In this guide we will show the process of replacing the Heatbed on the A1 mini

¶ When to use?

This guide should be used if the Heatbed of the A1 mini is faulty, and needs to be replaced.

Common issues that are caused by the A1 mini Heatbed are:

- Heatbed is not heating

- Heatbed surface is damaged

- Recommended by Bambu Lab Customer Support

¶ Tools and materials needed

- H2.0 Allen key

- 15 minutes of your time

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenane or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Steps to remove the old Heatbed

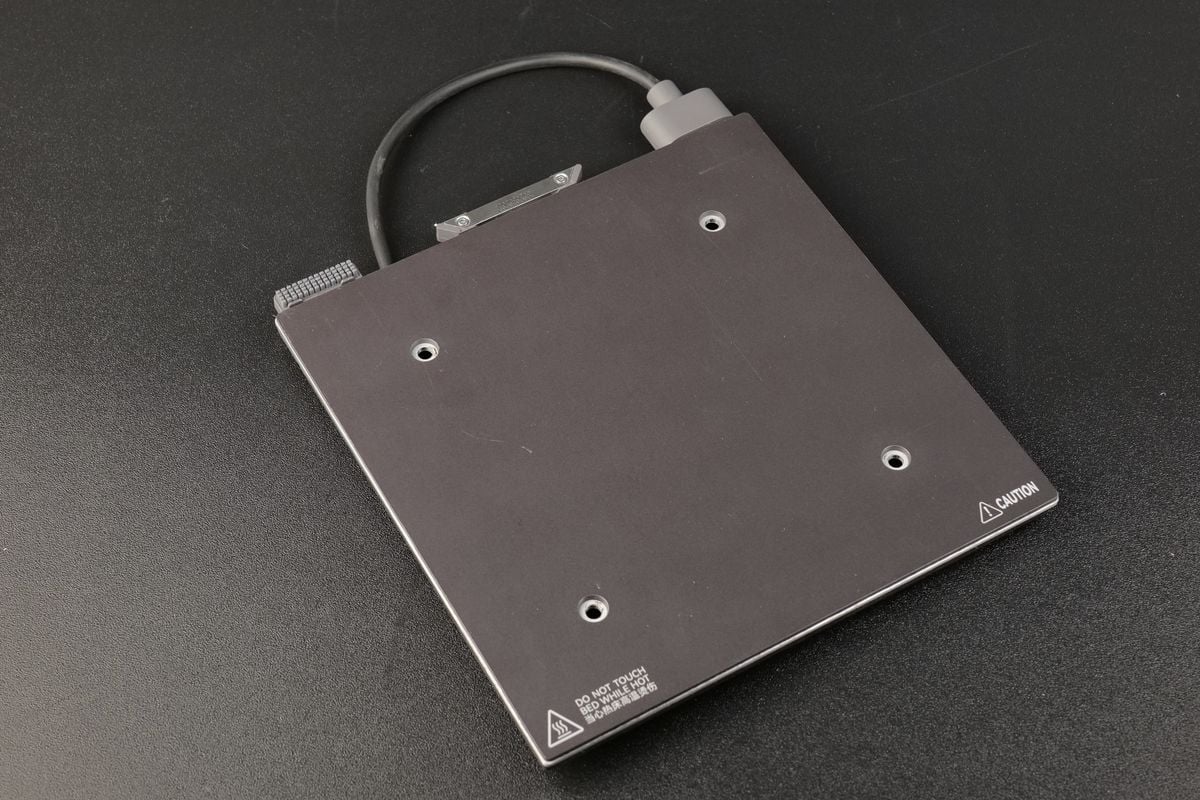

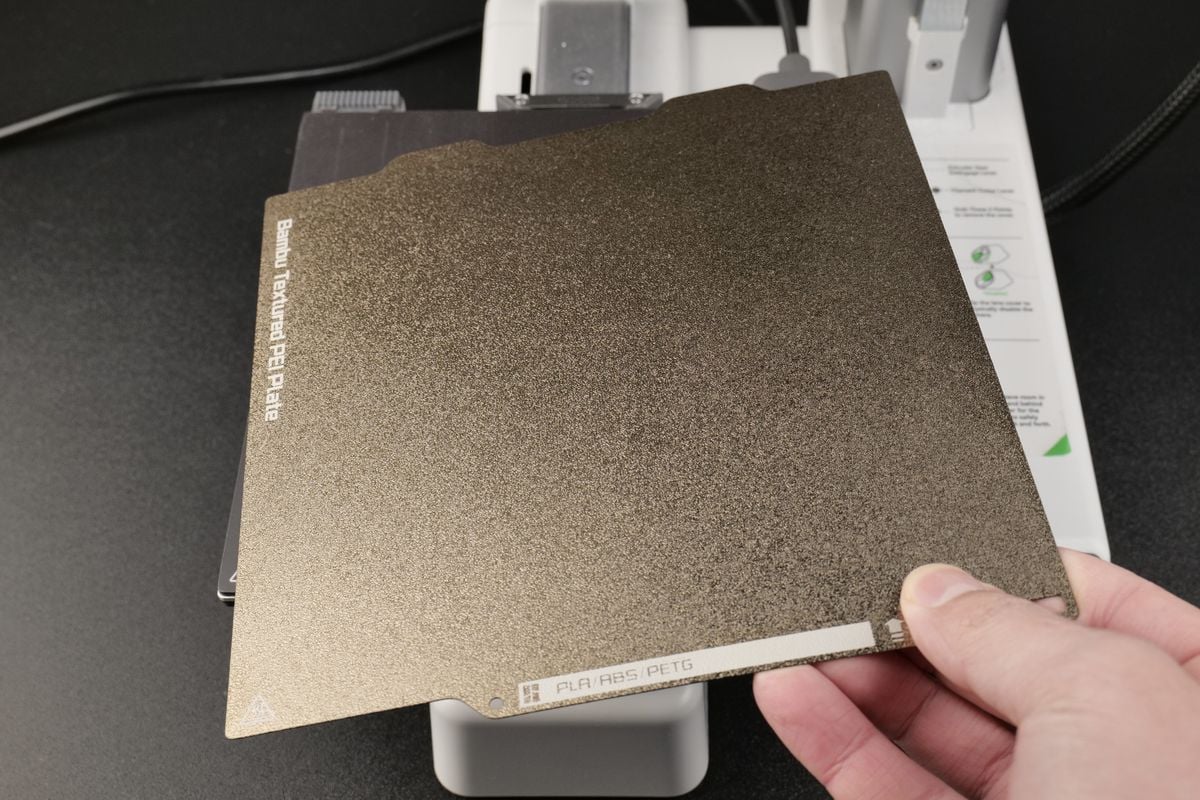

¶ 1. Remove the Textured PEI Plate

First, remove the Textured PEI sheet from the heatbed.

¶ 2. Remove the heatbed screws

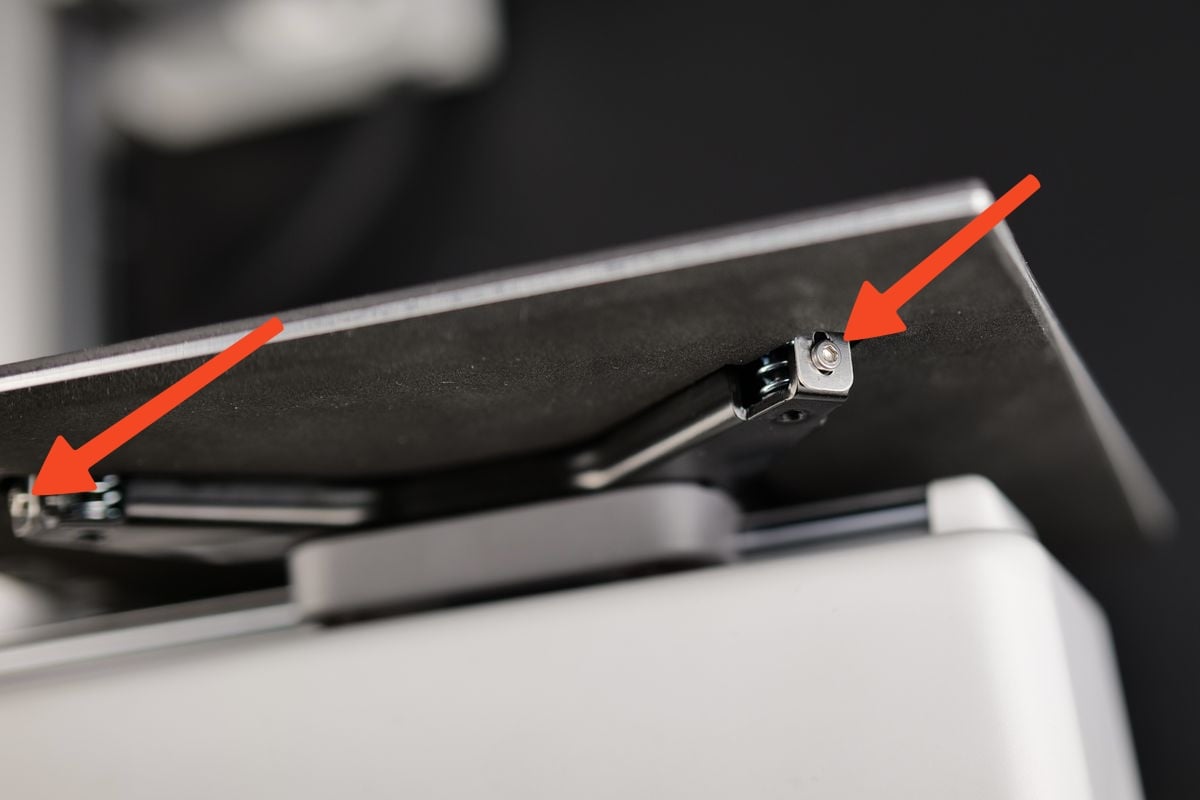

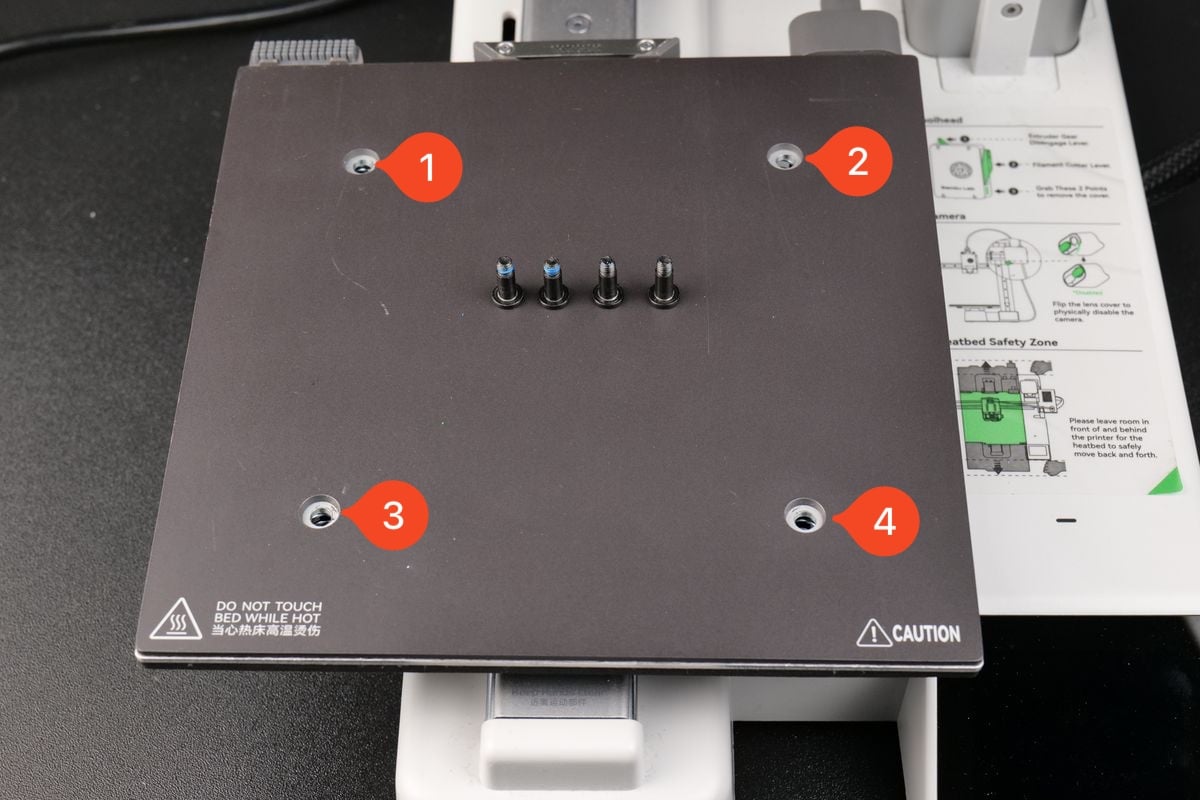

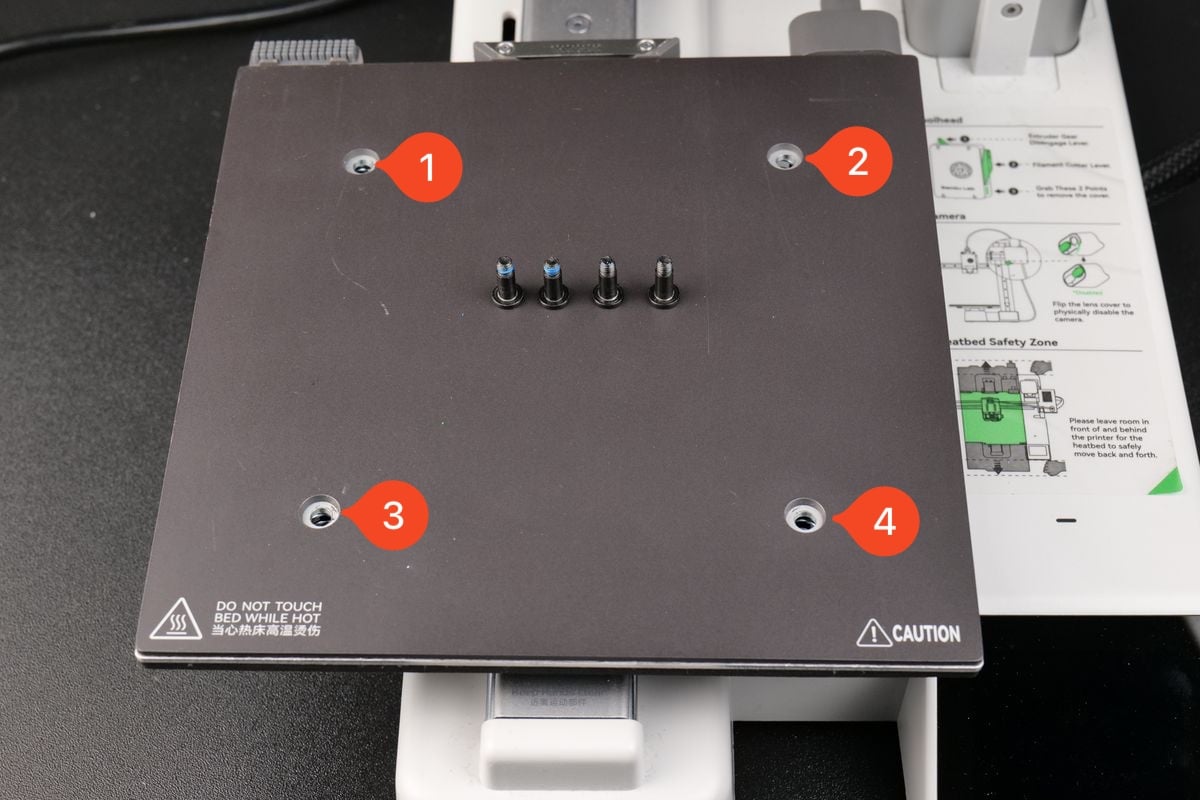

Start by removing the three tension screws of the heatbed.

Please note that there is no screw on the top right side of the heatbed

With the tension screws removed, you can remove all four heatbed screws.

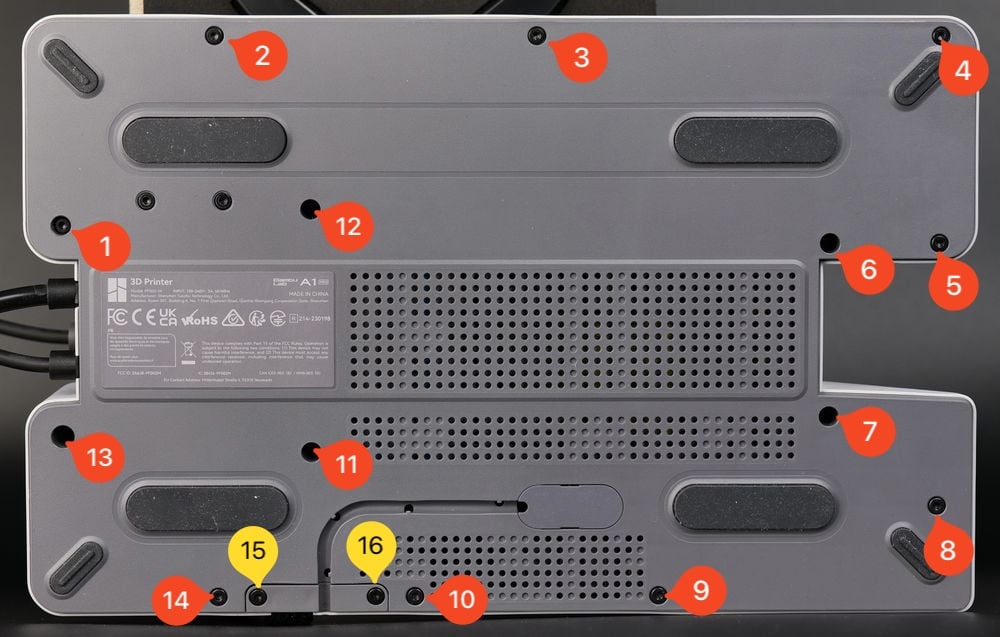

¶ 3. Remove the printer's bottom housing cover

Place the printer on its side, with the Z axis pillar facing the table.

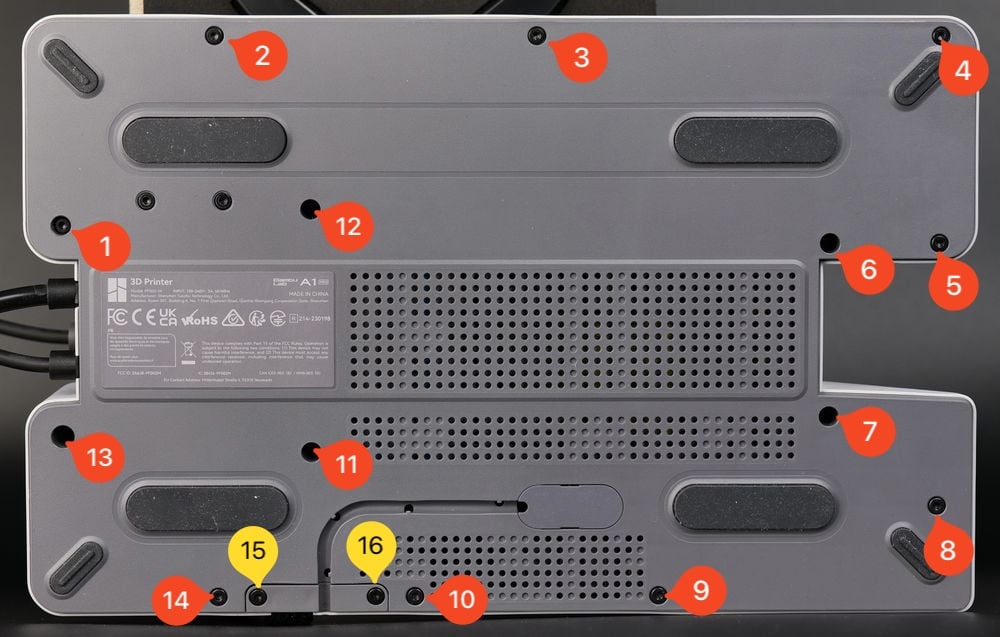

Then, remove the 16 screws holding the bottom cover in place, to access the MC board fan.

Please note that screws 15 and 16 are different, so keep track of them for when you will re-assemble the bottom cover.

After removing the screws, gently pry out the plastic bottom cover.

You can start from the top right side, and gently work your way around the printer until the cover gets loose.

¶ 4. Remove the plastic wire cover

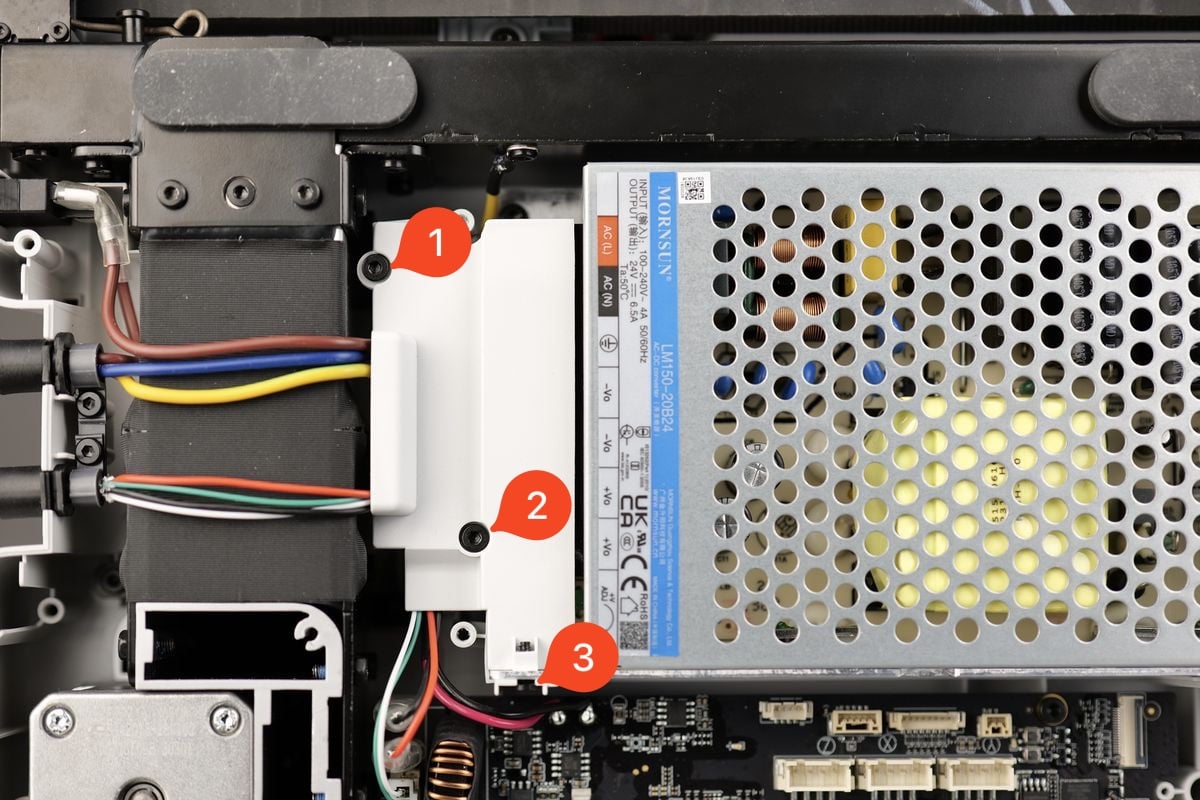

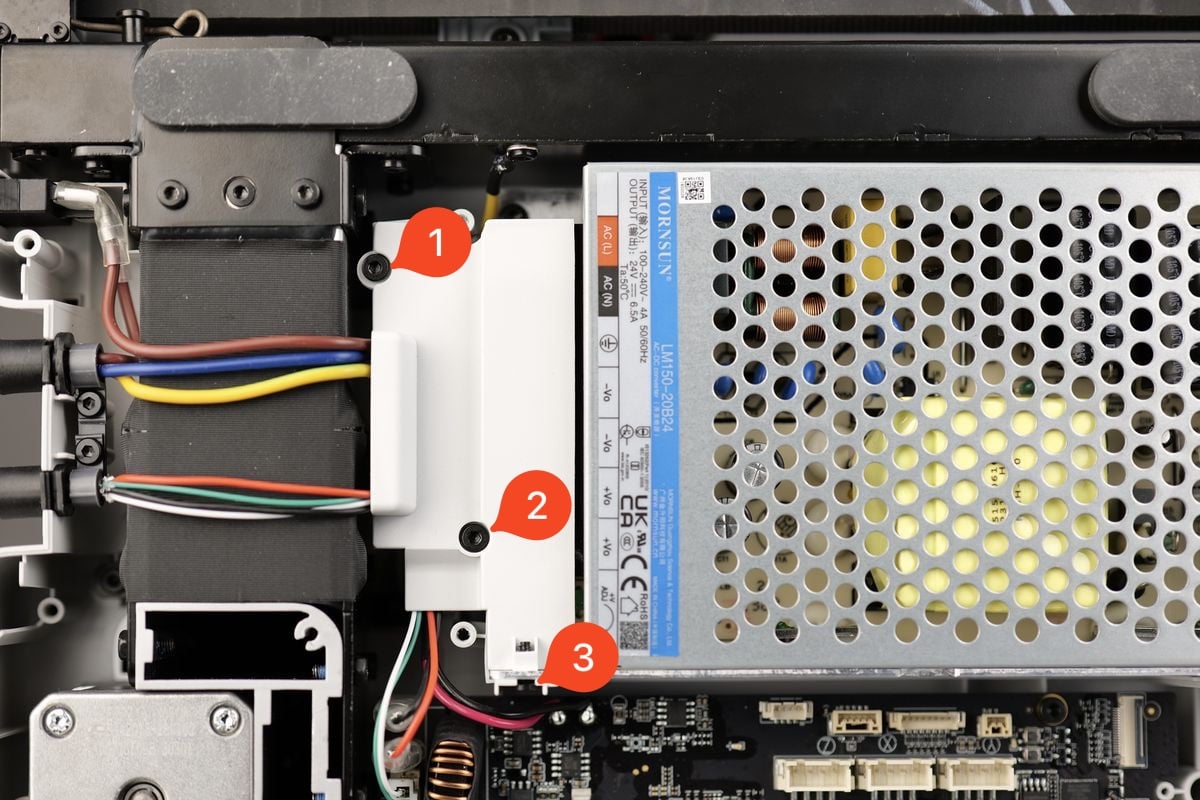

Carefully remove the three screws holding the plastic wire cover in place to access the power terminals of the Power Supply.

Please note that screw nr. 3 is on the side.

¶ 5. Disconnect the Heatbed wires

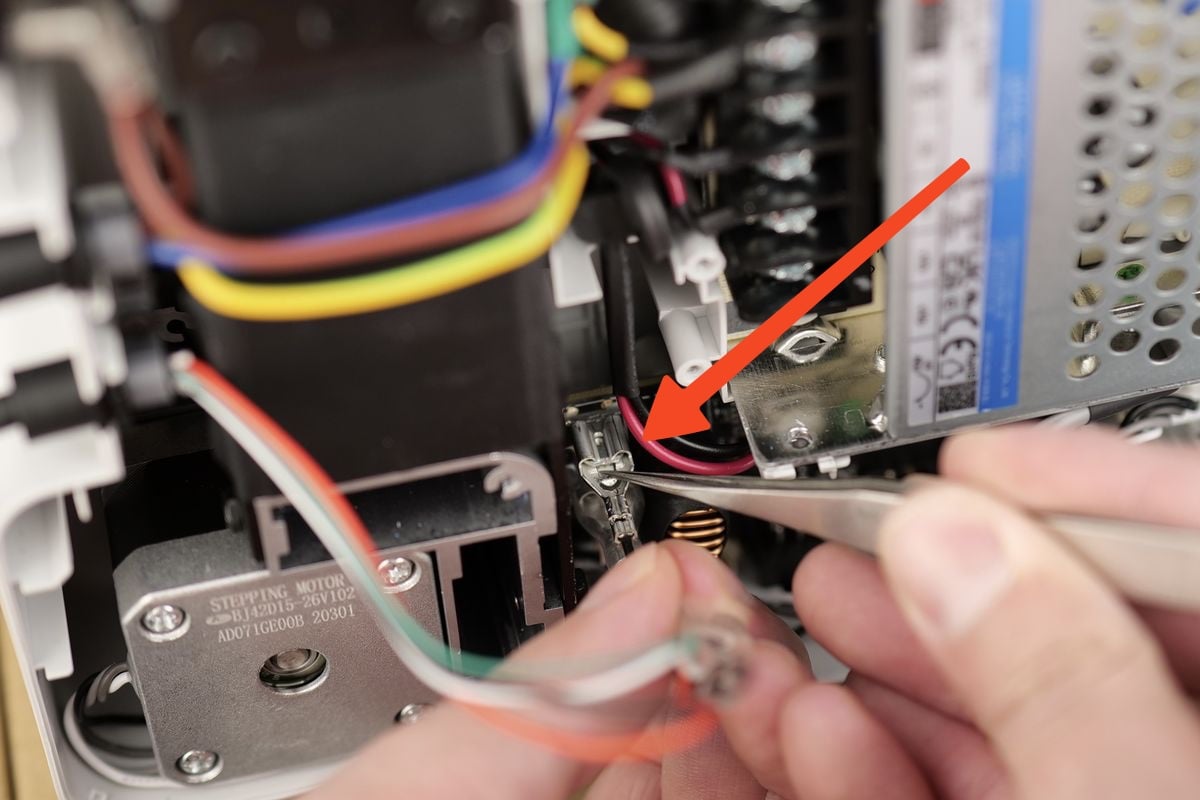

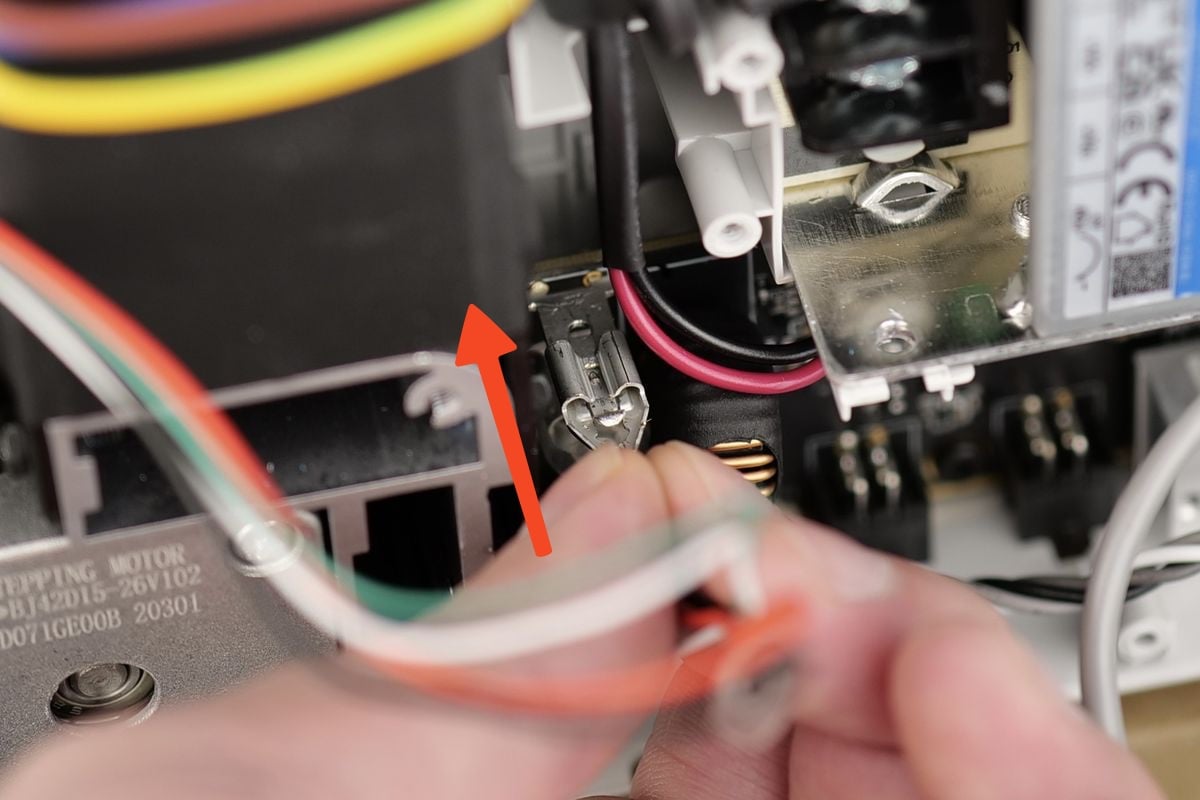

You can now remove the heatbed cables.

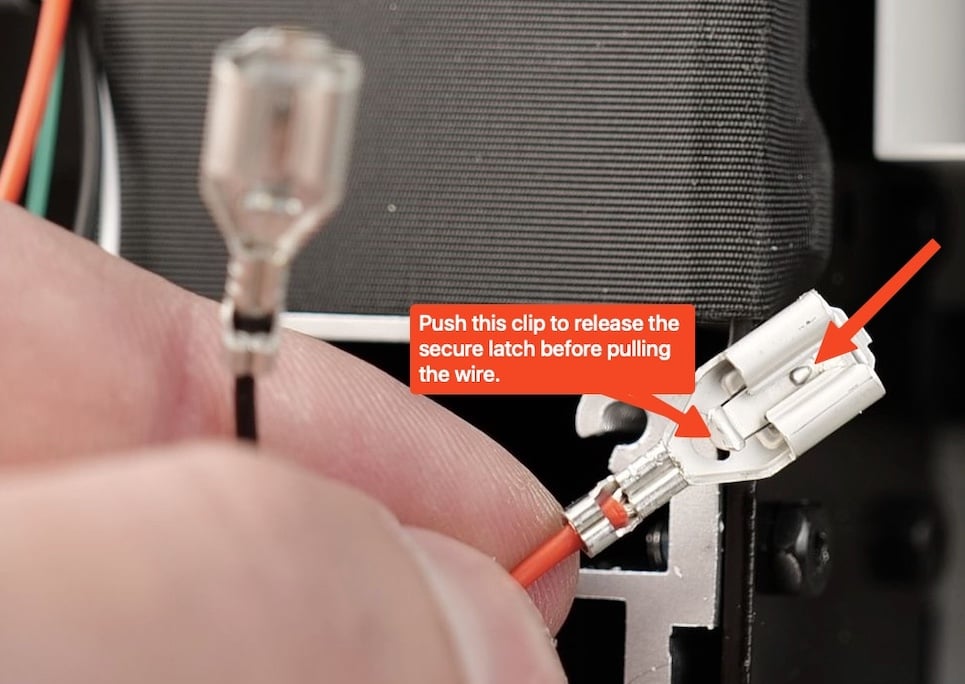

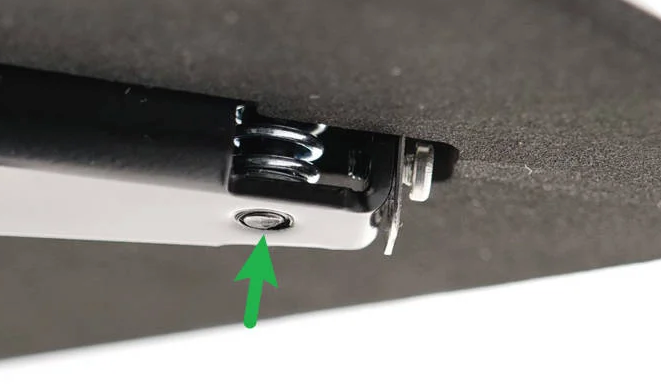

The connectors have a secure latch to hold them well-connected, so you will need to push on the small metallic clip when pulling the wires.

This picture shows the connector in more detail

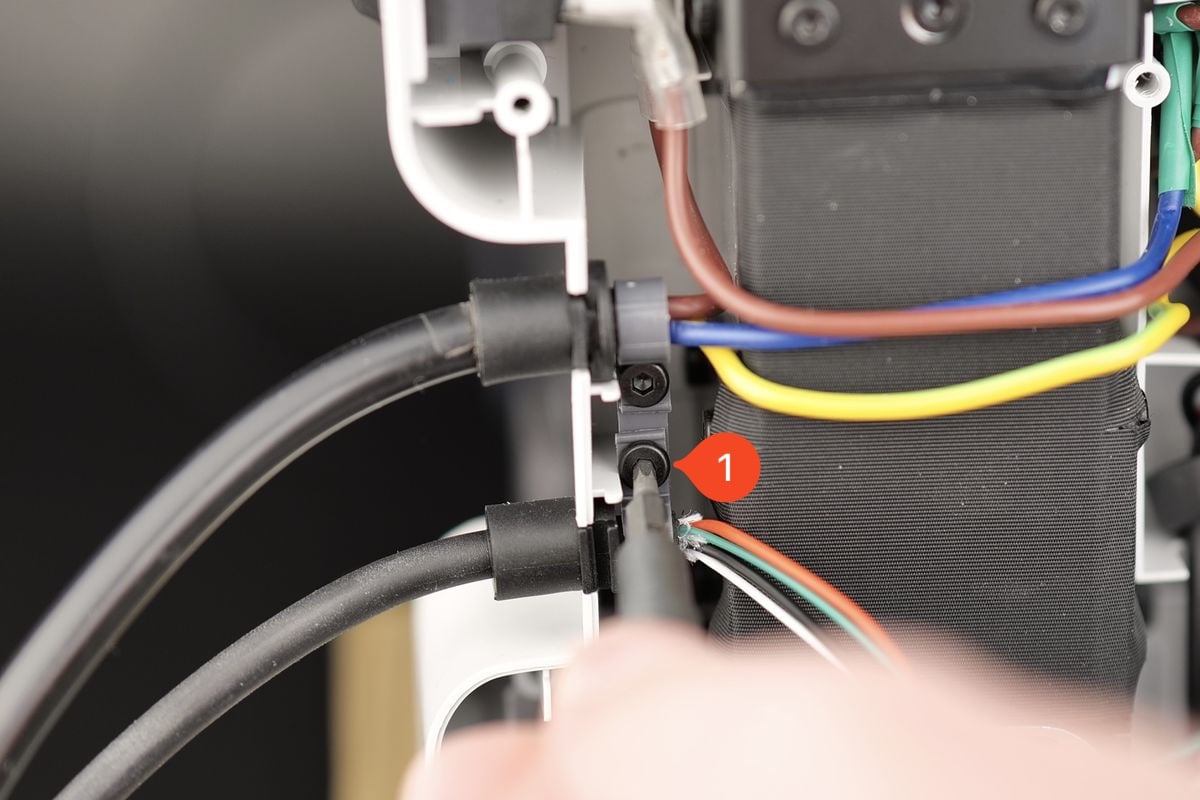

¶ 6. Remove the heatbed cable from the printer

The heatbed cable can now be released from the printer. Remove the screw holding the bracket in place and remove the cable.

The heatbed is now removed.

¶ Steps to install the new Heatbed

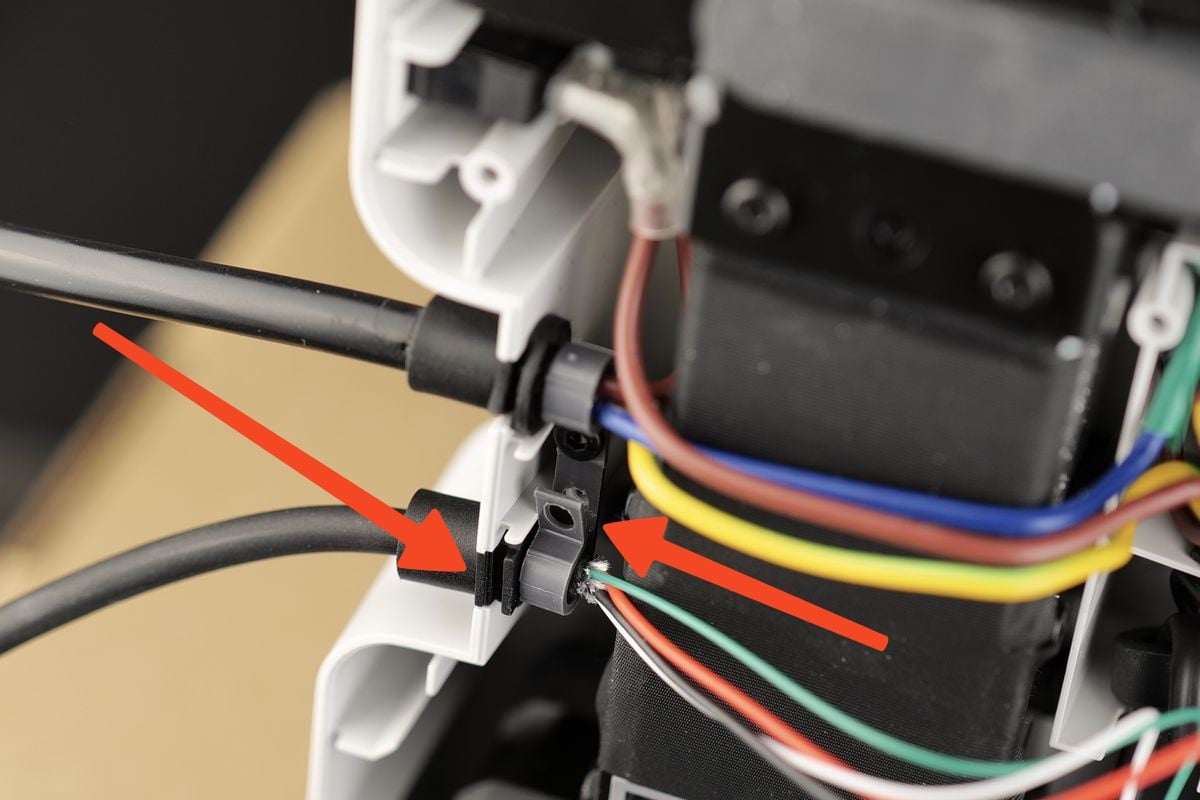

¶ 1. Attach the Heatbed cable to the printer

Carefully route the cable on the bracket, then tighten the screw while making sure not to overtighten it.

Ensure that the flat section of the cable is facing the base of the printer as shown in the image.

¶ 2. Re-connect the heatbed wires

Re-connect the thermistor cable, then carefully install the red and black wires to the Mainboard.

The Black wire is on top, while the Red wire is on the bottom.

Don't forget to push the rubber insulation over the heatbed wire connectors

¶ 3. Install the screws holding the plastic wire cover in place.

Arrange the wires coming from the heatbed cable and power cable as shown in the image, then re-attach the plastic cover back to the printer using the three screws

These screws will be threaded inside plastic standoffs. Avoid over-tightening them as you can damage the plastic threads.

¶ 4. Perform some wire management

Before putting the bottom cover back in place, ensure that the MC board wires are routed correctly, so they do not interfere with the MC board fan, as shown in the image below.

¶ 5. Install the back cover

You can now proceed with installing the bottom cover back to the printer.

Start by tightening screws 15 and 16 to ensure the side wire loom sits correctly.

Then, proceed with installing the other remaining screws, while ensuring you do not over-tighten them.

¶ 6. Install the heatbed and screws

Complete the installation by installing the headbed back in its position, then install the four heatbed screws.

Ensure that the heatbed cable doesn't have any twist in it before installing the screws, to avoid needing to disassemble it again

Tighten the screws until they are flush with the base of the heatbed carriage, then install the locking screws

¶ Verify the functionality

To ensure everything works as expected, turn on the printer and ensure the heatbed temperature is displayed, and the heating works as expected

This confirms the installation was correct.

¶ Calibration step after the operation

Follow the A1 mini Bed Tramming Wiki Article to level the bed, then perform a full calibration.

This step is important in ensuring a flat printing surface.

¶ Potential problems and solutions

If you encounter problems during the installation of a new heatbed, please check the potential problems and solutions listed below:

¶ The heatbed temperature is not reported / shows 0℃

Check the heatbed cables shown in Step 2 Re-connect the heatbed wires, and confirm the Green and White wire connector is fully inserted in the Motherboard.

¶ The heatbed is not heating

Check the heatbed cables shown in Step 2 Re-connect the heatbed wires, and confirm the Red and Black wires are fully inserted in the Motherboard.

¶ The first layer is inconsistent / Problems with first layer

Confirm that the Hotend Heating Assembly screws are tight, and bed leveling is enabled before starting the print

This Wiki article explains what to check and how to solve the problem

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.