¶ Observation

AMS failed to feed the filament to the extruder.

Possible root causes:

- Filament tangled or sagging and stuck

- The spool size exceeds AMS specifications or the cardboard spool is used

- The feed funnel of the first-stage feeder is seriously worn

- The roller support of the first-stage feeder was broken

- The PTFE tube inside AMS is worn

- The PTFE tube between AMS and printer is overbending

¶ Troubleshooting

¶ Tools, Equipment, and Materials

Please refer to the info inside each detailed troubleshooting wiki.

¶ Actions

¶ Step 1: Check if the spool conforms to the specifications or if any deformation is present

Please refer to this wiki to check if the spool used are within the AMS specifications; check if the width of the spool is between 50~68mm and the diameter is between 197~202mm; some spools may be deformed; please rotate the spool back and forth to check whether there is too much resistance at any position.

¶ Step 2: Check if the filament is tangled or sagged and stuck.

Please avoid using filaments unsupported by AMS, such as TPU/damp PVA.

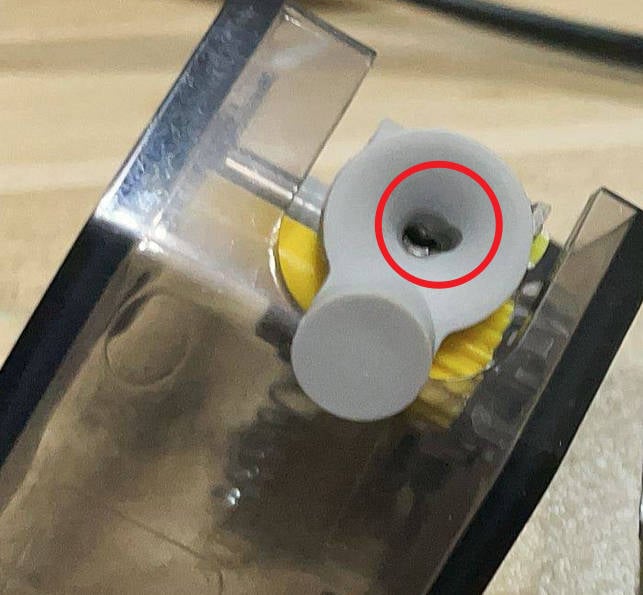

¶ Step 3: Check if the feed funnel of the first-stage feeder is seriously worn.

If there is wear, please refer to the wiki for replacement.

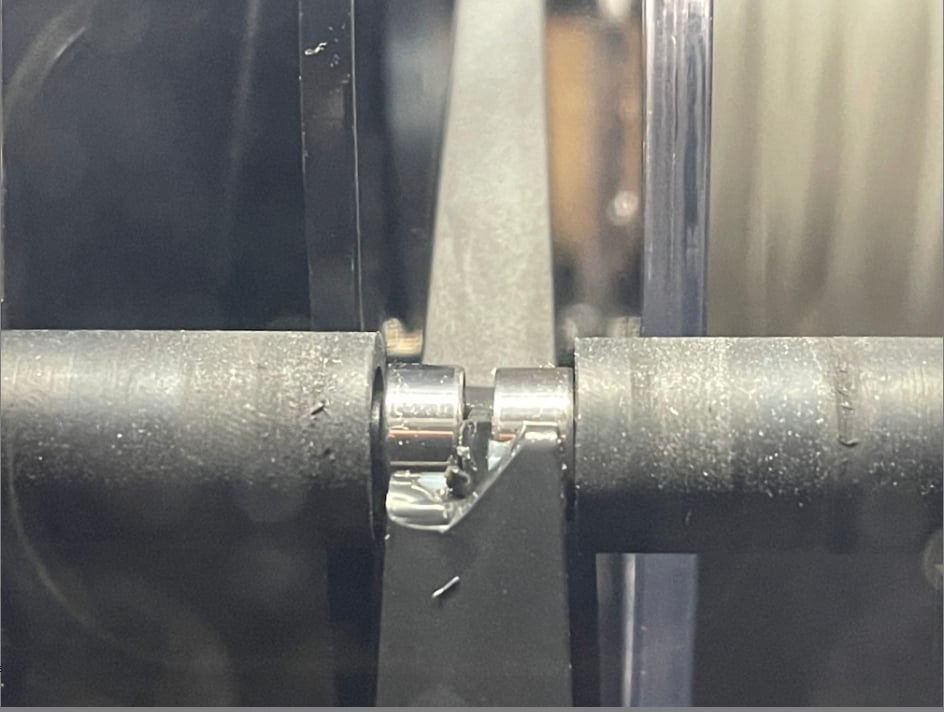

¶ Step 4: Check if the spring of the AMS buffer or Hub is stuck

The example on the left shows a stuck spring, while the example on the right demonstrates a properly functioning spring.

¶ Step 5: Check for wear on the PTFE tube inside the AMS.

Please refer to this wiki to disassemble AMS and check if the PTFE tube inside AMS is worn.

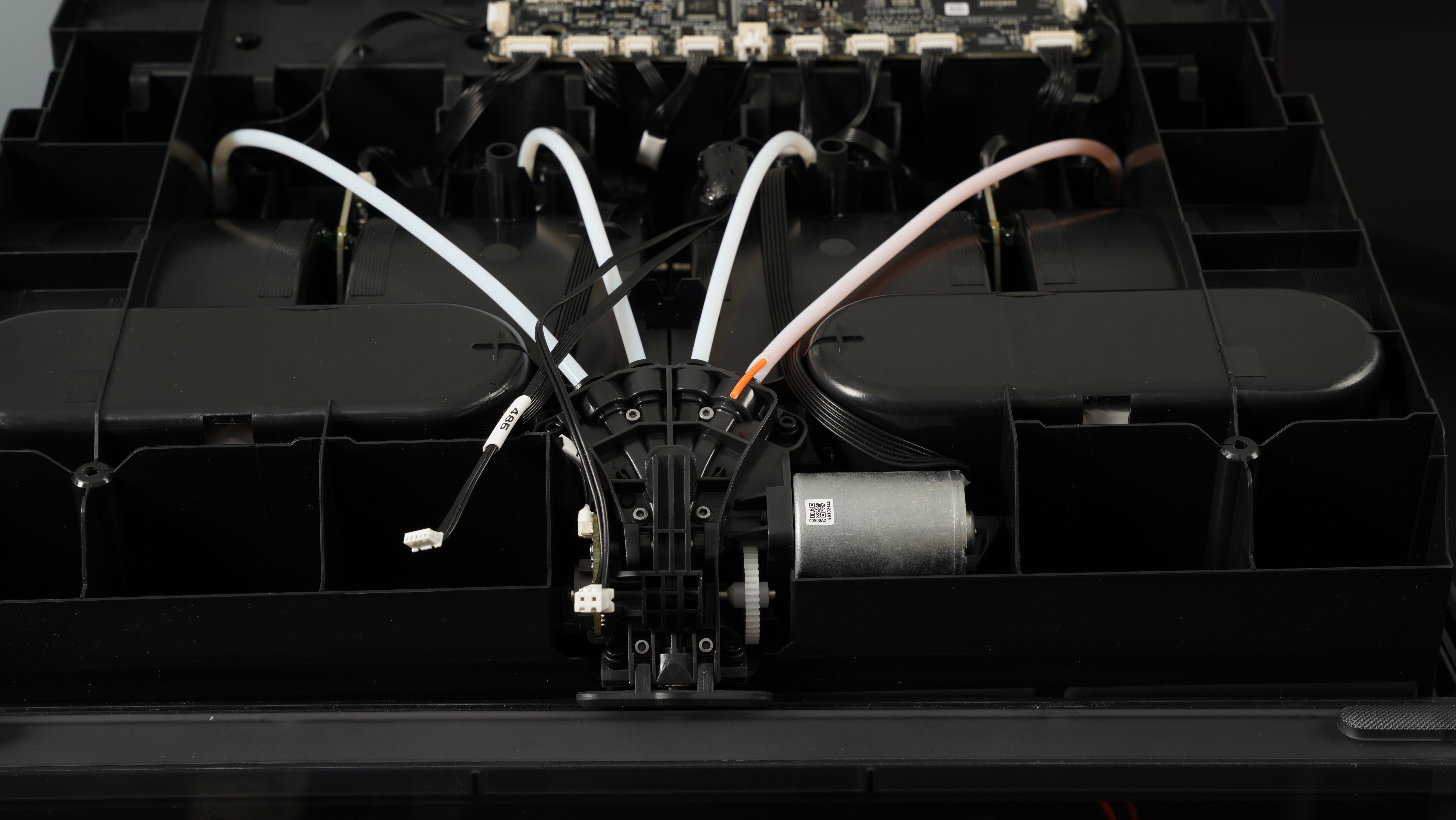

¶ Step 6: Check for any damage to the support of the rollers.

If any damage is found, please get in touch with the Bambu Lab after-sales support team for replacement.

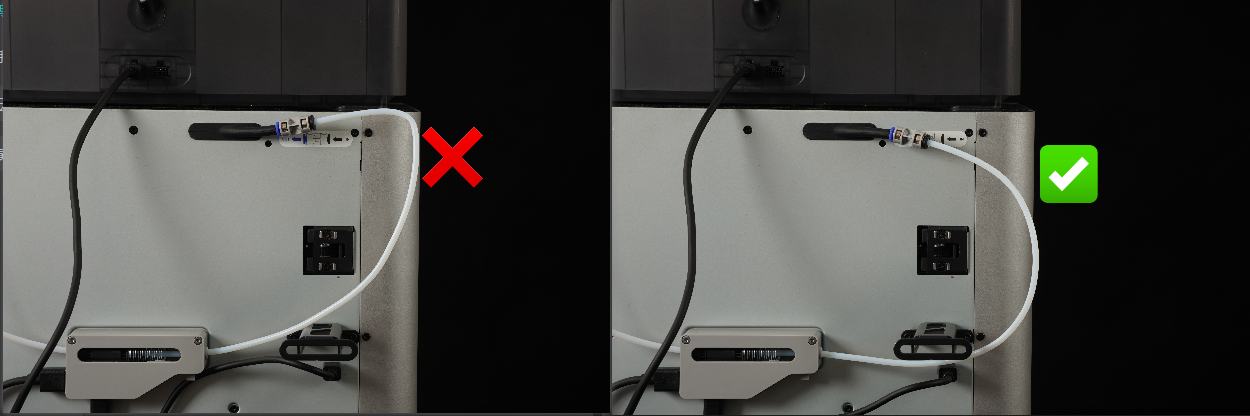

¶ Step 7: Check if the PTFE tube between the AMS and the printer is excessively bent.

Excessive bending of the PTFE tube between the AMS and the printer can cause additional resistance during filament feeding and retraction. Please refer to the diagram below to check for any bends.

If the issue persists after troubleshooting, please submit a customer support ticket.

¶ Equivalent Codes

The following HMS codes represent the same type of fault on different AMSs.

0700-7000-0002-0002 AMS 1

0701-7000-0002-0002 AMS 2

0702-7000-0002-0002 AMS 3

0703-7000-0002-0002 AMS 4

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.