The X1 and X1C are capable of printing fast, but in order to do that successfully, the material used for printing also needs to be compatible with fast printing.

There is a balance that needs to be found between printing speed and hot end temperature for silk filaments, and the easiest way to find it is to look at the external layer uniformity of the print. When the silk filament is printed with the right settings, the model should have a uniform shine.

A good indication of too high speed or a low printing temperature is having matte lines on the external layers and low layer adhesion which means that it's easy to break the model in Z direction.

¶ Lower printing speed

Most silk filament manufacturers recommend a printing speed between 40mm/s to 60mm/s, and this is because of how the silk filament performs when extruded.

The composition of silk filament is slightly different from regular PLA as it has some compounds that give the filament the specific shine we love. This additive makes the filament a bit elastic, and layer adhesion is also not that strong.

Lowering the print speed will improve the printing results when using silk filament. Considering that all filaments are different, and different brands have different needs, we recommend starting with the printing speeds recommended by the manufacturer, and then adjusting the print speed to be higher in incremental steps to shorten the printing time.

Going over 100 mm/s isn't recommended if you want to ensure good layer adhesion and a nice finish, but you might get away with it if multiple external walls are used. To control the speed and allow the material to be properly melted, we also recommend using the “Silent” mode from the screen menu.

¶ Increase hot end temperature

Another recommended setting to be changed is the hot end temperature. Regular PLA is usually printed at 210 to 215 °C with slower speeds, but you might need to increase the temperature to about 215 to 225 °C for a consistent flow and melting rate.

Silk filament usually requires a higher temperature for increased layer adhesion which is usually between 215 °C to 220 °C at low printing speeds. When the printing speeds are higher (e.g.: over 100 mm/s) the temperature used should be around 230 °C to 235 °C for best results.

¶ Control the gloss of the PLA Silk

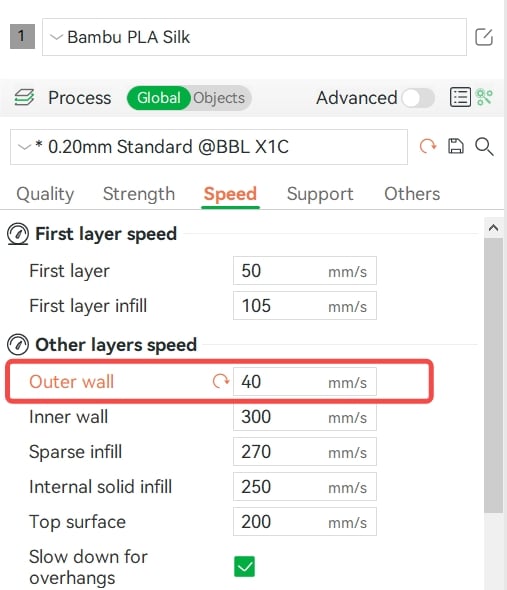

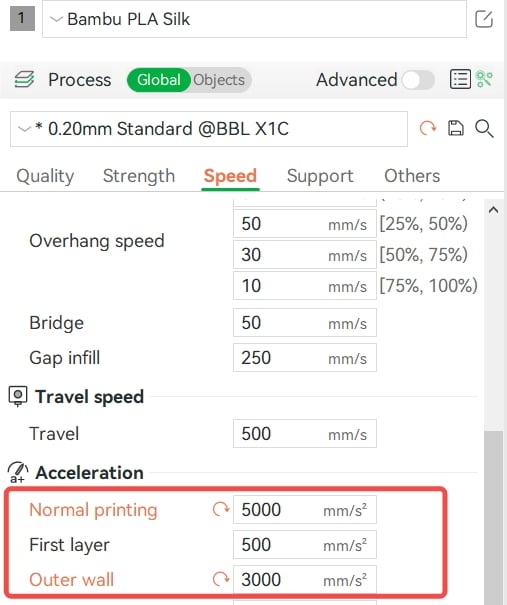

The gloss of the model's surface printed by PLA Silk can be controlled by printing temperature and speed. To get glossier finishes, higher printing temperatures and/or lower speeds are recommended. As for Bambu PLA Silk, the recommended Nozzle Temperature is 225 to 235 °C, and the recommended speed settings are as follows (the recommended Outer Wall Speed is 30 to 60 mm/s).