¶ Product Specifications

¶ Q: What are the overall dimensions, weight, and maximum print volume of the P2S printer?

| Item | Specification |

|---|---|

| Printer Dimensions | 392x406x478mm³ |

| Print Volume | 256×256×256 mm³ |

| Net Weight | 14.9 kg |

¶ Q: What is the noise level of the P2S during normal printing?

Under Silent Mode: Below 50 decibels.(Note: Tested at a distance of 1 meter)

¶ Q: What is the power consumption of the P2S during regular printing, at maximum load, and in standby mode?

| Voltage | 100-120 VAC/200-240 VAC,50/60 Hz |

| Maximum Power | 1200 W@220 V, 1000 W@110 V |

| Standby Power | Offline standby power consumption: 7.3-7.8W WiFi standby power consumption:7.8-8.2W |

| Steady-State Power (PLA) | 200 W@220 V, 100 W@110 V |

¶ Q: Does the P2S support 5G Hz WiFi?

The P2S supports dual-band WiFi (5G & 2.4G).

¶ Q: Does the P2S support wired network connection?

No.

¶ Q: What is the resolution and frame rate of the P2S camera?

The live view camera of the P2S has the following specifications: 1920*1080 resolution, 30fps (HD).

¶ Q: What advantages does the P2S have over the P1S?

The P2S has been optimized based on user needs for the P1S, including features such as a touchscreen, high-frame-rate camera, and more convenient network connection. For more product specifications, please refer to this page.

¶ Q: Is P1S upgradable to P2S?

The P1S does not currently support upgrading to the P2S model. Unlike the P1S, the P2S is not a partial component optimization, but a comprehensive iteration covering core hardware — key components such as the frame structure, mainboard, toolhead, screen, and air circulation system have all been redesigned. These components have fundamental differences from those of the P1S in terms of specifications, parameters, and functional logic, making it impossible to convert the P1S to the P2S model through simple component replacement.

¶ Q: What are the main differences between the P2S and X1C?

The P2S is an upgraded version of the P1S and is more suitable for comparison with the P1S. For detailed differences between the P2S and X1C, please refer to this page for additional product specifications.

¶ Q: What is the maximum print speed and acceleration of the P2S?

The maximum movement speed of the toolhead is 600 mm/s, and the maximum movement acceleration of the toolhead is 20,000 mm/s².

¶ Q: What are the maximum nozzle temperature and heat bed temperature of the P2S?

Maximum nozzle temperature: 300 ℃; Maximum heatbed temperature: 110 ℃.

¶ Q: What material is the pre-installed extruder gear of the P2S made of?

Hardened steel.

¶ Q: Is the pre-installed nozzle of the P2S made of stainless steel or hardened steel?

Hardened steel.

¶ Q: Does the P2S support printing with PPS-CF? (The maximum nozzle temperature is 300 ℃, and the technical parameters state that PPA printing is supported)

| Supported Filament Types | PLA、PETG、ABS、ASA、TPU、Support for PLA、Support for PLA/PETG、Support for ABS、PET、PA、PC、PVA、PLA-CF、PETG-CF、ABS-GF、ASA-CF、PA6-CF、PA6-GF、PAHT-CF、PPA-CF、PET-CF |

¶ Q: What material is the P2S side panel made of?

PC+ABS Plastic

¶ Product Functions & Principles

¶ Q: Does the P2S require an external power supply to use the filament drying function when connected to the AMS 2 Pro? If yes, what are the power supply parameters?

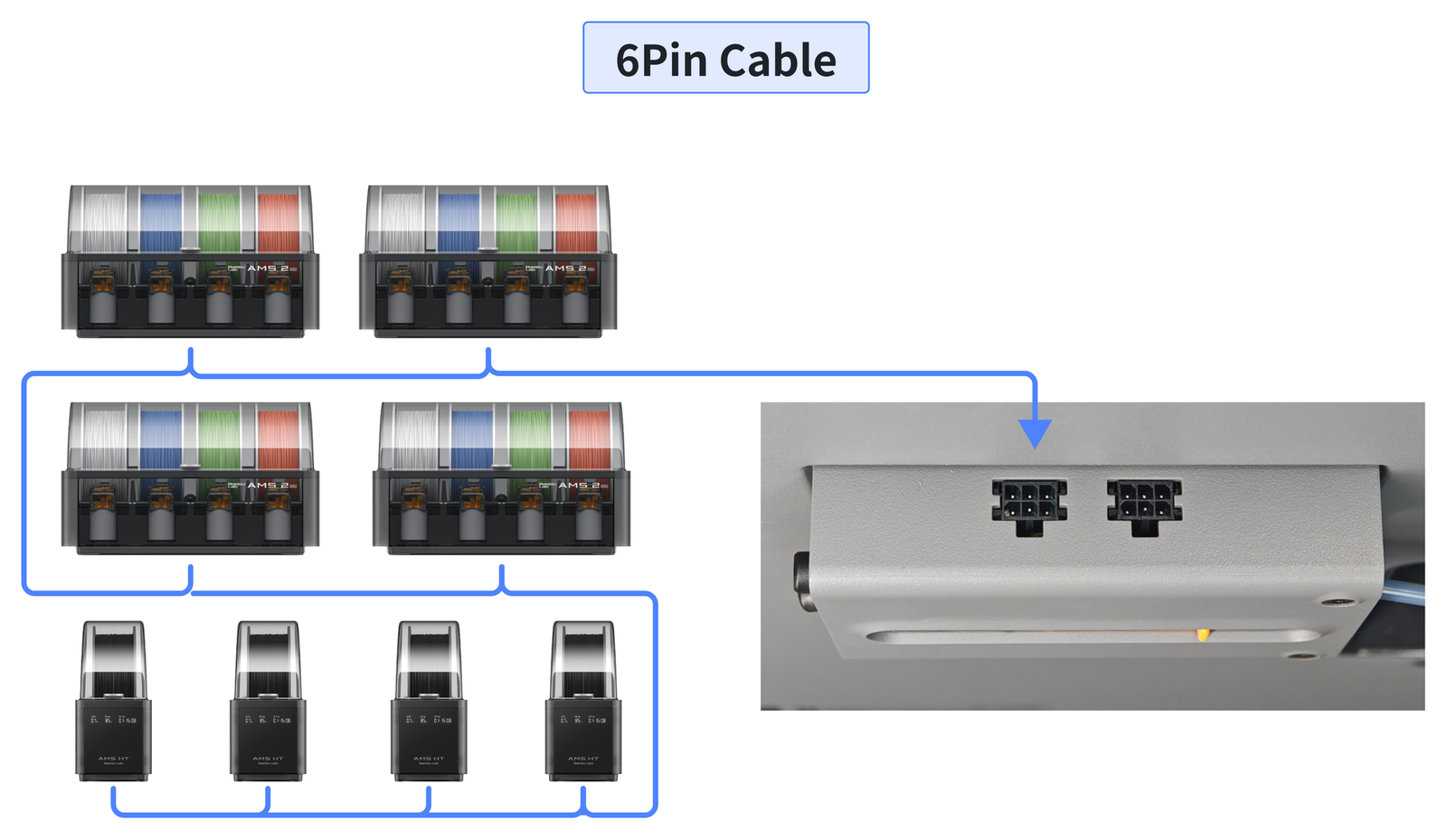

Connect the printer to a single AMS 2 Pro using a 6-pin cable to use the drying function of the AMS 2 Pro when the entire unit is in standby mode. During drying, print-related functions will be paused. If you need to dry filaments in multiple AMS 2 Pro units simultaneously, you must purchase additional official Bambu Lab power adapters to power the remaining AMS 2 Pro units.

- Power Adapter Parameters:

| Input Voltage Range | AC 100-240V 50/60HZ |

| Output | 24V/4A 96W |

¶ Q: The buffer of the P2S has two 6-pin ports on top. Does it support connecting two AMS/AMS 2 Pro/AMS HT units simultaneously?

The buffer does not support using two 6-pin ports to connect AMS/AMS 2 Pro/AMS HT units at the same time. One of the ports is a spare port, used for power supply and communication expansion of devices (e.g., time-lapse photography kits).

¶ Q: Does the standalone version of the P2S come with a buffer?

The standalone version is not equipped with a buffer; it needs to be purchased and installed separately.

¶ Q: Is the top cover glass of the P2S compatible with that of the P1S?

No, they are not compatible due to different sizes.

¶ Q: Are the cutter lever and blade of the P2S compatible with those of the P1S?

The cutter lever is not compatible, but the blade is.

¶ Q: Is the build plate of the P2S compatible with those of the X1C/P1S/A1?

The print volume of the P2S is 256×256×256 mm³, and it supports all current Bambu Lab build plates of this specification. However, older build plates do not support QR code recognition. If the device prompts that the build plate type cannot be recognized, you can manually select "Ignore" or disable the build plate detection function on the screen.

¶ Q: Are the belts and tensioners of the P2S compatible with those of the P1S?

No, they are not compatible due to slight differences in belt size and tensioner size.

¶ Q: Is the nozzle wiping silicone of the P2S compatible with that of the H2D?

No

¶ Q: Is the screen of the P2S compatible with that of the X1?

No, they are not compatible. Incorrect installation may risk damaging the screen and mainboard. Product damage caused by this is not covered under the product warranty.

¶ Q: Is the air filter of P2S compatible with other models?

No

¶ Q: The P2S has a fan installation slot on the left side. Does it support adding an auxiliary part cooling fan?

Yes, you can purchase official accessories for upgrading.

¶ Q: Is the heating assembly of the P2S compatible with that of the H2D or A1?

No

¶ Q: Are the extruder gears of the P2S compatible with those of the P1S?

No

¶ Q: Can the nozzles of the P2S be used interchangeably with those of the A1 or H2D?

The nozzle is compatible with that of the H2D but not with that of the A1. The hotend silicone socks are not compatible with either.

¶ Q: Does the P2S support high-flow nozzles?

Yes

¶ Q: Is the P2S compatible with the 1st-generation AMS?

Yes, but an additional buffer adapter for the P2S needs to be purchased.

¶ Q: Why does the buffer have two filament inlets, and what are their functions?

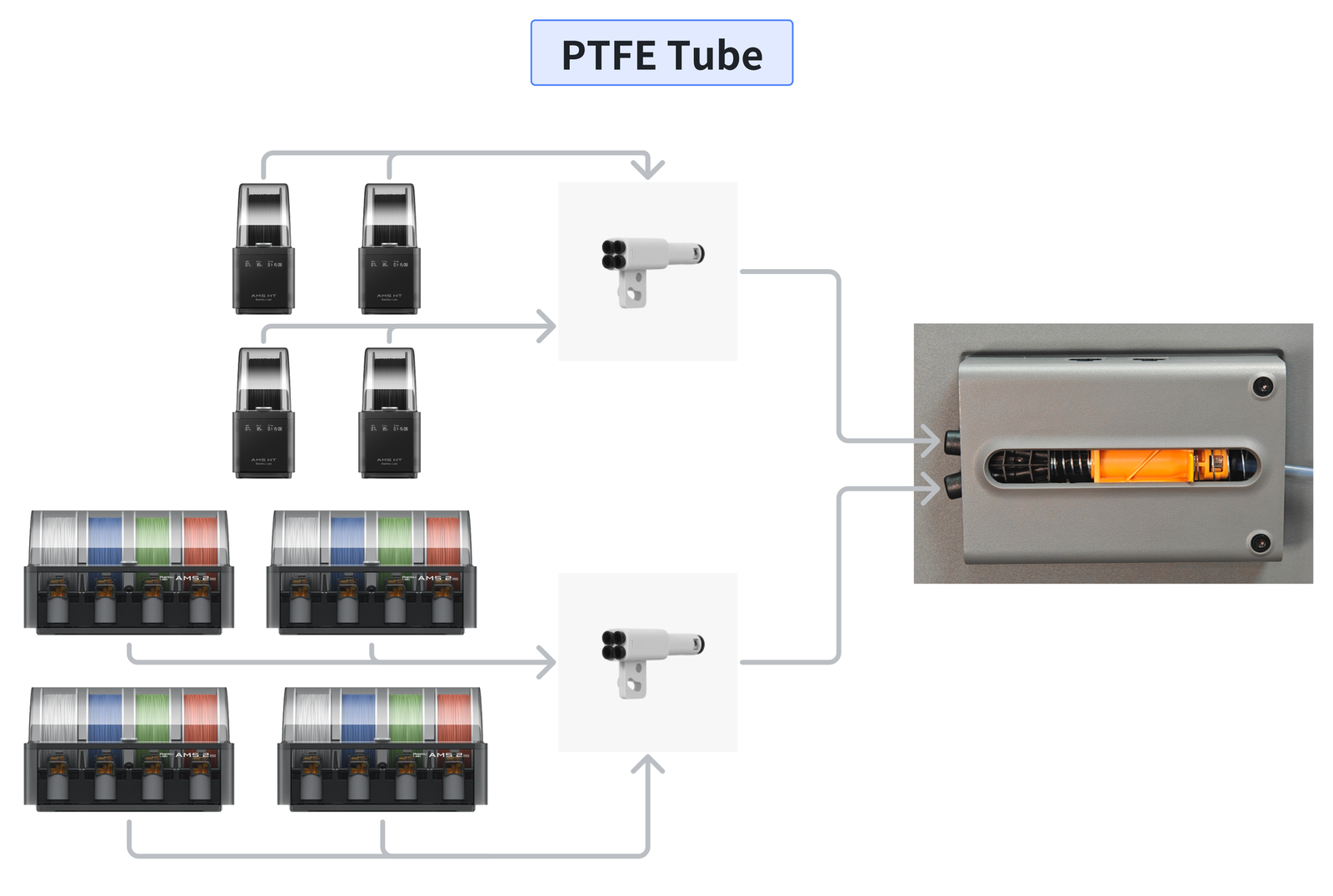

The buffer is equipped with two filament inlets, which offer the following advantages:

- Support for dual AMS connection: Two AMS units can be connected simultaneously.

- Flexible switching between AMS and external spool: When using an external spool for filament feeding, there is no need to remove the PTFE tube from the chamber inlet (as required for the X1/P1 series); quick switching can be achieved directly within the buffer.

¶ Q: What is the maximum number of AMS units that the P2S can support?

4 AMS 2 Pro units and 4 AMS HT units, totaling 8 units with 20 slots. Therefore, it supports a maximum of 20-color printing.

|

|

¶ Q: If purchasing an AMS 2 Pro for the standalone P2S, are additional accessories required?

Neither the standalone P2S nor the standalone AMS 2 Pro is equipped with a buffer suitable for the P2S. You need to purchase a buffer separately.

¶ Q: Does the P2S use a self-developed servo motor for the extruder motor?

Yes, the extruder motor used in the P2S is a Bambu Lab high-precision permanent magnet synchronous servo motor.

¶ Q: Does the P2S require an AMS to support filament tangling detection?

No, the extruder motor of the P2S is equipped with filament tangle detection.

¶ Q: What intelligent detection functions does the P2S have?

The live view camera of the P2S is equipped with multiple intelligent detection functions, including spaghetti detection, foreign object detection, nozzle clumping detection, build plate recognition, and silicone sock detection.

In addition, the printer has built-in various sensors to support filament runout detection, filament tangling detection, door open detection, and chamber temperature detection, ensuring safe and stable printing.

¶ Q: Does the P2S support dynamic flow calibration?

The printer is equipped with an eddy current sensor and supports active flow calibration.

¶ Q: Does the P2S support chamber temperature control, and how to control the temperature?

The P2S does not have an active chamber temperature function, but it can adjust the chamber temperature through a closed chassis and automatic switching between internal and external air circulation.

¶ Q: Why does the P2S no longer use carbon rods for the X-axis?

The X-axis of the P2S uses hollow steel rods, which have similar performance to carbon rods but offer advantages in maintenance. The surface of the steel rod is smooth, making it easier to clean attachments and more convenient for daily maintenance.

¶ Q: Air Filtration Effect

The P2S uses an activated carbon filter, which can effectively filter VOCs (Volatile Organic Compounds) and particles generated during printing.

¶ Q: Why does the P2S eliminate air exhaust and adopt internal circulation filtration instead?

- The method of drawing cool external air inward is more efficient at cooling the chamber than using an exhaust fan. It is more friendly to low-temperature filaments such as PLA/PETG, allowing printing without opening the cover when the ambient temperature is below 30℃;

- High-temperature filaments (e.g., ABS) are more likely to emit toxic gases during printing and require more circulation filtration. Internal circulation filtration can maintain the chamber temperature required for high-temperature filaments while minimizing air pollution in the printing environment;

- Using an exhaust fan would result in higher noise. Since the external air intake fan allows printing without opening the cover (or door), the internal noise of the machine can be effectively reduced.

¶ Q: Product Cooling Function

The P2S is equipped with 3 fans in total: a part cooling fan located on the front shell of the toolhead, a hotend fan near the hotend, and an auxiliary part cooling fan installed in the adaptive airflow component. If you need to improve part cooling performance, you can purchase the Bambu Lab P2S-specific auxiliary part cooling fan and install it on the left side of the chamber.

¶ Q: If the screen printing on the heatbed surface is damaged, what impact will it have on the live view camera function?

The live view camera automatically calibrates position and angle by recognizing the silkscreen on the heatbed surface, thus avoiding detection errors caused by viewing angle deviations and significantly improving detection accuracy and image capture quality. If the silkscreen on the hotbed surface is damaged or obscured, the camera may not be able to correctly recognize the mark, resulting in calibration failure.

¶ Q: Under what circumstances is it necessary to calibrate the live-view camera?

Calibration of the live view camera is required when the installation position of the heatbed or camera changes due to replacement or maintenance needs, or when detection deviation occurs.

¶ Q: The P2S has no exhaust fan. Will this lead to insufficient heat dissipation and thermal creep?

While the P2S lacks an external exhaust fan, it does feature an adaptive airflow switching component that allows it to enter external suction cooling mode. In this mode, the auxiliary cooling fan draws cool air directly into the printer cavity, lowering the temperature and dissipating heat from the hotend and printed parts. Meanwhile, any remaining hot air in the cavity is discharged through the discharge assembly and backplate, where it connects to the outside of the chamber.

¶ Product Usage

¶ Q: What is the minimum space required for proper placement of the P2S or P2SC?

For best printing results, place the printer on a flat, stable work surface. Leave ample space: at least 4 mm on the left and right sides and at least 10 cm at the rear to ensure the rear tube, purge chute, and side air intakes function properly.

¶ Q: What are the recommended ambient temperature and humidity for using the P2S?

Ambient temperature: 10-30 ℃; Humidity: below 85%.

¶ Q: Will the P1S be discontinued?

There are currently no such plans. Please stay tuned for official announcements.

¶ Q: Does the P2S come with a USB drive? What USB drive format is required, and are there any capacity limitations?

The printer does not include a USB drive.

-

USB drive format requirements:

USB 2.0 protocol or higher (minimum write speed must be greater than 10 M/s), supporting file formats FAT32 and exFAT. The printer only supports mounting one USB drive; multiple USB drives cannot be connected via a USB dock. -

Capacity limitations:

The printer itself has no USB drive capacity limit; the maximum capacity is limited by the file system format.

If the USB drive is formatted in FAT32, the maximum supported capacity is 2TB when formatted on Linux and Mac systems; the maximum supported capacity is 32GB when formatted on Windows systems. For Windows operating systems, if the USB drive capacity exceeds 32GB, it is formatted in exFAT by default. Linux and Mac OS do not have this format restriction.

If the USB drive is formatted in exFAT, the maximum supported capacity is 128PB.

¶ Q: Does the P2S come with a standard USB drive? What functions will be affected if no USB drive is used?

The printer doesn't include a standard USB flash drive. Print jobs can still be initiated without one, as the printer has built-in storage for printing files.

However, if a USB flash drive is not inserted, the following will occur:

- Recording and time-lapse photography will not be enabled;

- Printing over the LAN will not be possible;

- Print files cannot be sent to the printer for storage via Bambu Studio;

- Log files cannot be exported.

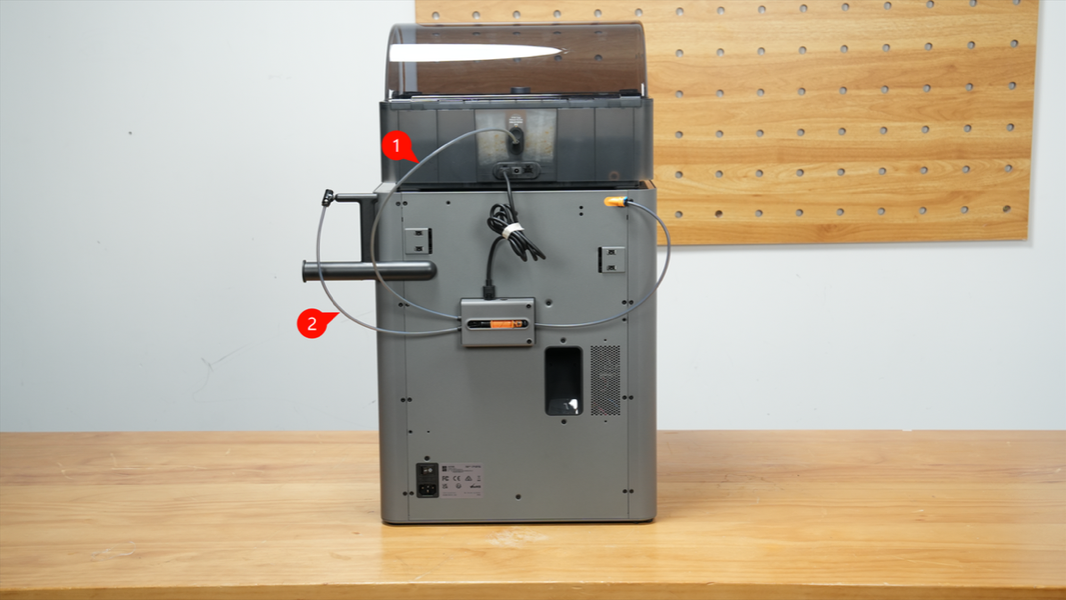

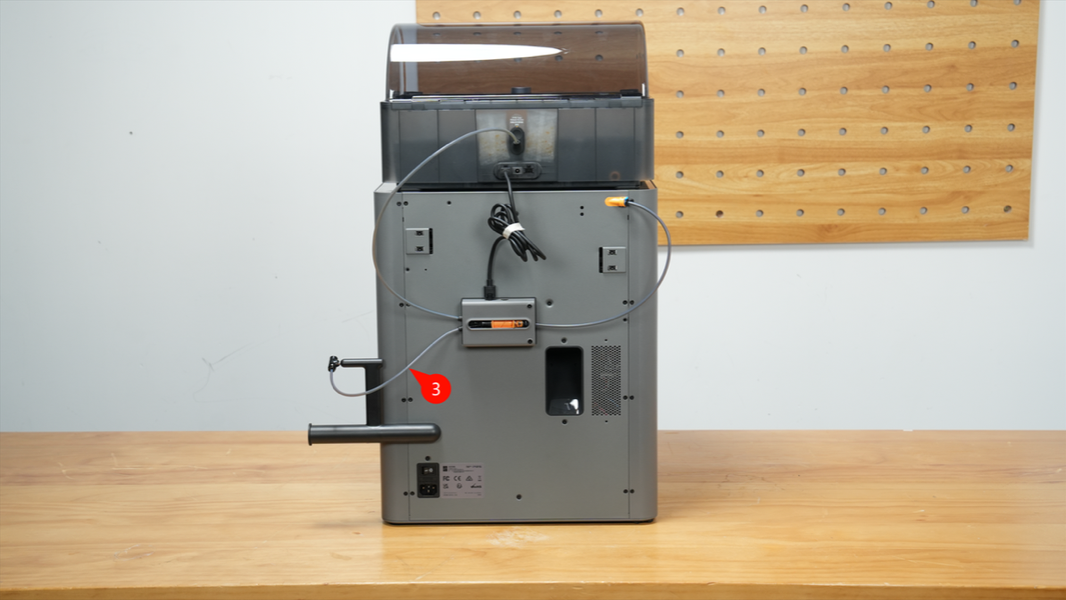

¶ Q: What are the lengths of the tubes (AMS, external spool, and filament buffer) on the rear of the printer?

|

|

|

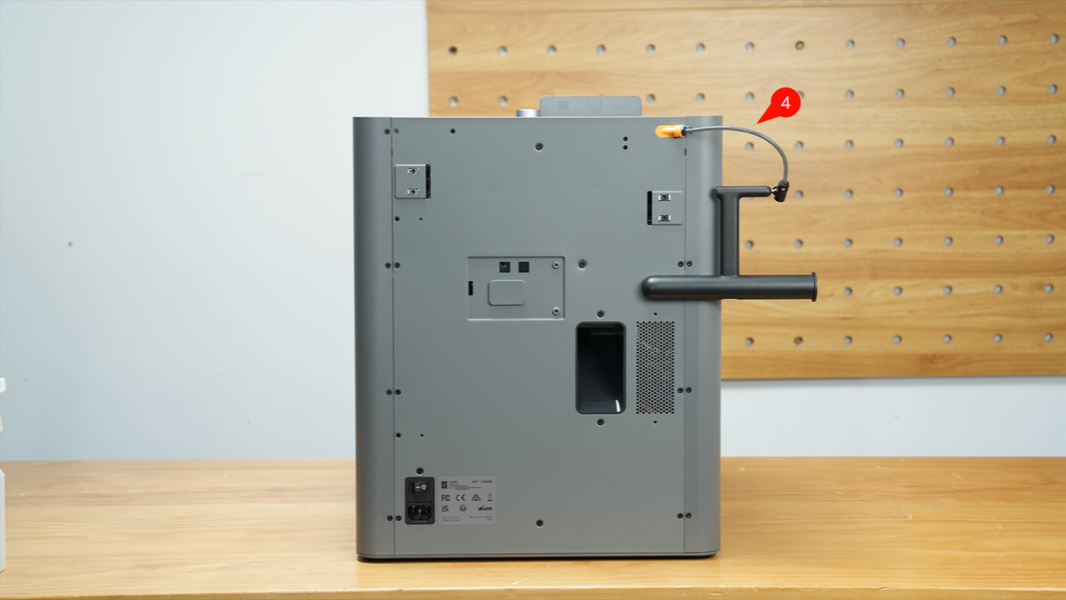

| Serial Number | Location | Recommended Length |

|---|---|---|

| 1 | AMS to Buffer | 600 mm |

| 2 | Upper Right External Spool to Buffer | 350 mm |

| 3 | Lower Right External Spool to Buffer | 280 mm |

| 4 | Left External Spool to Chamber Inlet | 180 mm |

¶ How to Use an External Spool for P2S TPU Printing?

It is recommended that you print TPU material using an spool holder. For detailed operation steps, please refer to: Printing Guide for TPU 90A & 85A with P-Series Printers

¶ Q: Can the P2S purge wiper be installed on an X1/P1 printer?

No, the accessory's dimensions are not compatible, and the waste removal process is significantly different, potentially causing damage.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!