¶ Introduction

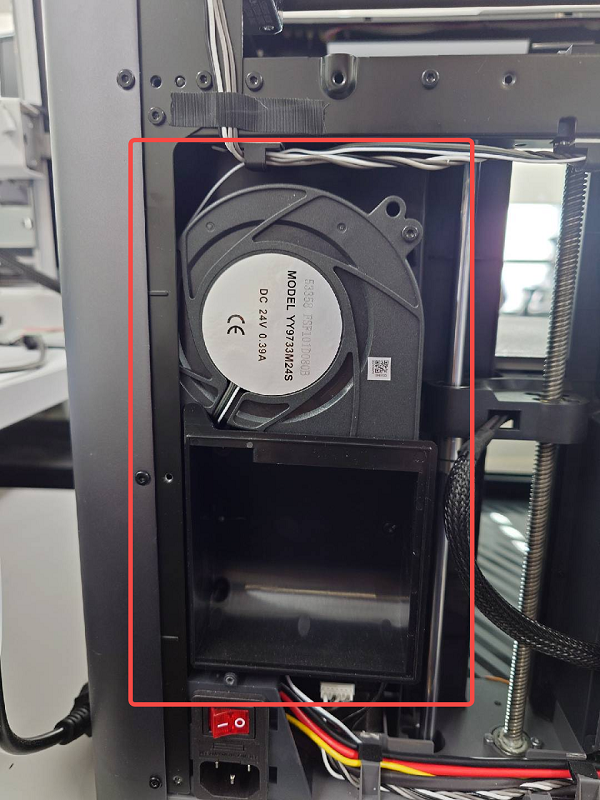

The X1E model adds an enhanced active air filtration module compared to the X1C. When printing, this module absorbs harmful gases and particles released by heating materials such as ABS, ASA, etc. The default speed setting for the air filtration fan is 70%, which is sufficient for most use cases.

|

|

¶ Enable Active air filtration

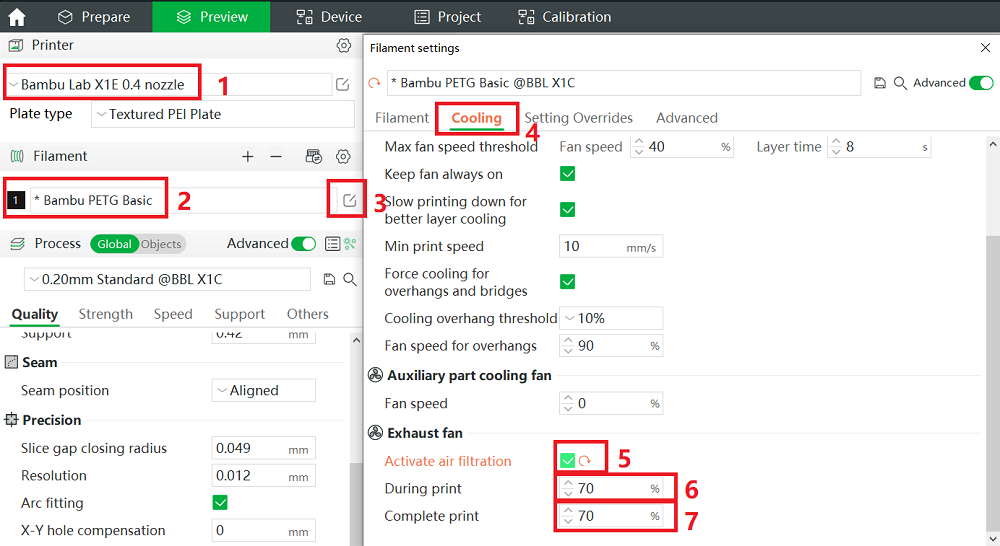

- Select the X1E model;

- Select the target filament type;

- Click the filament parameter edit button;

- Checking the Cooling parameter tab;

- Enable/disable the air filtration function;

- Set the filter fan speed during printing;

- Setting the filter fan speed after the printing is finished;

¶ Note

- The filter automatically switches off as the machine sleeps (10 minutes by default) and does not continue to run after printing has finished. Do not switch on the filter when the printer is in standby for a long period of time, as this will reduce the life of the filter cartridge.

- Set the filter fan speed according to the chamber temperature. If the speed is too low, negative pressure cannot be maintained in the chassis, thus allowing VOCs and particles generated by printing to escape through the gaps in the housing rather than through the filter; if the speed is too high, the airflow through the filter cartridge may be too short, resulting in a decrease in filtration efficiency.

- When the machine is in a high chamber temperature state, the back panel power supply cooling fan will run at full speed, at this time, if the air filter fan speed is lower than the default setting, it will result in the chassis not being able to maintain a negative pressure, making some of the gases to escape through the chassis gaps instead of through the filter element to be discharged.

- When the machine is at a high chamber temperature, the temperature of the air filter module's cartridge will increase, resulting in a decrease in the adsorption capacity of the porous carbon filter material inside.

¶ Life expectancy (based on 8 hours of printing per day)

When printing filament such as PLA and PC and their carbon fibre (CF) and glass fibre (GF) composites with low VOC and particulate emissions, the cartridges can be used for about 3 months;

When printing filament such as ABS, PETG, PA and their carbon fibre (CF) and glass fibre (GF) composites with high VOC and particulate emissions, the cartridge can be used for about 1 month;