¶ What it is

AMS active extrusion wheel assembly is a gear assembly in the AMS filaments hub that directly drives the filament.

¶ When to use

When the filament is stuck, and the filament stops in the filament hub or has obvious wear and filament notches are found.

¶ Tools and materials needed

- New AMS active extrusion wheel assembly

- H2.0 & H1.5 Allen keys

¶ Safety warning and Machine state before starting operation

Turn the printer power OFF and disconnect the AMS connection to the printer.

¶ Operation guide

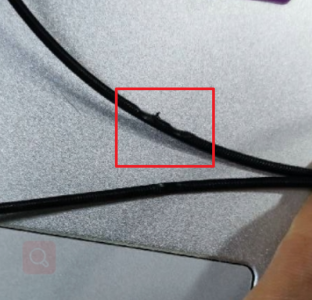

¶ Step 1 - Disconnect the PTFE tube

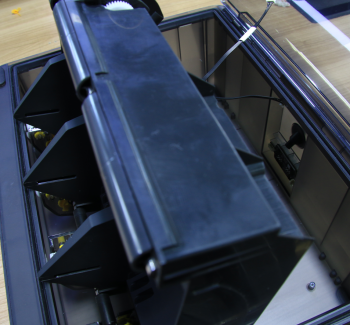

Open the AMS cover, press the button on the filaments hub and pull out the PTFE tube.

|

|

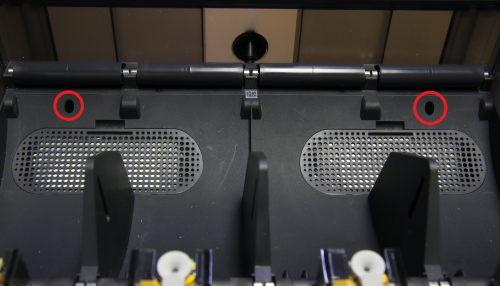

¶ Step 2 - (Disassembly) Remove 2 screws

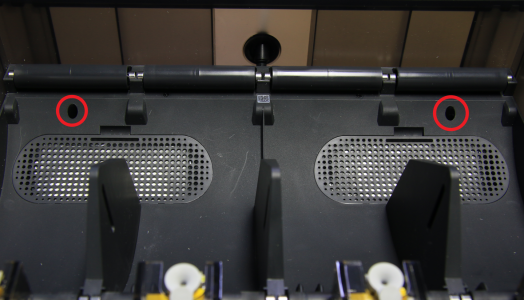

Remove the 2 screws, and then flip the middle frame upward. You can press the button on the filaments hub to avoid getting stuck.

|

|

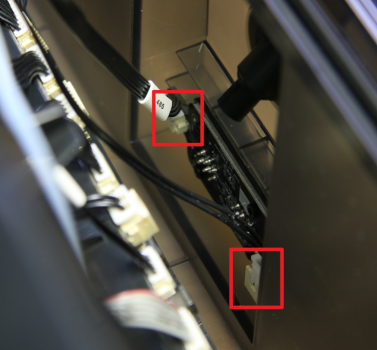

¶ Step 3 - Disconnect 2 cables

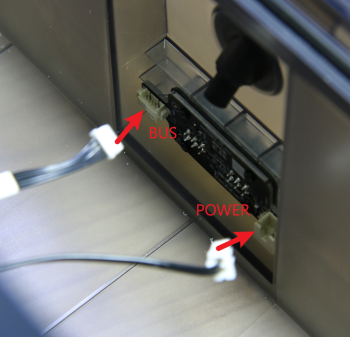

Disconnect the bambu bus cable and the power cable, and remove the middle frame module.

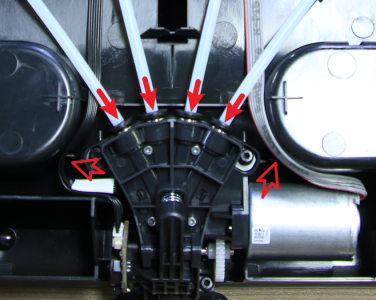

¶ Step 4 - Disconnect the 4 PTFE tubes

Depress the plastic couplers to disconnect the 4 PTFE tubes.

|

|

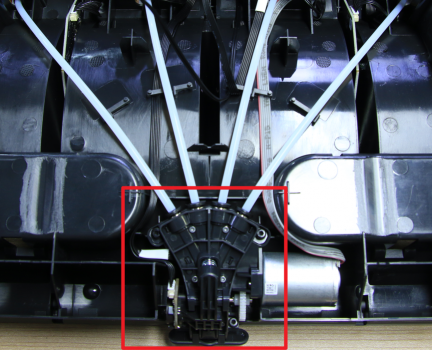

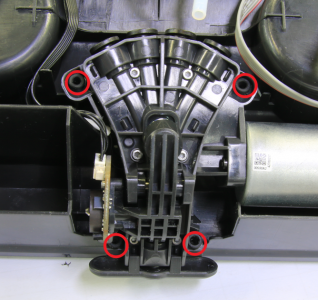

¶ Step 5 - Unlock the filaments hub

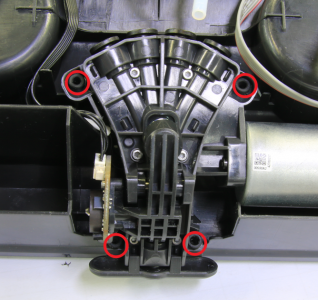

Remove the 4 screws, and turn the filaments hub assembly over.

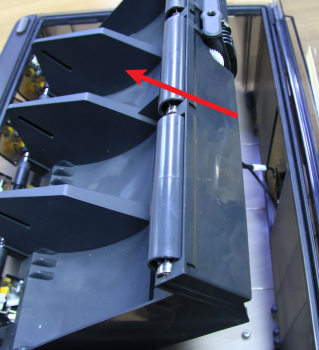

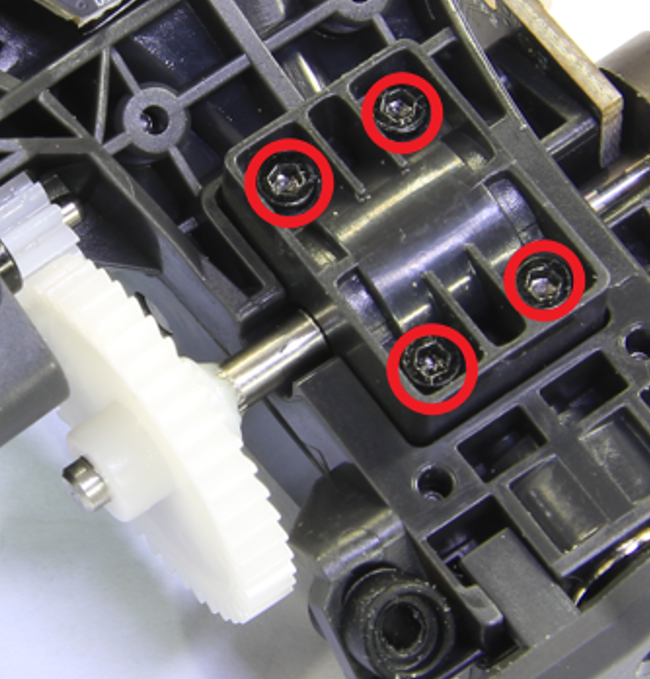

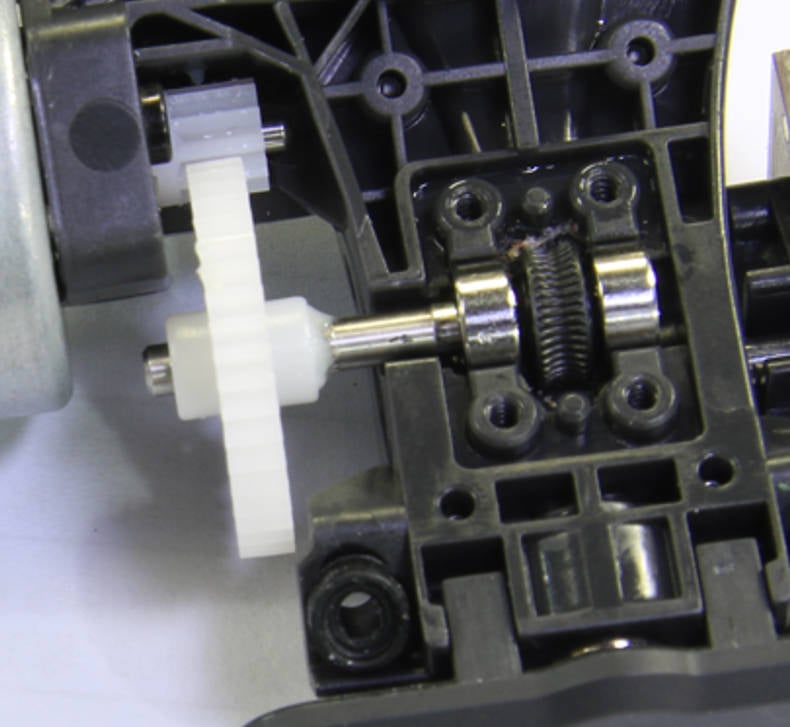

¶ Step 6 - Remove the driving gear unit

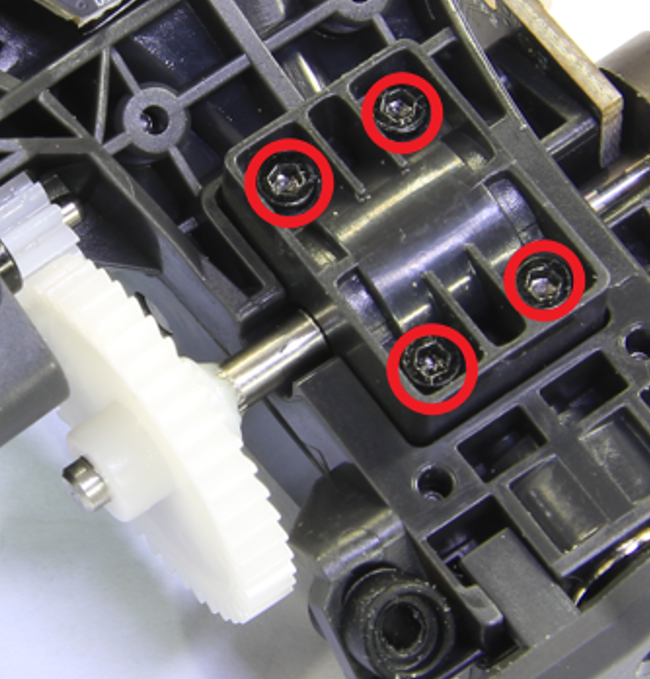

Unscrew the 4 screws, and then remove the protective cover and the AMS active extrusion wheel assembly.

|

|

¶ Step 7 - (Assembly) Install new AMS active extrusion wheel assembly

Install the new AMS active extrusion wheel assembly and the protective cover to the filaments hub, and secure the cover with the 4 screws.

|

|

¶ Step 8 - Install the filaments hub

Install the filaments hub module to the middle frame, and secure with the 4 screws.

¶ Step 9 - Connect 4 PTFE tubes

Arrange the cables, and connect the 4 PTFE tubes.

¶ Step 10 - Connect 2 cables

Place the middle frame into the AMS shell, connect the bambu bus cable and the power cable.

|

|

¶ Step 11 - Install middle frame and secure with 2 screws

Install the middle frame in place, secure with 2 screws.

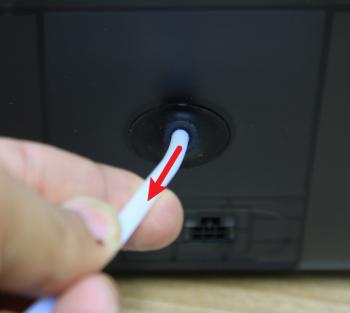

¶ Step 12 - Connect the PTFE tube

Check the tube bracket, and push in the PTFE tube, try to pull it out to make sure the tube is well connected.

|

.png) |

¶ How to verify completion/success

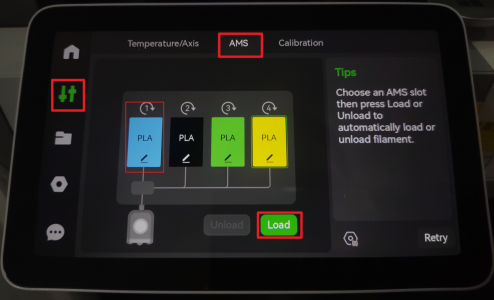

Connect the AMS to printer and power ON. Load filaments to the AMS, and click "Load" on the screen to start loading the filament.

If the loading process functions OK, the replacement is complete and success.

Otherwise, check the connections of the cables and filament tubes. If no errors are found and it still malfunctions, contact the Bambu Lab service team for further assistance.