¶ A1 mini Y-axis & Z-axis assembly

This article provides relevant guidelines and precautions for the disassembly and assembly of the A1 mini Y-axis and Z-axis.

The disassembly and assembly of replaceable accessories involved in this disassembly process can also be handled concerning this article.

¶ Parts List

The following are the after-sales spare part materials that will be involved in this guideline.

| No. | Name | Pic |

| 1 | Z Motor |

|

| 3 |

Z-axis coupler

|

|

| 5 | Y Motor |

|

| 7 | Y-axis Tensioner |

|

| 2 | Z-axis Top Cover |

|

| 4 |

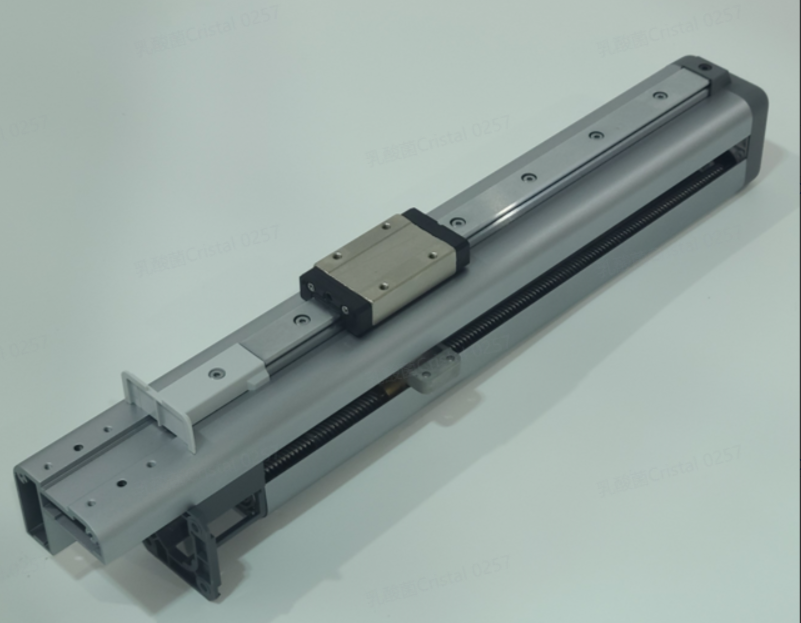

Z-axis Assembly

|

|

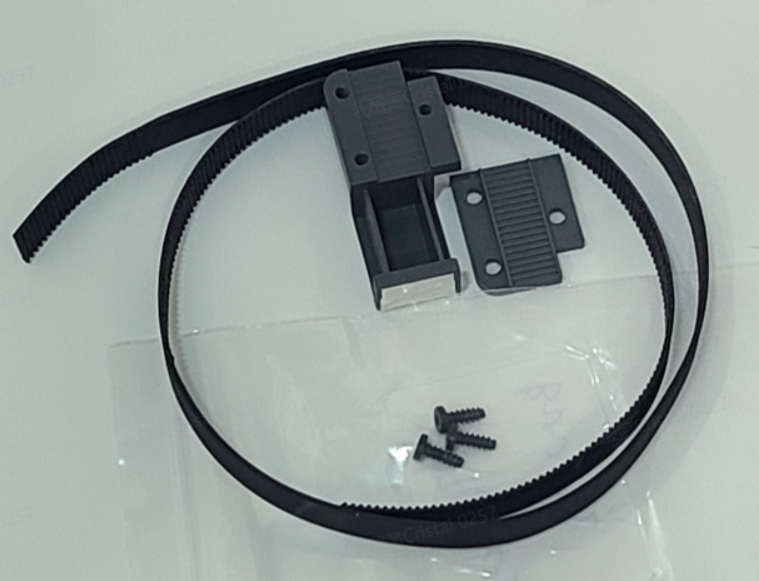

| 6 | Y Belt |

|

¶ Module List

None.

¶ Screw List

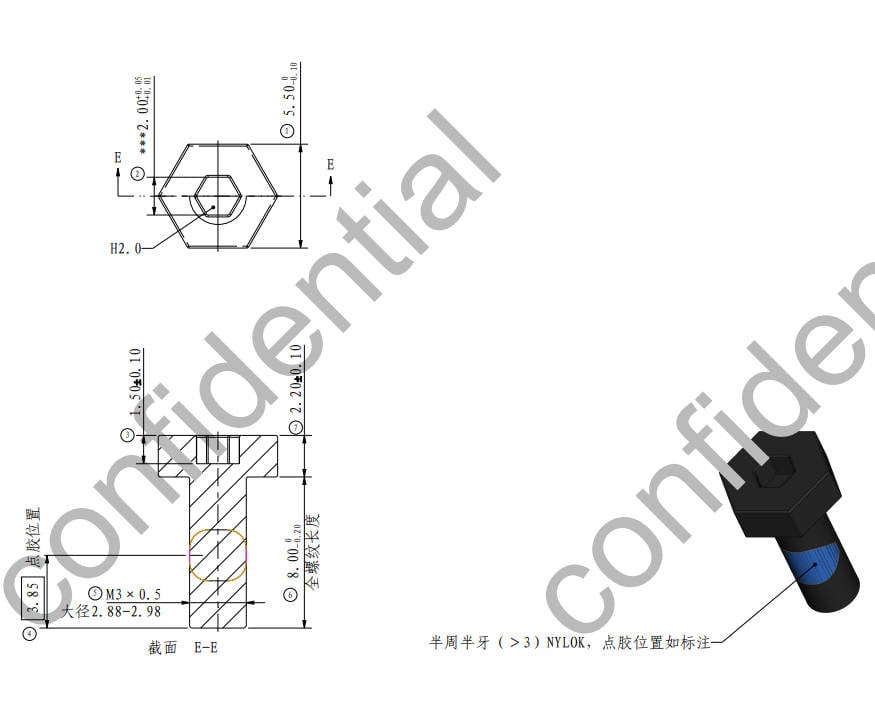

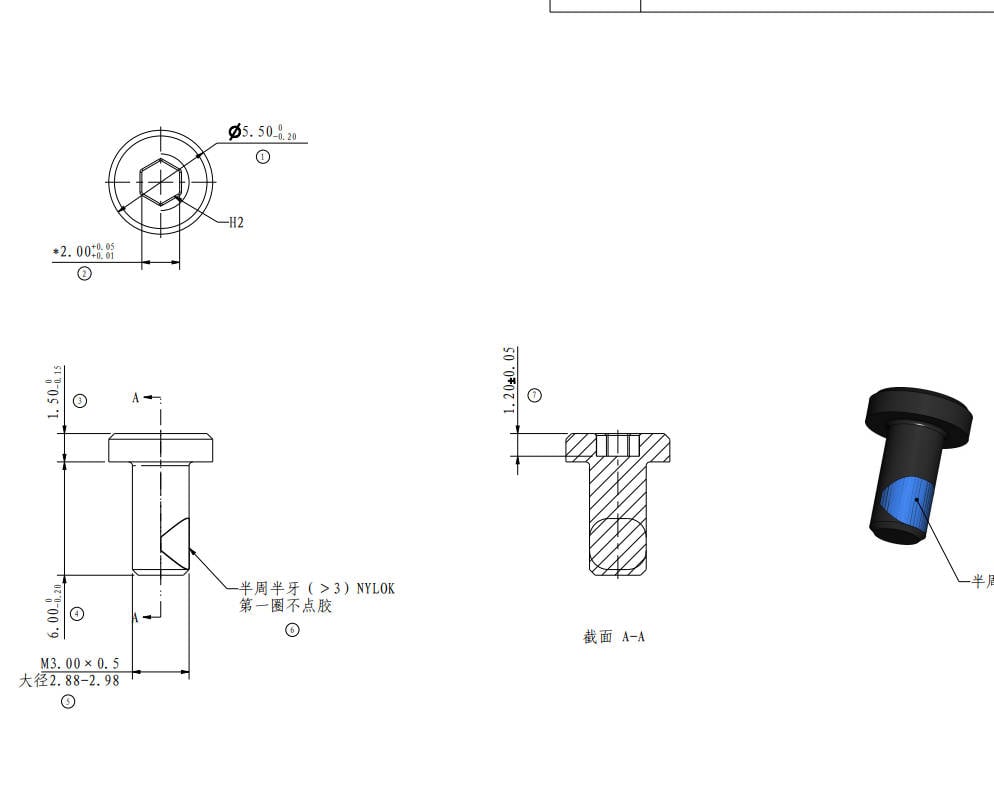

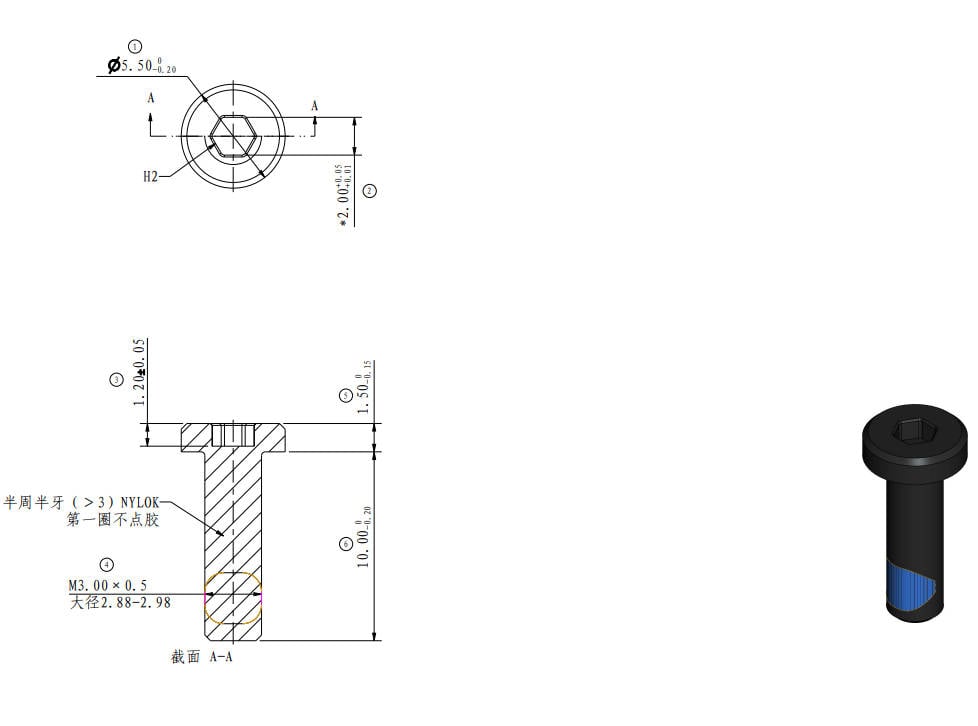

| Model | Position | Drawings | |

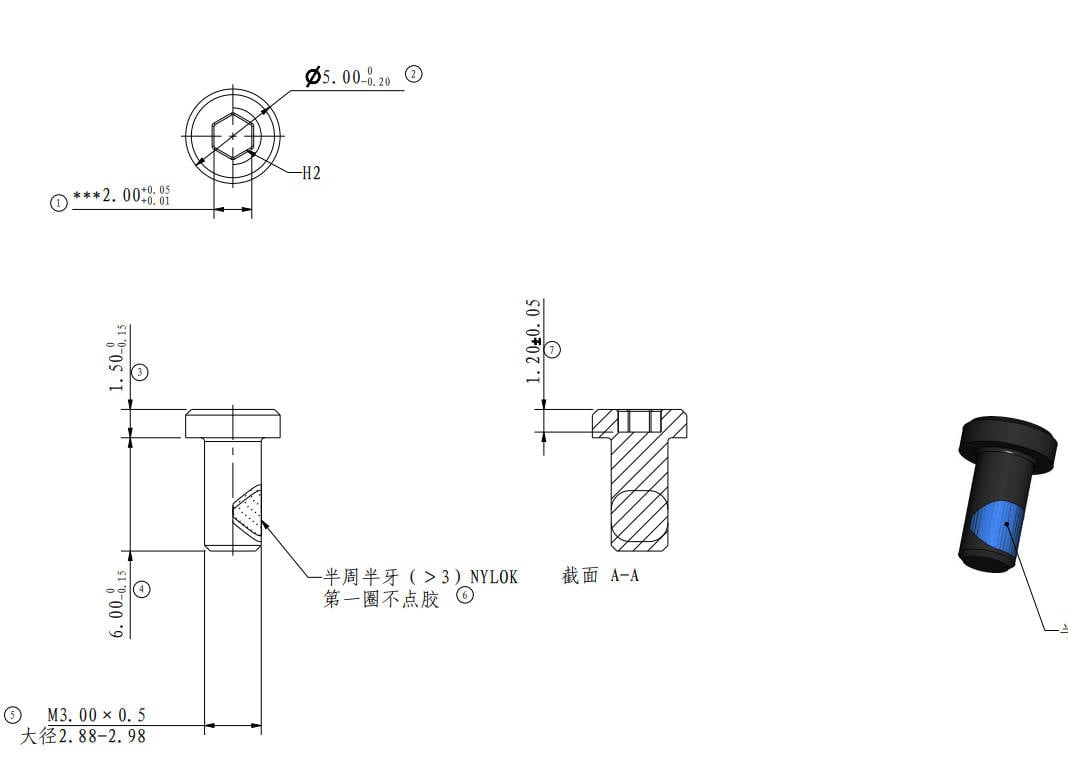

| Screw A | M3*8 | Z-Axis(6PCS) |

|

| Screw C | M3*6 | Z motor(3PCS) |

|

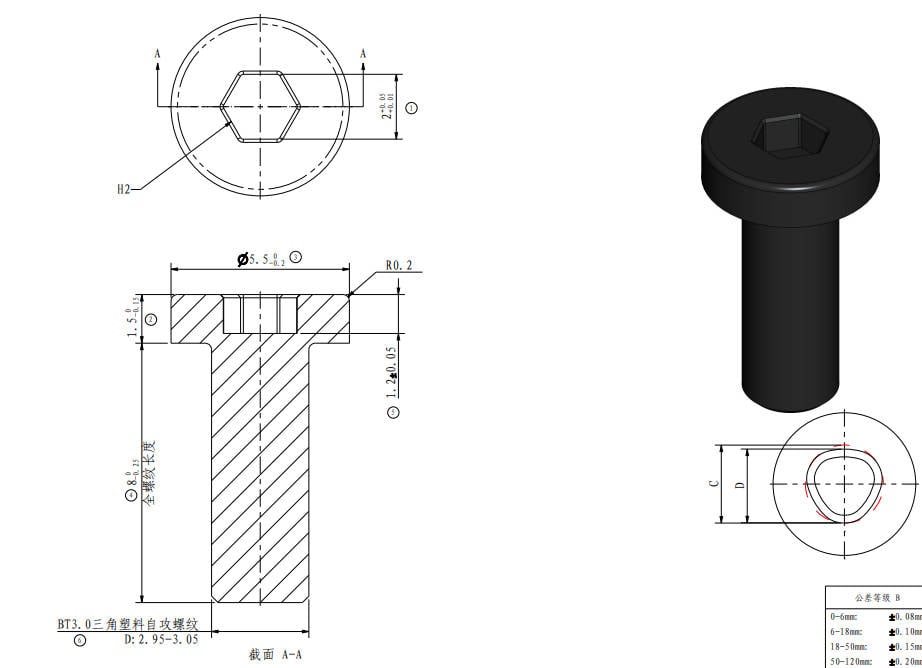

| Screw E |

BT3*8 B0022 |

Y Belt Block(3PCS) |

|

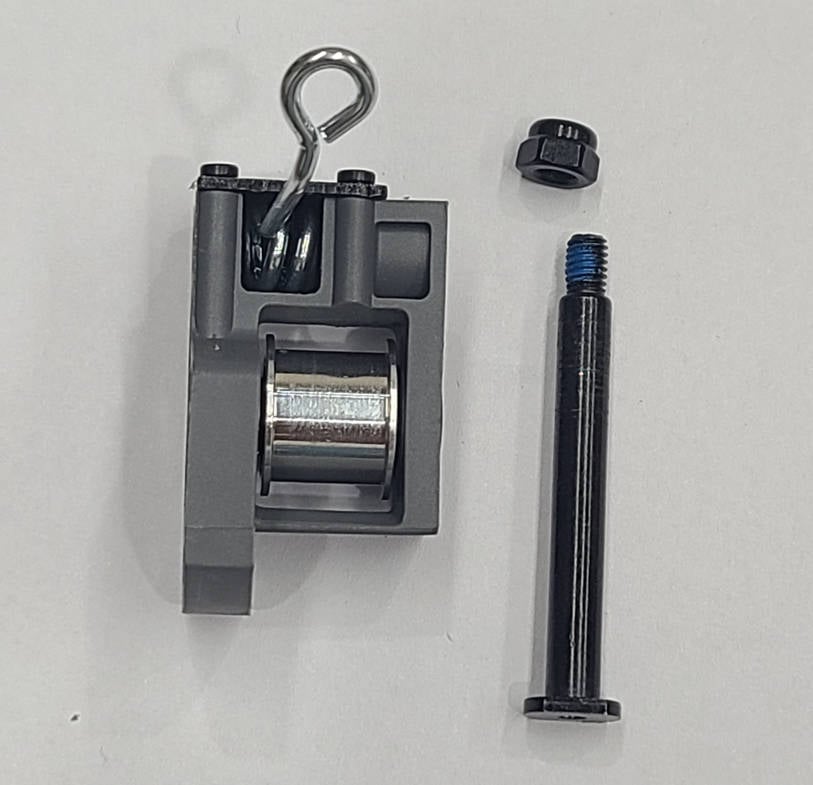

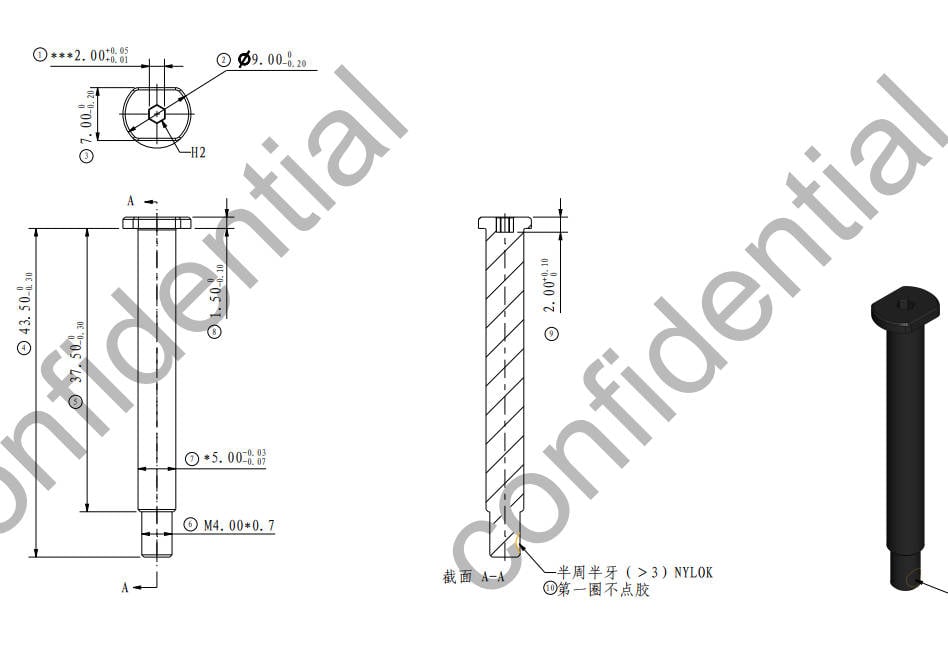

| Screw G | MG4*43.5 | Y tensioner shaft Sscrew(1PCS) |

|

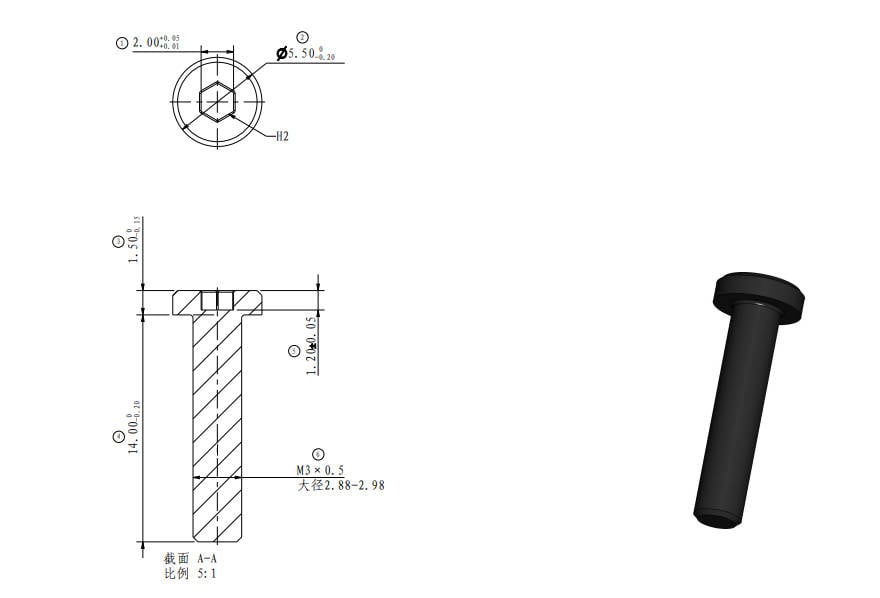

| Screw B |

M3*14 B0014 |

Z-axis Top Cover(1PCS) |

|

| Screw D |

M3*6 B00203 |

Y motor(4PCS) |

|

| Screw F |

M3*10 B00208 |

Y Tensioning Screw(1PCS) |

|

¶ Previous Operation

If needed, please refer to the A1 mini Bottom Base installation tutorial for the related previous operations.

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenance or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Video Guide

¶ Disassembling the Y-axis & Z-axis

¶ Step 1: Remove the Z-axis

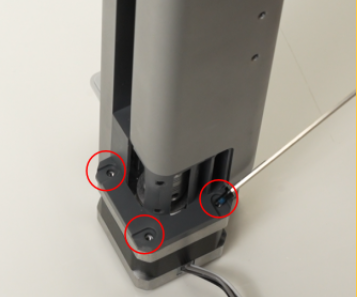

- Remove the 6 screws A, remove the Z-axis;

- Remove 1 screw B, and remove the Z-axis top cover.

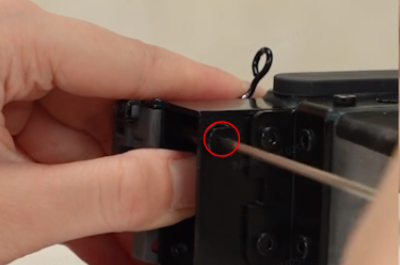

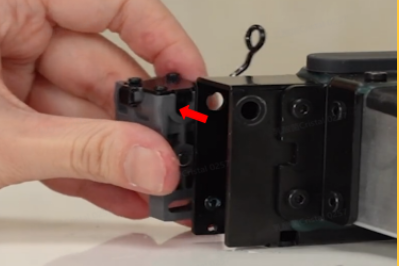

¶ Step 2: Remove the Z Motor

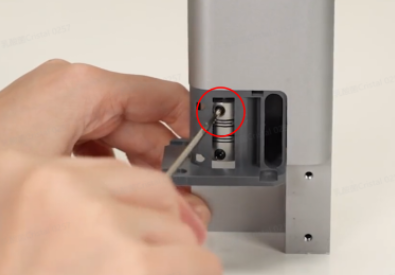

- Remove the 3 screws C. Loosen the 2 grub screws and remove the Z motor;

|

|

|

|

- Loosen the other 2 grub screws and remove the coupler & washer.

|

|

¶ Step 3: Remove the Y Motor

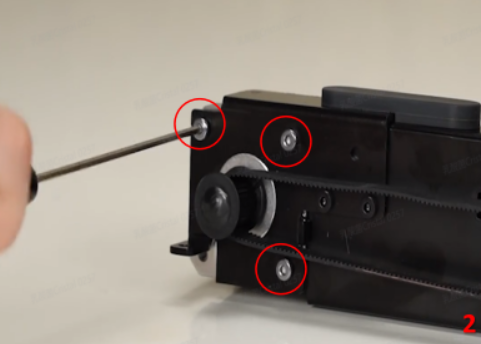

- Press the Y tensioning spring, and engage the tensioned state.; remove the 3 screws D; remove the Y-motor;

|

|

|

|

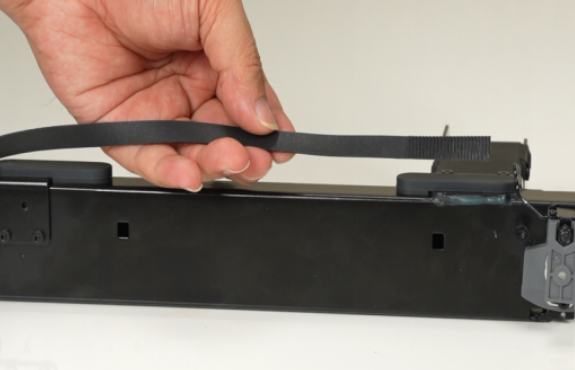

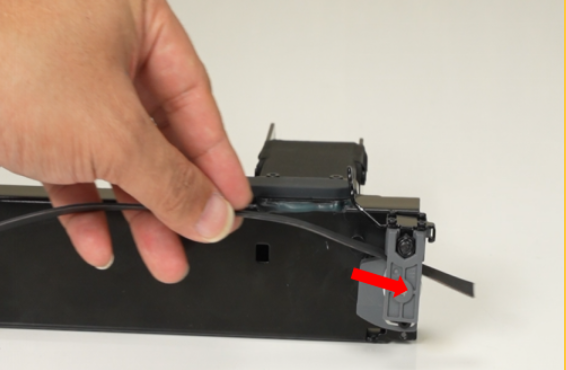

¶ Step 4: Remove the Y Belt

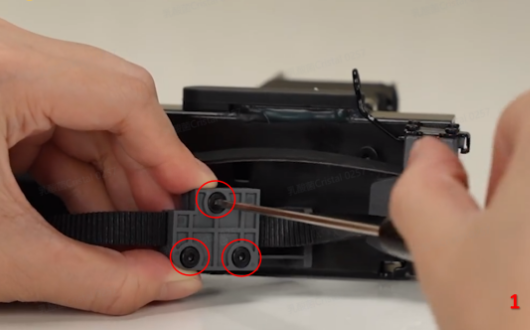

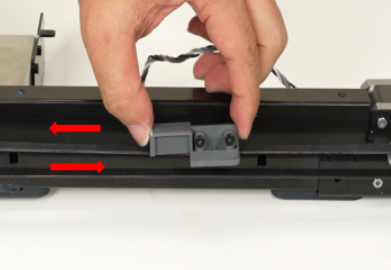

- Remove the Y belt by removing the 3 screws E. Open the belt press and strip the Y belt from the press to remove the Y belt.

|

|

|

|

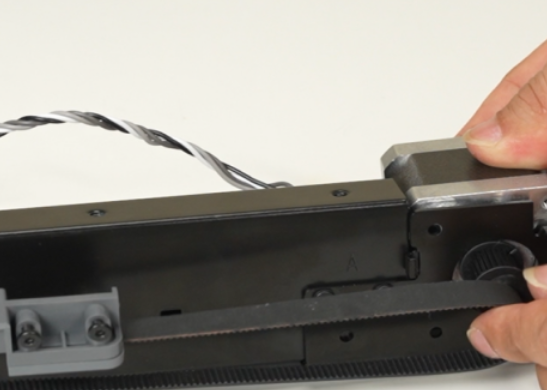

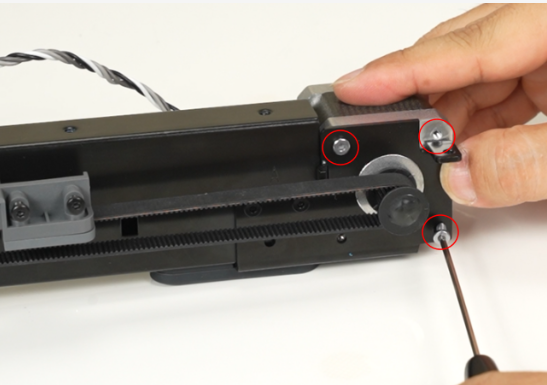

¶ Step 5: Remove the Y Tensioner

- Remove the anti-rotation tab by removing 1 tensioning screw F. Remove the Y tensioner by removing 1 screw G and nut.

|

|

¶ Assembling the Y-axis and Z-axis

¶ Step 1: Install the Y Tensioner

- Insert the shaft screw through the square steel.

- Attach Y tensioner onto the shaft screw and secure them with a nut. Tighten the screw and nut using a H2.0 wrench.

|

|

|

|

- Install an anti-rotation plate and loosely tighten one screw F, allowing it to be partially secured.

|

|

¶ Step 2: Install the Y Belt

- Verify the direction of the Y belt and thread it through the pulley as shown in the diagram.

|

|

- Apply a small amount of instant adhesive to the tooth surface of the belt mounting block.

- Adhere the belt with the tooth surface facing downward onto the pressure block.

- Perform operations in sequence

- Ensure that both ends of the belt come into contact with each other.

|

|

|

|

- Install the other belt pressure block, aligning it with the three screw holes, and secure it in place by tightening three screws E.

|

|

¶ Step 3: Install the Y Motor

- Thread the Y motor through the motor mounting bracket, ensuring the cable orientation is correct.

- Hang the drive pulley onto the Y belt and then install it in place. Secure the Y motor in place by tightening three screws D.

|

|

- Tension the spring and move the Y belt back and forth to confirm the smooth operation.

- Once confirmed, tighten the tension screw F to secure the tension.

|

|

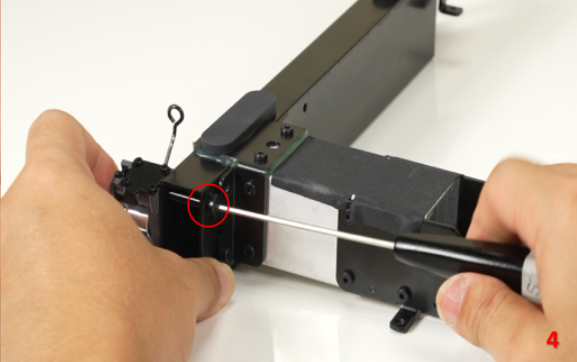

¶ Step 4: Install the Z Motor

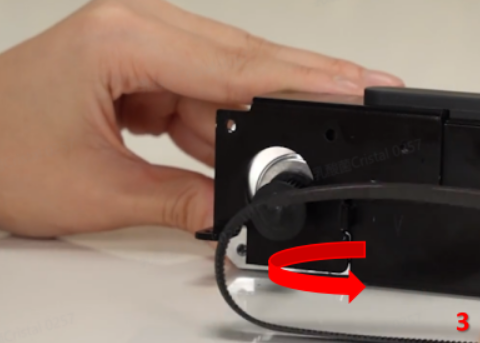

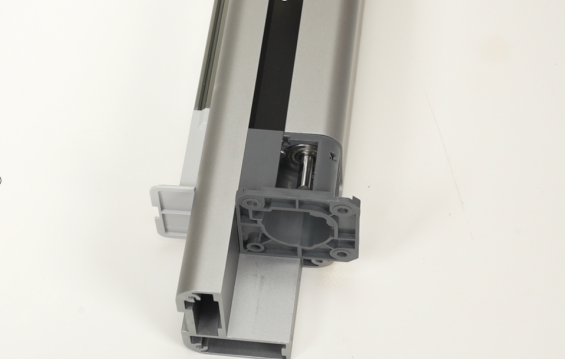

- Rotate the lead screw as shown in the diagram to expose the flat surface of the screw.

- Insert the washers and align the top thread position of the coupling with the flat surface of the lead screw. Install the coupling onto the Z-axis lead screw and tighten the two grub screws securely.

|

|

|

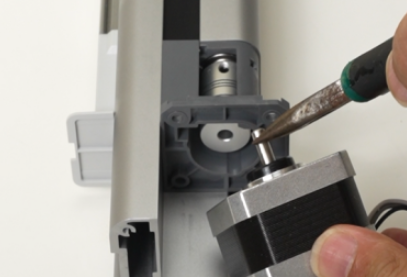

- Verify the orientation of the motor cable and rotate the motor shaft to align the flat surface on the shaft with the top position on the coupling.

|

|

|

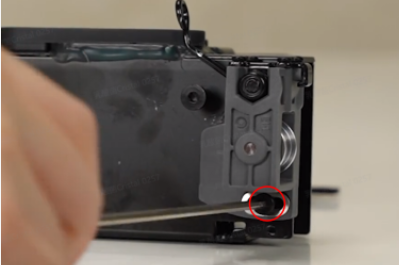

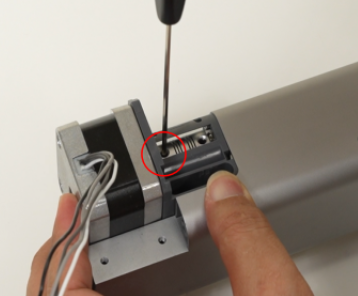

- Secure the Z motor in place by tightening the two grub screws on the coupling. Then, fix the Z motor by tightening three screws C.

|

|

|

Note: Check here whether the upper end of the screw rod is near the middle position. If not, you can adjust the position of the screw by re-locking the screw of the Z motor.

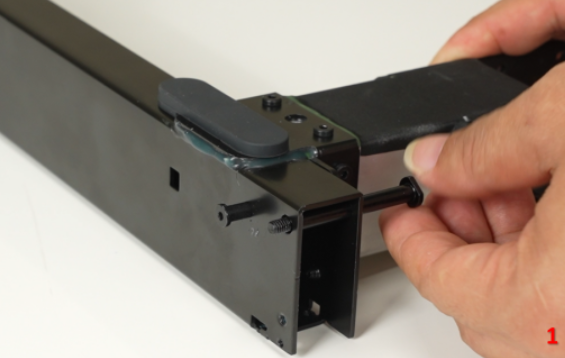

¶ Step 5: Install the Z-axis

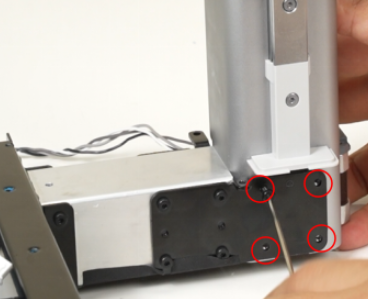

- Install the Z-axis top cover and tighten one screw B to secure it in place.

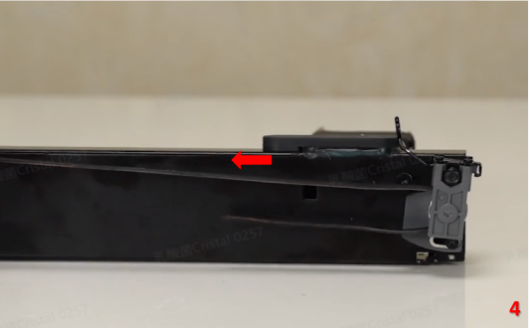

- Connect the Z-axis and Y-axis square steel together, ensuring that the screw holes are aligned.

- Secure the Z-axis and Y-axis in place by tightening six screws A for fixation.

|

|

|

¶ Calibration Step After the Operation

- Verify smooth operation of the Y belt movement.

- Confirm that the cables of the Y motor and Z motor are oriented correctly.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.