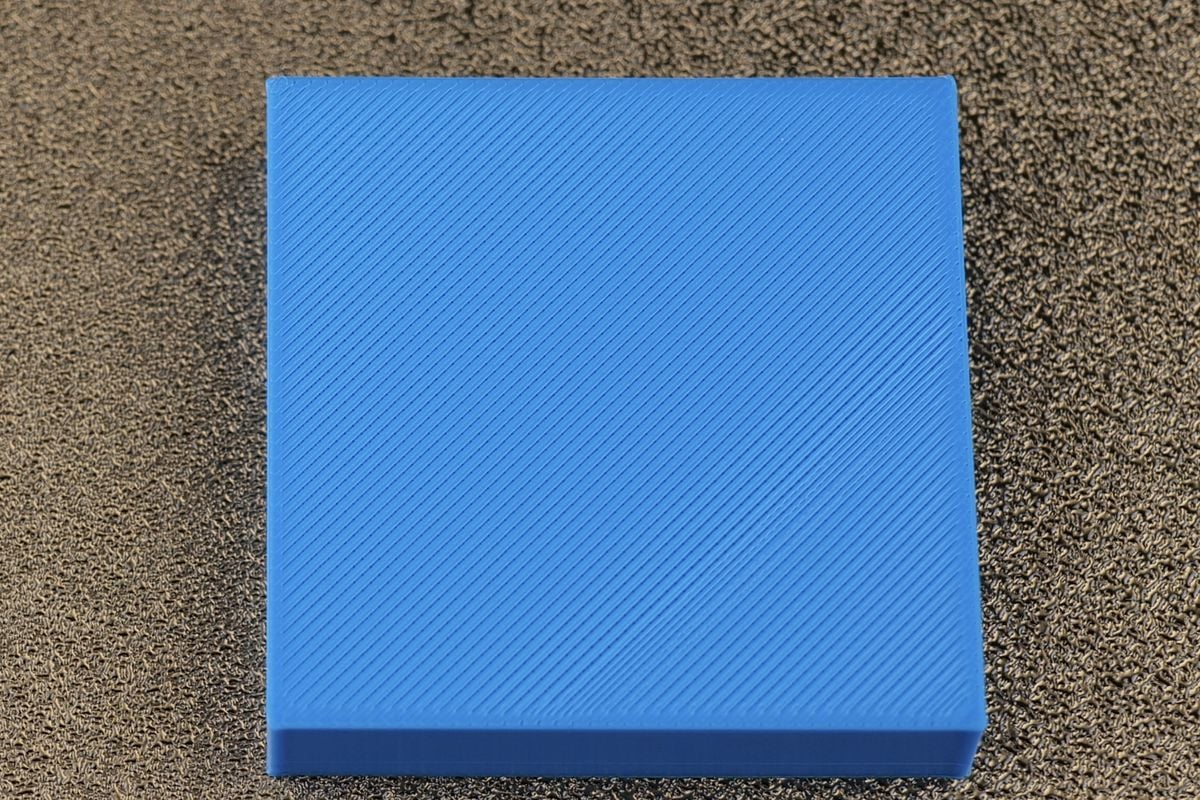

¶ Even gaps in the top layer (Under extrusion)

In the example below, the top layer on a print has even gaps between the printed lines

¶ Potential causes and solutions

¶ 1. Flow rate issues

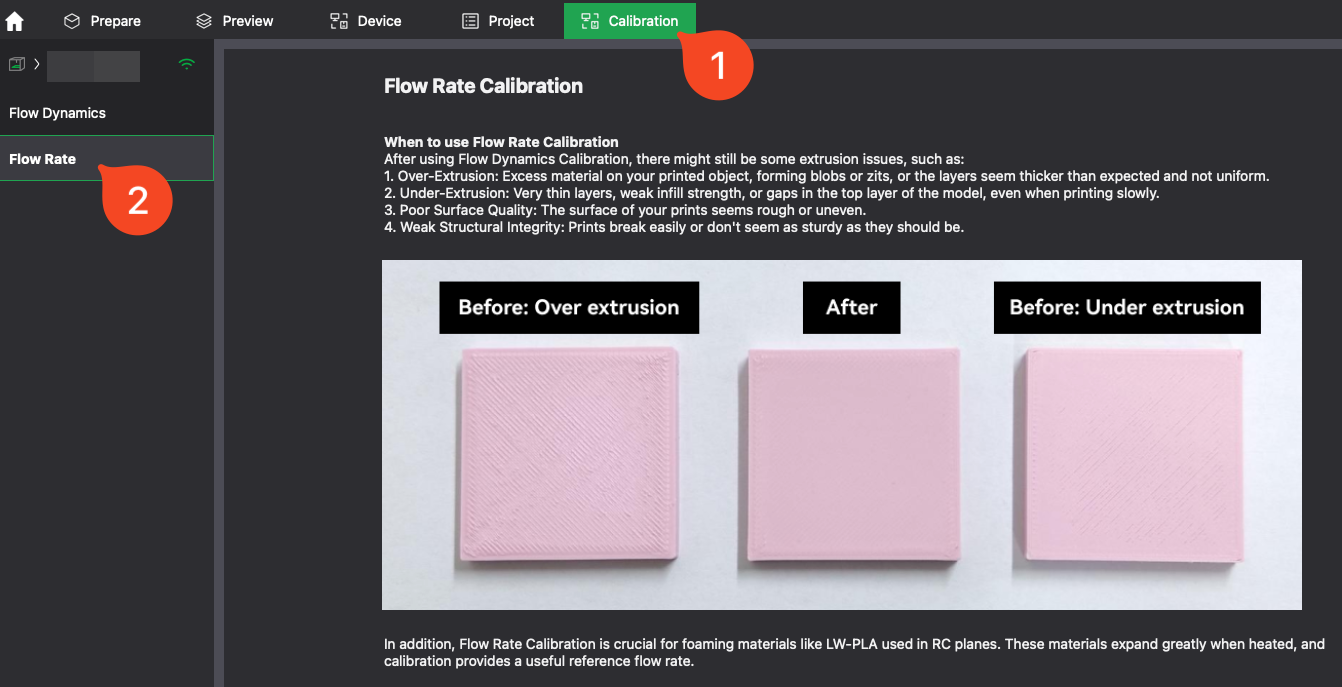

The most common reason for this problem is related to the Flow Ratio value in the Filament Settings page being a bit too low.

In the example below, the value is set to 0.98 which is considered normal for PLA filament with X1C. To solve this issue, increasing the flow rate to 1.00 should solve the problem and give you better results.

The best way to solve this problem is to follow the calibration process available in Bambu Studio, under the Calibration tab.

IMPORTANT: The Flow Rate can be impacted by a partially clogged nozzle, debris inside the extruder and the filament path adding extra drag on the filament

We strongly recommend performing the Flow Rate Calibration only after checking the items listed above. Otherwise, the results will be incorrect.

¶ 2. Extruder issues

Another reason for under-extrusion can be related to the extruder. If the extruder maintenance hasn't been done in a while, the gears of the extruder will not spin as smoothly.

Filament debris can also be deposited on the extruder gears, leading to under extrusion due to less grip on the filament.

We strongly recommend cleaning the extruder if under-extrusion is present on your print, before performing any calibration. (Procedure described in this wiki article)

¶ 3. Partial clog in the nozzle

A partial clog in the nozzle can lead to under-extrusion or inconsistent extrusion.

Different types of filament, or burnt filament can be deposited inside the hotend which changes the nozzle performance.

The solution to this is to perform a few cold pulls to ensure the nozzle is free from any debris. (Procedure described in this wiki article)

We strongly recommend cleaning the hotend if under-extrusion is present on your print, before performing any calibration.

¶ Inconsistent gaps in top layer

In the example below, the top layer on a print has inconsistent gaps between the printed lines

¶ Potential causes and solutions

¶ 1. Incorrect Nozzle Size

The most common reason for such inconsistent top layers is when the incorrect nozzle is used when slicing the model in Bambu Studio

For this particular example, the file was sliced with a 0.6mm nozzle while the actual nozzle installed on the printer was 0.4mm.

Bambu Studio has certain checks in place to avoid this problem, but if you encounter such results, check the nozzle installed on your printer, and the value used in Bambu Studio

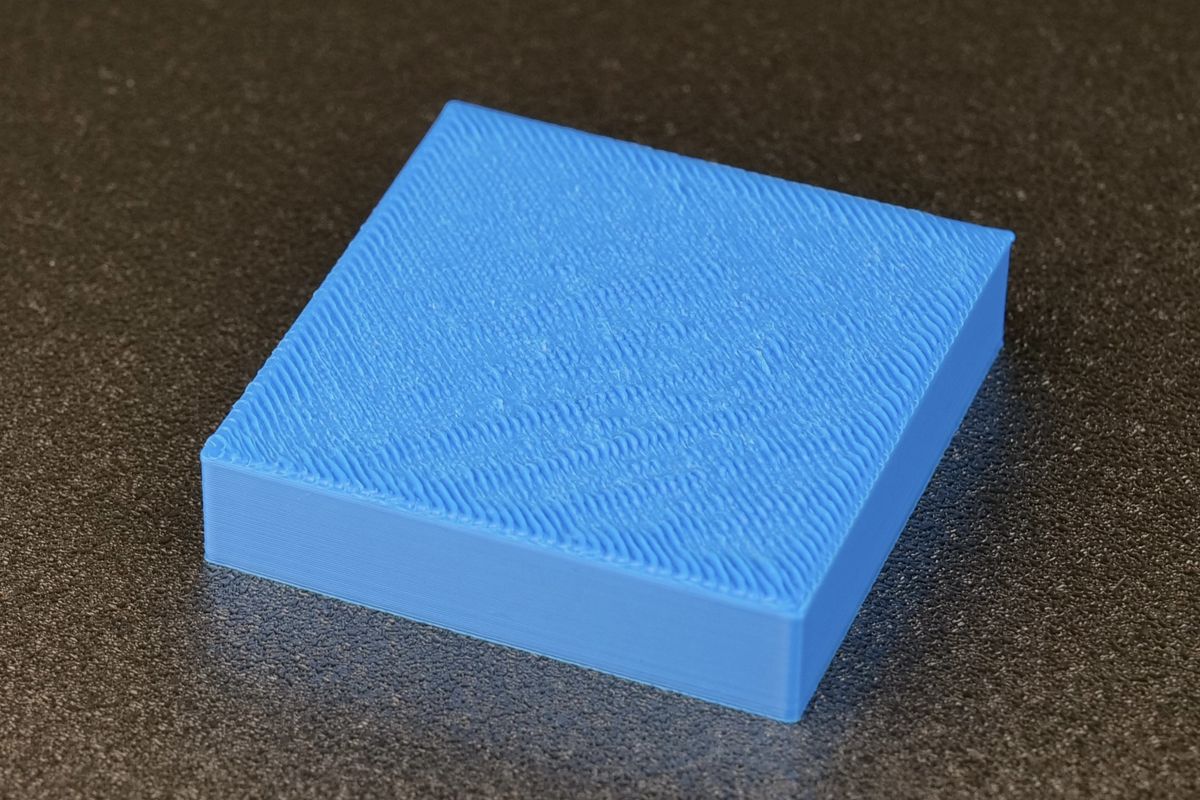

¶ Top layers overlapping

In the example below, the top layer has overlapping lines, and during printing you can hear the nozzle grinding over the layers.

¶ Potential causes and solutions

¶ 1. Flow rate too high

The most common issue for this problem is over-extrusion. This happens if the flow rate value is set too high in the slicer.

Usually, this problem occurs when the default flow rate values are changed after a calibration done with a dirty extruder or partially clogged hotend.

It is very rare for the filament to require more than a 1.00 flow rate value in the Filament profile.

If you have performed a calibration, and the flow rate is over this value, we recommend

IMPORTANT: It is very rare for the filament to require more than a 1.00 flow rate value in the Filament profile.

If you have performed a calibration, and the flow rate is over this value, we strongly recommend cleaning the extruder and the hotend before performing the Flow Rate Calibration again.

¶ 2. Incorrect nozzle selection in slicer

Another reason for the top layer lines to be overlapping is the wrong nozzle being selected in the slicer.

As an example, if the 3D model is sliced for the 0.6mm nozzle, and printed with a 0.4 mm nozzle installed on the printer, the result can be similar to the one shown in the picture.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page - We will do our best to respond promptly and provide you with the assistance you need.