In this guide, we will show how to replace the Hotend Heating Assembly on the A1 mini

¶ When to use?

This guide is intended for use if there is a problem with the Hotend Heating Assembly for your A1 mini

Common issues that may indicate the need for replacement of the A1 mini Hotend Heating Assembly include:

- The Hotend Heating Assembly is wrapped in plastic due to a print failure

- The heater or thermistor is not working anymore

- The hotend metal latch is not working anymore

- Recommended by Bambu Lab Technical Support

¶ Tools and materials needed

- Bambu Lab Hotend Heating Assembly for A1

- H1.5 & 2.0 Allen key

- Flat tweezers

- 25 minutes of your time

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's electronics, ensuring safe and effective maintenance. For any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide the assistance you need.

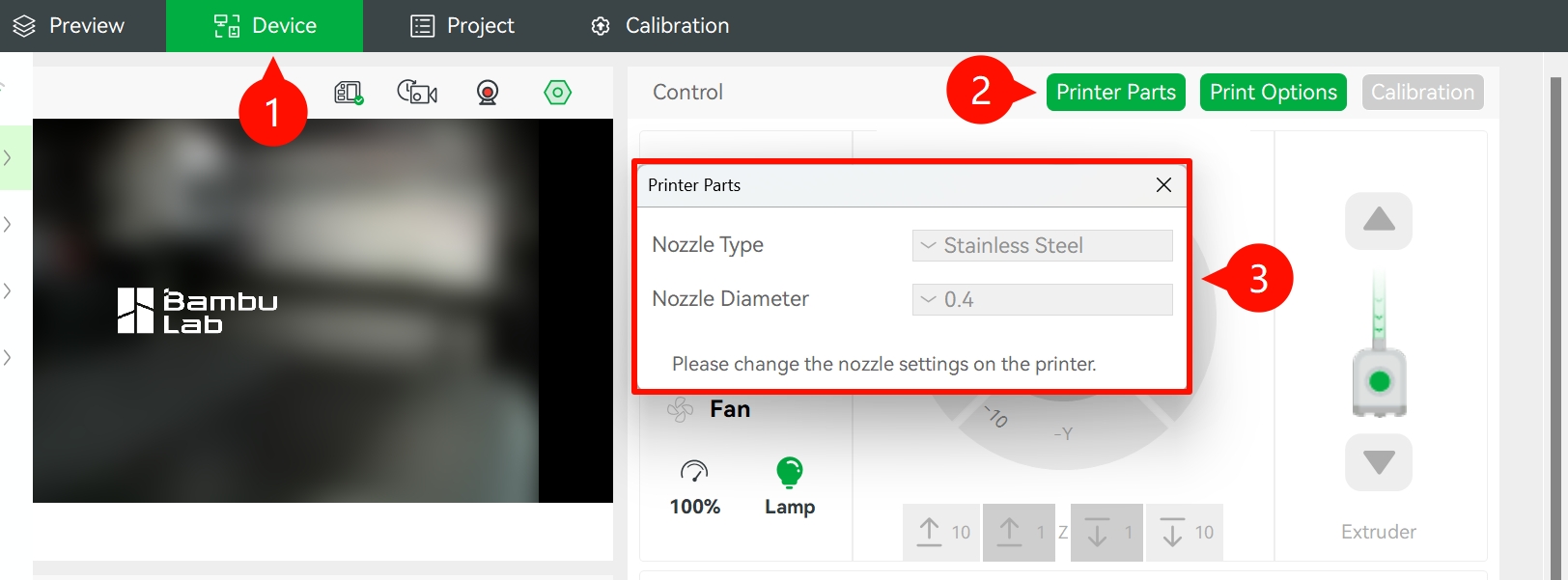

¶ Bambu Studio Software Settings Notice

In the latest version of Bambu Studio (Bambu_Studio_win_public-v02.01.01.52-20250616155614), the option to modify nozzle information under the "Printer Parts" section has been disabled (as shown in the screenshot below) and is now for display purposes only.

Some users may mistakenly consider this a software or hardware issue due to changes from previous versions. However, this adjustment is intended to enhance operational consistency and user safety. Nozzle changes must be performed directly on the printer. Allowing modifications via the software interface could mislead new users into thinking that a physical nozzle replacement is unnecessary before printing.

Note: If you have replaced the nozzle with one of a different specification, please remember to sync the nozzle information on the device.

¶ Video Guide

¶ Remove the Old Hotend Heating Assembly

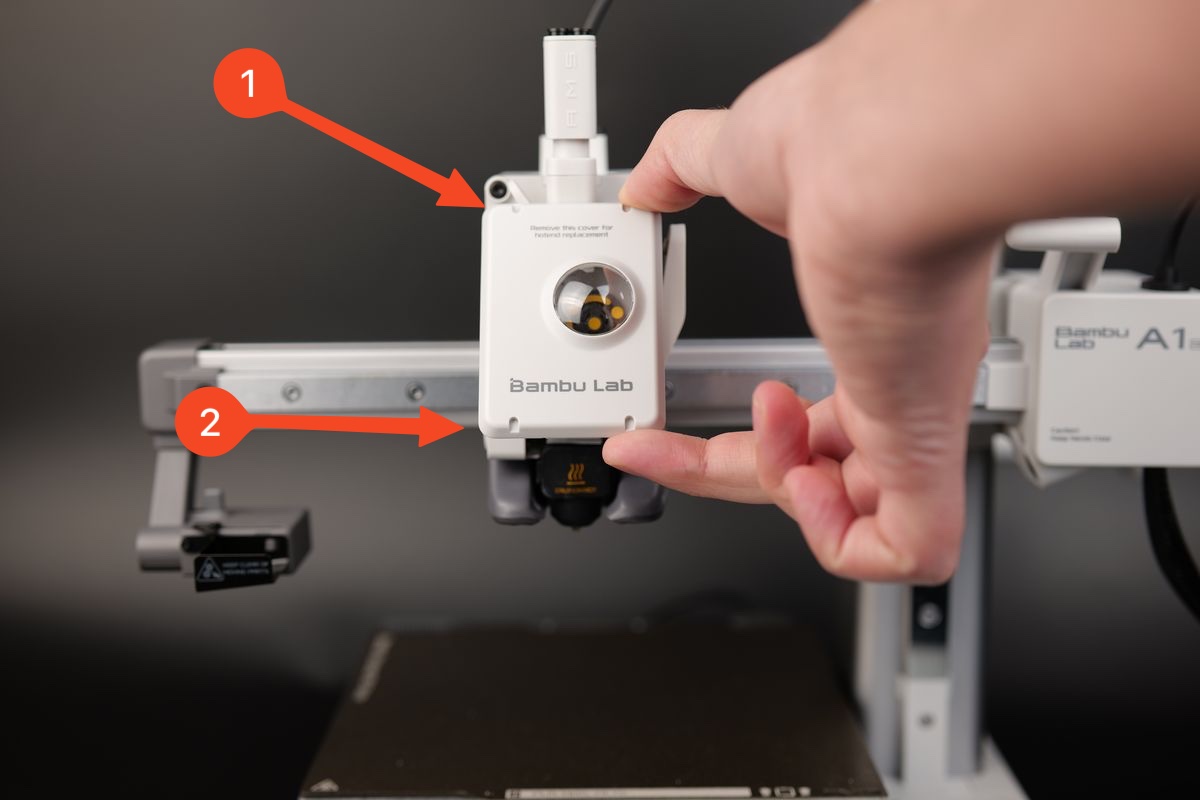

¶ 1. Remove the toolhead front cover

Grab the base of the front cover and gently pull towards you.

The clips holding the cover in place will be released, allowing you to remove the front cover.

|

|

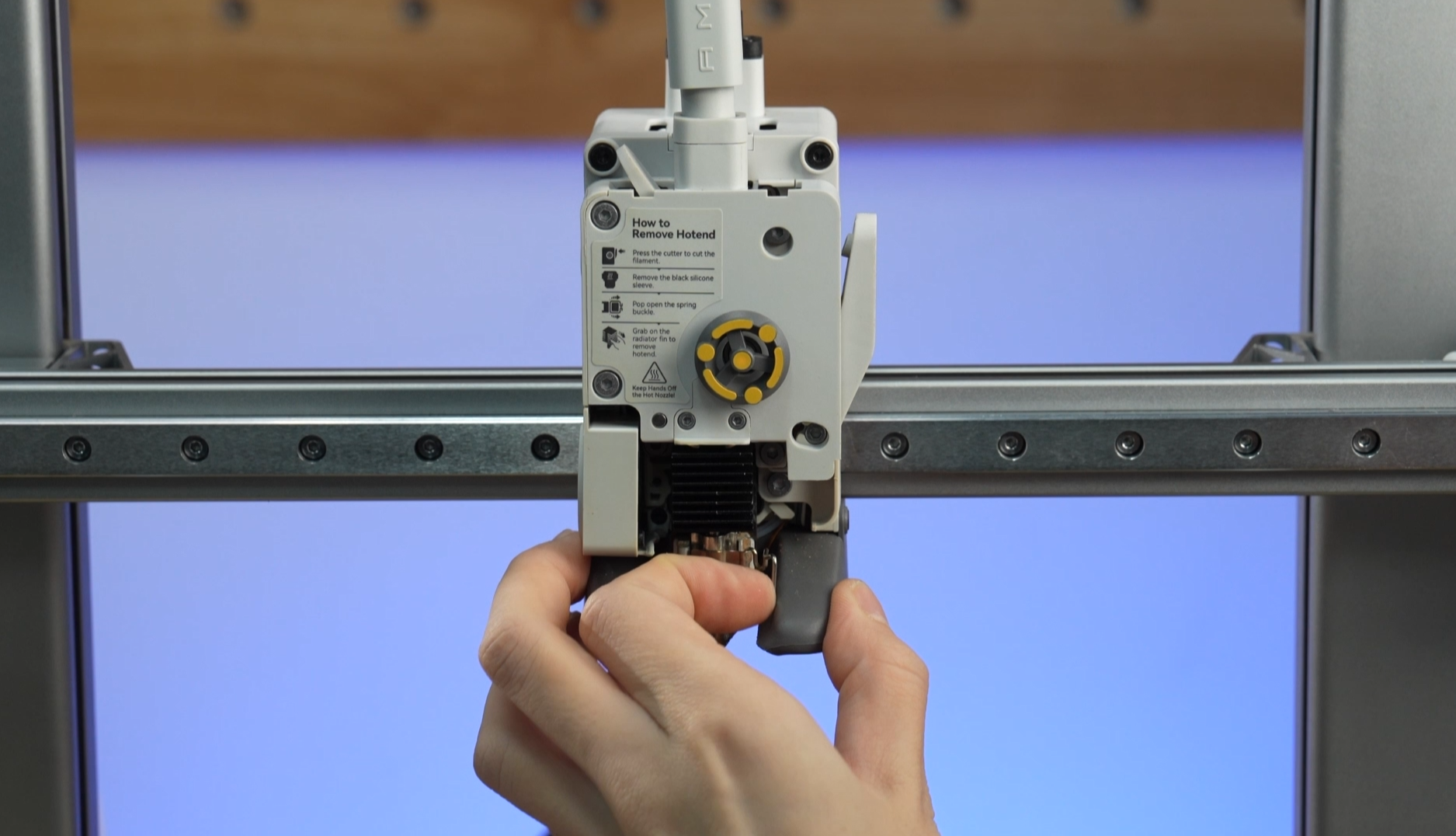

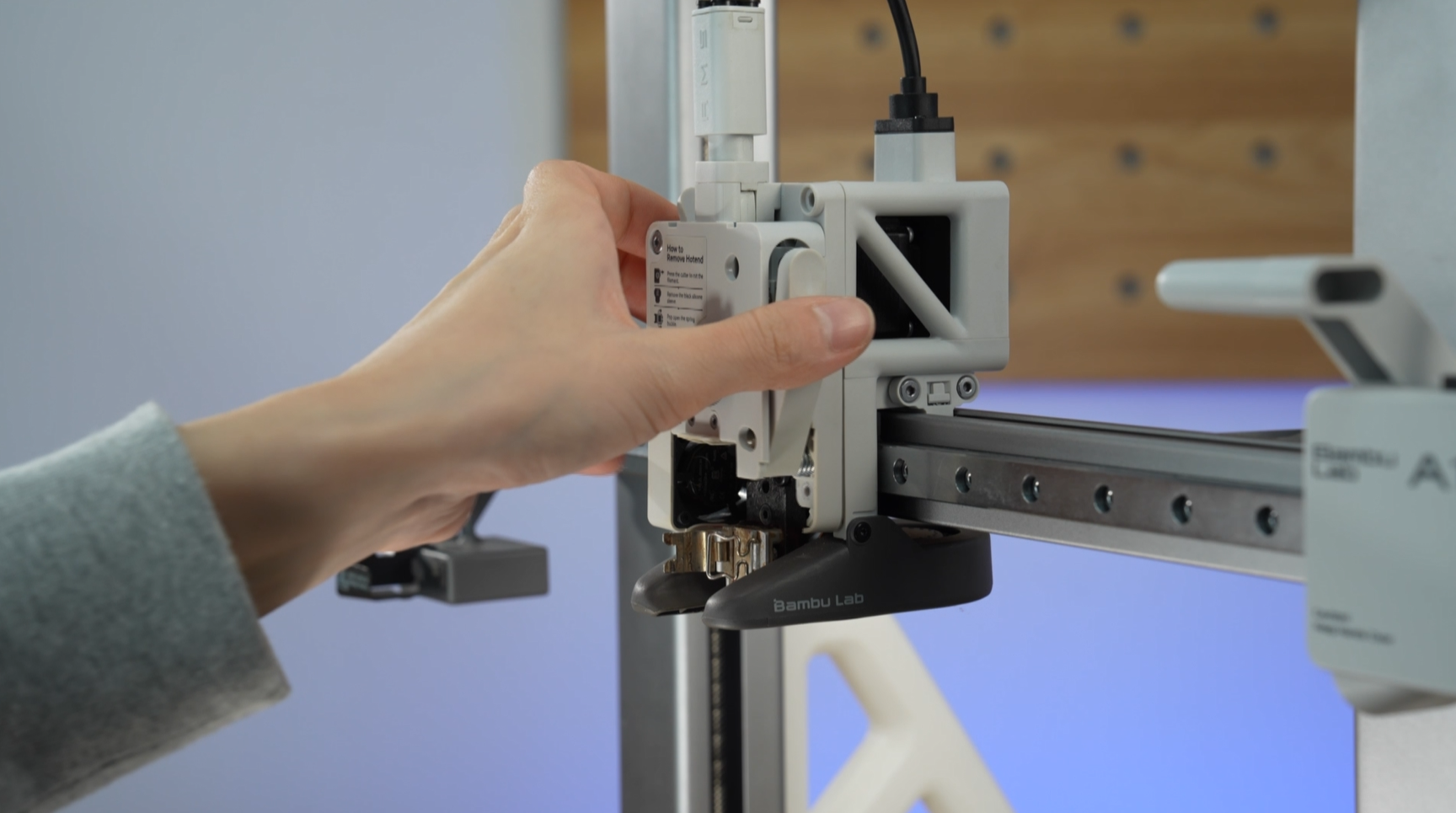

¶ 2. Remove the hotend

Remove the silicone sock for hotend by gently pulling it towards you, and open the buckle, then remove the hotend.

All the steps are labeled on the extruder sticker.

|

|

|

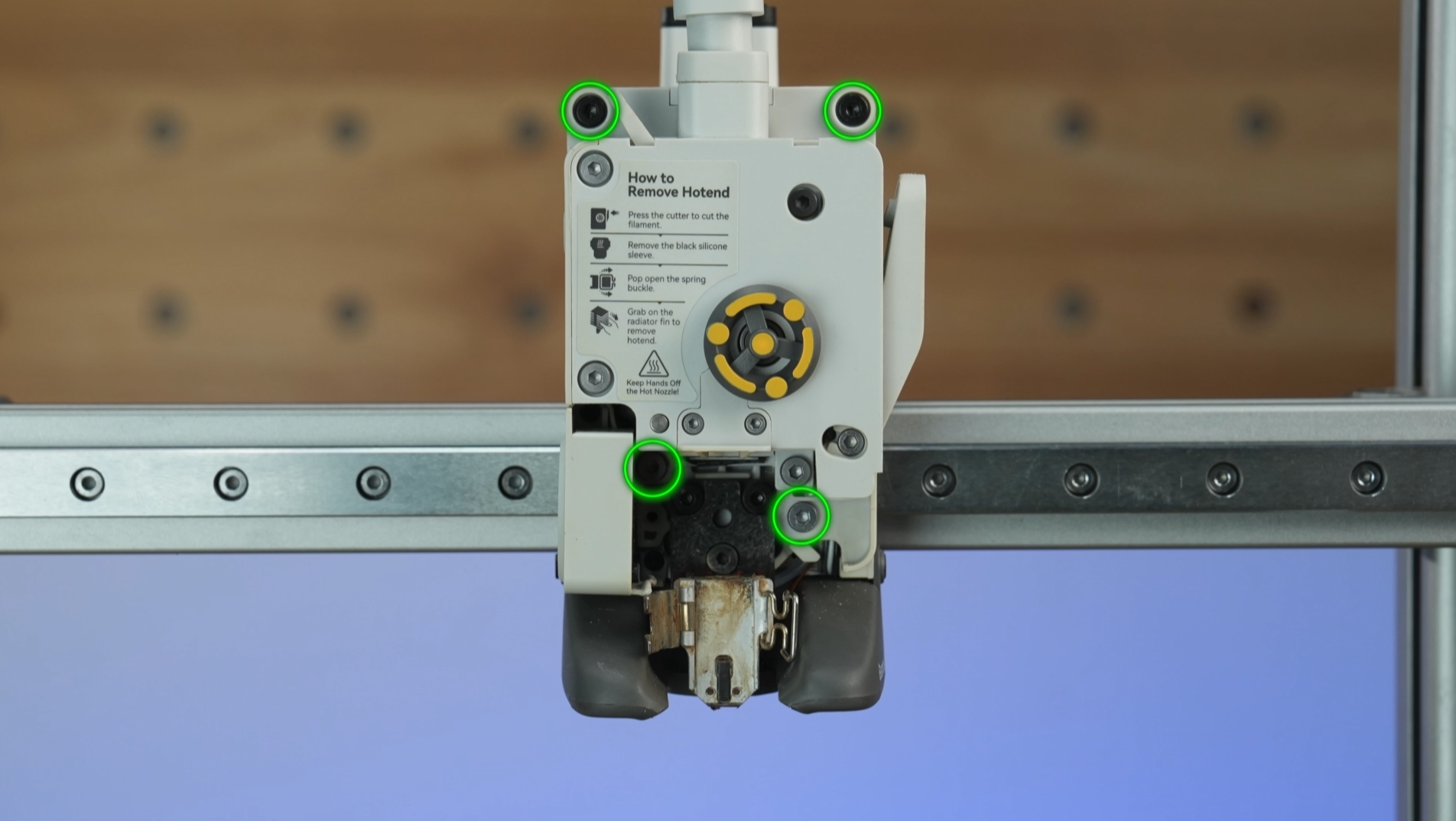

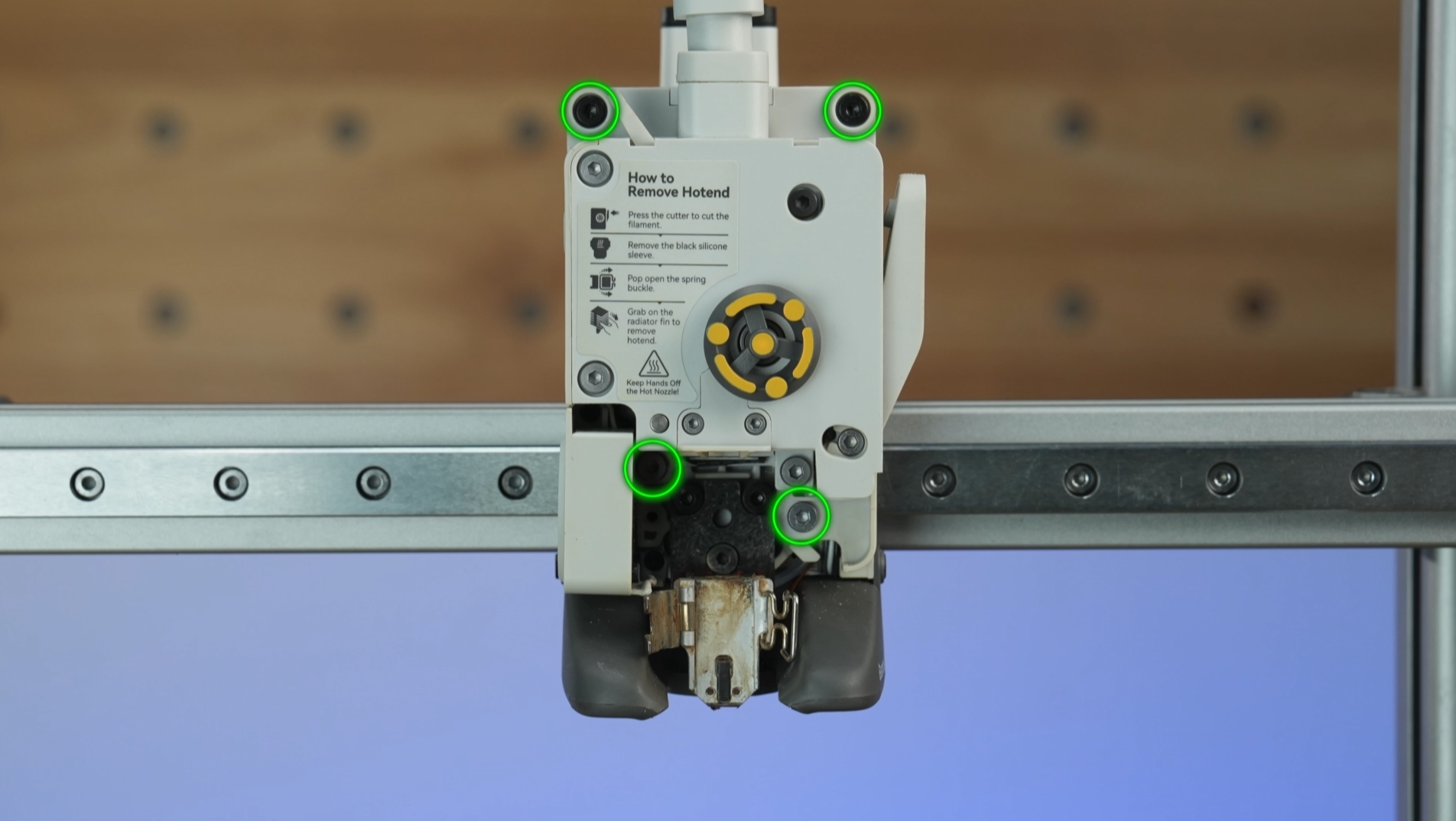

¶ 3. Remove the extruder screws

Remove the screws as shown in the picture, and gently pull the extruder forward a little.

Note: Do not pull out the extruder with force, as it may easily break the motor wire.

|

|

¶ 4. Remove the toolhead rear housing

Carefully open the toolhead rear housing by pulling on the bottom section as shown below.

|

|

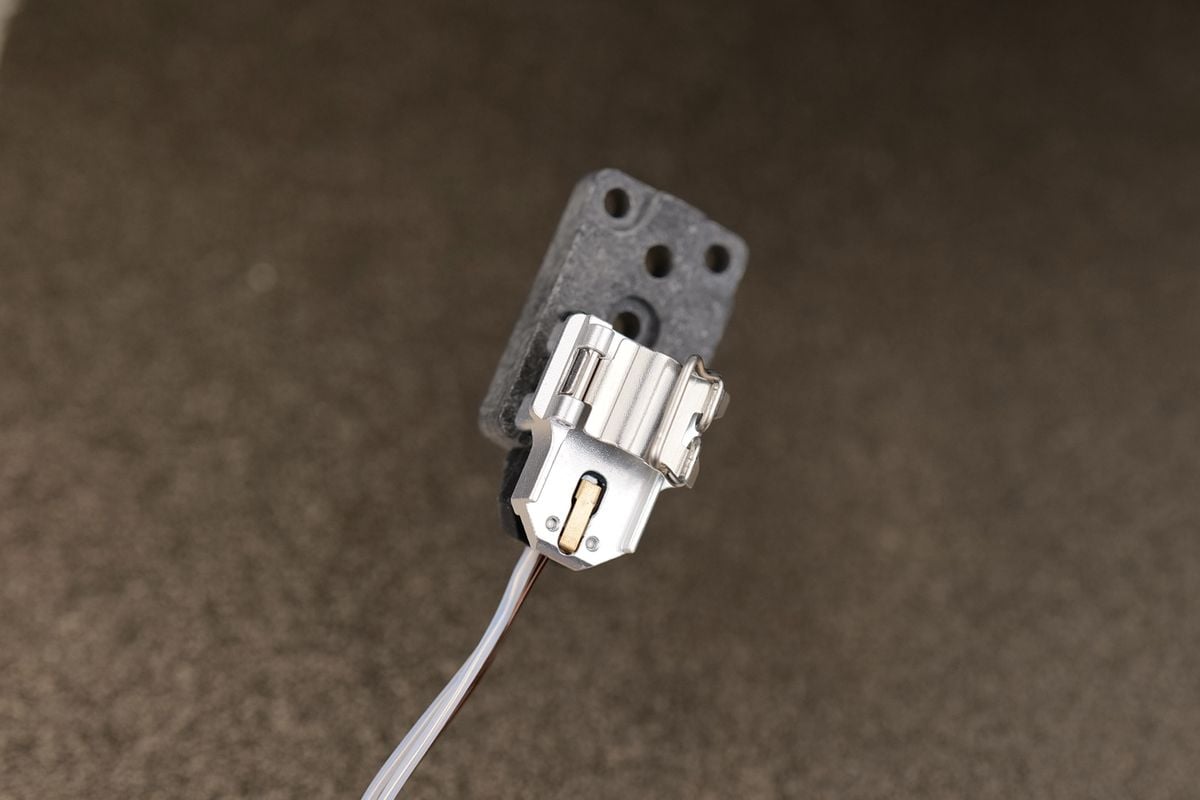

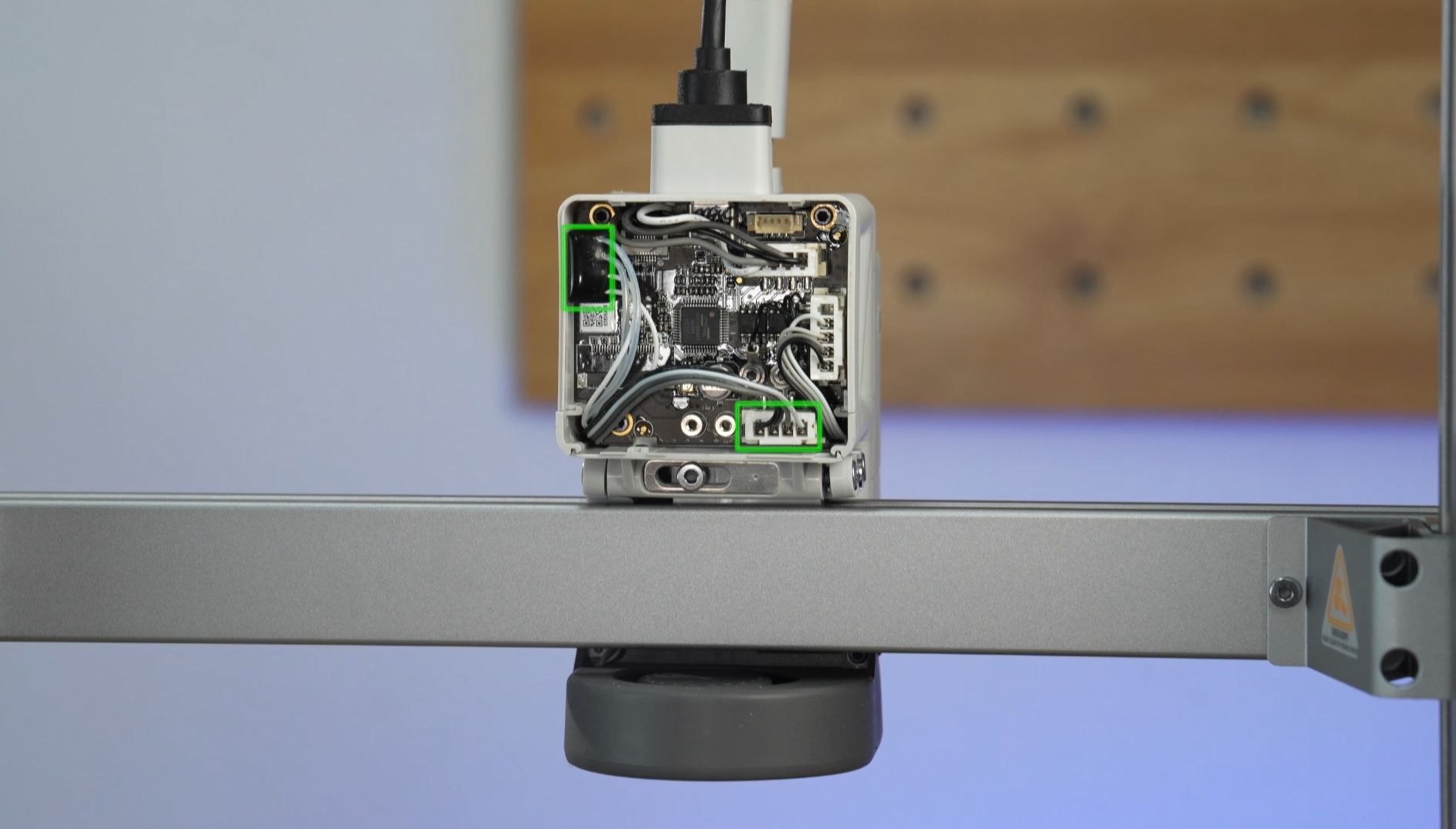

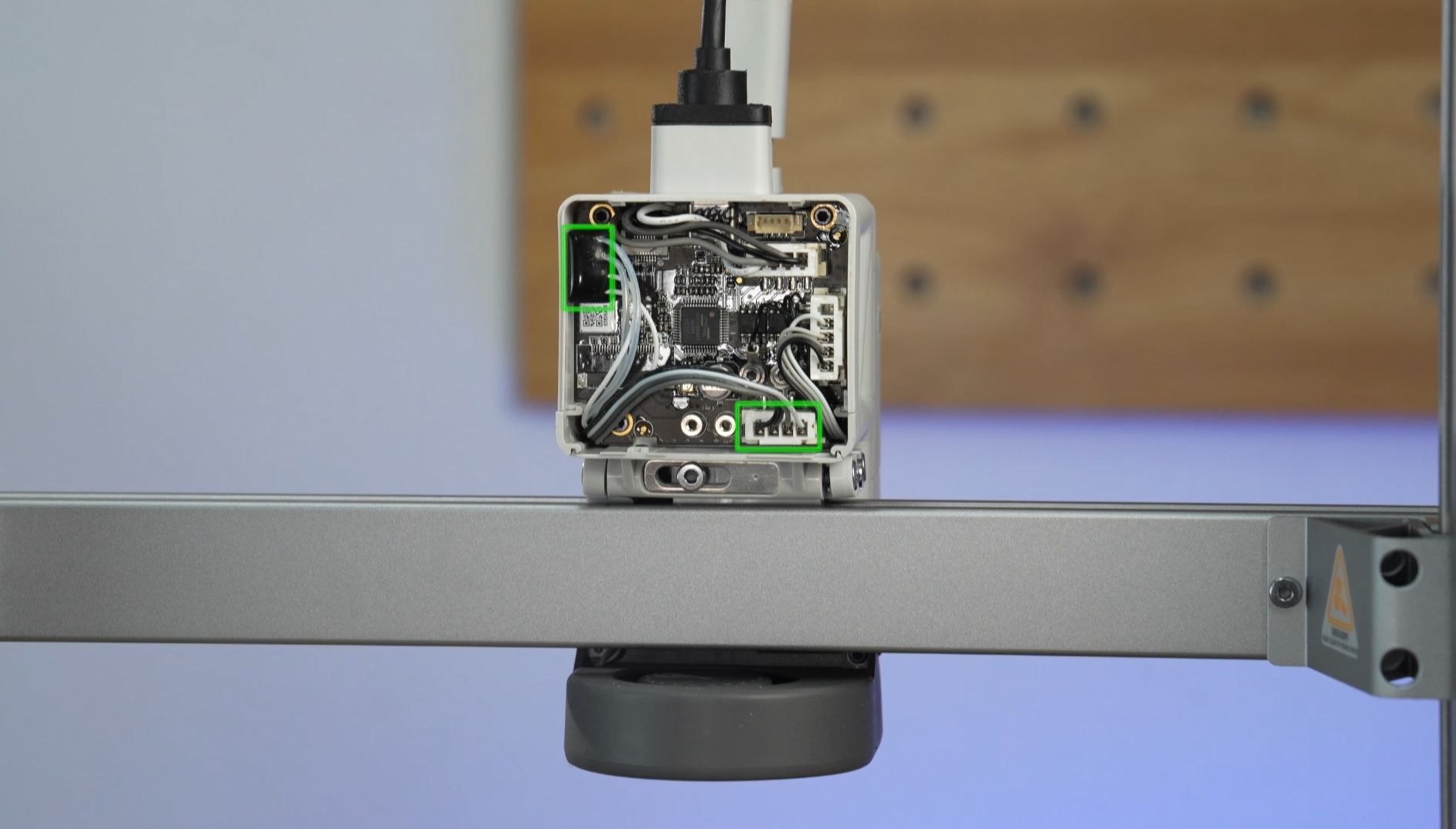

¶ 5. Disconnect the cables

Remove the hotend heating assembly cable and part cooling fan cable attached to the TH Board.

|

|

¶ 6. Remove the right cable cover

Gently push out the right cable cover to remove it.

|

|

|

¶ 7. Remove the cables

Remove the cables carefully from the cable channel.

|

|

¶ 8. Remove the hotend heating assembly

Remove the hotend heating assembly by removing the 3 screws from the hotend heating assembly.

|

|

|

|

¶ Install the New Hotend Heating Assembly

¶ 1. Install the Hotend Heating Assembly

- Install the new hotend heating assembly, aligning the clips and making sure the top of the heating assembly is against the white alignment line on the toolhead.

|

|

- Install the 3 screws.

Note: The specification of the 3 screws fixing the hotend heating assembly is M3*10.

¶ 2. Install the right cable cover

- Push the cable into the clip, using tweezers to help.

|

|

- Pass the cables through the right cable channel, and push the cable cover back.

|

|

Note: Be extremely careful when routing cables.

¶ 3. Install the extruder

Put the extruder back in place and install the 4 screws.

|

|

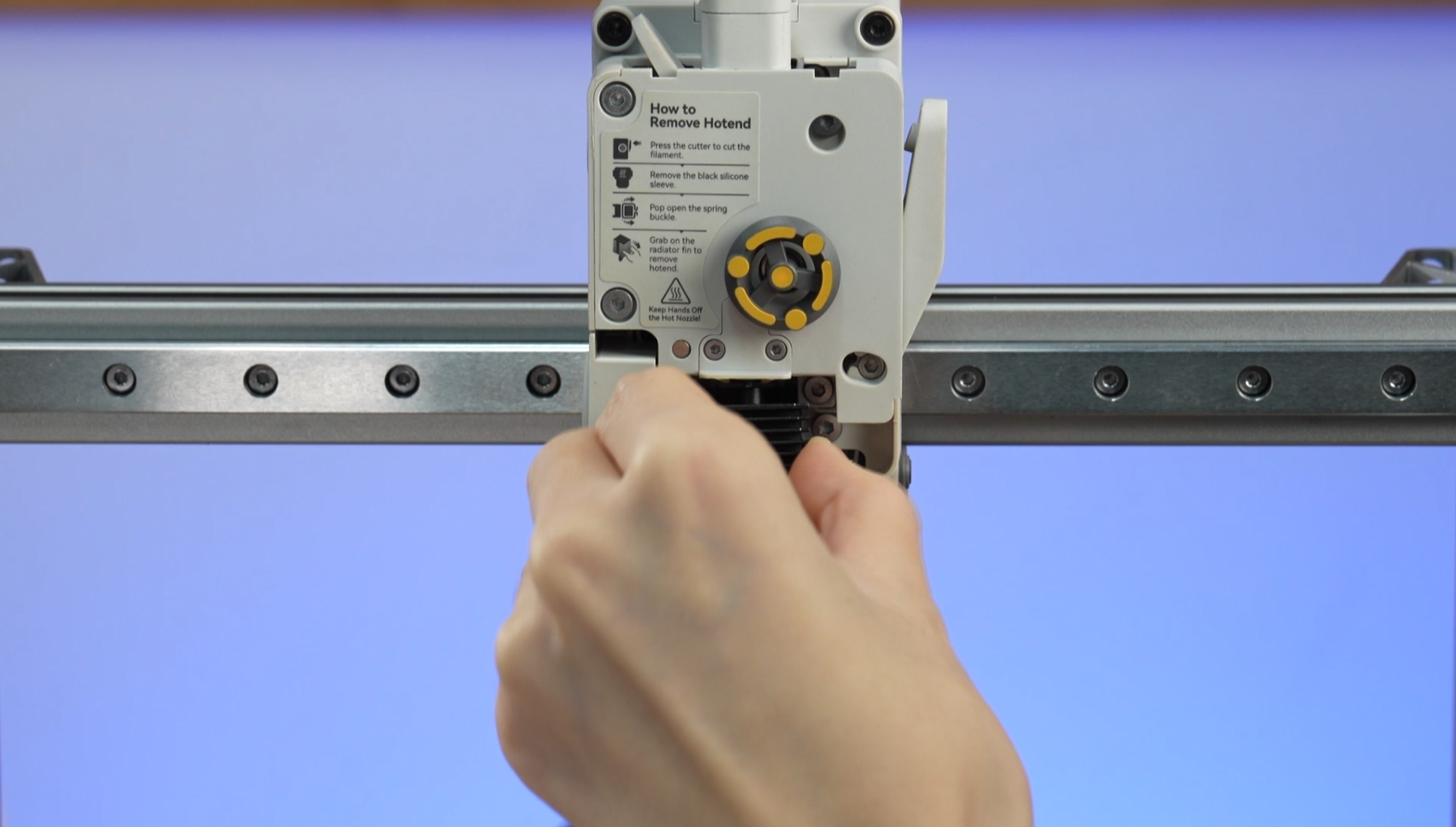

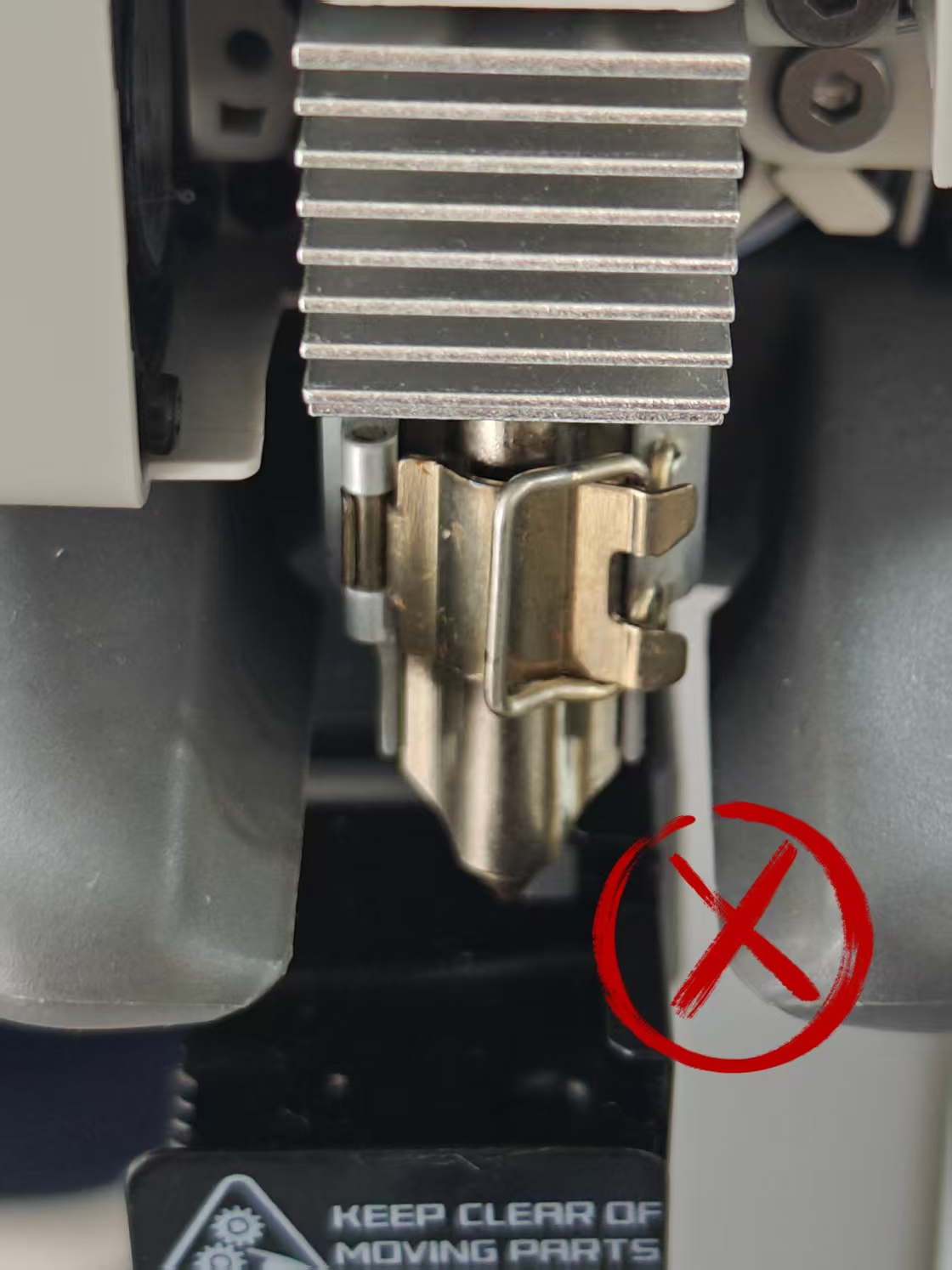

¶ 4. Install the hotend

Follow the guidance available on the extruder sticker to re-attach the hotend to the toolhead

Then, lock it in place using the clip and install the silicone sock.

|

|

|

|

| Fasten the heating assembly correctly | Fasten the heating assembly incorrectly |

|

|

¶ 5. Install the toolhead front cover

Simply attach the toolhead front cover on the top of the toolhead by aligning the clips, then gently push on the bottom side. You will hear the clips when the installation is complete.

¶ 6. Re-connect the cables

Re-connect the hotend heating assembly cable and part cooling fan cable as shown below.

¶ 7. Install the toolhead rear housing

Simply align the two brackets on the rear housing towards the top, then push it until you hear a few clicks.

|

|

¶ Sync Nozzle Information on the Device

If you have replaced the hotend with one of a different diameter or material, please refer to the animation below to update the nozzle information on the screen:

¶ Verify the functionality of the A1 hotend heating assembly

To ensure everything runs smoothly, set the hot end temperature to 100°C. If successful, the screen will show the temperature.

¶ Calibration step after the operation

We recommend conducting a full calibration of the printer after this operation.

Additionally, it's strongly advised to wash the PEI textured plate before use, as it may have been contaminated during this process.

¶ Potential problems and solutions

If you encounter problems during the installation of a new Hotend Heating Assembly, please check the potential problems and solutions listed below:

¶ The hotend temperature is 0℃

Check the Hotend Heating Assembly connector and confirm it is correctly inserted, as shown in Re-connect the cables

It is important to carefully align the connector pins to the TH Board.

If the issue persists, the thermistor wires might have been damaged (white wires)

¶ The hotend cannot be heated

Check the Hotend Heating Assembly connector and confirm it is correctly inserted, as shown in Re-connect the cable

It is important to carefully align the connector pins to the TH Board.

If the issue persists, the heater wires might have been damaged (Translucent wires)

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend reaching out to technical support team before initiating the operation. We will do our best to respond promptly and provide the assistance you need. Click here to open a new ticket in our Support Page.