This is an introduction to the main components of the P1 series printer so that you can get a general picture of the printer.

¶ How does the P1 series work?

The Bambu Lab P1 inherits the X1 series' renowned kinematics and motion control technology and the wealth of sensors that ensure its reliability. It can connect the automatic material system (AMS) for multi-color printing. Great for beginners, professionals, or others who enjoy the fun of being creative, the P1P has been designed for easy setup and use in minutes. Additionally, it allows upgrading and customizing hardware with mod-friendly features for people to enjoy the fun of making their one-of-a-kind 3D printer.

|

|

|

Most of the time, the printable objects are files with the .stl extension that holds the 3D model, which needs to be processed before it’s ready to be printed with a piece of software called a slicer.

In our case, with the Bambu Lab Studio, the slicer takes that .stl file and slices it into layers, which are then printed by the P1P. All these slices are then converted into code, a language that tells the machine how to move its axis to print the model.

Aside from movement, the slicer can include a variety of other settings in the created file, such as filament temperatures, printing speeds, and the generation of supports for some regions of the print.

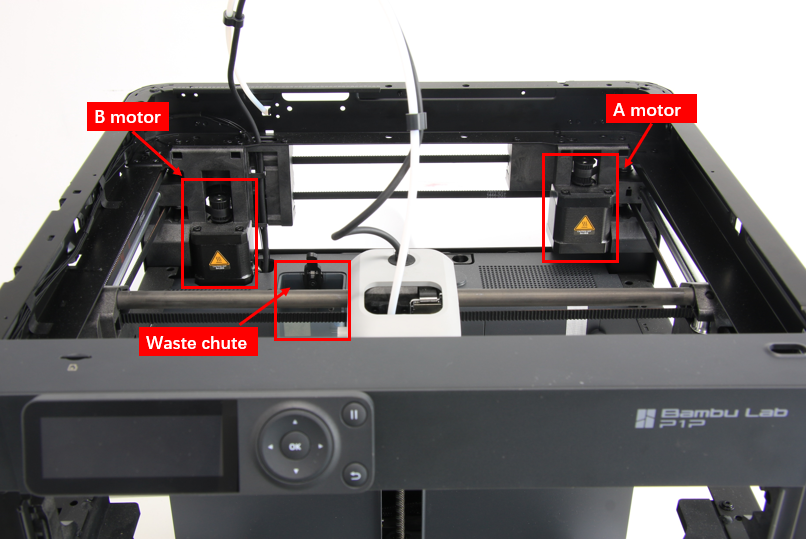

¶ CoreXY Motion System

The Bambu Lab P1P uses a CoreXY motion system controlled by two stepper motors. The X and Y stepper motors work together to move the print head.

Every stepper motor has an independent belt connected to the print head, so a pair of belts control its position. A CoreXY motion system allows the P1P to print much faster than a traditional cartesian printer because the weight is lower, which is essential when printing fast.

More information about the CoreXY motion system is available at this link.

¶ Z axis

The Z-axis is comprised of three lead screws that are connected to a single stepper motor using a belt.

Other 3D printers use three lead screws with a fixed bed to perform automated bed tramming, but this is not the case on the P1P. This leveling system is unnecessary as the P1P heatbed can be trammed using the three leveling knobs underneath the bed if required.

The P1P comes pre-leveled from the factory and supports auto-bed leveling.

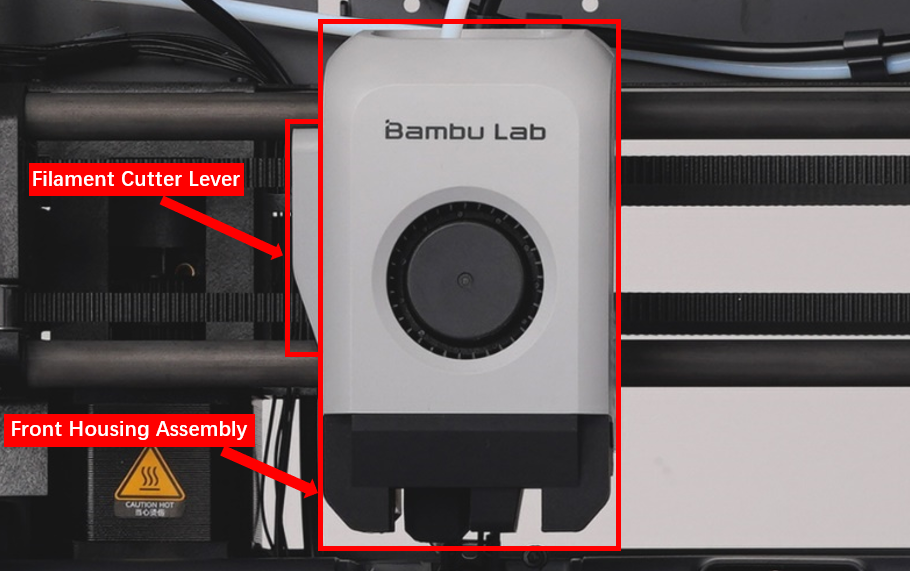

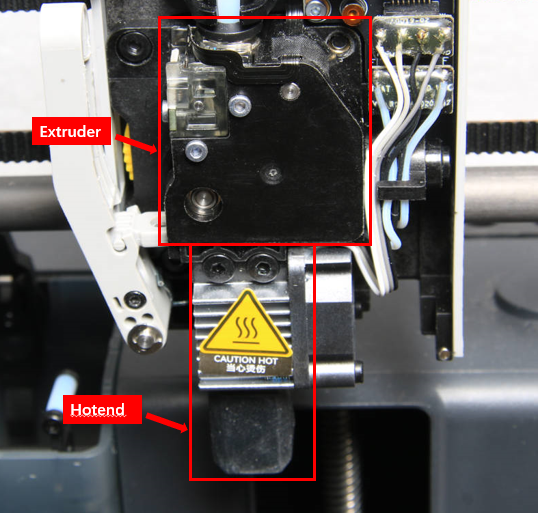

¶ Extruder

The extruder is responsible for pulling the filament from the spool, feeding it to the hotend, melting it, and pushing it through a small nozzle to generate the printed model. It'sit's also one of the essential parts of a 3D printer because it must accurately control the amount of filament pushed through the hotend.

¶ Hotend

The hotend is the printer part responsible for melting the filament deposited in thin layers to create the model. Different temperatures are used for various types of filament materials. For example, PLA filament can be printed at lower temperatures at around 210-220 ℃, while other filaments like PETG and ABS require higher temperatures at around 250-260 ℃

Bambu Lab P1P comes with an all-in-one design for the hotend. This means that the nozzle is integrated into the heat block and connected to the heatsink via a thin metal tube for best performance.

Having this design allows the hotend to heat up much faster than a regular hotend, and the all-in-one design minimizes issues that might come up when swapping nozzles.

¶ Heatbed

Usually, the printing surface needs to be hot to help the printed layers adhere, so a heatbed is used.

With the P1 series 3D printer, the heatbed can reach 100 °C, which can be controlled according to the type of filament used.

If no heat were used for the printing surface, the filament deposited would cool too fast, and the tension between the layers would make it warp.

¶ Build Plate

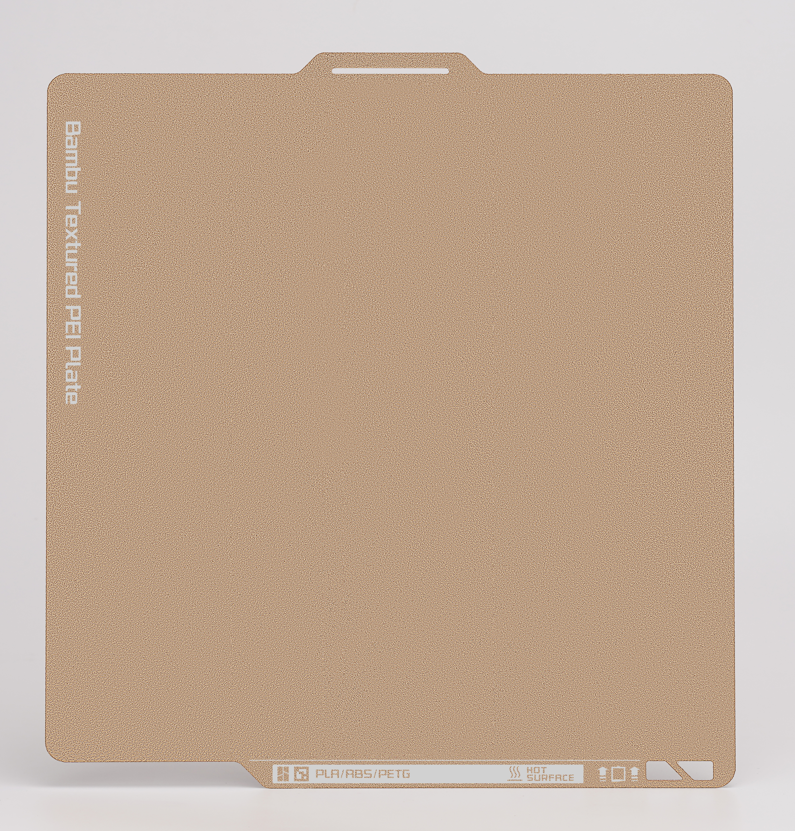

With the P1 printer, a Bambu Textured PEI Plate is provided. The build plate attaches magnetically to the heatbed with plastic guides in the back to ensure a correct position.

The Bambu Textured PEI Plate is a flexible magnetic build plate with sprayed dual-side PEI coating. During printing, the plate will provide excellent adhesion and easy print removal after cooling.

¶ Compatibility with AMS and AMS hub

P1P is compatible with AMS and the AMS hub, supporting up to 16 colors of 3D printing and various filaments.

Check the tech specs to see the supported filaments. Shop AMS and AMS hub if needed.

¶ Belt Tensioners

The P1P has adjustable belt tensioners in the back that might need to be adjusted for the best performance. The Belt Tension Monitor (BTM) will monitor the tension of the belts and let you know if they need to be adjusted.

¶ Sensors & Electronics

Vibration Suppression: Yes

ABL: Yes

Auto Z Offset Adjustment: Yes

Chamber Monitoring Camera:

Low Rate Camera 1280 x 720 / 0.5fps

Timelapse Supported

Led: Yes

Display: 2.7-inch 192x64 Screen

Connectivity: Wi-Fi, Bluetooth, Bambu-Bus

Storage: Micro SD Card

Control Interface: Button, APP, PC Application

USB Output Power: 5 V/1.5 A

For more information, please check out this page (Click here).