¶ AMS Interface Board

¶ What it is

The AMS interface board is a circuit board that provides 24V power and also handles communication between the AMS and the printer. For X1E, this board also carries a network cable port for Ethernet connection.

¶ When should you replace the interface board?

Should there be a power supply or communication failure with the AMS. This interface board may also need to be replaced when the Ethernet fails.

¶ Tools and materials needed

- New AMS interface board

- H2.0 Allen key.

¶ Parts List

| No. | Descriptions | Pics | No. | Descriptions | Pics |

|---|---|---|---|---|---|

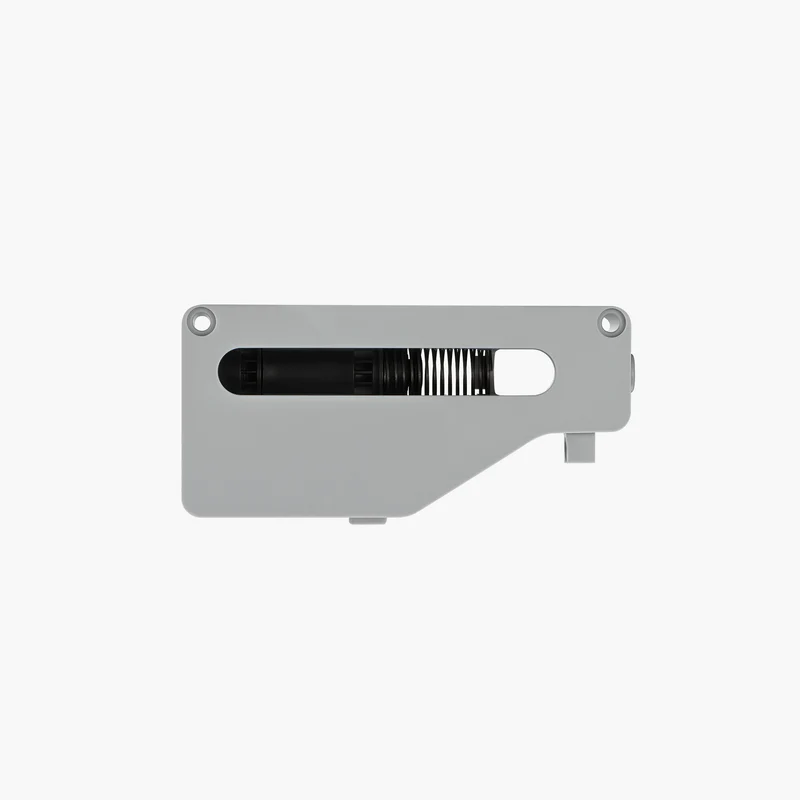

| 1 | Filament Buffer |

|

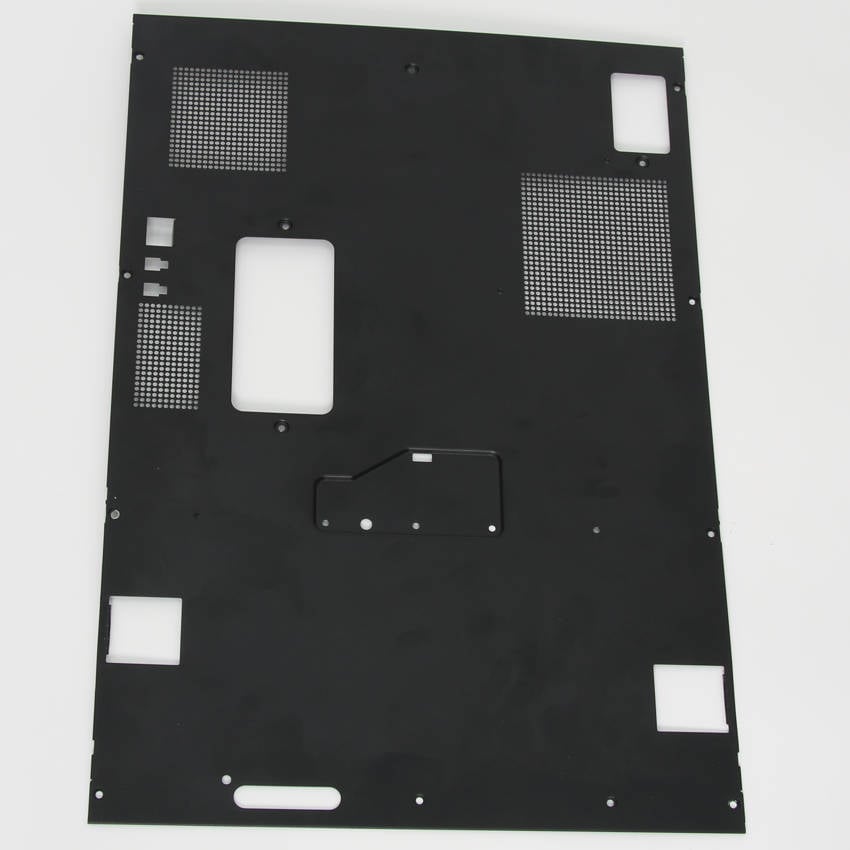

2 | X1E Rear Metal Panel |

|

| 3 | AMS Interface Board |

|

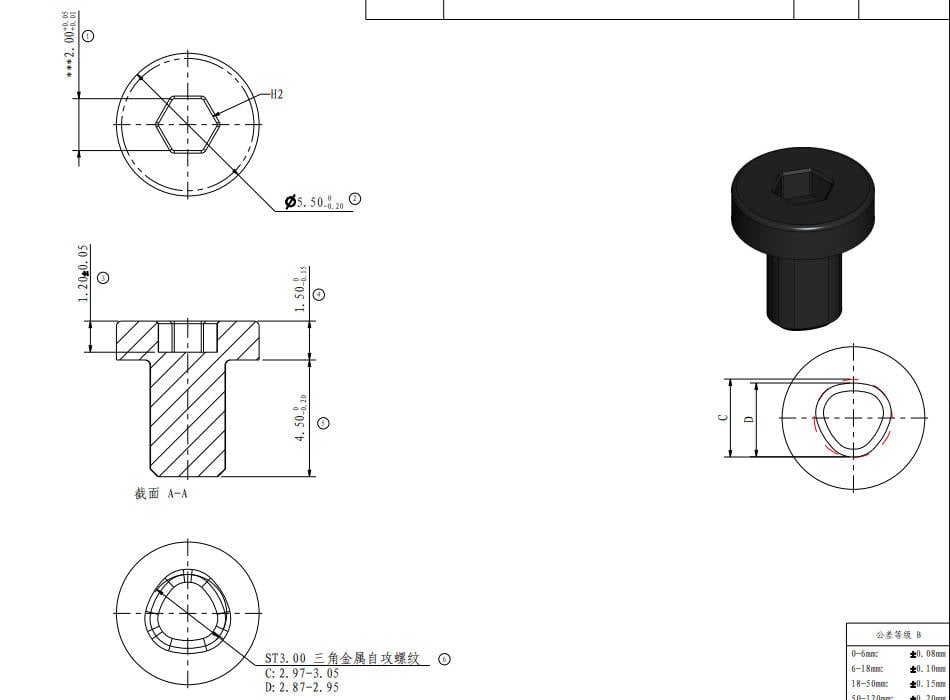

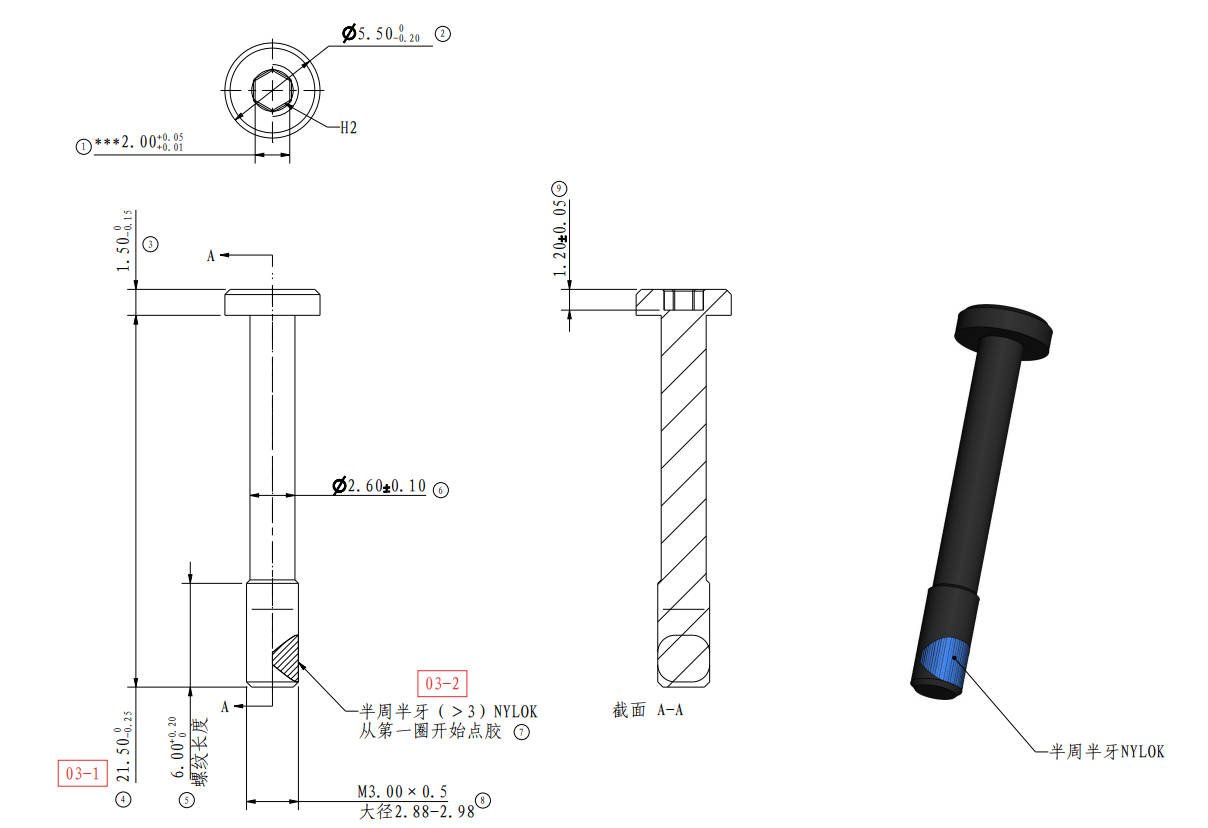

¶ Screws List

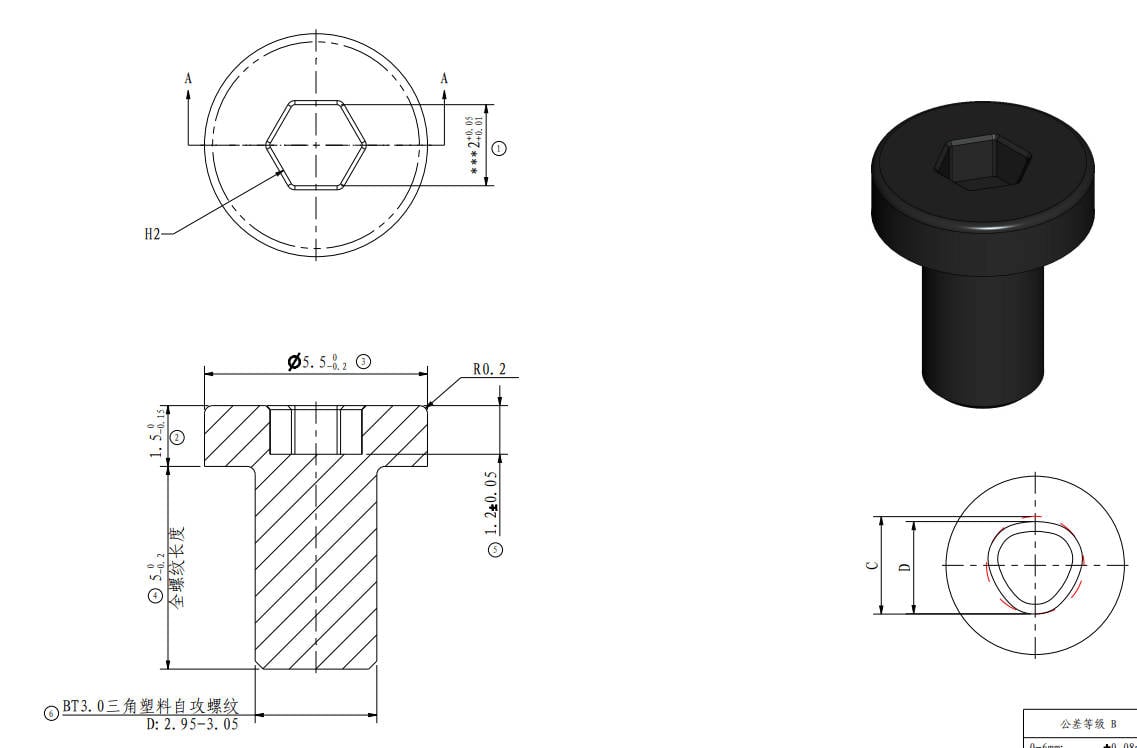

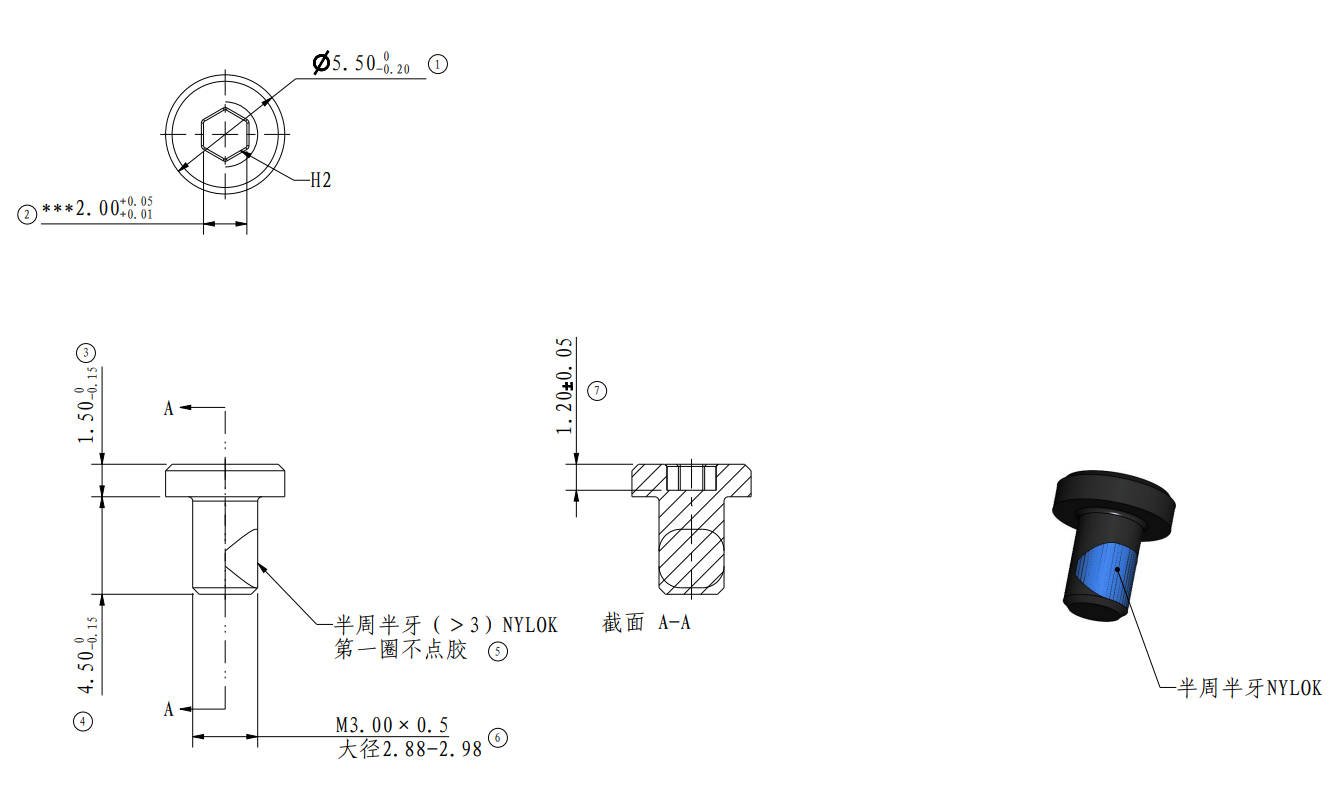

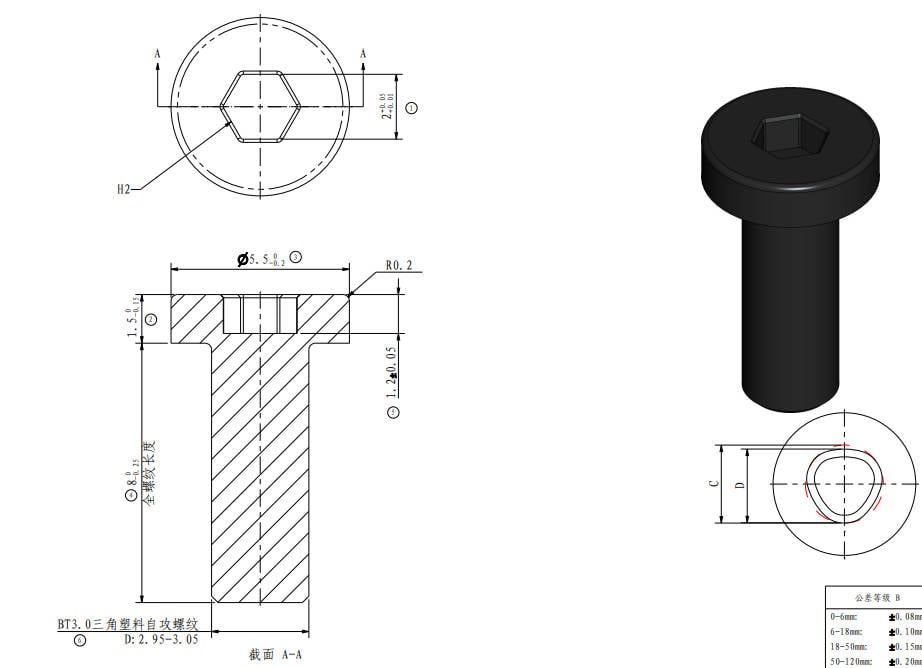

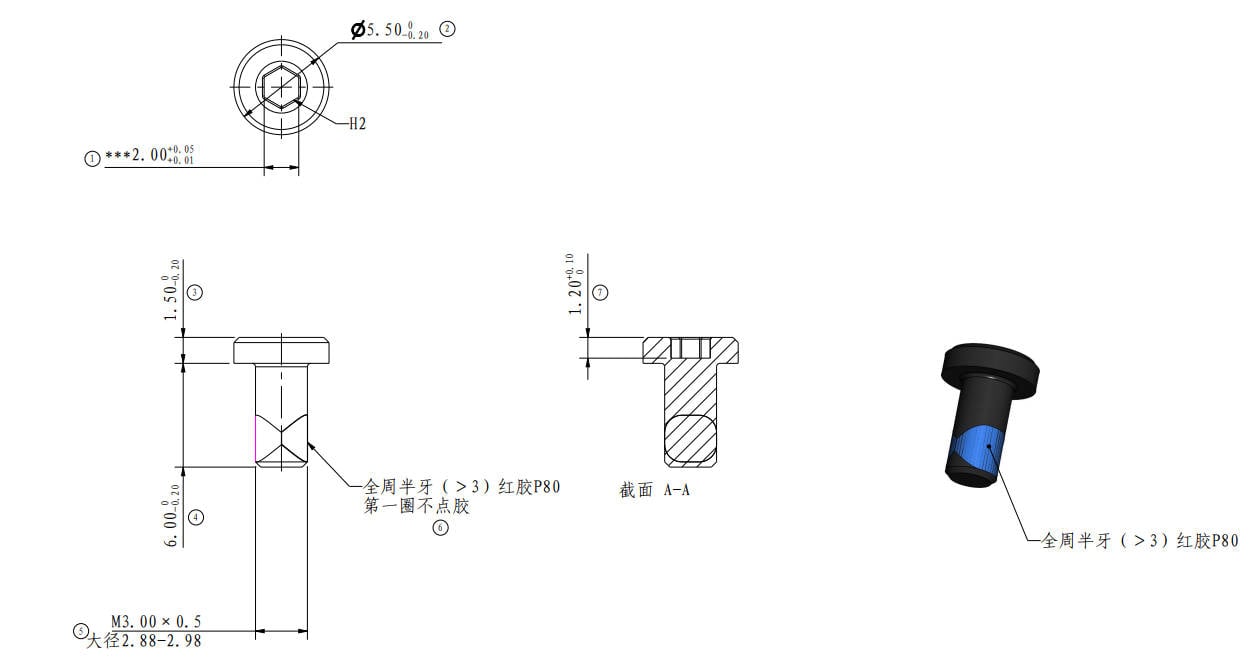

| Model | Position | Drawing | Model | Position | Drawing | ||

| Screw A | ST3*4.5 | Rear Panel |

|

Screw B | BT3*5 | Rear Panel |

|

| Screw C | M3*4.5 | Rear Panel |

|

Screw D | BT3*8 | AMS Interface Board |

|

| Screw E | M3*6 | AMS Interface Board |

|

Screw F | M3*23 | Filament Buffer |

|

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenane or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Operation guide - Disassembly

¶ Step 1 - Disconnect the power cord

Disconnect the power cord from the power socket.

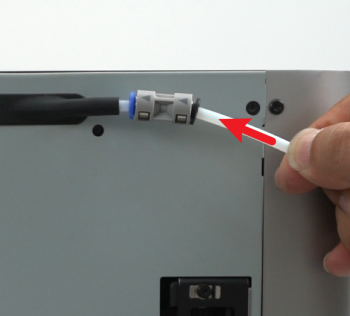

¶ Step 2 - Disconnect the PTFE tube and 4-pin Cable

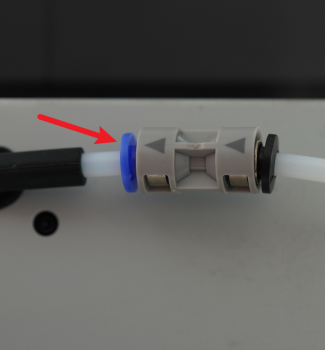

Press on the plastic coupler to disconnect the PTFE tube. Unlock the 4-pin cable and disconnect it from the printer.

|

|

¶ Step 3 - Remove the Filament buffer

Remove the 2 screws F holding the filament buffer in order to remove it.

|

|

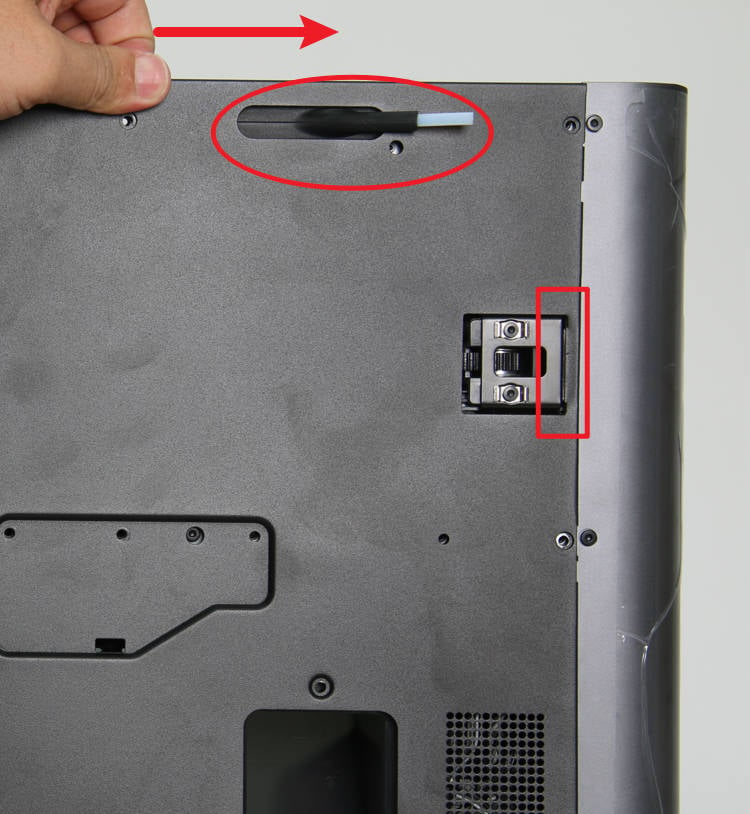

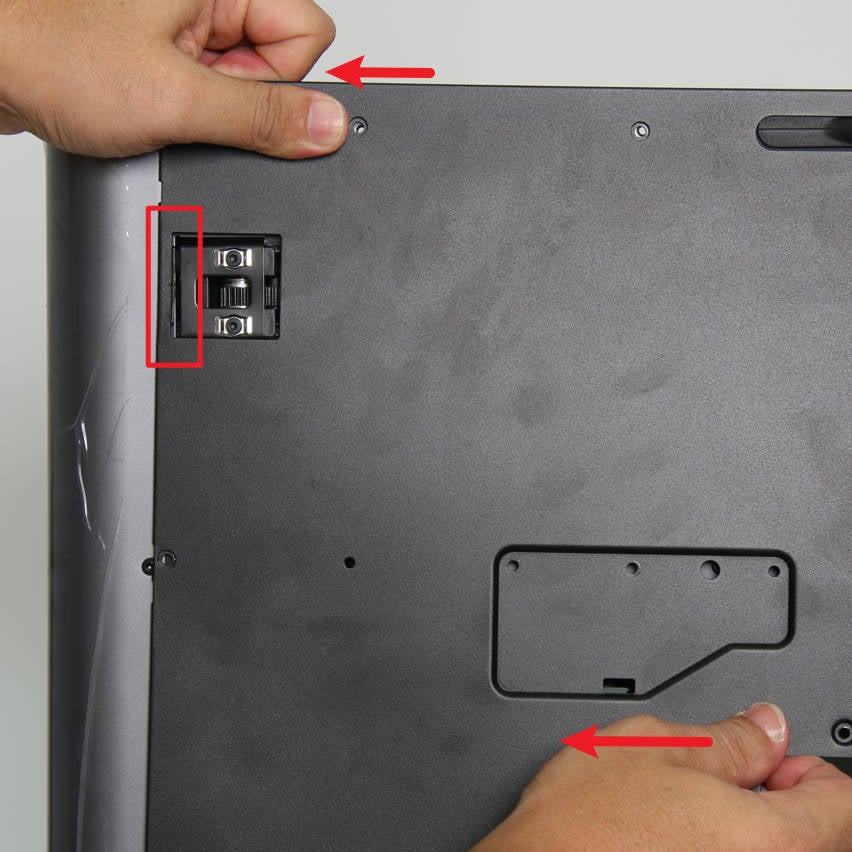

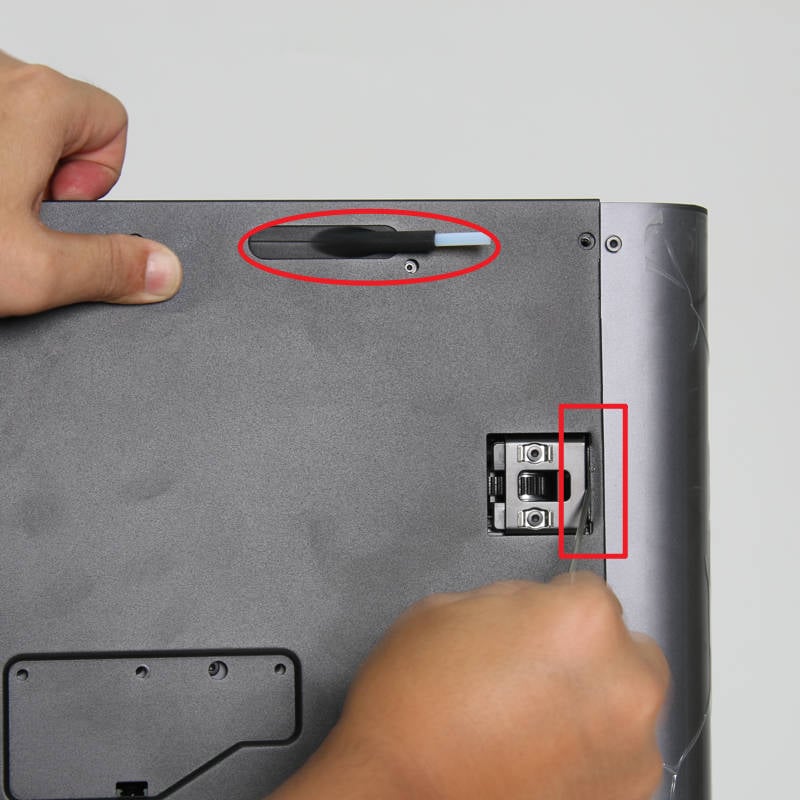

¶ Step 4 - Remove the Rear Panel

Remove the glass cover, and then as shown in Figure 1-4-1, remove 9 screws A, 4 screws B, and 1 screw C with the H2.0 hex key;

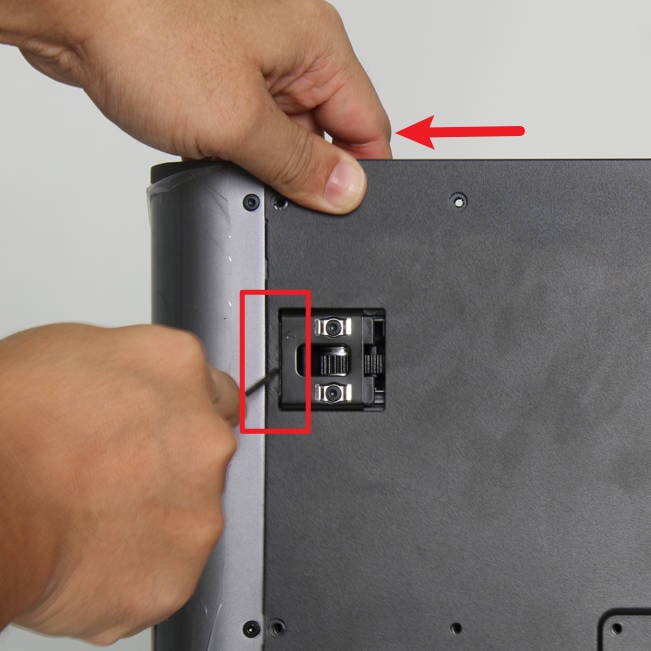

As shown in Figure 1-4-2, first push the rear panel to the right a little bit, and loosen the rear panel from the tensioner on the right side;

As shown in Figure 1-4-3, apply force to the left, release the rear panel from the left tensioner, and remove the rear panel.

|

|

|

|

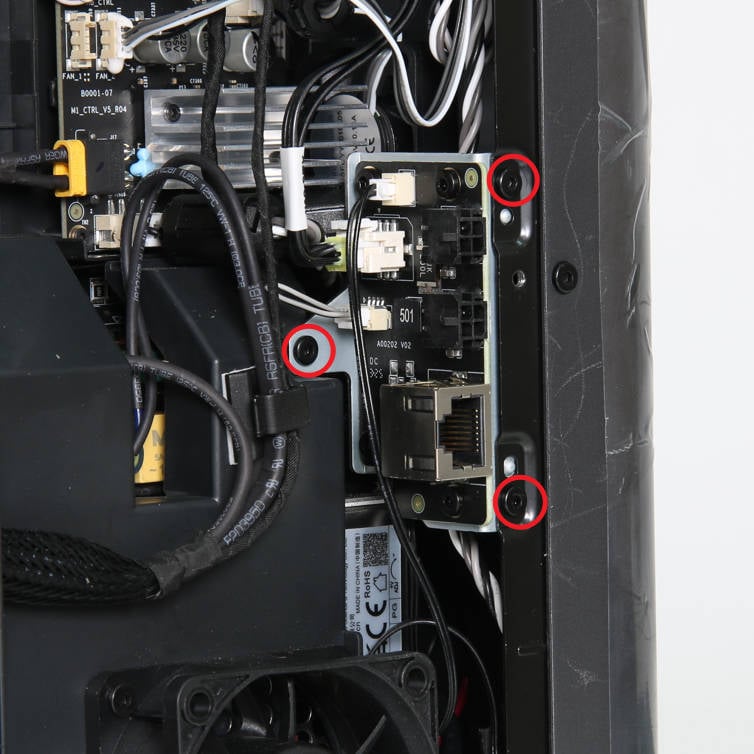

¶ Step 5 - Remove the AMS Interface Board

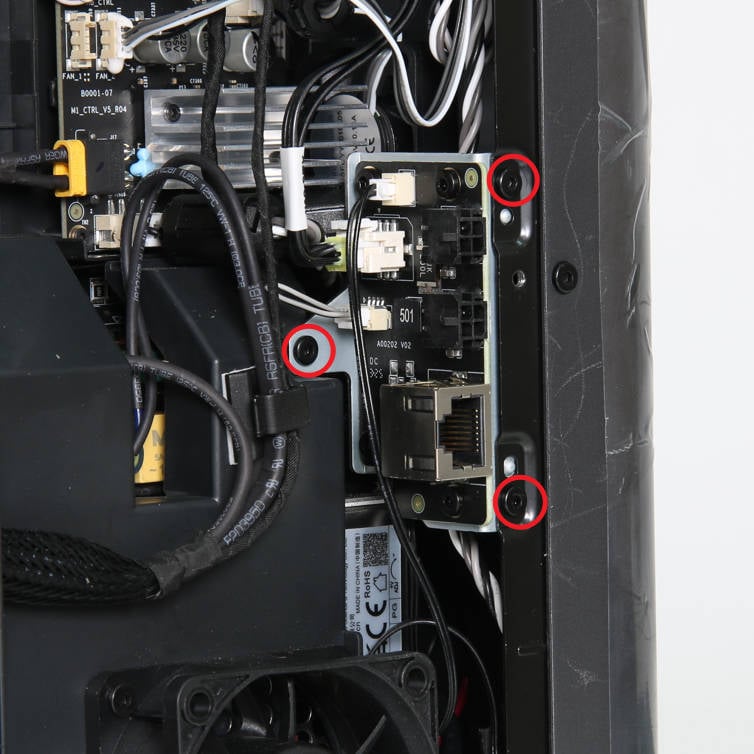

As shown in Figure 1-5-1, remove 2 screws D and 1 screw E with the H2.0 hex key to loosen the board;

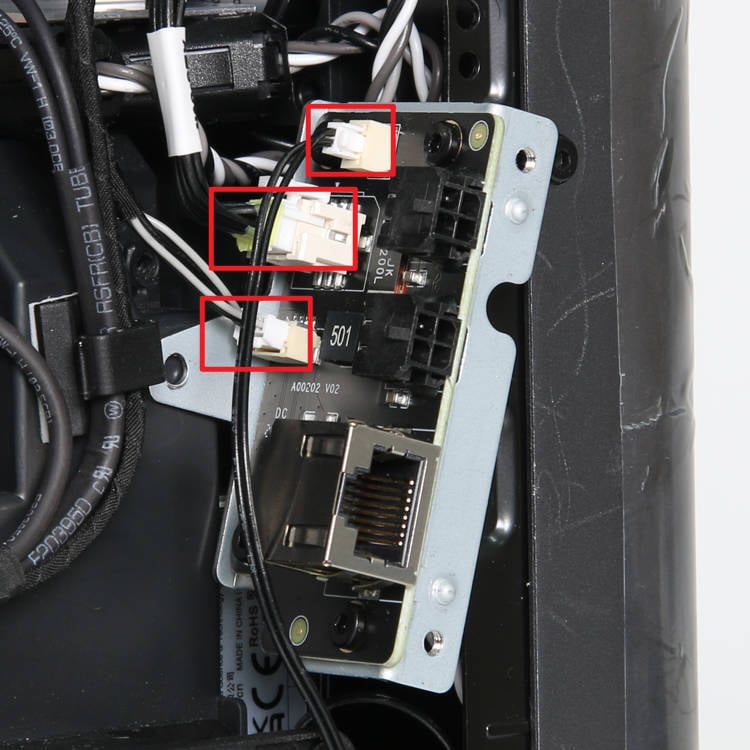

As shown in Figure 1-5-2, disconnect the three connectors and remove the AMS interface board;

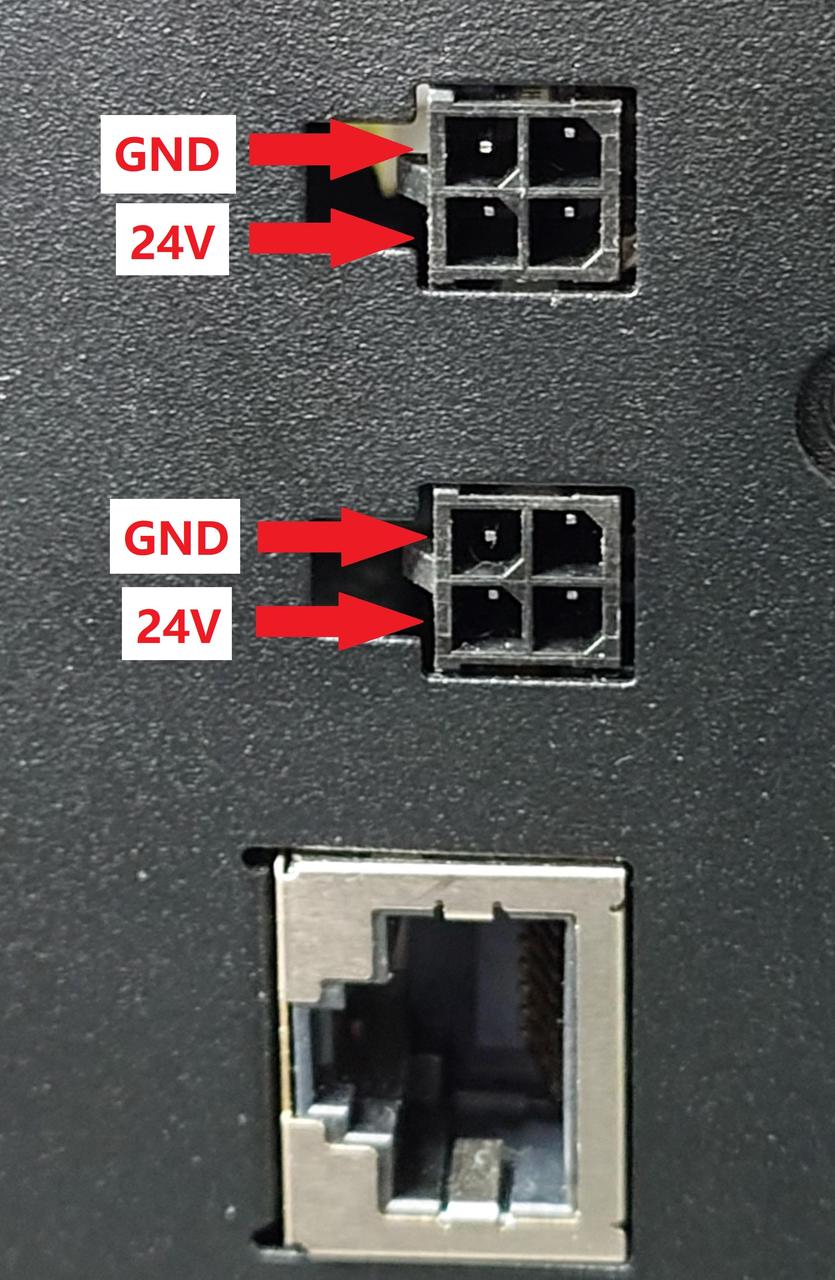

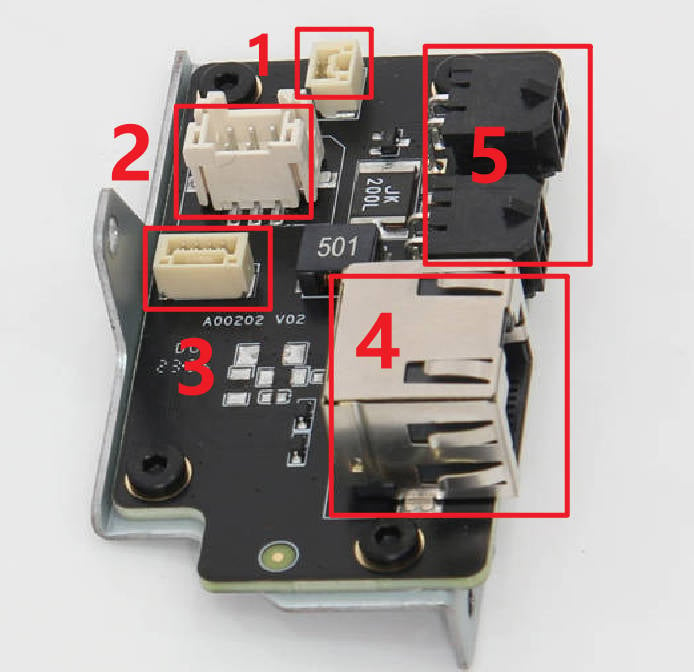

Figure 1-5-3 illustrates the components connected to each interface on the AMS interface board:

| Interface number in picture | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Connected components | Chamber Heater Control Board | MC board | Network Interface Board | Network Cable | AMS |

|

|

|

¶ Operation guide - Assembly

¶ Step 1 - Install the AMS Interface Board

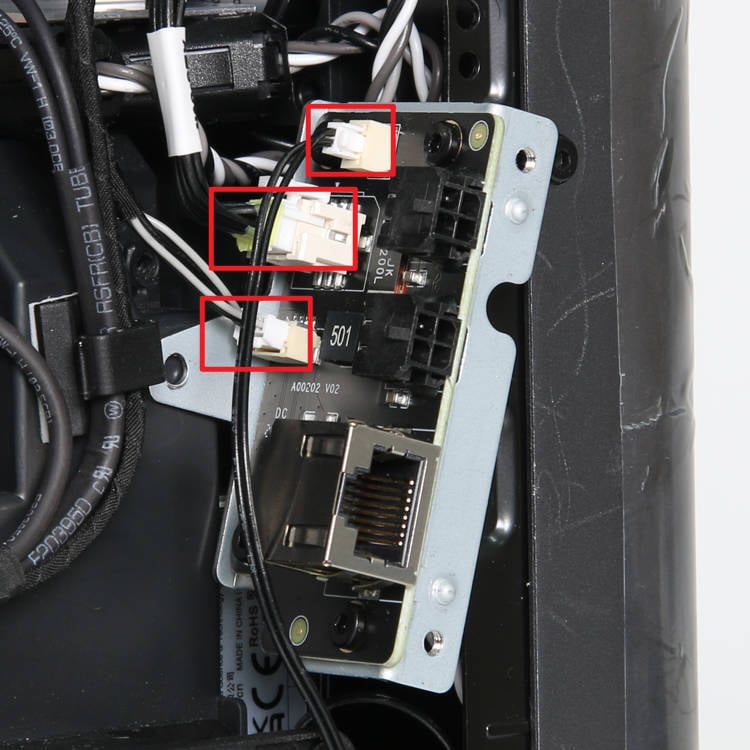

As shown in Figure 2-1-1, according to the descriptions of the above interfaces, connect the 3 connectors in sequence;

As shown in Figure 2-1-2, install the AMS interface board, and lock in 2 screws D and 1 screw E.

|

|

¶ Step 2 - Install the Rear Panel

As shown in Figure 2-2-1, first pass the tube bracket through the rear panel, and then install the part near the tensioner on the right side in place, you can the hex key to press the edge to install it;

As shown in Figure 2-2-2, pull the rear panel to the left and install the part near the left tensioner in place, you can use the hex key to press the edge to assist in the installation;

As shown in Figure 2-2-3, lock in 9 screws A, 4 screws B and 1 screw C to fix the rear panel.

|

|

|

¶ Step 3 - Install Filament Buffer

Install Filament Buffer, and lock in 2 screws F to fix it in place.

¶ Step 4 - Connect the PTFE tube and 4-pin Cable

Connect the PTFE tube by simply pushing it against the PTFE outlet at the back of the machine, and connect the 4-pin Bambu bus cable.

|

|

NOTE: The 4-pin cable should not be inserted in the wrong direction; if it is inserted in the wrong direction it may cause damage to the printer and the AMS motherboard.

¶ Verify the functionality

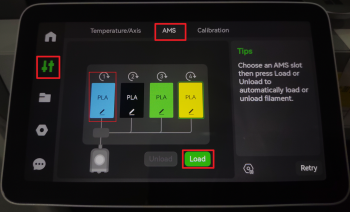

Connect the power cord and turn on the power. On the display screen, press the AMS label on the screen as shown below, it will display the AMS control panel. Press "Load" to run the filament loading process, if the process is completed without any error, the AMS interface board replacement is complete and successful.

Should you come across any issues, first retrace your steps and check all connections to try again. If problems persist, contact the service team for further assistance.

|

|

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.