ensure that the "Z hop while retraction" + "Z hop upper boundary" ≤ 256mm. In this way, the height of the tool head raised during the retraction will not exceed the height limit of the printing volume. You can refer to this wiki to learn more about retraction Settings: Retraction | Bambu Lab Wiki.

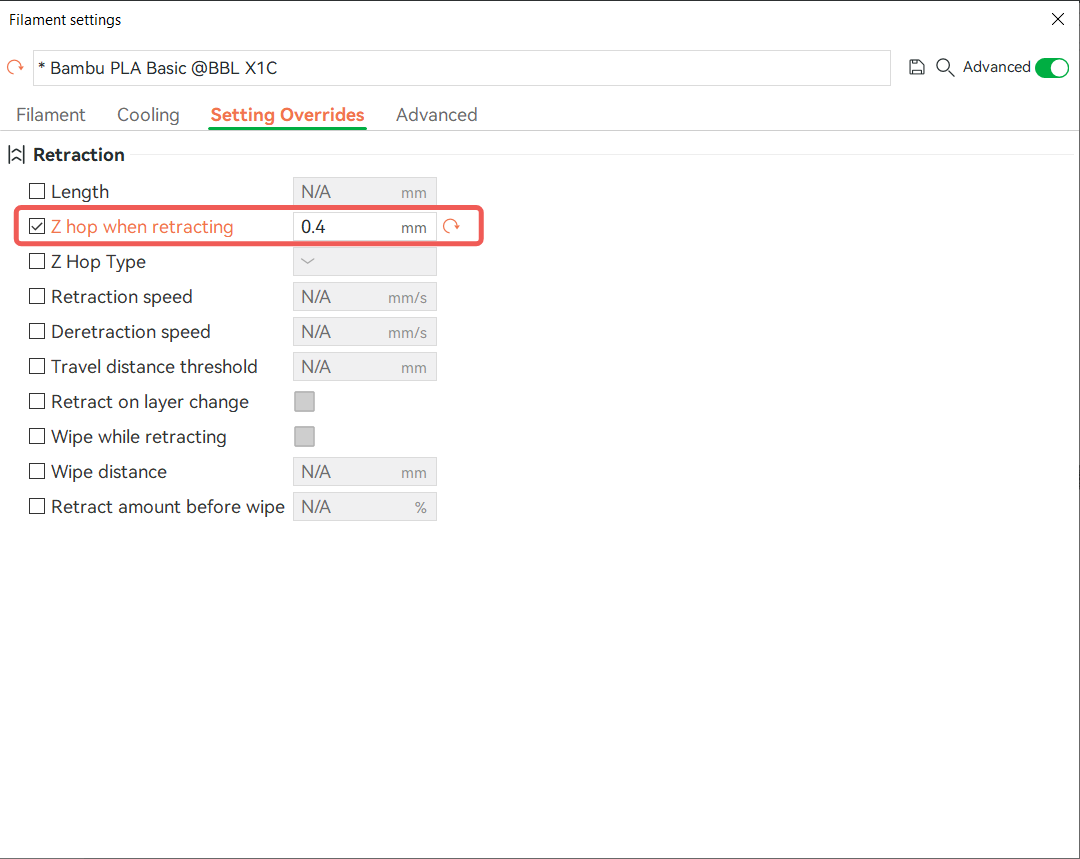

4. In the Filament settings →Setting Overrides, if you have modified the retraction parameter for a certain filament, please also ensure that the "Z hop while retraction" + "Z hop upper boundary" ≤ 256mm.