¶ Overview

The Batch Engraving function is designed specifically for efficient processing of standardized small-sized items. Built on advanced visual algorithms, Bambu Suite can recognize materials that are similar to the sample, locate them, and generate the same design. It simplifies the design adjustment process, significantly improves engraving efficiency, and makes your manufacturing process more convenient and efficient.

This function captures the processing plane through the BirdsEye Camera, accurately identifies the positions of multiple materials, and achieves batch replication of patterns based on shape similarity. This not only optimizes typesetting efficiency, but also further enhances the automation level of the overall production process.

¶ Operation Procedures

-

Placing materials

-

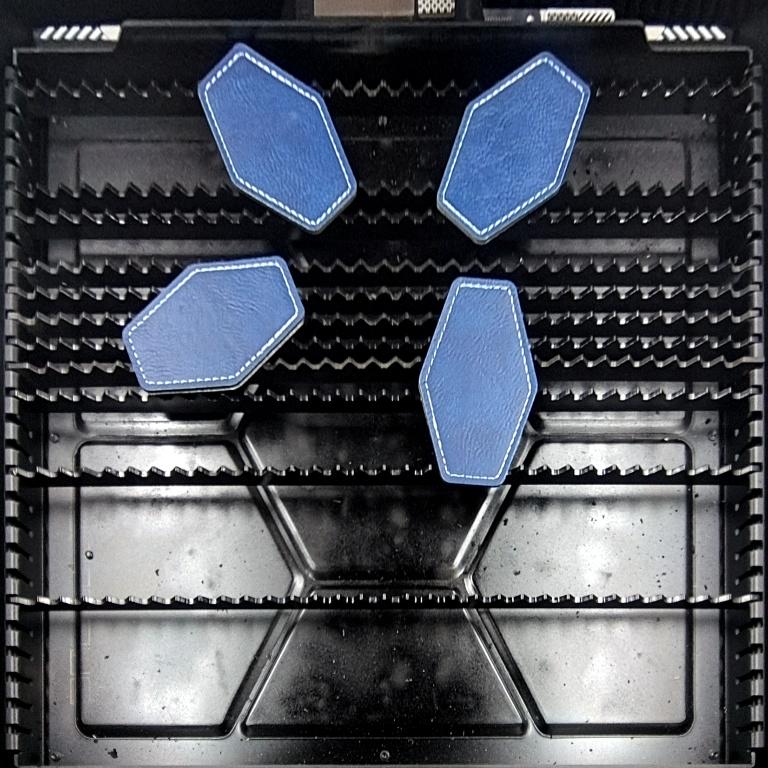

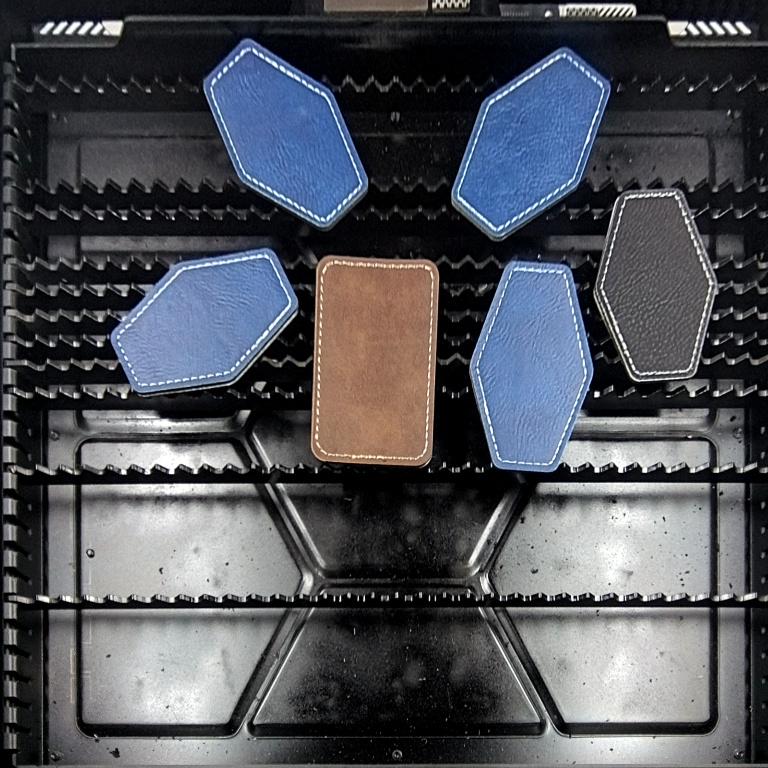

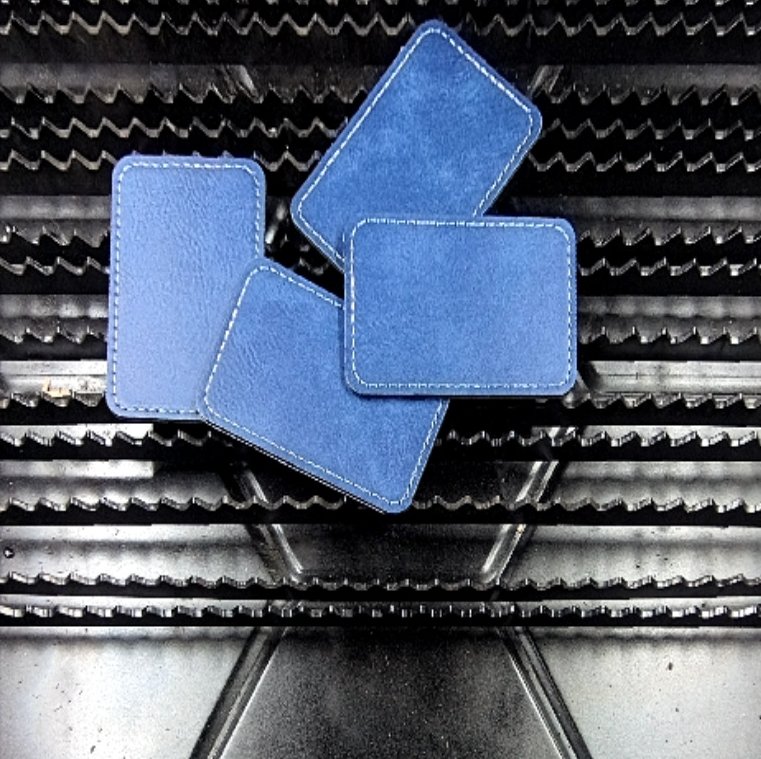

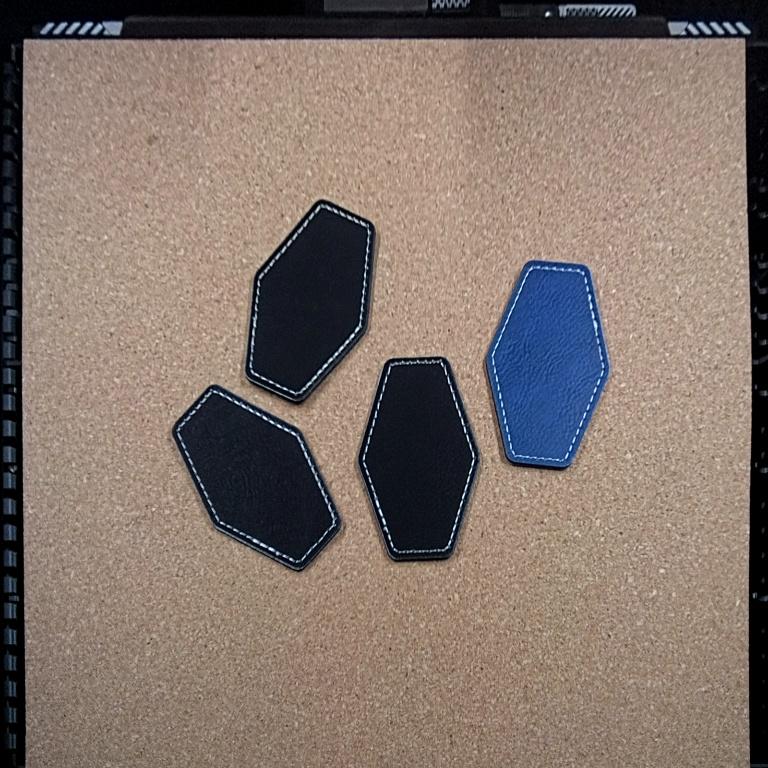

Place materials of the same size, shape, and color onto the plate (Unless the fine contour extraction is enabled, it is recommended to place it at intervals of more than 5mm).

-

The object should be placed within the field of view of the overhead camera and should not exceed the boundary of the plate processing area or the field of view of the BirdsEye Camera.

-

| Correctly placed | Incorrect placement:Different Shapes | Incorrect placement:Object Overlap |

|---|---|---|

|

|

|

- Design Preparation

- Import/create patterns on the design canvas and customize them as needed (no manual duplication required).

- Enter Processing Setup

- Click Prepare Project → Select material type.

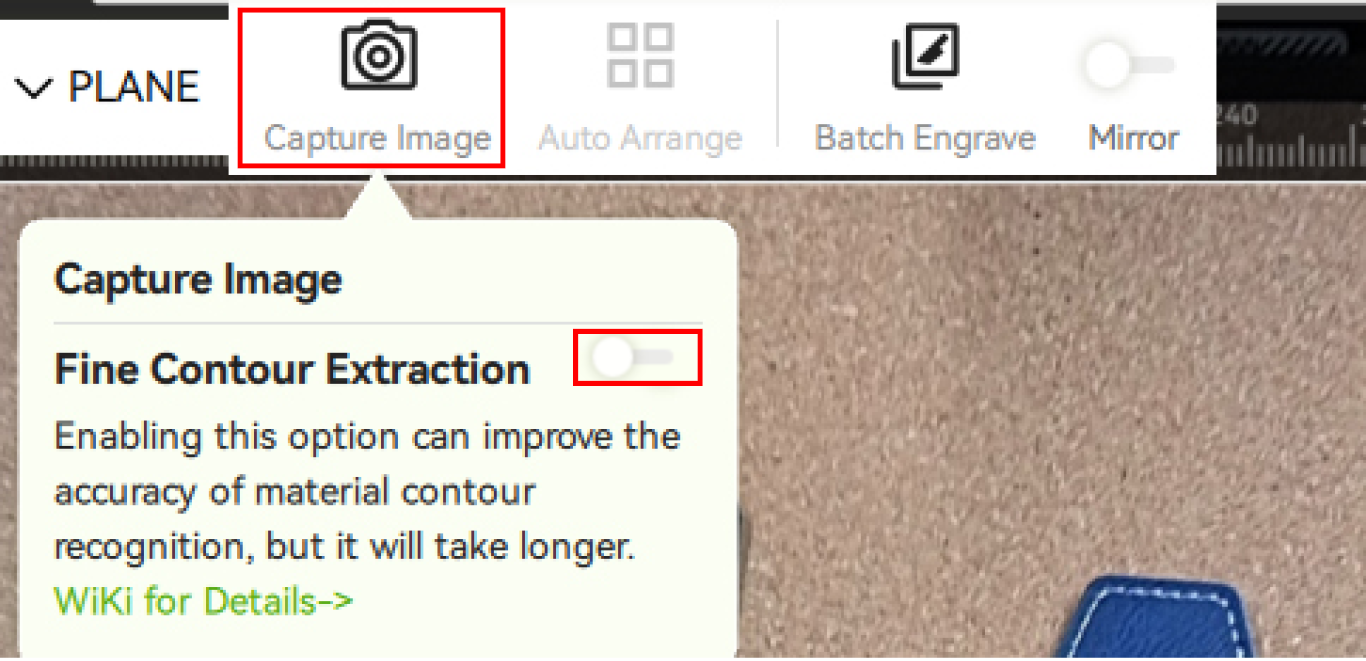

- Enable Fine Contour Extraction (Optional)

If you need a finer material outline, you need to manually turn on the Fine Contour Extraction switch. By default, the fine outline is turned off, which means that the default automatic plate placement uses a relatively rough outline. In most cases, using the fine outline will get a more accurate material outline boundary, but the outline extraction process will be more time-consuming.

- Move the mouse over the Capture Image button, and turn on fine contour extraction in the floating window.

- It is recommended to enable this option to increase the success rate when objects area placed tightly or when objects are relatively thin or tiny.

- Enabling fine contour extraction will improve the accuracy of contour processing, while also increasing the calculation time of contours. Batch Engrave and Auto Arrange will wait for the completion of fine contour calculation.

- When starting fine contour extraction for the first time, the "Fine Contour Extraction AI Model" will be downloaded online. After downloading, the fine contour of the target object can be processed when taking photos.

5. Capture Positioning Image

- Click Capture Image to obtain a BirdsEye Camera view of the processing platform. Bambu Suite will automatically extract material contours. This step takes about 8-10 seconds. Please be patient and wait for the material image to refresh on the interface.

- Set Reference Position

- Drag the pattern onto any material surface and adjust the position and angle of the pattern.

- Batch copying and placing patterns

- Click Batch Engraving, Bambu Suite automatically detects other similar materials, and copies the pattern onto them with identical relative positions.

- Execute Processing

- Click Start, Bambu Suite will carve all patterns at once.

¶ Matters needing attention

-

Image Capture Requirements

- Before using batch engraving, it is necessary to ensure that the BirdsEye Camera is correctly installed to capture the background image of the plate using the overhead camera, and that the photo can be taken normally in Bambu Suite.

-

Material Consistency

-

All materials must be identical in shape and type, otherwise batch copying of patterns and automatic placement results may be incorrect.

-

The material color should have a certain difference from the background plate to ensure that the contour boundaries of the objects extracted by Bambu Suite are clear.

-

The material size needs to be between 2cm and 30cm (shortest edge length). Materials that are too small are difficult to identify, while materials that are too large may exceed the field of view or processing range of the overhead camera.

-

The material thickness should be less than 5mm. If the material is too thick, the shadow of the material may affect the accuracy of contour extraction.

-

-

Reference Position Setup

- You must manually position the first pattern on one material to establish the alignment standard for batch copying.

-

Fine Contour Extraction

- Fine contour extraction can improve the success rate of batch engraving, especially for small objects and tightly arranged objects

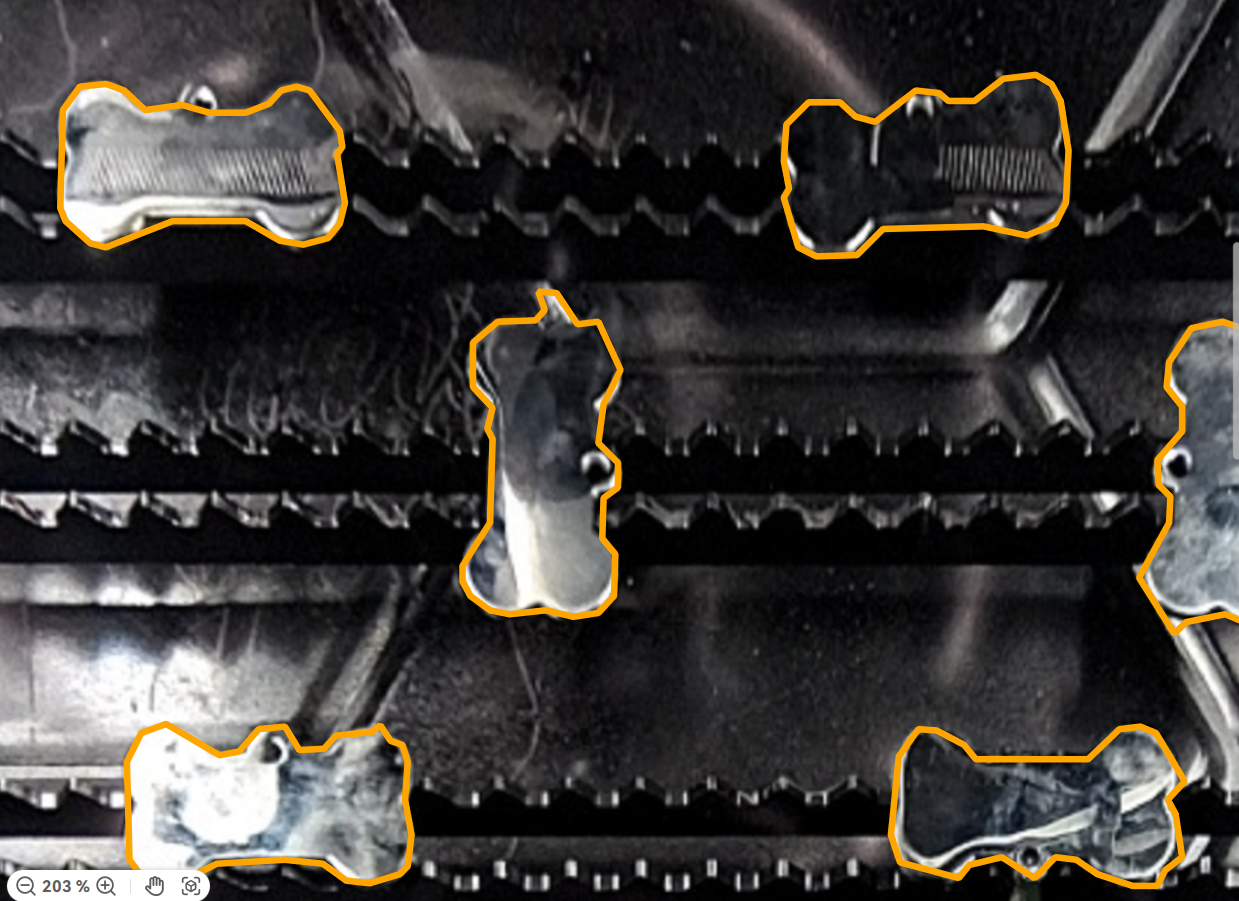

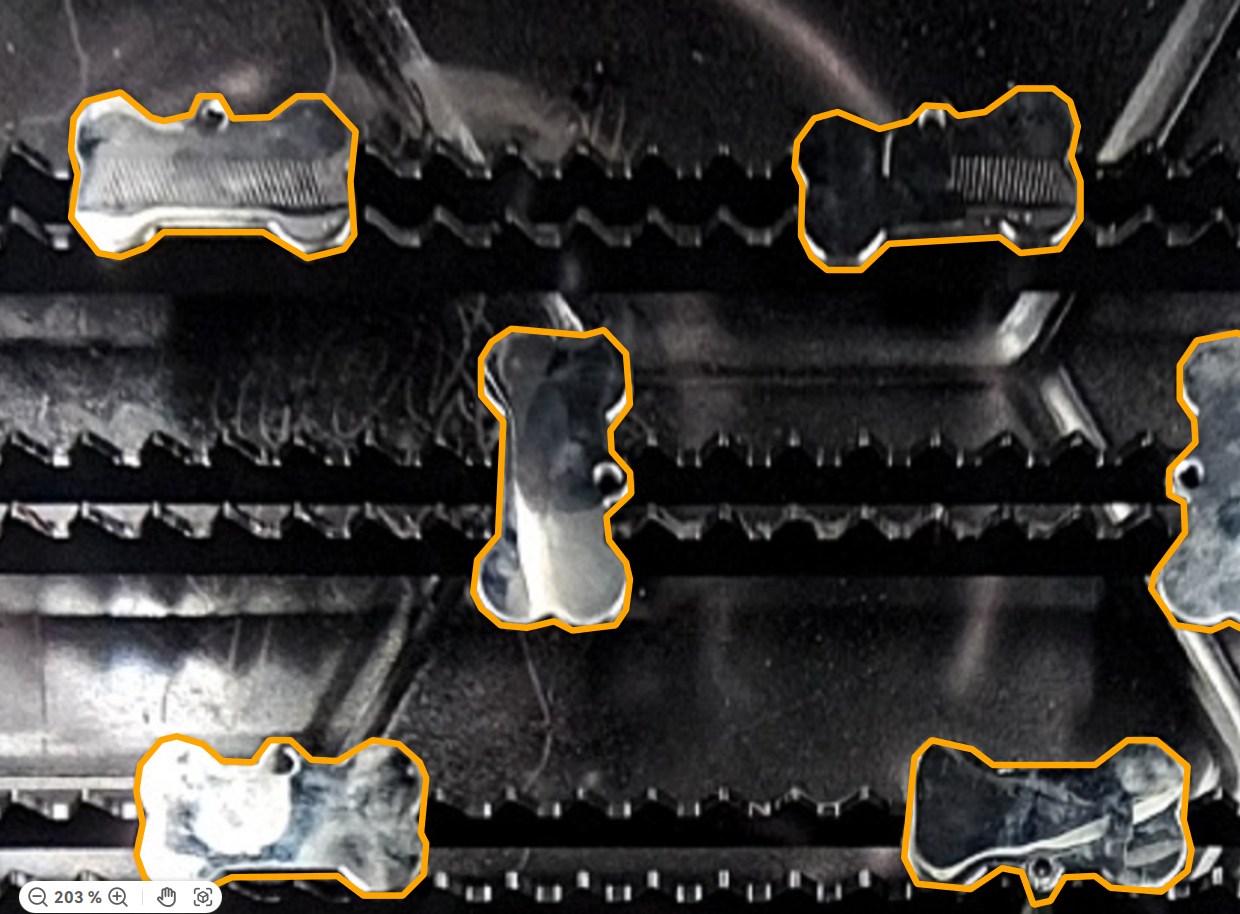

| Default Contour Extraction | Fine Contour Extraction | |

|---|---|---|

| Accuracy of contour | Coast |

Fine(Higher success rate of batch engraving) |

| Object Size | Laser Plate:object size>=20mm*5mmCuting Plate:object size>=5mm*5mmUnofficial Plate:not supported | Laser Plate:object size>=20mm*5mmCuting Plate:object size>=5mm*5mmUnofficial Plate:object size>=30mm*30mm (Objects smaller than the recommended size also have the opportunity for batch carving, but as the object becomes smaller, the recognition accuracy will decrease) |

| Object Placement | Placement interval > 5mm Objects are not allowed to be placed tightly together, which will cause the recognized object contours to stick together  |

Avoid overlapping placement For objects smaller than the required size, recommend placement interval > 5mm Objects are allowed to be placed tightly.  |

| Processing Time | <1s ,generally, it completed immediately after taking a photo (It subjects to your computer performance and task priority defined by the operating system) |

<1s ,generally, it completed immediately after taking a photo (It subjects to your computer performance and task priority defined by the operating system) |

-

Plate cleaning

- The condition of the plate affects the accuracy of contour extraction. It is recommended to clean the plate thoroughly before using the batch engraving function.

| Engraving wastes | Scratches on plate | Only supports official |

|---|---|---|

| - Smaller wasts (less than 5mm in length and width) usually does not affect the extraction of batch engraved target contours. - Larger waste may be identified as engraved objects. |

- Minor engraving scratches usually do not affect batch engraving. - If the engraving scratches are severe, it may affect the accuracy of contour extraction. The plate shown in the following figure is not suitable for batch engraving. |

- The materials need to be placed on official plates. Unofficial plates may be identified as processed materials as a whole. Enable Fine contour extraction: Support unofficial plates |

|

|

|

- Processing time

The processing time depends on your computer hardware and operating system running status. Usually, the calculation of batch engraving is completed within 1 second after determining the engraving pattern and position.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!